Hydrostatic pressure index is one of the important indexes of waterproof and moisture permeable fabrics. Hydrostatic pressure refers to the resistance encountered by the water through the fabric, under standard atmospheric pressure conditions, the fabric to withstand a continuous rise in water pressure, until the back of the fabric seepage water droplets, at this time,…

Category Archives: Textile Testing

Hydrostatic pressure resistance is a key measure of waterproof, breathable fabrics. It refers to the resistance when water passes through the fabric. It indicates how much the fabric resists water penetration. The hydrostatic pressure resistance method measures two things. It tests the fabric’s waterproofness and its nature. Fabrics’ water repellency can be measured by three…

The introduction of cool fabrics Summer clothing’s moisture absorption and quick-drying functions are lacking. They do not meet people’s needs, especially after intense exercise and sweating. The existing fabrics have limited moisture transfer and thermal conductivity. Developers created moisture-conducting and cool-sensitive fabrics that are unidirectional. The development of cool-sensitive fabrics focuses on two things. First,…

Hydrostatic pressure resistance is a key test of waterproof, breathable fabrics. It refers to the resistance to water passing through the fabric. It indicates the fabric’s resistance to water penetration. The test results relate to the fabric’s waterproofness and its nature. We can measure a fabric’s water repellency by three indexes: the water stain level,…

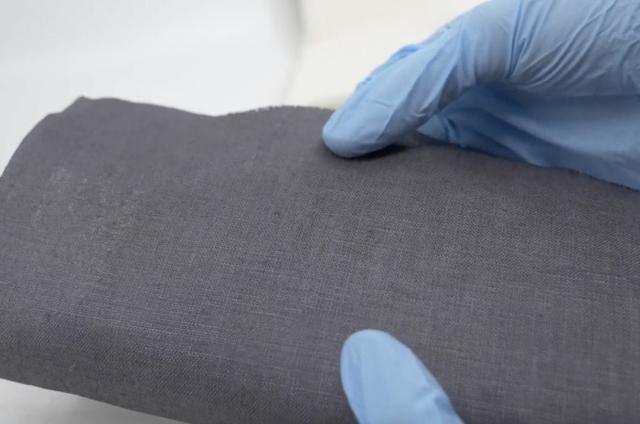

Pilling of garments refers to a common problem. When worn, garments suffer friction. This exposes the surface fibres of the fabric. They then form pilling. With continued friction, the fibres become entangled and form small balls. Pilling is a dynamic performance. The pilling speed often changes with the wearing time. As consumers demand thin, soft,…

Functional clothing is increasingly popular. Cool textile technology has matured. So, the cool textile function is now practical. The relevant departments made two product standards. They aim to regulate the market and assess cool textiles. One is FZ/T 73067-2020 “contact cool knitted garments”. The other is FZ/T 62042-2020 “cool fabric bedding”. Both standards started on…

In life, you may find that some fabrics are warm to the touch and some are cool to the touch. The specific heat capacity of pure substances varies. This is understandable. But, some clothing fabrics are the same substance in a different form. Why do people feel such a big temperature difference? In terms of…

Imagine this: when you go out in summer, you can’t avoid sweating. Even with enough sun protection. If the sweat on your clothes can’t evaporate in time, your skin will be sticky and uncomfortable. No, if you wear a quick-drying T-shirt, sweat will evaporate right away. Then, you will be in a good mood! Therein…

Performance textiles have grown rapidly in recent years. This is because multifunctional fabrics are becoming more popular. Sportswear and fashion utilize them. Capturing this profitable market is now as much an art as a science. How can brands and manufacturers do it? What are performance textiles? Engineers create performance textiles for multifunctional garments. Textiles perform…

Textile Experiments is an experimental textbook describing the structure and performance testing of textile materials. Its main content is: textile fibres, yarns, fabrics of the basic structural parameters of the test: textile fibres, yarns, fabrics of various physical properties of the test; textile fibres, yarns, fabrics of the quality assessment. Each experiment includes the preparation…