Application of Martindale Abrasion and Pilling Tester

The Martindale abrasion and pilling tester can test cotton, hemp, and silk woven fabrics. It can also test other textiles and membranes. These include knitted fabrics, woolen textiles, and artificial leather. It can also test gloves and labor protection materials.

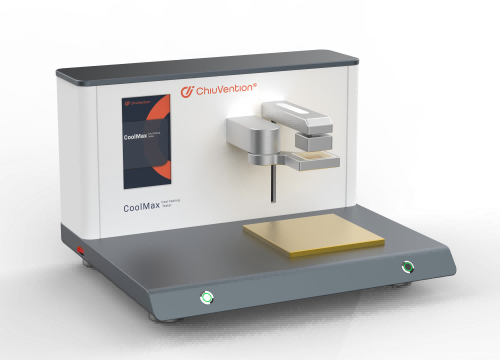

Smart Martindale Abrasion Tester

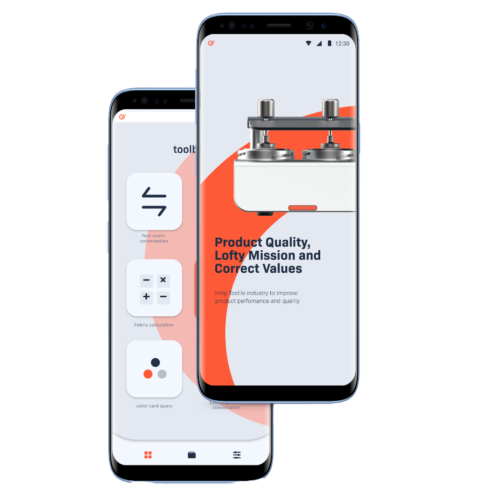

The ChiuVention Martindale Abrasion Tester connects via IoT to the SmarTexLab APP on phone/PC and can integrate with ERP/LIMS via API. It syncs test orders and sample data, automates testing, records results, and generates real-time reports accessible on SmarTexLab or ERP/LIMS.

Users can monitor multiple testers, adjust abrasion and pilling test settings, receive alerts, and control tests remotely. SmarTexLab also enables automated martindale test scheduling, live support, maintenance reminders, and OTA upgrades for seamless operation.

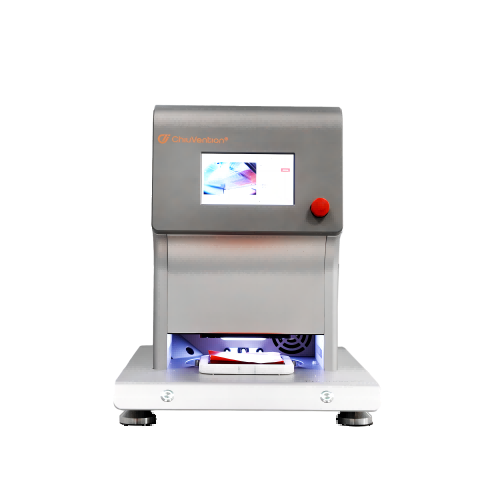

Calibration-free Martindale Tester

The dual action of the servo driver and position sensor allows the Martindale Tester Machine to achieve accurate testing continuously.

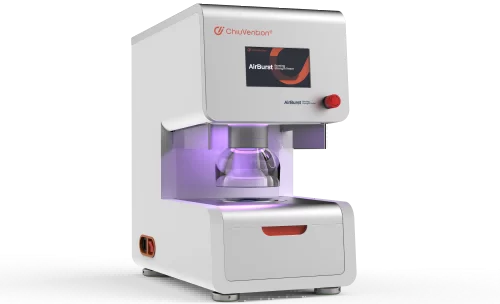

Flip-up cover for easy observation and operation

The upper cover flips up easily and locks with one hand. This lets the operator watch the Martindale fabric test without hassle. It also makes it easier to install consumables and samples. The cover’s slow-lowering device keeps the operator safe while using the Martindale abrasion machine.

Easy to use

Many world-class textile testing institutes use this Martindale pilling test machine, which testers recognize as easy to use.

The original digital drive achieves a higher level of test accuracy.

This Martindale Pilling Tester runs on an exclusive and patented digital algorithm. It drives dual servo motors and precision slide rails. This replaces the traditional analog drive. It can generate a perfect Lissajous curve. We tested rubber simulation specimens with double the weight. We ran over 10 million tests, which is like three years of non-stop use, at ultra-high friction. The Lissajous curve is still accurate and perfect. So, the Martindale Fabric Test is more reliable.

One-click to shift the testing modes

This Martindale Abrasion and Pilling Tester is easier than the conventional one. You don’t need to remove the top plate and change the pins. Just click one key to switch the testing modes. You can switch from abrasion to pilling test(e.g. Abrasion, Pilling, Line).

Ergonomic design

You can move the guide plate of this Martindale Tester with one hand. It closes and has an anti-collision function. This pilling tester machine is friendlier to operators.

Reliable Martindale Test

The machining and assembly are accurate. This makes the abrading table and specimen holder run parallel. The holder in this Martindale Tester has a small run out to the table (less than 0.05mm). This is better for getting reliable Martindale test results.

Designed in Germany, quality is our life.

This ISO Standard Abrasion Tester is developed in-house and in cooperation with a team of renowned German industrial designers. ChiuVention is dedicated to high-quality textile testing equipment. We offer efficient and reliable testing solutions.

Customer Feedback

“I purchased this Martindale Tester through ChiuVention’s agent-ATI Corp., who has more than 20 years of experience in textile testing instrument marketing and service in the U.S., and they can support me very timely. This Fabric Abrasion Tester does well both in testing accuracy and functional design (such as switching test mode from the screen and friendly details for testers, etc.).”

“We knew about this Martindale Tester at ChiuVention’s French agent. It is very stable and has a unique design. Its features are on par with top brands of test instruments. And It has a very reasonable price. So, without a doubt, it became our final choice.”

OUR BROCHURE

FLYER

Martindale Test Standards

ISO 12945-2-2020 ISO12947-1-1998 ISO12947-2-2016

ISO12947-3-1998 ISO12947-4-1998

GB/T 21196.1-2007 GB/T 21196.2-2007

GB/T 21196.3-2007 GB/T 21196.4-2007

GB/T 4802.2-2008

ASTM D4970/4970M-22

ASTM D4966-22

BS EN 530-2010

Optional standards

BS EN 388-2016+A1-2018 Protective gloves for mechanical hazards;

SATRATM31 A/B Abrasion Resistance Test for Leather;

PUMA; BS EN 16094-2012 Laminated wood flooring,

Test method for the determination of micro-scratches;

ISO 20344-2021 Item 6.12 Personal protective equipment,

Test methods for footwear and boots;

BS EN 13520-2002 Test methods for footwear, uppers,

linings and insoles, abrasion resistance;

ISO 5470-2-2021 Rubber or plastic, coated fabrics,

determination of abrasion resistance

ISO 17076-2-2011 GB/T 39507-2020

TECHNICAL DATA

Abrasion test

(198±2)g

Weight of the holder and the spindle

60.5±0.5mm Max stroke of movement

Pilling test

(155±1)g

Weight of the holder and the spindle

24±0.5mm

Max stroke of movement

INSTALLATION

220V 50/60Hz Power Supply

Other voltages require an extemal transformer

| Smartindale 4 | 65kg | 650*510*280mm |

| Smartindale 6 | 75kg | 650*510*280mm |

| Smartindale 9 | 90kg | 510*850*300mm |

Climatic Environment

The unit is intended to operate within the following conditions

25+/-5 deg Celsius Temperature | 30-65 RH % Humidity |

<2000m above sea level Altitude | -25-+ deg Celsius.Storage |

For more information, please check the Download Brochure

Accessories of Martindale Tester

Accessories

Fuse tube 2pcs

Foam wool 9 pcs Φ38 mm

Wool felt 18 pcs Φ90 mm,Φ140 mm

Wool abrasive 9 pcs Φ140 mm

Sampling plate 3 pcs Φ38 mm,Φ90 mm,Φ140 mm

Sampler 1 pc for pilling test

Sampler 1 pc for abrasion test

Press 1 pc Φ126mm,2.5kg

Fixture1 9 sets for pilling test

Fixture 2 9 sets for abrasion test

Weight 1 9 sets 12Kpa

Weight 2 9 sets 9Kpa

Rubber ring 9 pcs

Test pen 1pc

Connection shaft 9pcs for pilling test

Connection shaft 9pcs for abrasion test

Stainless steel ring 9pcs 260g

Optional Accessories

EMPA990 rating chart card 1 set Knitted + Woven

SM50 rating chart card 1 set IWS + ASTM

SM25 abrasion-resistant wool cloth 1 pack 1.6 X 5m/pack

SM26 woven wool felt 1 box 24 pcs/box Φ140mm

SM26 woven wool felt 1 box 24 pcs/box Φ90 mm

SM28 polyurethane ether foam 1box 250 X 200mm/pc, 25pcs/box

Ball Plate Φ120mm

We also provide another type of Pilling Tester.

You can also click here to learn more about the Martindale Test.

GET A QUOTE

The Martindale abrasion and pilling test evaluates fabric durability and resistance to wear. The abrasion test simulates natural wear by rubbing fabric against a standard abrasive material under controlled conditions. It measures fabric thinning or hole formation through a Lissajous motion and a set number of cycles.

The pilling test assesses the formation of small fiber balls on fabric surfaces, which impacts their appearance. The fabric is rubbed against a standard fabric under pressure and subjected to Lissajous motion for a set number of cycles. Pilling is rated from 1 (severe) to 5 (none).

Both tests use the same machine but focus on different aspects of fabric wear: abrasion tests the fabric’s resistance to rubbing, while pilling tests the formation of pills.

Instrument, sample, and conditioning preparation

Prepare the Martindale Tester

Conduct an abrasion test according to the following requirements:

ISO 12947-1、ISO 12945-2

Cover the abrasion table with a circle of felt. Use woven or non-woven felt. Note: Non-woven fabric is for M & S tests only. Both kinds of felt are available from the laboratory. Then, cover the wear table with standard wear fabric. The wear fabric must meet ISO 12947-1 standards. You can get it from ChiuVention.

Condition all samples and standard fabrics in a standard atmosphere for testing.

Conduct all wear and pilling tests in a standard atmosphere of 20 ± 2 °C and 65% ± 2% RH.

Take the Abrasion test as an example

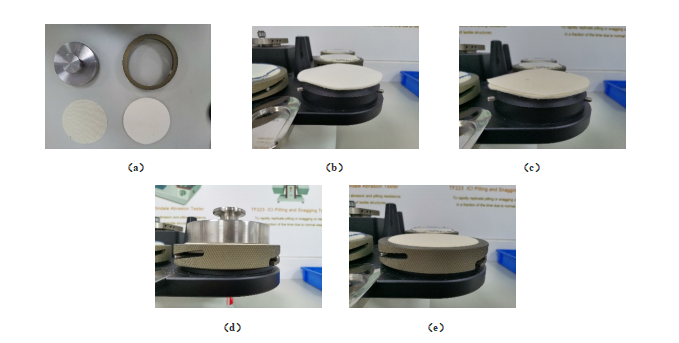

Prepare abrasive

Cut a set of felt and standard fabric based on the test needs after adjusting them.

Place the felt in the center of the grinding table as shown in Figure 1-(b);

Place the standard fabric in the center and cover it on the felt as shown in Figure 1- (c);

Put the snap ring on the grinding table and press the standard felt with a heavy hammer as shown in Figure 1-(d).

Tighten the snap ring and remove the heavy hammer as shown in Figure 1-(e);

Repeat the above operation for the rest of the grinding table of the machine

Prepare test samples

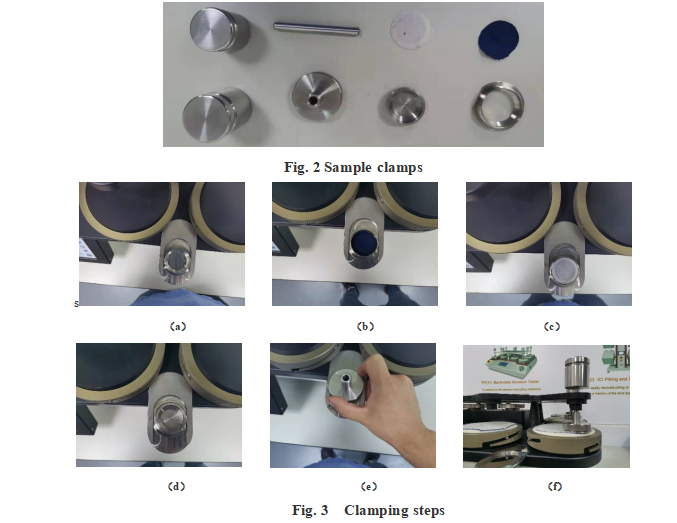

Put the compression nut into the clamping table as shown in Figure 3 – (a);

Put the sample to be tested face down into the compression nut as shown in Figure 3 – (b);

Place the sponge on the sample to be tested as shown in Figure 3- (c);

Place the fixture inserts on the sponge with the conical part downward as shown in Figure 3- (d);

Screw the clamp socket onto the compression nut as shown in Figure 3-(E). Make sure the fixture is tight. This will stop the sample from falling off during the friction test.

Insert the fixture pin shaft through the shaft sleeve and into the assembled fixture as shown in Figure 3 – (f). And put the weight required for the test requirements.

Note: we number all parts of a grinding station. The correct number of parts must be used in the correct station. For example, all components marked with No. 1 should be assembled and used in station 1.

Repeat the above process for all samples to be tested.

Adjust the Martindale Tester settings. Then, begin the test following the steps.

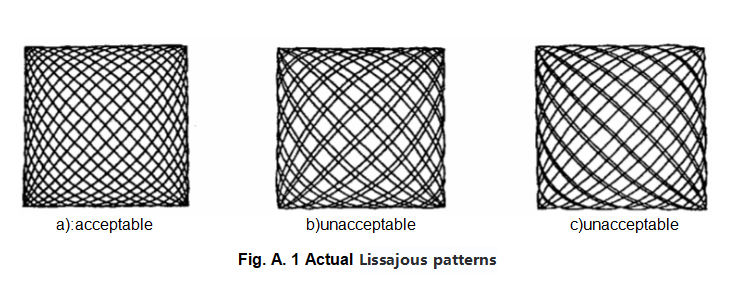

Lissajous pattern Inspection method

Obtain each table’s Lissajous graphs as follows.

Move the material from the grinding table. Cover the table with a piece of white paper. The paper should be round, with a diameter of (100±5) mm. It should be very flat and have a minimum mass of 100 g/m2.

Put a steel sleeve in the guide. It should match the specimen pin’s diameter. Then, put in a common ballpoint pen so that its tip touches the paper. A complete Lissajous pattern is formed after 16 times of friction.

Draw two parallel lines. They should intersect the outer curves of the Lissajous pattern. Draw two more lines for the other two sides. Make sure that these lines cross at right angles. Measure each side properly to an accuracy of 0.2 mm. Check the 31 lines drawn and, importantly, the symmetry of the Lissajous pattern. If the curves coincide with each other or are unevenly spaced (see Figure A.1), please consult us.

Clean the Martindale Abrasion and Pilling Tester after each use with a soft cloth and mild solution to prevent dust buildup. Lubricate moving parts as recommended to ensure smooth operation. Regularly calibrate the equipment and inspect for wear or damage, replacing parts as needed.

Schedule professional maintenance checks with a qualified technician. Keep records of maintenance and repairs for efficient troubleshooting. For specific guidelines, troubleshooting, or spare parts, contact us for assistance.

Frequently Asked Questions of Martindale Tester

Testing accuracy and stability of this Martindale TesterThe Martindale Tester uses dual servo driver motors and precision slide rails. This replaces the old mechanical drive to create a perfect Lissajous curve. We conducted strict tests using rubber analog samples and double pressure weights. These tests ran over 10 million times, which is like three years of constant use. The results show that the Lissajous curve is accurate, and the operation is stable. So the testing accuracy and stability of this Martindale Tester is higher.

How to ensure better Martindale test results for your samples?To improve Martindale test results, follow these best practices:

Prepare Samples: Cut fabric samples to the required size. Then, condition them in a controlled space at 21°C and 65% humidity for 24 hours.

Choose the Right Abrasives: Pick standard abrasives like worsted wool. Check them often for consistency.

Optimize Testing Parameters: Use the right weight, either 9 kPa or 12 kPa. Then, find the right cycle count for the fabric type.

Test several samples: Use specimen breakage and mass loss methods for complete results.

Examine the results closely. Look for patterns and problems. Then, write down your observations.

Regular maintenance: Calibrate and clean the Martindale tester regularly to ensure accurate results.

Train staff on test procedures. Also, keep up with industry standards.

Using these strategies will boost the reliability and accuracy of Martindale test results. This will give better insights into fabric durability.

What is a good score of the Martindale Test? Or how to evaluate whether a textile is qualified?The Martindale Abrasion Pilling Test results show abrasion counts and pilling ratings. The criteria for passing or excelling in these two score metrics will vary. This depends on the test criteria, product type, and use scenario. The following are common determination criteria:

Abrasion count

The abrasion resistance test shows how much a material wears down from friction and use. Usually, a higher number of abrasion counts indicates a better durability of the fabric. The following are some common reference values:

General textiles (e.g., everyday clothing)

Pass standard: 10,000 times or more.

Excellent standard: 20,000 cycles or more

High-demand textiles (e.g., furniture fabrics, car interiors, outdoor equipment)

Qualifying criteria: more than 15,000 times.

Standard of Excellence: 30,000 cycles or more

Some products need to be very durable. For example, furniture fabrics used in public places can handle 50,000 to 100,000 abrasion cycles. This level of durability shows excellent abrasion resistance.

Pilling grade

Experts usually base the pilling grade on visual evaluation and classify it from 1 to 5:

Grade 1: Very severe pilling.

Grade 2: Significant pilling

Grade 3: Moderate pilling; still acceptable

Grade 4: Slight pilling, almost negligible.

Grade 5: No visible pilling.

A pilling level of 3 is acceptable. Levels 4 and above are excellent.

Standards for different industries

Everyday clothing: Pilling level 3 or higher is acceptable. Level 4 or above is excellent.

Home textiles and furnishing fabrics usually need a level 4 or higher for pilling. This is to meet tough quality standards.

Outdoor and Functional Fabrics: They must withstand tough conditions. This means they need abrasion resistance of 30,000 or more. Also, you need a pilling level of 4 or higher for excellence.

Check the industry standards and customer needs for each product. For example, look at ISO 12945 and ASTM D4970.

There are many types of fabric abrasion and pilling testers, how could I select from them?There are a variety of commonly used textile abrasion pilling test equipment, which are mainly selected according to different test methods and standards. The following are a few common types of equipment and their characteristics:

Martindale Abrasion Pilling Tester

Usage: The Martindale tester is the top choice for checking textile abrasion and pilling. It’s widely used for flat abrasion and pilling tests on fabrics.

Principle: Friction is applied to the sample using a set pressure and a circular movement. This simulates how fabric wears down and pills over time.

Applicable materials: For knitted fabrics, woven fabrics, non-woven fabrics, and other textiles.

Standards: Conform to international standards such as ISO 12945-2 and ASTM D4970.

Advantages:

Reliable test results

Widely used

Works for many types of textiles

Suggestion for selection: Martindale is a great option if you want a test that meets global standards and works with many types of fabrics.

ICI Pilling Box Tester

Purpose: This is mainly for testing pilling in textiles. It’s especially good for woolen and knitted fabrics.

Principle: Placing the textile sample in the pilling box shows how clothes rub together when worn. This helps us see how much they pill.

Applicable materials:

Knitted fabrics

Woolen fabrics

Other fabrics that tend to pill.

Standard: Follow ISO 12945-1, BS 5811 and other standards.

Advantages: Great for woolen fabrics and materials that pill easily. The testing conditions match real use environments closely.

Suggestion: If you test woolen or knitted fabrics, pick the ICI pilling box. It simulates real wear better.

Taber Abrasion Tester

Usage: Used to test the abrasion resistance of textiles, not the pilling test.

Principle: Rotating two abrasive wheels on the sample creates strong abrasion. This tests how textiles wear under certain conditions.

Applicable materials:

Industrial textiles

Carpets

Leather

Other materials need high abrasion resistance.

Standards: Conform to ASTM D 3884 and other standards.

Advantages: Suitable for abrasion resistance testing, especially for industrial use textiles.

Suggestion: To see how well textiles hold up to wear in industry, use the Taber abrasion tester.

Random Tumble Pilling Tester

Purpose: To mimic how textiles pill from friction during washing and wear.

Principle: It simulates textile pilling by rolling the sample. The friction from the cork and the device creates the wear.

Standard: ASTM D3512.

Advantages: The simulated environment is realistic. It’s great for testing how textiles pill during washing.

Selection advice: If you’re worried about pilling in the wash, this device might be perfect for you.

Selection advice:

Choose according to your testing needs:

The Martindale tester is the most common choice for testing many fabrics. It works well for pilling and abrasion resistance.

For pilling of woolen or knitted fabrics, the ICI Pilling Box Tester is more suitable.

For testing technical textiles and abrasion resistance, choose the Taber abrasion tester.

Choose according to the test standard:

Ensure your equipment meets the test standard you’re using, like ISO 12945 or ASTM D4970. When testing textiles for export or global markets, ensure a close match to the standards.

What are the key parameters for Martindale Test?Key parameters include:

- Load: The weight applied during testing, typically around 9 kPa.

- Number of cycles: The total number of rubbing cycles, often set to 1000 or more depending on the test requirements.

- Speed: The rate at which the fabric is rubbed, which can be adjusted based on fabric type.

The Martindale Tester uses dual servo driver motors and precision slide rails. This replaces the old mechanical drive to create a perfect Lissajous curve. We conducted strict tests using rubber analog samples and double pressure weights. These tests ran over 10 million times, which is like three years of constant use. The results show that the Lissajous curve is accurate, and the operation is stable. So the testing accuracy and stability of this Martindale Tester is higher.

To improve Martindale test results, follow these best practices:

Prepare Samples: Cut fabric samples to the required size. Then, condition them in a controlled space at 21°C and 65% humidity for 24 hours.

Choose the Right Abrasives: Pick standard abrasives like worsted wool. Check them often for consistency.

Optimize Testing Parameters: Use the right weight, either 9 kPa or 12 kPa. Then, find the right cycle count for the fabric type.

Test several samples: Use specimen breakage and mass loss methods for complete results.

Examine the results closely. Look for patterns and problems. Then, write down your observations.

Regular maintenance: Calibrate and clean the Martindale tester regularly to ensure accurate results.

Train staff on test procedures. Also, keep up with industry standards.

Using these strategies will boost the reliability and accuracy of Martindale test results. This will give better insights into fabric durability.

The Martindale Abrasion Pilling Test results show abrasion counts and pilling ratings. The criteria for passing or excelling in these two score metrics will vary. This depends on the test criteria, product type, and use scenario. The following are common determination criteria:

Abrasion count

The abrasion resistance test shows how much a material wears down from friction and use. Usually, a higher number of abrasion counts indicates a better durability of the fabric. The following are some common reference values:

General textiles (e.g., everyday clothing)

Pass standard: 10,000 times or more.

Excellent standard: 20,000 cycles or more

High-demand textiles (e.g., furniture fabrics, car interiors, outdoor equipment)

Qualifying criteria: more than 15,000 times.

Standard of Excellence: 30,000 cycles or more

Some products need to be very durable. For example, furniture fabrics used in public places can handle 50,000 to 100,000 abrasion cycles. This level of durability shows excellent abrasion resistance.

Pilling grade

Experts usually base the pilling grade on visual evaluation and classify it from 1 to 5:

Grade 1: Very severe pilling.

Grade 2: Significant pilling

Grade 3: Moderate pilling; still acceptable

Grade 4: Slight pilling, almost negligible.

Grade 5: No visible pilling.

A pilling level of 3 is acceptable. Levels 4 and above are excellent.

Standards for different industries

Everyday clothing: Pilling level 3 or higher is acceptable. Level 4 or above is excellent.

Home textiles and furnishing fabrics usually need a level 4 or higher for pilling. This is to meet tough quality standards.

Outdoor and Functional Fabrics: They must withstand tough conditions. This means they need abrasion resistance of 30,000 or more. Also, you need a pilling level of 4 or higher for excellence.

Check the industry standards and customer needs for each product. For example, look at ISO 12945 and ASTM D4970.

There are a variety of commonly used textile abrasion pilling test equipment, which are mainly selected according to different test methods and standards. The following are a few common types of equipment and their characteristics:

Martindale Abrasion Pilling Tester

Usage: The Martindale tester is the top choice for checking textile abrasion and pilling. It’s widely used for flat abrasion and pilling tests on fabrics.

Principle: Friction is applied to the sample using a set pressure and a circular movement. This simulates how fabric wears down and pills over time.

Applicable materials: For knitted fabrics, woven fabrics, non-woven fabrics, and other textiles.

Standards: Conform to international standards such as ISO 12945-2 and ASTM D4970.

Advantages:

Reliable test results

Widely used

Works for many types of textiles

Suggestion for selection: Martindale is a great option if you want a test that meets global standards and works with many types of fabrics.

ICI Pilling Box Tester

Purpose: This is mainly for testing pilling in textiles. It’s especially good for woolen and knitted fabrics.

Principle: Placing the textile sample in the pilling box shows how clothes rub together when worn. This helps us see how much they pill.

Applicable materials:

Knitted fabrics

Woolen fabrics

Other fabrics that tend to pill.

Standard: Follow ISO 12945-1, BS 5811 and other standards.

Advantages: Great for woolen fabrics and materials that pill easily. The testing conditions match real use environments closely.

Suggestion: If you test woolen or knitted fabrics, pick the ICI pilling box. It simulates real wear better.

Taber Abrasion Tester

Usage: Used to test the abrasion resistance of textiles, not the pilling test.

Principle: Rotating two abrasive wheels on the sample creates strong abrasion. This tests how textiles wear under certain conditions.

Applicable materials:

Industrial textiles

Carpets

Leather

Other materials need high abrasion resistance.

Standards: Conform to ASTM D 3884 and other standards.

Advantages: Suitable for abrasion resistance testing, especially for industrial use textiles.

Suggestion: To see how well textiles hold up to wear in industry, use the Taber abrasion tester.

Random Tumble Pilling Tester

Purpose: To mimic how textiles pill from friction during washing and wear.

Principle: It simulates textile pilling by rolling the sample. The friction from the cork and the device creates the wear.

Standard: ASTM D3512.

Advantages: The simulated environment is realistic. It’s great for testing how textiles pill during washing.

Selection advice: If you’re worried about pilling in the wash, this device might be perfect for you.

Selection advice:

Choose according to your testing needs:

The Martindale tester is the most common choice for testing many fabrics. It works well for pilling and abrasion resistance.

For pilling of woolen or knitted fabrics, the ICI Pilling Box Tester is more suitable.

For testing technical textiles and abrasion resistance, choose the Taber abrasion tester.

Choose according to the test standard:

Ensure your equipment meets the test standard you’re using, like ISO 12945 or ASTM D4970. When testing textiles for export or global markets, ensure a close match to the standards.

Key parameters include:

- Load: The weight applied during testing, typically around 9 kPa.

- Number of cycles: The total number of rubbing cycles, often set to 1000 or more depending on the test requirements.

- Speed: The rate at which the fabric is rubbed, which can be adjusted based on fabric type.