Hydrostatic pressure resistance is a key test of waterproof, breathable fabrics. It refers to the resistance to water passing through the fabric. It indicates the fabric’s resistance to water penetration. The test results relate to the fabric’s waterproofness and its nature.

We can measure a fabric’s water repellency by three indexes: the water stain level, hydrostatic pressure, and water penetration. The hydrostatic pressure resistance level is water permeability. The water staining level is water rejection. The higher a fabric’s hydrostatic pressure limit, the more water repellent it is.

Water Repellency

Water repellency is a fabric’s ability to stop water from soaking in, under a certain pressure. It includes preventing water from wetting the fabric. Waterproof performance is mainly tested by hydrostatic pressure. It is also tested by water spray and rain tests.

What is waterproof and moisture permeable functional fabric?

Waterproof and moisture-permeable fabric means two things. First, water at a certain pressure does not soak into the fabric. Second, it lets sweat escape as water vapor. This prevents sweat from accumulating and condensing on the body and fabric. The goal is to keep the garment comfortable. This fabric is a high-tech, unique, functional material. The words “understand, waterproof and moisture permeability” seem contradictory. But, they are consistent with the fabric’s structure and processing. Water in different states has different-sized molecules. This allows for their movement. This fact forms a key principle of waterproof and moisture-permeable fabrics.

Waterproof and moisture permeable finishing mechanism

The water vapour molecule is 0.0004 microns in diameter. The smallest raindrops in light fog are 20 microns. The largest raindrops are 400 microns. A film with a pore diameter between those sizes would be both waterproof and breathable. Wouldn’t that be ideal?

Recent advances in science and technology have improved outdoor gear, like punch trousers. They now use GORE-TEX and FIRST-TEX. These are waterproof, breathable fabrics. The small holes are between the water droplets and the vapor molecules, in the film state. It allows water vapour to pass, but blocks the water droplets. This achieves waterproofing and moisture permeability. For example, GORE-TEX film has 9 billion tiny holes per square inch. They are 20,000 times smaller than a water droplet, so rain can’t get through. The holes are 700 times larger than water vapour molecules, so sweat can escape. This keeps the body comfortable and dry.

Hydrostatic pressure test

Hydrostatic pressure test: It is a key measure of waterproof, breathable fabrics. It refers to the resistance when water passes through the fabric. It measures how well the fabric resists water penetration. Under standard conditions, one side of the fabric faces rising water pressure. If the back of the fabric exudes a set number of water droplets, the measured water pressure is hydrostatic pressure. This method measures more than just the fabric’s waterproofness. It also relates to the fabric’s nature.

Hydrostatic pressure test principle

A common method to test fabric water permeability is the hydrostatic pressure test. It uses the pressure on the fabric to show the resistance to water passing through it. Under standard conditions, we apply rising water pressure to one side of the specimen. This continues until three seepage points appear on the other side. Record the water pressure at the third seepage point. The specimen’s waterproof performance is then evaluated.

Waterproof performance key indicators

As living standards rise, people want more from their clothes. They seek better quality and comfort. The rise in outdoor sports has increased the demand for waterproof gear. We usually think “waterproof” means fabrics stay dry after contact with water. It should also mean they resist water penetration. The main indexes of fabric waterproof performance are: water staining grade, hydrostatic pressure resistance grade, and water penetration amount.

Hydrostatic pressure resistance grade

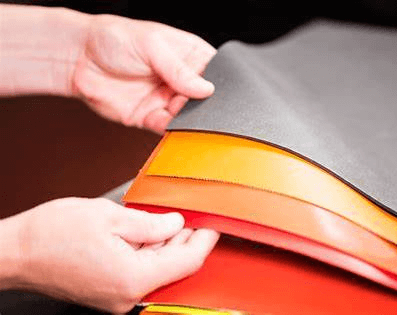

1. Laminated composite waterproof fabrics use special adhesives. They bond ordinary fabrics through a lamination process to form waterproof laminated fabrics. The laminates can be two-layer or multi-layer fabrics.

2. Waterproof agents treat coated waterproof fabrics. A direct or transfer method accomplishes this.

The hydrostatic pressure on the fabric measures its resistance to water. At standard conditions, rising water pressure hits one side of the specimen. This continues until three seepage points appear on the other side. We record the water pressure at the third seepage point. The specimen’s water resistance is then evaluated.

Water Staining Grade

1. Water-repellent textiles use finishing agents with low surface energy. They act on the surface of the fibres. This reduces the textiles’ critical surface tension. Water will not wet them as a result.

2. Water Staining Test. Currently, we use a spray method to test the water staining level of textiles.

Waterproof and moisture permeability standard

1. Waterproof and moisture-permeable fabrics, or “breathable fabrics,” are special. They keep out water at a certain pressure. At the same time, they let sweat in the form of vapor escape. This prevents sweat from building up between the body and the fabric. It helps keep the wearer comfortable. It is a functional fabric. And it has unique features. It is waterproof, moisture-permeable, and windproof. It is warm, too.

2. GB/T 40910-2021 evaluates ‘textile waterproof and moisture permeability.’ It uses three tests: ‘hydrostatic pressure,’ ‘water level,’ and ‘moisture permeability rate.’

The waterproof and moisture-permeable performance has three levels: Grade Ⅰ, Grade Ⅱ, and Grade Ⅲ.

Grade Ⅰ means it has waterproof and moisture-permeable performance. Grade Ⅱ means it has better performance. And grade Ⅲ means it has excellent performance. Grade Ⅲ is better than Grade Ⅱ, and Grade Ⅱ is better than Grade Ⅰ.

Hydrostatic pressure test standard

GB/T4744-2013 Detection and evaluation of waterproof performance of textiles hydrostatic pressure method

GB/T24218.16-2017 Textile nonwovens test methods. Part 16: Test methods for water permeability resistance (hydrostatic method).

FZ/T01004-2008 Determination of water permeability of coated textiles

ISO811-1981 Determination of water permeability of textiles hydrostatic pressure test

ISO1420-2016 Determination of water permeability of rubber or plastic coated textiles

ISO9073-16-2007E Test methods for textile nonwovens. Part 16: Water penetration resistance (hydrostatic pressure).

AATCC127-2014 Determination of water penetration resistance hydrostatic pressure test

JISL1092:2009 Test Method for Water Repellency of Textiles

Fabric waterproof performance

Fabric waterproof is a special requirement for performance. There are two kinds of waterproof: waterproof and impermeable.

Waterproof

In business, “waterproof” is often omitted. The correct term is “splash-proof.” It is commonly used as follows: At the sizing machine’s fabric feeding point, we add hydrophobic additives to a tank of liquid. The fabric is then soaked, rolled, and dried in the tank. This forms a hydrophobic coating on the fibre’s surface.

Hydrophobic compounds can change the fibre’s surface tension. This limits its activity and reduces water adsorption. If the fibre’s surface tension is lower than water’s, it will form a rollable droplet, like a lotus leaf does with dew. People know this as ‘dial water.” This is also known as ‘water repellent’, abbreviated as W/R.

The fabric’s pores allow air and water vapour to pass through. However, water can seep or soak up if it stays in one place for too long or is under pressure. On a rainy day, water-repellent clothes can shed water. But, if the inner layer and undergarment get wet depends on the rain’s amount and duration. The garment’s waterproof effect will decay with washing and use. It will become ineffective. So, waterproofing reduces water absorption by the fabric. It isn’t truly waterproof, but we shorten it to ‘waterproof’.

Impermeability

Waterproof means to resist and block water. That’s true waterproofing.

True waterproof fabrics can outlast waterproof fabrics in terms of durability. They are more stable, both physically and chemically. They usually do not fail after washing and prolonged use. A true waterproof treatment must form an impermeable barrier on one side of the fabric. This requires a high water pressure rating, e.g. 3000mm or more.

We achieve impermeability by using an adhesive film on the fabric’s underside. This prevents water penetration. Two common methods are coating and lamination.

Coating is a waterproof film on one side of the fabric. Glue or a film makes it. It prevents infiltration. Commonly used methods are direct coating (dry, wet, hot melt) and transfer coating.

The lamination method is to make a fabric composite. It uses a waterproof film, or “membrane.” This method unifies the fabric and the membrane, regardless of the fabric’s waterproofness. The membrane always prevents water from penetrating.

Another method is hot melt calendering. It bonds the fabric to a polymer waterproof film. This prevents water penetration.

Purpose.

We measure true waterproofing (impermeability) by its water pressure resistance. ‘Millimetres of water column’ express it. In a test, we use a fixed area of waterproof fabric. It prevents water from penetrating through its surface. When the water pressure increases, the third drop of water seeps out. The pressure at that point is the fabric’s water pressure resistance value. Fabrics with a water pressure of over 1000mm can be waterproof.

Hydrostatic pressure test method

There are several methods of hydrostatic pressure test under laboratory conditions:

(1) Increase the water pressure continuously on one side of the fabric. Find the highest hydrostatic pressure the fabric can withstand. It is the point before a specified number of water drops appear on the other side. Adopts this test method for compact fabrics like canvas, tarpaulin, and tent fabrics.

(2)Under the specified conditions, apply rising water pressure to one side of the specimen until it reaches the specified value. Then, check for infiltration within the specified time. If there are no water infiltration points or wetting on the surface, the specimen passes the test. FZ/T 01004-2008 uses this method to test if coated fabrics meet the requirements.

(3) Keep a certain water pressure on one side of the fabric. Then, time how long it takes for the first drop of water to seep out from the other side.

(4) Maintain a certain water pressure on one side of the fabric. Then, measure the water that passes through the fabric per unit of time.

The hydrostatic pressure test is a simple, fast detection method. It can be accurately quantified and has good reproducibility.

The international ISO 811 and ISO 1420 use the hydrostatic method. Most countries based their standards on these two. The test principles of ISO 811 and ISO 1420 are basically the same. They apply water pressure to one side of a specimen and observe for penetration. The difference is that ISO 811 is for general fabrics, while ISO 1420 is for coated fabrics. Also, there are some differences in the test results. ISO 811 continues to increase the water pressure in the test until the specimen seeps. It records the pressure as the result. ISO 1420, however, maintains a specified water pressure for a time. If the specimen does not seep, it passes the test.

Note the problems when testing hydrostatic pressure.

(1) Before placing the fabric, discharge the air in the fixture. Then, wet the fabric’s front side and clamp it. This avoids inaccurate data from air pressure affecting the water pressure.

(2) In some composite fabric tests, the fabric’s reverse side is not waterproof. So, you must cut the test sample larger than the instrument sink. This prevents water from getting into the fabric. It could affect the hydrostatic pressure test.

Factors affecting the hydrostatic pressure resistance of fabrics

The level of fabric waterproof index depends on the following factors:

(1) The tightness of the fabric. The greater the distance between the yarns, the lower the hydrostatic pressure resistance. Generally the tighter the fabric structure, the better its water resistance.

(2) The thickness of the fabric. Thicker fabric has better moisture and water pressure resistance.

(3) The thickness of the yarn. The moisture-absorbent fibres in compact fabrics have a capillary effect. Reducing the yarn radius can improve the fabric’s water permeability.

(4) The quality of the composite membrane. The larger the pore size of the membrane, the worse the hydrostatic pressure resistance of the coated fabric.

(5) Coating thickness. The coating is too thin. The agent can’t form a continuous film on the surface. This reduces the coated fabric’s hydrostatic resistance. A thick coating improves the fabric’s hydrostatic resistance.

(6) The uniformity of the coating. The better the quality of the coating, the better the water penetration resistance. Uneven coating, the lower the hydrostatic pressure value.

Fabrics’ Water Permeability (Water Repellency) It is their ability to repel liquid water. It is the ability of water to penetrate from one side of the fabric to the other.

For the waterproofness and water permeability of fabrics, there are 3 main factors:

1. Wettability of the fibre surface

If the fibres’ contact angle θ<90°, the fibre aggregate is a water-conducting material. Its tight structure will increase capillary suction, drawing up water. If θ > 90°, the fibre is water-repellent. A tighter fabric structure (i.e. less porosity) improves water repellency. So, we can only discuss the fabric’s waterproofness if we know the fibres’ contact angle.

2. Coating of fabric

A continuous, impermeable, and water-insoluble film on a fabric’s surface makes it waterproof. It is not great for clothing. You can use it for tarps or ponchos. Applying the waterproof, porous coating film will make the fabric excellent. It will be waterproof, and it will allow air and water to pass through.

3. The environment

Non-hygroscopic materials make water-repellent or coated fabrics. So, changes in humidity won’t affect their waterproof performance. Water-conducting fabrics, on the other hand, are mostly hygroscopic fibre materials. As relative humidity rises, the fibre absorbs more moisture. This expands the fibre and boosts its capillary action. So, the fabric’s water conductivity increases. The effect of temperature is the same as humidity. Therefore, the environment has a great influence on the water-conducting fabrics.

Fabric waterproof performance test

Spray method: AATCC 22-2005 water repellency test

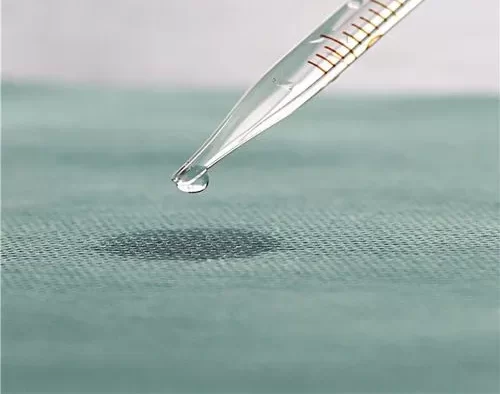

Test Procedure: Under the specified condition, spray water on a taut specimen. This will wet its surface. The pattern’s size relates to the fabric’s water repellency. Comparing the result with a standard pattern assesses it.

The spray method tests fabric water repellency. It involves spraying or dripping water onto the specimen. After a while, observe the water stains on its surface. Then, compare the results with various wetting degree samples. The spray method simulates the degree of wetting of clothing when exposed to a light rain.

This method is applicable to all water repellent treated and untreated fabrics. The water repellency results depend on the fibres, yarns, and treatment. They also depend on the fabric’s structure.

Spray the sample with 250mL of distilled water at 45° from a standard nozzle, 150mm below it, for 25-30 seconds. Then, tap the bottom of the ring holding the sample once on a solid object, with the test surface facing it. Then, rotate the ring 180° and tap once. Compare the sprayed specimen’s surface to a standard drawing card. This will rate its water repellency.

There are 5 levels of evaluation, with level 5 being the best and level 1 being the worst. level 5 – no droplets on the test sample; level 4 – slight wet spots; level 3 – obvious wet spots; and level 4 – no droplets.

Level 5 – no water droplets on the test sample. Level 4 – slight wet spots on the test sample. And level 3 – visible rain drops on the test sample. Level 2 – partially wet on the test sample. Level 1 – completely wet on the test sample.

Hydrostatic Pressure: AATCC 127-2003 Water Resistance.

Hydrostatic Pressure Test Procedure: Apply water pressure to one side of the specimen at a constant rate. Stop when it seeps through the other side in three places. You may apply the water pressure to the specimen from above or below.

The hydrostatic pressure method tests how well a fabric resists water at a set pressure. It applies to all fabrics, including waterproofed ones.

A fabric’s water repellency depends on its fibres, yarns, and structure. Tests don’t measure the same as water sprayed or rained on the fabric. The hydrostatic pressure method measures fabric waterproofness. It has two types: static and dynamic pressure methods. The hydrostatic method applies pressure to one side of the fabric. It then measures the water under this pressure, the time for it to drop, and the pressure at a set water level. The hydrostatic pressure value can be the water column height or pressure.

It measures water permeability per unit area and time (mL/cm2-h). For water-repellent fabrics, we time how long it takes for water droplets to appear on the other side. Alternatively, we observe the number of droplets after a set time.

In the AATCC 127-2003 test, test the diagonal of at least three 200mm × 200mm samples. The two sides of the sample have different water resistances. The test, well marked, used (21 ± 2) ℃ distilled water. It tested a 100cm2 area, with the surface in contact with the water. The water pressure increased at a rate of 60mbar/min (or 10mm/s). If three different places on the sample oozed droplets, the test ended.

Rain Shower Method: AATCC 35-2006

The Rain Shower Method tests a fabric’s water repellency. It exposes the fabric to air during a simulated downpour. This method is applicable to any fabric with or without a water repellent finish.

We test the water repellency of single-ply or composite fabrics at various speeds of water impact. The test results are about the fabric’s water repellency. It depends on the fibres, yarns, and fabric structure.

Wrap the test sample around the absorbent paper. We weighed it. After the test, we will weigh the absorbent paper again. The difference in weight is the water permeability of the sample. The absorbent paper’s weight must not differ by more than 1g before and after the test. A difference greater than 5g indicates very poor water resistance in the fabric.

In the rainfall tester test, AATCC 35-2006 is to weigh a 15.2cm × 15.2cm standard absorbent paper behind the sample. The weight must be accurate to 0.1g. The sample gripper will clamp the sample onto the vertical rigid surface. Place it in the middle of the shower, 30.5 cm from the nozzle. Spray the specimen horizontally with a stream of water at (27±1)°C for 5 min.

At the end of the shower, carefully remove the absorbent paper and quickly weigh it to the nearest 0.1 g. Calculate the increase in the weight of the paper during the 5 min shower time and take the average of the test data. If it is greater than 5.0g, report it as +5.0g or >5.0g.

Core Suction Method

The core absorption method, or grossing, is the most common and simplest way to test fabric absorbency.

The test sample is usually cut into long strips. An iron frame table suspends one end. The other end either touches water or submerges in it. After time (f), measure how high the water climbed (h) through the fabric’s capillary tubes and pores.

Good hydraulic conductivity fabrics are highly absorbent. They have a fast water absorption rate (i.e., core suction rate). They also have a high hydraulic conductivity height, or a large climb height per unit time. If the fabric’s structure, fibre, yarn, and colour hide the water climbing, add a little dye to the water. The naked eye cannot see it well.

At the microscopic level, v is the core suction velocity. It depends on the fibre’s properties and the liquid’s thermal equilibrium. In the macroscopic, it depends on the pores’ morphology and direction.

The core suction velocity is the height value of water rising in unit time, i.e. v(cm/s)=h/t. The size of core suction velocity directly influences the strength of water conductivity. Therefore, we can use core suction to test the fabric’s ability to conduct water.

Comparison of waterproof test methods

1 According to the test method classification

① field test. The field test costs a lot of money and takes a long time, usually takes about half a year. After finishing, we regularly test the waterproofness of the fabric. This is to check its durability. Although this method is long and costly, the data obtained from the test is accurate.

② Simulation test. Simulation testing must have an environmentally controlled room. The room has an artificial rain tower. It can create a torrential downpour. Water flows from 10m high at 450L/(m²-h) to a mannequin. The 2,000 holes at the top produce 5mm diameter droplets. They fall at 40km/h, reaching a maximum of 90% humidity. By adjusting this, you can imitate showers of different intensities over an area of about 2m. Sensors fill the surface of the mannequin. They detect the time and place of the last water transmission and other indicators.

This testing method takes only a few days. It’s much shorter than field testing, but more expensive.

Revised active sentence: It takes only a few days to complete this test. But, it is more costly than field testing.

③ Laboratory testing. The lab test is better than the field and simulation tests. It costs less, takes less time, and gives similar results. There are two categories for testing the waterproofness of fabrics. After finishing them to be waterproof and moisture-permeable, they are now ready. The first category is hydrostatic pressure test. The second category is the spray test. It tests water from a certain height and angle on the fabric. It measures the time to soak the fabric from one side to the other. After a time, it measures how much water the fabric absorbed. It also checks for water damage. The ISO4920 rainproof performance test uses this principle.

2 according to the form of pressure classification

① dynamic method. To test the fabric’s water pressure, I increased it. I measured until the other side of the fabric showed a specified number of water droplets. This indicated the fabric’s hydrostatic pressure limit.

② static method. To test the fabric, I must maintain a certain water pressure on one side. I need to determine how long it takes for water to penetrate to the other side.

3 can withstand hydrostatic pressure value according to the size of the classification

① low-pressure test method. Standard test methods are:

China’s national standard GB/T4744-1997 ‘textile fabric permeability determination of hydrostatic pressure test

The low-pressure method of FZ/T01004-1991. It is a Chinese industry standard. It’s for ‘coated fabric water permeability determination of hydrostatic pressure test.’

CGSB-4.2No.26.3-1995 is a Canadian Standard. It is for a hydrostatic pressure test to find the water permeability of textile fabrics.

ISO 1420:1987 is a test for the water permeability of rubber and plastic coated fabrics.

Japanese Industrial Standard JISL1092 ‘Hydrostatic Test for Water Resistance of Textiles A’.

AATCC Standard AATCC127 tests textiles for water resistance. It is the Hydrostatic Test.

ASTM D751 (1995) tests water resistance of coated fabrics.

② High-pressure test methods. Standard test methods are:

FZ/T01004-1991 is a high-pressure method for testing coated fabric water resistance. It is a hydrostatic pressure test.

ISO1420:1987 ‘rubber and plastic coated fabrics impermeability determination of hydrostatic test

JISL1092 ‘Hydrostatic test for water resistance of textiles B’.

ASTMD751(1995) ‘Procedure for the Determination of Water Resistance of Coated Fabrics A’.

US Federal Standard Test Method FED-STD-191A5512

ASTMD3393 ‘Standard Note on Water Resistance of Coated Fabrics

Test Procedure

1 Humidification and test atmosphere

We perform moisture conditioning and test atmospheres as specified. If everyone agrees, we can humidify and test at room temperature or in the actual environment.

2 Specimen preparation

After taking the sample, minimise handling of the specimen and avoid forceful folding. No treatment (e.g. ironing) other than moisture adjustment. Cut at least 5 specimens from different parts of the fabric. Their size must meet the test area’s requirements. They should be as representative as possible. Do not cut the specimens for testing. Avoid conducting tests on areas with deep folds or creases. If we must find the hydrostatic pressure at the joints, we should make the joints in the middle of the specimen.

3 Starting the test

①Use clean distilled water or deionised water for each specimen.

② Wipe the test water from the clamping device (hydrostatic pressure tester). Then, clamp the wetted specimen so its front side touches the water. Before the test starts, clamp the specimen. The test water must not pass through it under pressure. (Note: If the fabric’s front side is unknown, one side of the single-coated fabric must touch the water. Test the other two sides separately and report the results separately.

③ Apply a water pressure that rises at 6.0kPa/min ± 0.3kPa/min (60cmH₂0/min ± 3cmH₂O/min). Then, observe the water seepage.

(Please indicate in the report if you choose a different rate of water pressure rise, such as 1.0 kPa/min.)

④ Record the hydrostatic pressure when the third droplet on the specimen first appears. Disregard those fine water droplets that form and then do not increase in size. Continuous water droplets that seep out at the same place on the fabric are not cumulative. If the third droplet appears at the edge of the clamp, its hydrostatic pressure must be higher than the other samples’ lowest. If not, we will exclude the data. We will test additional specimens until we obtain normal results.

(Note: If the fabric leaks or bulges during the test, record the pressure and explain the issue in the report.))

Analysis of test results

The hydrostatic pressure values for each specimen, and their mean, P, are in kPa (cmH₂O) with one decimal place. For different specimen types from the same sample (e.g., jointed and unseamed), calculate the average hydrostatic pressures for each type.

For different specimen types of the same sample, we give separate tests of hydrostatic pressure resistance and waterproof performance.

In recent years, the Entry-Exit Inspection and Quarantine Bureau has raised its water pressure test for textiles. It is now much higher than in the past. European customers demand higher hydrostatic resistance in textiles. The minimum is usually above 5.88kPa, with some requiring over 9.8kPa. The sampling test results showed that 44% of samples failed a 5.88kPa standard. Also, 69% failed a 9.8kPa standard. This directly affects exports.

Common problems in hydrostatic pressure testing

Problems caused by improper operation in the hydrostatic pressure testing process

Before clamping the specimen, remove any air between it and the water. Then, clamp the specimen for the test of the experiment. If there is air between the specimen and the water, the water cannot fully contact the specified area. Some parts of the specimen may not have water droplets. This will affect the experiment’s results.

② During the test, try to ensure that the edge of the specimen clamping device does not seep or leak. If the specimen seeps at the edge of the clamping device, water will leak out during the test. This will cause the test pressure to rise erratically. It will affect the accuracy of the results.

Problems arising from the determination of the test endpoint

The test standard, ‘Testing and Evaluation of Textile Waterproof Performance Hydrostatic Pressure Method,’ says to record the hydrostatic pressure when the third droplet appears on the specimen. The test ends at that point. Selecting the wrong test endpoint will affect the experiment’s results. This will lead to incorrect conclusions.

Some special cases are as follows:

① If the third water droplet appears at the edge of the clamping device and has a lower hydrostatic pressure than the lowest value of other normal specimens of the same sample, reject this data. Keep testing additional specimens until you obtain normal results. The clamping device may damage the specimen’s edge. The test could cause water to seep through the edges. We must analyze the test results. We need to check if the test value is lower than the lowest value of other normal test specimens. If it is, we need to add extra specimens.

②In the standard notes, record the pressure if the fabric ruptures, or a water column sprays, or composite fabrics bulge. Explain these phenomena in the report. The occurrence of the above conditions should be the end point of the test of the experiment.

Handling problems of abnormal situations

①If the hydrostatic pressure test has a high dispersion, the average results passed. However, an individual test failed. One should note this in the report.

② If the specimen is already wetted when it contacts the water before the test, the result is 0. The report will note the specimen is already wetted.

Determination of waterproof and moisture permeability

Waterproof and moisture permeability performance means two things. First, the specimen must resist wetting by water, known as “wet through.” Second, it must allow water vapor to escape. It is generally measured by water level, hydrostatic pressure, and moisture permeability rate.

The fabric’s resistance to water is its level of water absorption. A drenching instrument tests it by simulating a rainfall scenario. It observes the wetting of the fabric surface. This is from ‘Testing and Evaluating Waterproofing in Textiles – Water-soaking Method.”

Hydrostatic pressure is the pressure per unit area when the specimen is penetrated by liquid water. The ‘Testing and Evaluation of Waterproofing Performance of Textiles Hydrostatic Pressure Method’ tests how much water pressure a specimen can withstand without leaking. It does this by applying rising water pressure to one side of the specimen. It stops when three seepage points appear on the other side.

Moisture permeability performance measures a fabric’s ability to transmit water vapor. It is key to assessing product comfort. The ‘textile fabric moisture permeability test method part 2: evaporation method’ defines it. Placing a sealed cup with distilled water and a fabric sample in a set temperature and humidity. Measure the cup’s permeability after a set time. A higher rate means better product performance. The higher the moisture permeability, the better the product. It will better regulate the body’s heat and humidity. It will also remove more moisture and be more comfortable for the user.

Waterproof and moisture permeability labelling

Waterproof and breathable products must pass a test. It’s the ‘textile waterproof and breathable performance assessment.’ The instructions for use can show their performance.

1. the national standard number: ‘textiles waterproof and breathable performance assessment’.

2. The corresponding performance and grade: waterproof and moisture permeability Ⅲ, Ⅱ, and Ⅰ. Ⅲ highest performance, Ⅰ lowest.

How to buy waterproof and breathable products?

Waterproof, breathable fabrics are sewn into punching suits, ski suits, and sportswear. They are a popular mid-range and high-end product. The rain does not seep in and the sweat can escape. This makes the garments very comfortable. When buying and selling, first check the fabric. If possible, choose a product made of 3 or more layers of functional pressure rubber fabric. It will be more durable and have better performance. Secondly, check the pressure rubber strip. It’s a high-quality punching jacket. Also, check the fabric. A simple test is to look at the pressure rubber strip. Clothes with small holes in the stitching will leak in a storm. Professional, rush-made clothes will have waterproof adhesive strips in the seams. They will be completely waterproof. So, when shopping, check the pressure glue areas. They should feel good. There should be no wider pressure glue strip. Finally, consider the breathable system. In humans, sweat is key. So, underarm ventilation is very important. So, those higher-quality punching jackets will have a zip or mesh in the armpit. This can help sweat evaporate and improve breathability. It ensures a more comfortable fit.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com