More accurate and reliable tests

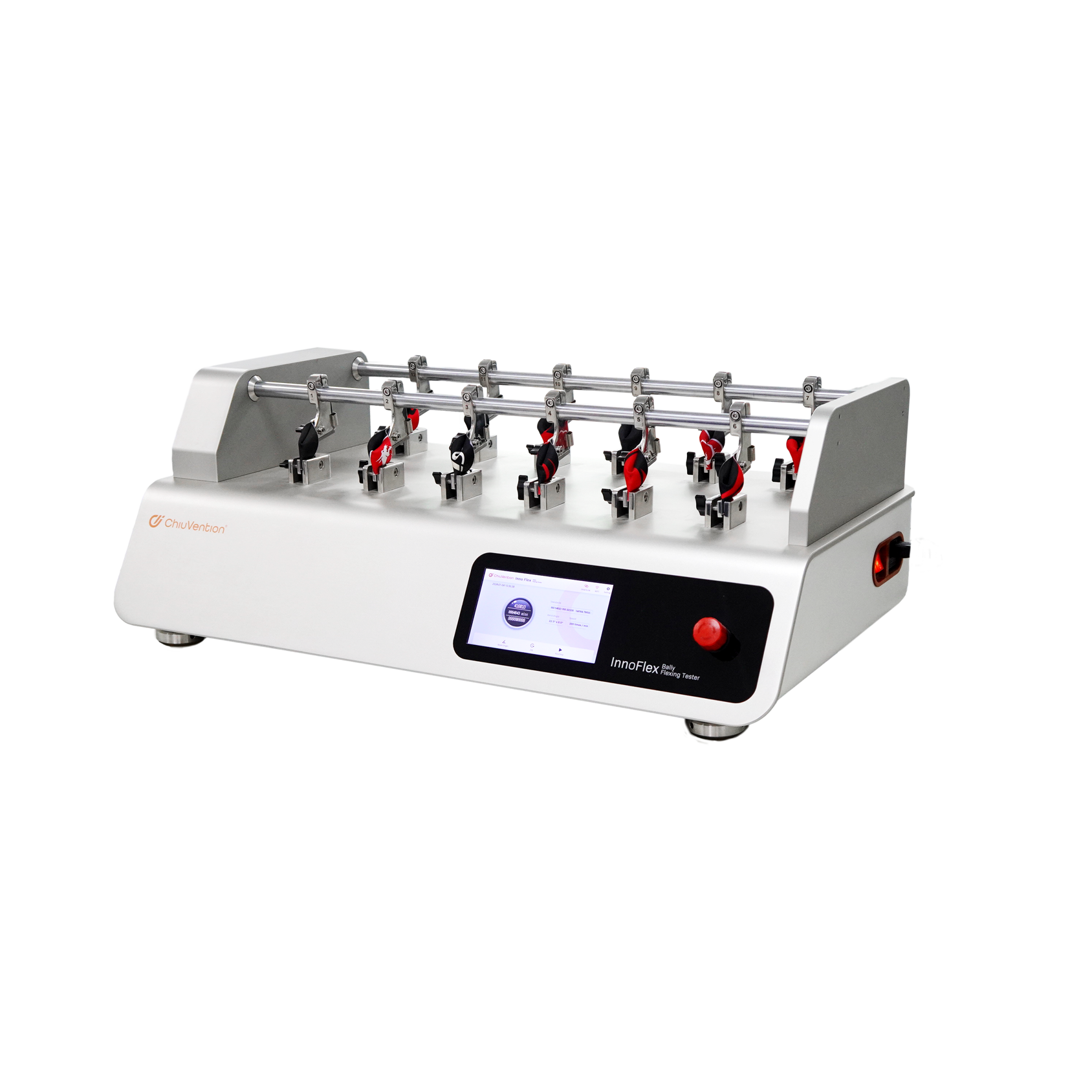

Microcomputer program control and advanced servo motor bring accurate positioning. The InnoFlex Bally Flexing Tester can return to its original position. It stays stable during the flexometer test. This stability makes the tests more accurate and reliable.

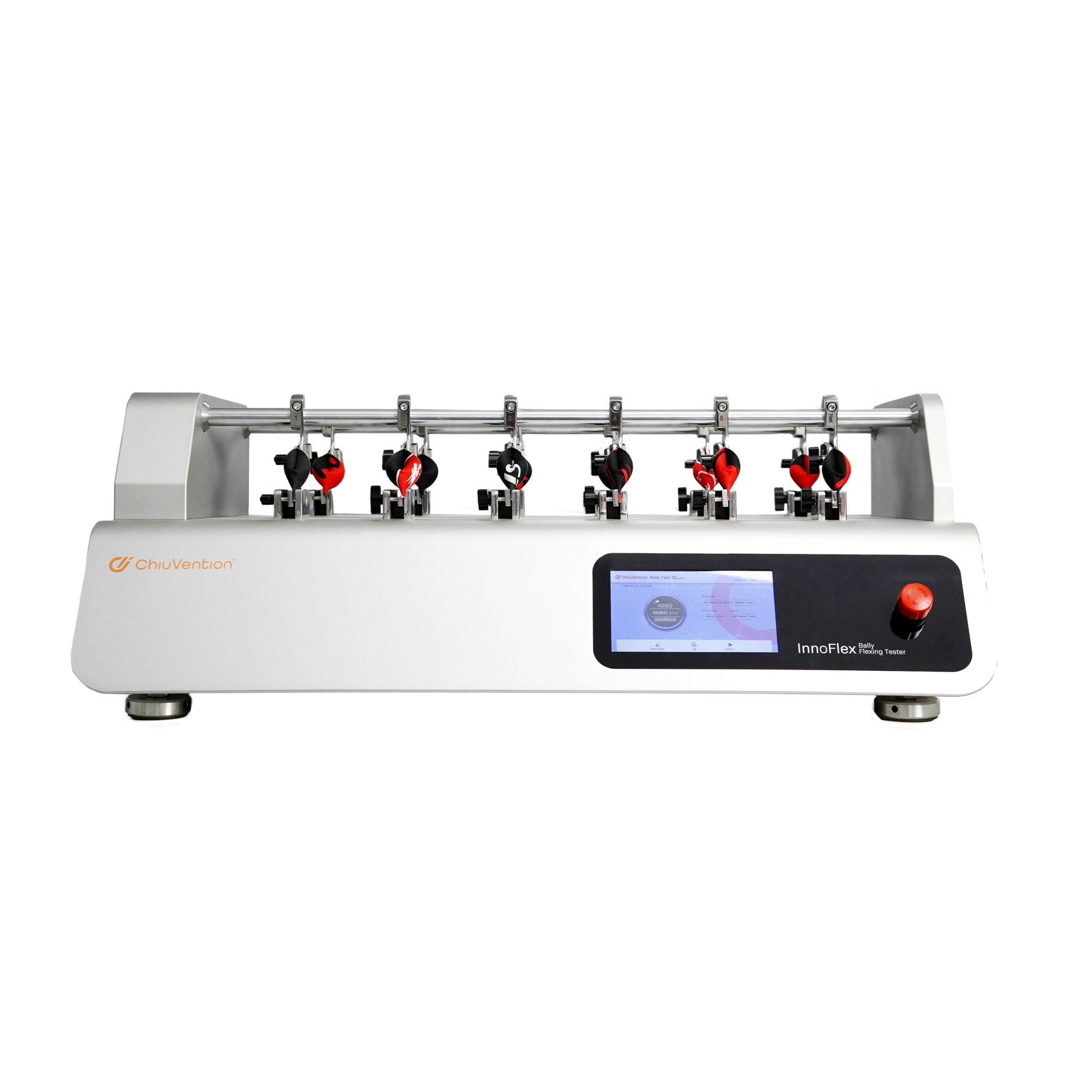

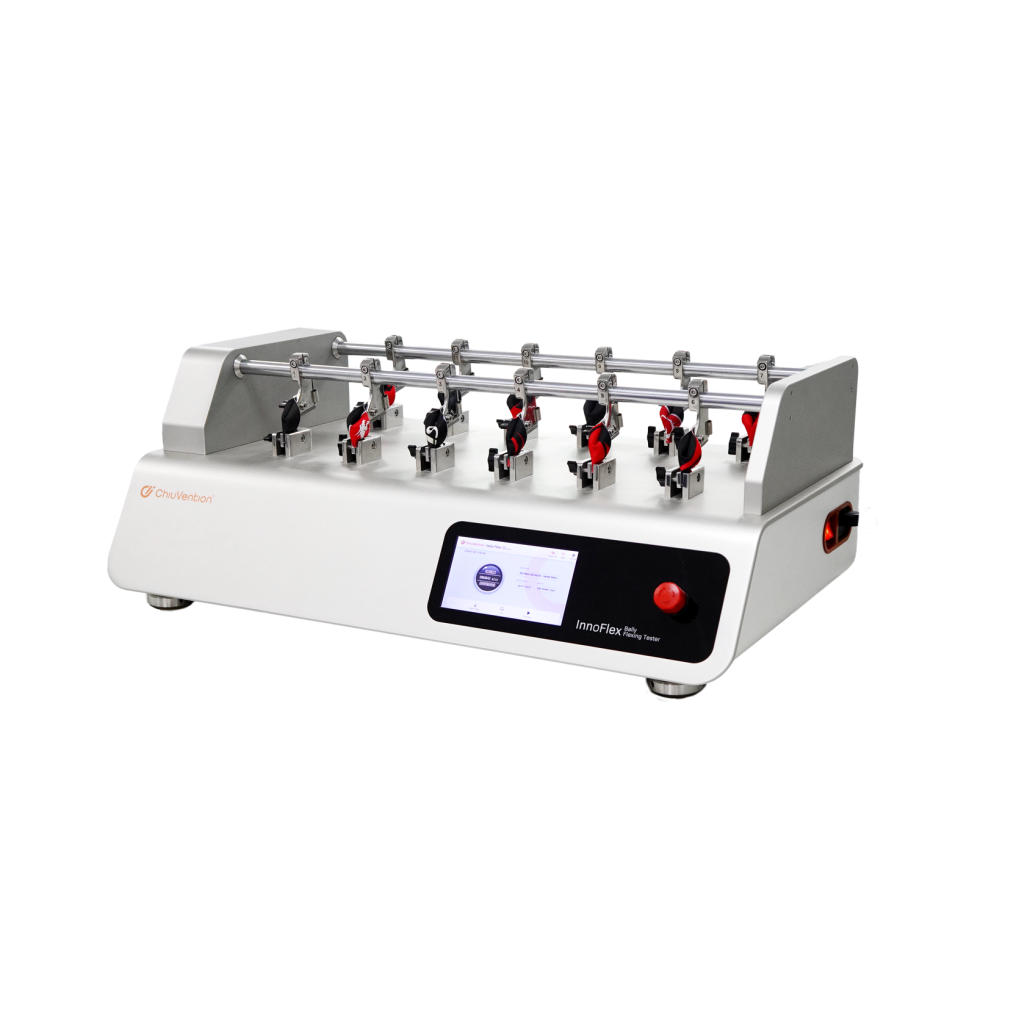

Smart Leather Folding Endurance Tester

This folding endurance tester connects to the SmarTexLab app. The ChiuVention team made the app. It works on smartphones using WIFI. It lets testers set parameters. They can watch the folding test and get alerts on their smartphone. They can also share the flex testing results in real-time.

Efficient and durable

You can select from 12 workstations of this InnoFlex Bally Flexing Tester. You can choose single-station or multi-station mode. The running times of each mode can be counted separately, so you can test a variety of samples at the same time. The NSK bearings are from Japan. Precision mold-casting stainless steel makes the flexing tester. This Bally Flexing Tester has a scratch-resistant appearance and a longer service life.

More user-friendly

The noise of this InnoFlex Bally Flexing Tester is only 60 dB, much lower than other Bally Flexing testers in the market. The interface is ergonomic. It can save the running data, even if the power fails.

Designed in Germany, quality is our life.

All our textile testing instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our instruments of outstanding quality. 100% source factory and factory price.

The Specification of InnoFlex Bally Flexing Tester

Testing station: 12 stations

Testing speed: 100 rpm

Working stroke swing angle 22.5° ± 0.5°

Test times: 0 to 9,999,999 (adjustable)

Greatest clamping distance

The maximum folding thickness of the test sample is 7 millimeters.

Upper and lower spacing

The spacing between the upper and lower clamps is 25mm

Standard accessories

Cutter die: 70 x 45 mm

Standards

ISO 5402-1:2017

ISO 32100:2018

ISO 20344-2011

Optional Standard

SATRA TM 55

Power: 220V, 50/60Hz Other voltages require an extemal transformer

Weight 55kg

Dimension: 850 x 490 x 287mm (D x W x H)

ChiuVention provides more smart textile testing equipment. Contact us for details of textile testing machines.

Frequently Asked Questions

It is a machine used to test the flexibility and durability of leather. It does this through repeated folding. It bends leather in a controlled manner. This shows how well it resists cracking or breaking.

Clamp or hold a leather sample at both ends. A movable plate or arm then folds the sample at a fixed bend point with a consistent force and rate of flexion. Sensors count the number of folds before failure.

The textile flex tester measures how many double folds a material can withstand. The folds happen at a set bend radius and force.

It resists cracking from flexing. Flexing ages it and shows how many cycles it takes to crack.

Tear strength – It introduces a controlled tear to find resistance to propagation.

We use bend radius, flexing rate, and flexing force to simulate different conditions. These conditions cause aging from acceleration.

Sample size/thickness – To accommodate different leather grades.

Temperature and humidity – For climate chamber testing.

Efficient and durable