New intelligent pilling and snag test, more efficient

The ICI Pilling and Snag Tester is connected via IoT to the SmarTexLab APP in the phone/PC. And the app can connect to ERP/LIMS via an API. Or, the instrument can connect directly to ERP/LIMS. There are test orders and sample information in the system, and the ICI Pilling and Snag Tester can start the test and record the sample info, test process, and test results. The system will then summarize these into a test report. The report can be sent to SmarTexLab or ERP/LIMS. The relevant parties can view the report in real time.

The operator can remotely monitor the test status of multiple instruments simultaneously and receive an alert directly on their smartphone when the test is over.

In SmarTexLab, you can set up programs to start or stop the ICI Pilling and Snag Tester. You can chat with ChiuVention service staff for quick support. You’ll get reminders that instruments need calibration, maintenance, and new consumables. Regular OTA remote upgrades are available.

Flexible configurations to suit all standards

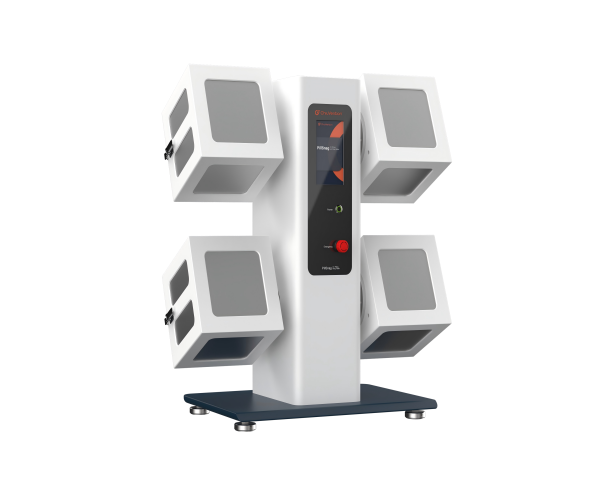

It can be flexibly configured with a variety of standards, 2 or 4 stations, and It can also be equipped with round or octagonal boxes specified by European clothing brands, and European or Japanese standard hook and loop boxes are also available.

More reliable test results

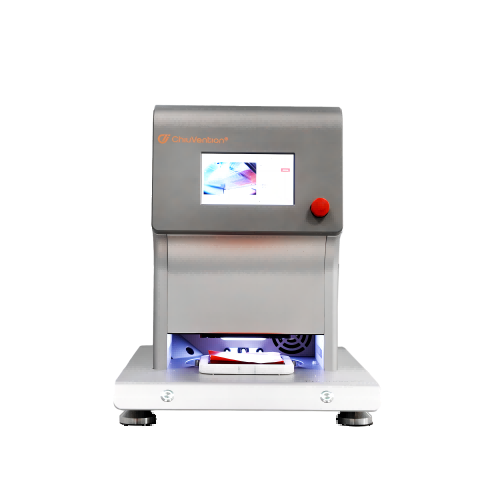

The ICI Pilling and Snag Tester is able to simulate real usage scenarios and provide reliable pilling and hooking test results. Standardized testing procedures and a sophisticated control system ensure consistency and repeatability of each test result.

Multiple testing modes to meet different needs

The ICI Pilling and Snag Tester can carry out a variety of modes of testing, such as dry friction, wet friction, etc., to meet the needs of different textile testing.

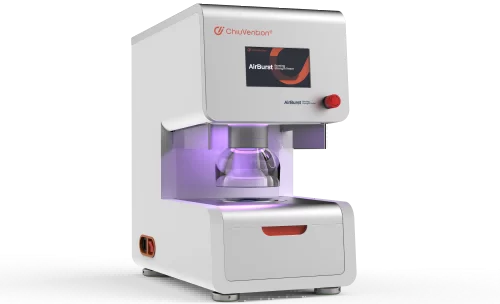

4 work stations, higher efficiency.

With 4 sample fixtures, multiple samples can be tested at the same time, further improving testing efficiency.

Designed in Germany, quality is our life.

All our textile testing instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our instruments of outstanding quality. 100% source factory and factory price.

Application Examples of PillSnag ICI Pilling and Snag Tester

Apparel Fabrics

Socks

Home Textiles

Automotive Interiors

Customer Feedback

“The pilling and snag tester is smart, we can get the test report from cloud. It is more efficient than convetional way.”

“Through the use of this ICI Pilling and Snag Tester,we improved the quality of socks and obtained more orders from the brand buyers.”

OUR BROCHURE

PillSnag ICI Pilling and Snag Tester Standards

Standard

ISO 12945-1 GB/T 4802.3 NEXT TM19 BS 5811

Optional Standard

BS 8479 JIS L1058 Method D-2

The Specification of PillSnag ICI Pilling and Snag Tester

Forward and reverse rotation function

Chamber interior dimensions 235mm *235mm * 235mm (excluding cork lining)

Chamber rotation speed 30–70 rpm (adjustable)

Chamber rotation count 2–999999 times (settable)

2 or 4 Chambers can be customized

Standard Accessories & Consumables

Sampling board 1 pc 125*125 mm

Polyurethane specimen tube 16pcs 140* φ31.5 mm

Cork liner 24 pcs

Optional Accessories & Consumables

Polyurethane specimen tube set of 4 140*φ31.5 mm

Cork liner pack of 6

Mounting jig per set

Pilling Standard Photographs set of 4*5 (20pcs)

Sampling board 114*114 mm

BS 8479 Octagonal box

Power 220V 50 / 60 Hz Other voltages require an extemal transformer

Weight about 100 Kg

Dimension 470 * 860 * 900mm(D*W*H)

Frequently Asked Questions

A fabric textile tensile tester is a machine. It measures the strength and stretchiness of fabrics. It works by gripping a strip of cloth or other materials, such as leather, paper, or yarn, on both ends. Then, you pull it until it breaks. Advanced sensors measure the force needed to remove the fabric. They also measure how far it stretches before breaking. This gives quantitative data on the fabric’s tensile properties.

The most common testing machine used for tensile testing is the universal testing machine(UTM). It features two crossheads: one is adjusted to accommodate the length of the specimen, while the other is driven to apply tension to the test specimen. These testing machines can be either electromechanical or hydraulic.

For accurate testing, the machine must have appropriate capabilities for the test specimen, including sufficient force capacity, speed, precision, and accuracy. Various accessories, such as grips, extensometers, and temperature chambers, are used to adapt the machine for different materials and testing conditions.

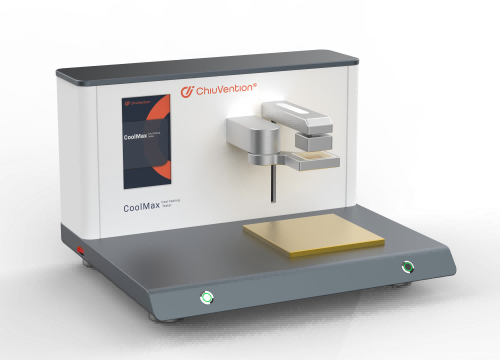

The SmartPull Fabric Textile Tensile Tester software is easy to use. It presents detailed tensile test results. These include elongation, time, greatest force, and modulus. They also include breaking force and more. It allows you to compare past results. You can also export data and create custom tensile strength test reports.

Preparation

Check the equipment: Before starting the calibration, make sure that there is no physical damage to the Tensile Strength Tester itself, and that the sensors, fixtures, display, and other parts are working properly.

Ensure leveling: The Tensile Strength Tester must be placed on a level workbench to avoid tilting the machine resulting in inaccurate testing. Use a level or the leveling function that comes with the machine to check.

Calibrate the load cell (force transducer)

Selection of standard weights: Select standard weights of known accurate quality. It is usually necessary to use calibration weights that comply with national or international standards. The range of the weights should cover the operating range of the Tensile Strength Tester.

Hanging weights: Hang the weights on the transducer according to the operating manual of the Tensile Strength Tester. Make sure the weights are hung at the correct position and angle to prevent deviations in the test force values.

Record display readings: After loading the weights, observe and record the force values displayed by the Tensile Strength Tester and compare them with the actual force values of the weights.

Adjust the calibration coefficient: If the force value displayed by the Tensile Strength Tester does not match the actual force value of the standard weights, use the calibration function that comes with the machine or adjust the calibration coefficient through the software until the displayed force value is consistent with the weights.

Displacement sensor calibration

Check the zero point of the displacement sensor: without loading any force, check whether the displacement displayed by the Tensile Strength Tester is zero. If there is deviation, reset the zero point of the displacement transducer.

Measure standard displacement: Using a standard calibration fixture, set the tensioner to move a certain distance (e.g., 10 mm, 50 mm, etc.) and then record the displacement reading displayed by the tensioner.

Adjusting Displacement Calibration: Compare the actual displacement with the displacement displayed by the Tensile Strength Tester. If there is a deviation, adjust accordingly according to the equipment manual.

Speed calibration

Set Speed: Set the tensioner to a known travel speed (e.g. 10 mm/min) and start the tensioner.

Use a stopwatch or other measuring tool: Use a stopwatch to measure the actual distance and time traveled by the fixture or fixture beam and calculate the actual speed.

Adjust the speed parameters: If the actual speed does not match the set speed, make adjustments according to the calibration method of the device to ensure the accuracy of the speed setting.

Verify the calibration

After completing the calibration of the load cell, displacement sensor, and speed, perform the following verification steps:

Repeat the calibration process: Load the weights and measure the displacement and velocity again to verify that the calibration is accurate and stable.

Compare reference equipment: If possible, compare tensile test results with other calibrated reference Tensile Strength Testers to ensure consistency.

Adjustment of environmental conditions

When calibrating, make sure that the environmental conditions are consistent with actual use, including temperature and humidity. These conditions can affect the tensile test results, so ensuring the stability of the environment in which the Tensile Strength Tester is located is a critical part of calibration.

The SmartPull Fabric Textile Tensile Tester weighs 90 kilograms. This is due to its optimized design. So, it’s easier to move and use. This tensile machine uses the latest technology. This includes AC servo motors and precision ball screws. They make force accuracy better. It’s improved hardware and software make the testing 20% more reliable.

It has an emergency stop button and an overload protection system. It also has travel range limits and warns about abnormal torque or issues. Its ergonomic design reduces injury risks.

Before using our tensile testing equipment, check the installation guide for environmental needs and machine securing. Connect electricals according to source rating specifications. Initialize when empty and tare the tester. Next, calibrate in ascending and descending order. Use deadweights certified for 20% to 100% of the capacity range. Save calibration results for further use.

People replace consumable parts. These parts include grips, jaws, load cell mounts, couplings, pulleys, and drive belts. They wear out over time. Calibrated spare sensors and load cells can cut potential downtime. Other recommended spares are fuses, cords, and pneumatic component kits. Their typical replacement frequency varies. The frequency of use determines their usage.

elect matching international test standards based on fabric type. Set suitable grips, jaws, or fixtures. Input the recommended test speed, pre-tension rate, and gauge length as per standard. Specify the allowed elongation percentage without damage. Check if the data recording rate meets the standard. Zero the balance force sensor. Verify the alignment and centering of loaded fabric samples. Start the auto-return on the sample break.

Use pneumatic grips with rubber coating to hold dense, woven fabrics. Use smooth, lightweight mechanical clamps for light, sheer fabrics to avoid damage. Inspect across the width to check the center while loading. Observe the tensioning display to check for slackness or issues. Start a pre-tension cycle to correct minor orientation deviations.

If you see variability, recheck the grip pressure settings. Also, replace worn-out jaws. Recalibrate the load cell if accuracy declines beyond the permissible limit. Confirm that you have pre-conditioned the specimen. Verify that mounted gauge length dimensions are accurate. Increase the sample size or test repeats for more statistical confidence. Compare against certified reference equipment. The room temperature and humidity were stable throughout the entire test duration.