More reliable test results.

The sample in the test chamber can tumble at a high, constant speed. The compressed air flows smoothly to the chamber to prevent the sample from sticking to the cylinder walls. The liner surface is flat and closely adhered to the walls to avoid movement. All this guarantees more reliable test results.

The impeller can be taken apart.

It can be replaced with different shapes to meet various standards.

Impellers of different shapes can be fitted to meet ISO, ASTM, JIS, GB/T, and other standards.

Low noise running

The impeller is rotating smoothly with no abnormal noise. It is very friendly for labs.

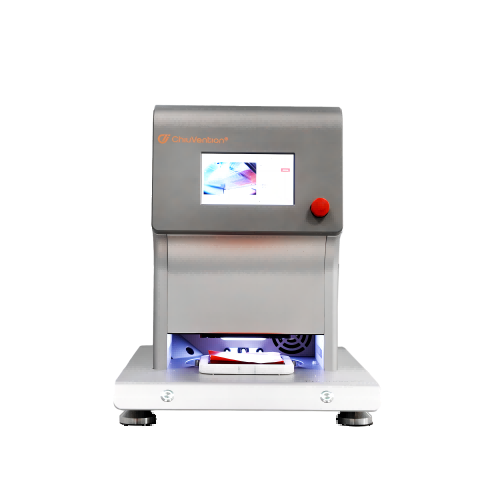

Convenient for observation

The transparent acrylic window and each chamber have light. They provide a good view of the sample test status.

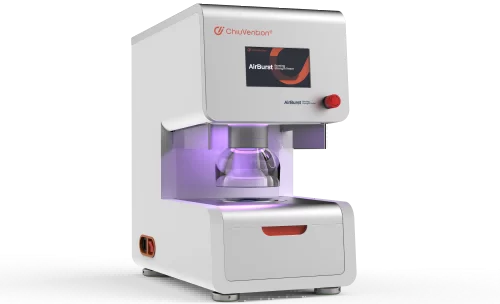

Smart Tumble Pilling Test

The instrument connects to the SmarTexLab APP via IoT on a smartphone or computer. It can also connect directly to ERP/LIMS. The operator can remotely monitor the status of multiple tests on the smartphone. He can also modify the test requirements, get a reminder before the test ends, and stop or repeat the test. The operator can use online chat to get quick support from ChiuVention customer service. Also, receive reminders to calibrate, maintain, and replace consumables on the instrument. Lastly, perform OTA remote upgrades regularly.

Application Examples of TumblePill Random Tumble Pilling Tester

Knitted Fabric

Woven Fabric

Woolen Fabric

Chemical Fiber Fabric

Customer Feedback

“Another ChiuVention Greatwork! I like the design and will test it from the French agent company.”

“This Random Tumble Pilling Tester is easy to operate, very smart panel, and the test is smooth.”

OUR BROCHURE

The Test Standards of TumblePill Random Tumble Pilling Tester

ASTM D3512

Optional Test Standards

ISO 12945-3

JIS L 1076 D

GB/T 4802.4

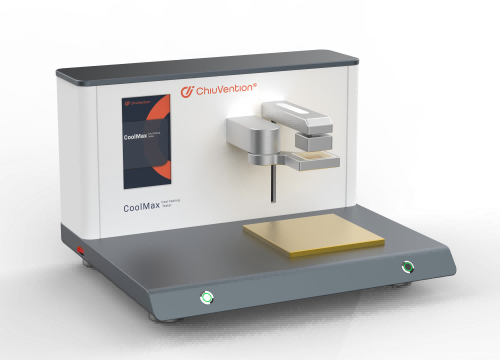

The Specification of TumblePill Random Tumble Pilling Tester

Number of test chambers: 4

Sample size: square 100×100 mm; or round 100cm2

Test chamber specification: Diameter φ146±1mm Depth 152.4±1mm

Impeller length: L=121mm

Impeller shaft diameter: φ12.7mm

Rotation speed: 1200r/min (speed adjustable)

Standard Accessories & Consumables

Sampling board 1 pc 105 *105 mm

Gas pipe 1 pc 2m Φ8 mm

Leather belt 2 pcs

Impeller 1 4 set Apply for ASTM, JIS

Optional Accessories & Consumables

Impeller 2 1 set Apply for JIS

Impeller 3 1 set Apply for ISO, GB/T

Cork liner pack of 50

Cotton sliver 1yds/pack

Pilling Standard Photograph pack of 5

Dust collector 1 pc

Power 220 V 50 / 60 Hz Other voltages require an extemal transformer

Weight about 70 kg

Dimension 560*360*620mm(L*W*H)

Frequently Asked Questions of TumblePill Random Tumble Pilling Tester

1. Woven Fabrics

Cotton: Often used in apparel, cotton fabrics can be prone to pilling, making them ideal candidates for pilling tests.

Polyester Blends: Fabrics that combine polyester with natural fibers like cotton tend to pill more due to the synthetic fibers acting as anchors for pilling formation.

2. Knitted Fabrics

Sweaters and Knitwear: Knitted fabrics, such as those used in sweaters, are particularly susceptible to pilling because of their looped structure.

Activewear Fabrics: Many athletic materials are knitted and can benefit from pilling resistance testing to ensure durability during wear.

3. Fleece and Microfiber

Fleece Fabrics: Soft fleece materials often pill due to their fluffy texture and are commonly tested for pilling resistance.

Microfiber: These fabrics can also develop pills and require testing to assess their performance over time.

4. Synthetic Fabrics

Acrylic: Acrylic fabrics are known for their softness but can be prone to pilling, making them suitable for testing.

Nylon: Similar to polyester, nylon blends may also be tested for their resistance to pilling.

5. Blended Fabrics

Cotton-Polyester Blends: These combinations are frequently used in casual wear and require assessment for pilling due to the interaction of fibers.

Important Considerations:

The Random Tumble Pilling Tester simulates the friction and abrasion that fabrics experience during normal use, such as washing and wearing.

Fabrics treated with silicone resin may not yield reliable results in this test, as silicone can transfer onto the cork liners used in the tester, affecting the outcome.

In summary, the Random Tumble Pilling Tester is versatile and applicable to a wide range of woven and knitted fabrics, especially those used in everyday apparel where pilling can impact appearance and quality.

Random Tumble Pilling Tester

- Test Method: ASTM D3512

- Procedure: Fabric samples are placed in a cylindrical chamber lined with cork and subjected to random tumbling with abrasive materials (like cork balls or cotton lint). The samples undergo continuous agitation to simulate the pilling process.

- Evaluation: The degree of pilling is assessed visually after a specified duration, allowing for a qualitative evaluation of the fabric’s pilling resistance.

- Suitability: Particularly effective for knitted fabrics and those that experience random friction during normal wear.

Martindale Pilling Test

- Test Method: ISO 12945-2

- Procedure: Fabric samples are mounted on a circular platform and rubbed against an abrasive surface (usually emery paper) in both warp and weft directions for a predetermined number of cycles.

- Evaluation: Pilling is assessed visually using a grading system. This method provides quantitative data on fabric wear and is suitable for woven fabrics.

- Suitability: Known for accurately simulating real-life wear conditions, making it effective for assessing durability.

ICI Pilling Box Test

- Test Method: ISO 12945-1

- Procedure: Fabric samples are placed in a box lined with cork and subjected to controlled rubbing. The samples are tumbled for a specified duration.

- Evaluation: Visual assessment of pilling is performed, with results graded according to established criteria.

- Suitability: Versatile for various fabric types, including woven and knitted materials.

Comparison Summary

- Testing Environment:

- The Random Tumble Pilling Tester simulates random friction, making it more representative of real-life conditions where fabrics rub against each other.

- Martindale and ICI tests use more controlled environments, focusing on specific rubbing patterns.

- Fabric Types:

- The Random Tumble Pilling Tester is particularly suited for knitted fabrics, while Martindale is better for woven fabrics due to its method of abrasion.

- ICI can accommodate both types but may not replicate real-world scenarios as effectively as the Random Tumble method.

- Data Output:

- The Random Tumble method provides qualitative assessments based on visual inspection, while Martindale offers more quantitative data through cycle counts and grading systems.

- ICI also provides visual evaluations but may not be as comprehensive in data collection as Martindale.

- User Experience:

- The Random Tumble Tester may require less operator intervention during testing due to its automated tumbling process.

- Martindale and ICI tests often require more manual setup and monitoring.

In conclusion, while the Random Tumble Pilling Tester excels in simulating real-world conditions and is particularly effective for knitted fabrics, other methods like the Martindale and ICI tests offer different advantages depending on the fabric type and testing requirements. Each method serves its purpose within the textile industry, providing valuable insights into fabric durability and performance.