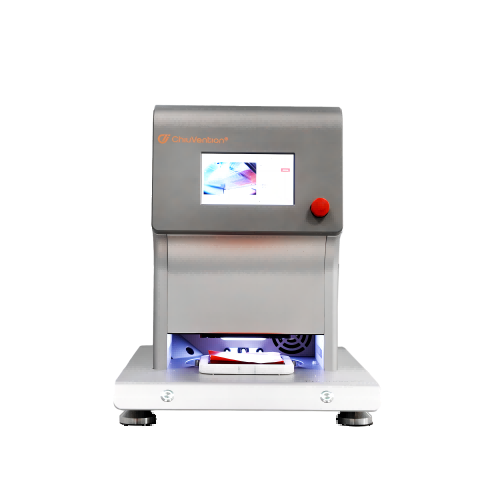

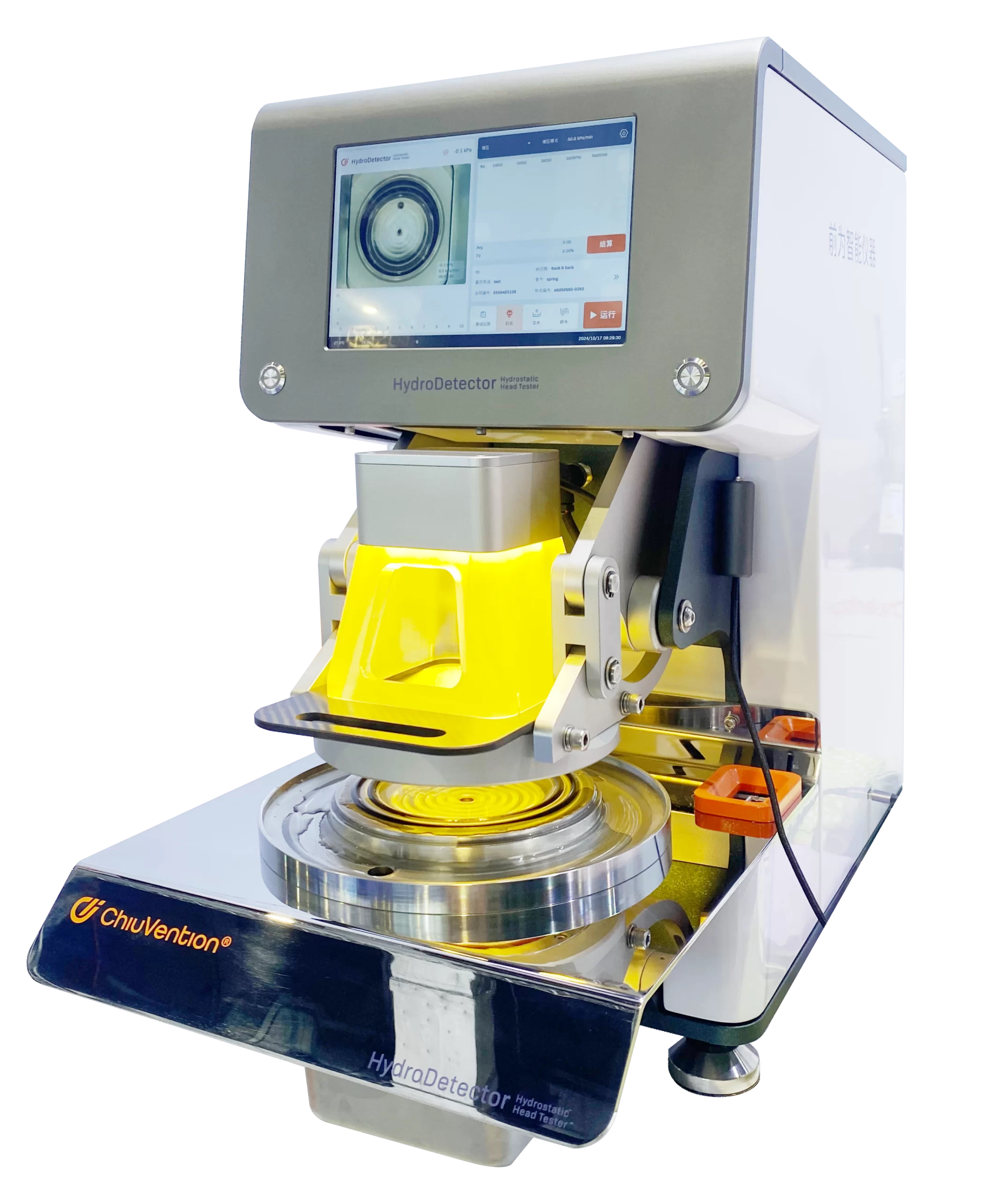

AI Detects the water droplets.

The system has visual detection with smart judgement. It uses a high-definition camera to record the testing process. AI algorithms automatically identify and determine compliant water droplets or other test-ending conditions. They then end the test and notify the operator via smartphone or buzzer. This testing instrument supports continuous learning and upgrades. It enables more accurate detection and judgement. It has remote OTA (Over-the-Air) updates for better functionality.

Intelligent Assistance Mode

The system includes a video playback feature. After automated testing, complex samples can be quickly reviewed via video playback. If there is an error in judgment, manual annotation can quickly correct it.

Adaptive Sample Clamping System

The servo clamping system can automatically adjust the clamping force based on the testing pressure by using advanced algorithms. This keeps enough clamping force to prevent water leaks and also protects the sample’s integrity.

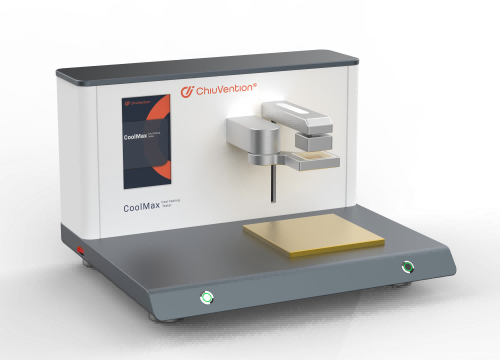

Servo-Mechanical Pressurization

The servo-mechanical pressurization system applies pressure at a standard rate. This ensures stability and prevents large water droplets from spraying after sample rupture.

High-pressure testing is possible.

HydroDetectors are capable of high-pressure testing up to 600 kPa. You can customize higher test pressures.

Powerful and User-friendly Control Screen

The control screen is powerful and as easy to use as a smartphone. It allows convenient viewing of the testing process and results. Test videos and results can be exported in several formats for review. The test results can be edited and corrected based on manual judgment. With the IoT app, users can monitor tests remotely. They get alerts when tests finish. They can view or send test reports, or upload them to the LIMS.

Besides, this instrument does not need compressed air, eliminating noise. Its unique design allows for rapid replacement of fixtures and mesh clamps.

Wide range of applications

This Hydrostatic Head Tester is suitable for a wide range of materials, such as textiles, film materials, paper, construction materials, etc., and the water column pressure range can be adjusted according to different materials and testing requirements.

Designed in Germany, quality is our life.

All our textile testing equipment is developed in-house and in cooperation with a team of renowned German industrial designers, which makes our textile testing machines of outstanding quality. 100% source factory and factory price.

Application Examples of HydroDetector Hydrostatic Head Tester

Waterproof Clothing

Outdoor Equipment

Building Materials

Protective Clothing

Customer Feedback

“The feature that automatically monitors water infiltration is fantastic! We learned about ChiuVention in 2023 and cooperated many times.”

“Through the use of this Hydrostatic Head Tester, the quality of our protective clothing is improved and our products have been highly recognized by the hospital.”

OUR BROCHURE

FLYER

HydroDetector Hydrostatic Head Tester Standards

Standard

AATCC 127 Option 2, ISO 811, GB/T 4744, GB/T 40910, JIS L1092

Optional Standard

ISO9073-16, EN 1734

ISO 1420, AATCC 208

IS 7016(Part7), NWSP 080.6.RO(15), GB/T 24218.16, FZ/T 01004

The Specification of HydroDetector Hydrostatic Head Tester

Standard test head 100cm2

Units Pa, kPa, mmHg, cm H₂O

Pressure range 0~600 kPa (50m water column )

Higher test pressures customizable

Rising speed of water pressure 1~60 kPa/min, with variable and adjustable speed

Power 220 V 50 / 60 Hz Other voltages require an extemal transformer

Weight 94 Kg

Dimension 360*670*635 mm(L*W*H)

GET A QUOTE

Frequently Asked Questions of Hydrostatic Head Testing

What are the main functions of hydrostatic pressure tester?Measuring a material’s waterproofness shows how much water pressure causes leaks.

Testing waterproofing treatment effectiveness: This checks if coatings or treated materials work well.

Quality control: Used during production to ensure that products meet waterproof performance standards.

Research and development testing studies how well new materials or processes resist water.

Outdoor gear testing: Testing how well tents, raincoats, and backpacks resist water.

Testing building materials: checking how well items like waterproof membranes and coatings perform.

What are the maximum and minimum testing pressures of the device?0~600 kPa (50m water column ), this Hydrostatic Head Tester can test bigger water pressure than many other machines in the market.

We can also customize a pressure test capacity of more than 600 kPa for you.

Can it test different types of fabrics and materials?Of course, this hydrostatic head tester can test outdoor apparel, tents, outdoor gear, medical textiles, performance fabrics, military and defense, automotive and upholstery fabrics.

How precise is the pressure measurement?The instrument uses an AI algorithm. It adjusts based on sample thickness and hydrostatic pressure resistance. This way, it releases different pressures for different materials. The sample clamping pressure can be adjusted during testing. This makes the pressurization smooth and stable. As a result, the test accuracy is very high.

Does it comply with relevant international standards (e.g., ISO 811, AATCC 127)?Yes, and it applies to many test standards, such as

AATCC 127 Option 2, ISO 811, GB/T 4744, GB/T 40910, JIS L1092, ISO9073-16, EN 1734, ISO 1420, AATCC 208, IS 7016(Part7), NWSP 080.6.RO(15), GB/T 24218.16, FZ/T 01004

Is the rate of water pressure increase adjustable?Yes, the rate of water pressure can be adjusted.

What's the average time for a single test?It depends on how well materials resist hydrostatic pressure. The HydroDetector can use AI to monitor water penetration on textile surfaces.

You don’t have to wait by the machine. You’ll get reminders on your phone when the 3rd drop of water shows up.

Is the user interface user-friendly? Is a Chinese interface available?Yes, 2 languages can be used, English and Chinese.

Can it automatically record and store data?Our HydroDetector Hydrostatic Head Tester has IoT technology. This lets the machine connect to a smartphone or PC.

and the test report and test process can be recorded and stored, and then checked on your smartphone or PC. Also, you can link this machine to LIMS and ERP.

Is it possible to export data to Excel or other formats?Yes, you can export the data, usually in PDF format.

Is there any accompanying data analysis software?Yes, this is an Intelligent Hydrostatic Head Tester.

Is hydrostatic head testing different from Waterproof Testing? Why?Yes, hydrostatic head testing is different from waterproof testing, though they both aim to evaluate water resistance. Here’s a breakdown of how they differ and why:

Hydrostatic Head Testing vs. Waterproof Testing

Hydrostatic Head Testing

Purpose: Measures a material’s resistance to water penetration under pressure.

Procedure: A sample is exposed to increasing water pressure until seepage occurs, measured in mm H₂O or Pa.

Applications: Used for waterproof fabrics, outdoor gear, and membranes.

Outcome: Provides a numerical value indicating water resistance.

Waterproof Testing

Purpose: Assesses overall water impermeability under various conditions.

Procedure: Includes submersion, rain exposure, spray, and sealing tests, varying by industry.

Applications: Used for electronics, footwear, construction materials, and packaging.

Outcome: Typically results in a pass/fail determination based on water exposure criteria.

Key Differences

Focus: Hydrostatic Head Testing quantifies pressure resistance, while Waterproof Testing evaluates broader impermeability.

Measurement: Hydrostatic Head provides numerical values (mm H₂O, Pa); Waterproof Testing is often pass/fail.

Scope: Hydrostatic Head is mainly for fabrics, whereas Waterproof Testing applies to diverse products.

Summary:

While hydrostatic head testing is a specific type of waterproof testing focused on measuring water resistance under pressure, it includes a broader array of tests that may involve submersion, rain simulation, or splash resistance for various products. The difference lies in the methodology and the scope of the application.

Measuring a material’s waterproofness shows how much water pressure causes leaks.

Testing waterproofing treatment effectiveness: This checks if coatings or treated materials work well.

Quality control: Used during production to ensure that products meet waterproof performance standards.

Research and development testing studies how well new materials or processes resist water.

Outdoor gear testing: Testing how well tents, raincoats, and backpacks resist water.

Testing building materials: checking how well items like waterproof membranes and coatings perform.

0~600 kPa (50m water column ), this Hydrostatic Head Tester can test bigger water pressure than many other machines in the market.

We can also customize a pressure test capacity of more than 600 kPa for you.

Of course, this hydrostatic head tester can test outdoor apparel, tents, outdoor gear, medical textiles, performance fabrics, military and defense, automotive and upholstery fabrics.

The instrument uses an AI algorithm. It adjusts based on sample thickness and hydrostatic pressure resistance. This way, it releases different pressures for different materials. The sample clamping pressure can be adjusted during testing. This makes the pressurization smooth and stable. As a result, the test accuracy is very high.

Yes, and it applies to many test standards, such as

AATCC 127 Option 2, ISO 811, GB/T 4744, GB/T 40910, JIS L1092, ISO9073-16, EN 1734, ISO 1420, AATCC 208, IS 7016(Part7), NWSP 080.6.RO(15), GB/T 24218.16, FZ/T 01004

Yes, the rate of water pressure can be adjusted.

It depends on how well materials resist hydrostatic pressure. The HydroDetector can use AI to monitor water penetration on textile surfaces.

You don’t have to wait by the machine. You’ll get reminders on your phone when the 3rd drop of water shows up.

Yes, 2 languages can be used, English and Chinese.

Our HydroDetector Hydrostatic Head Tester has IoT technology. This lets the machine connect to a smartphone or PC.

and the test report and test process can be recorded and stored, and then checked on your smartphone or PC. Also, you can link this machine to LIMS and ERP.

Yes, you can export the data, usually in PDF format.

Yes, this is an Intelligent Hydrostatic Head Tester.

Yes, hydrostatic head testing is different from waterproof testing, though they both aim to evaluate water resistance. Here’s a breakdown of how they differ and why:

Hydrostatic Head Testing vs. Waterproof Testing

Hydrostatic Head Testing

Purpose: Measures a material’s resistance to water penetration under pressure.

Procedure: A sample is exposed to increasing water pressure until seepage occurs, measured in mm H₂O or Pa.

Applications: Used for waterproof fabrics, outdoor gear, and membranes.

Outcome: Provides a numerical value indicating water resistance.

Waterproof Testing

Purpose: Assesses overall water impermeability under various conditions.

Procedure: Includes submersion, rain exposure, spray, and sealing tests, varying by industry.

Applications: Used for electronics, footwear, construction materials, and packaging.

Outcome: Typically results in a pass/fail determination based on water exposure criteria.

Key Differences

Focus: Hydrostatic Head Testing quantifies pressure resistance, while Waterproof Testing evaluates broader impermeability.

Measurement: Hydrostatic Head provides numerical values (mm H₂O, Pa); Waterproof Testing is often pass/fail.

Scope: Hydrostatic Head is mainly for fabrics, whereas Waterproof Testing applies to diverse products.

Summary:

While hydrostatic head testing is a specific type of waterproof testing focused on measuring water resistance under pressure, it includes a broader array of tests that may involve submersion, rain simulation, or splash resistance for various products. The difference lies in the methodology and the scope of the application.