Tests are easy and fast.

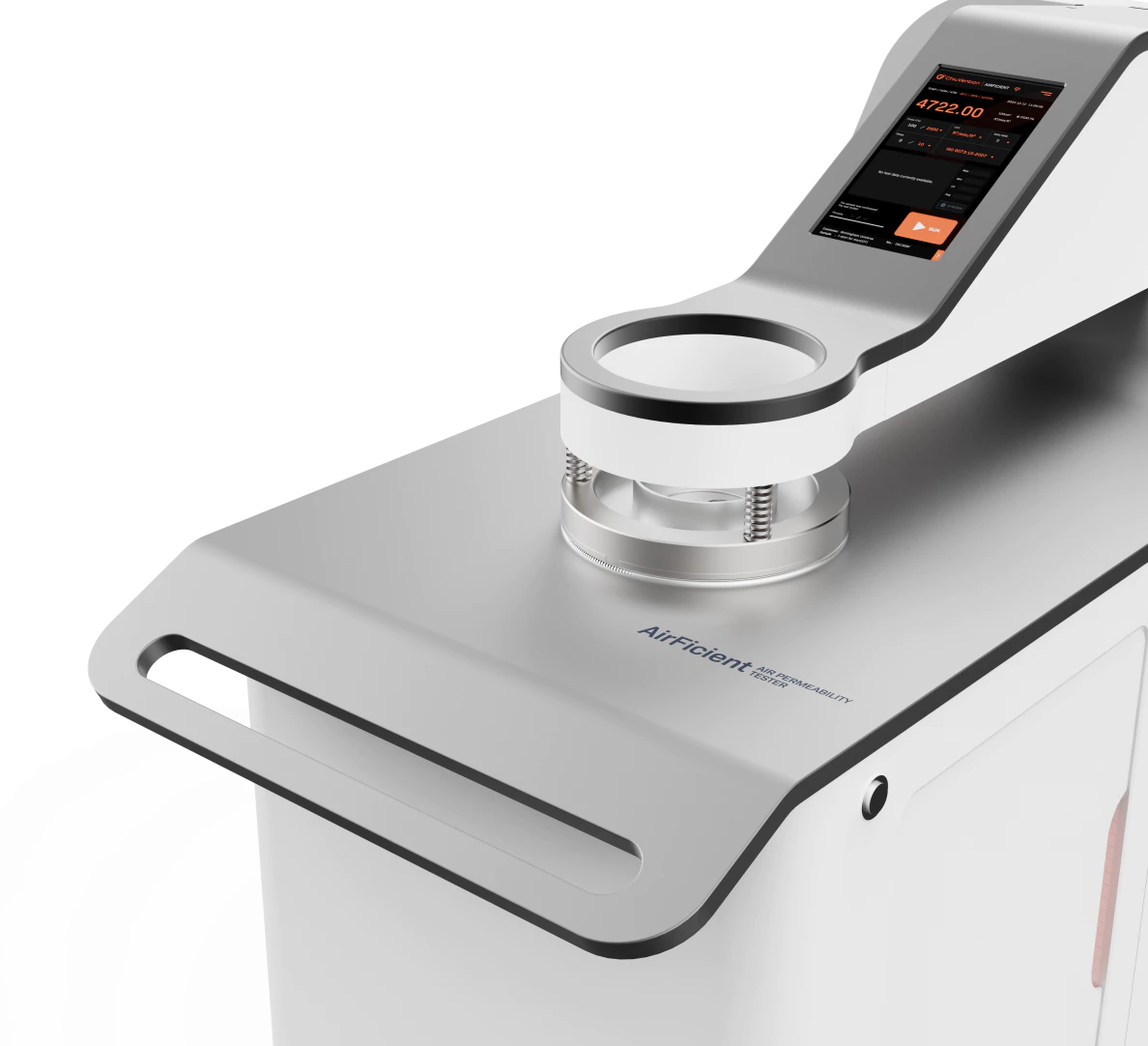

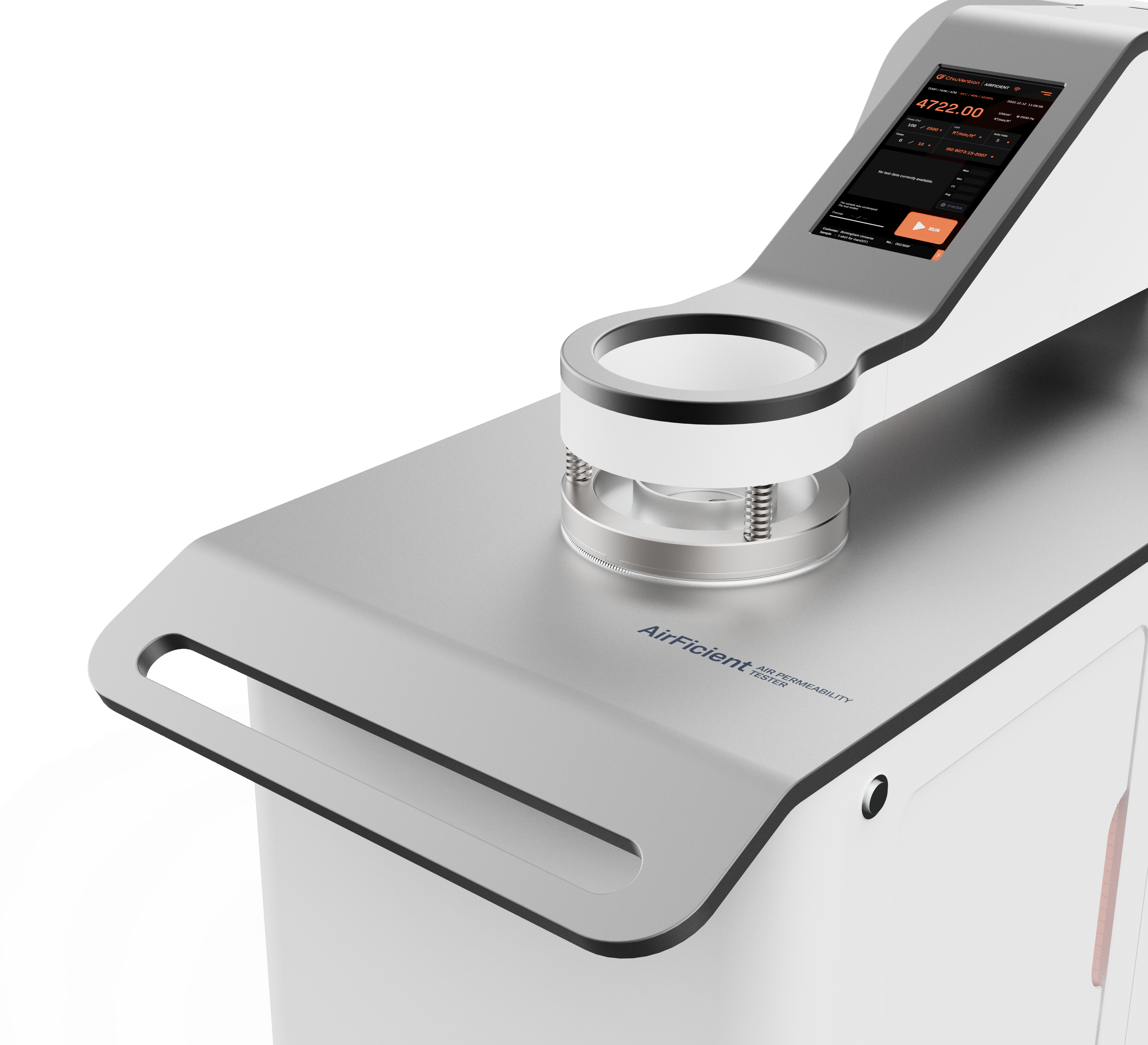

The AirFicient Air Permeability Tester is easy to use. You can select the air permeability test standards and units from the operation screen. The Air Permeability Tester can recognize the test fixture head’s different ranges. You can start the air permeability testing and get the air permeability test result quickly.

The air passes up through the fabric. This forms a pressure difference between the front and back of the fabric. We measure the amount of air that goes through the fabric under a certain pressure. This gives us the fabric’s air permeability value.

More reliable air permeability test results

Test results are highly consistent with third-party authoritative testing organizations. High-quality core components and range conversion components, bringing high repeatability and reliability to test results.

Self-designed calibration system ensures accurate testing at all times.

The calibration system of the air permeability test apparatus has been tested by a third party and is authoritative and reliable, making it convenient for users to calibrate it at any time.

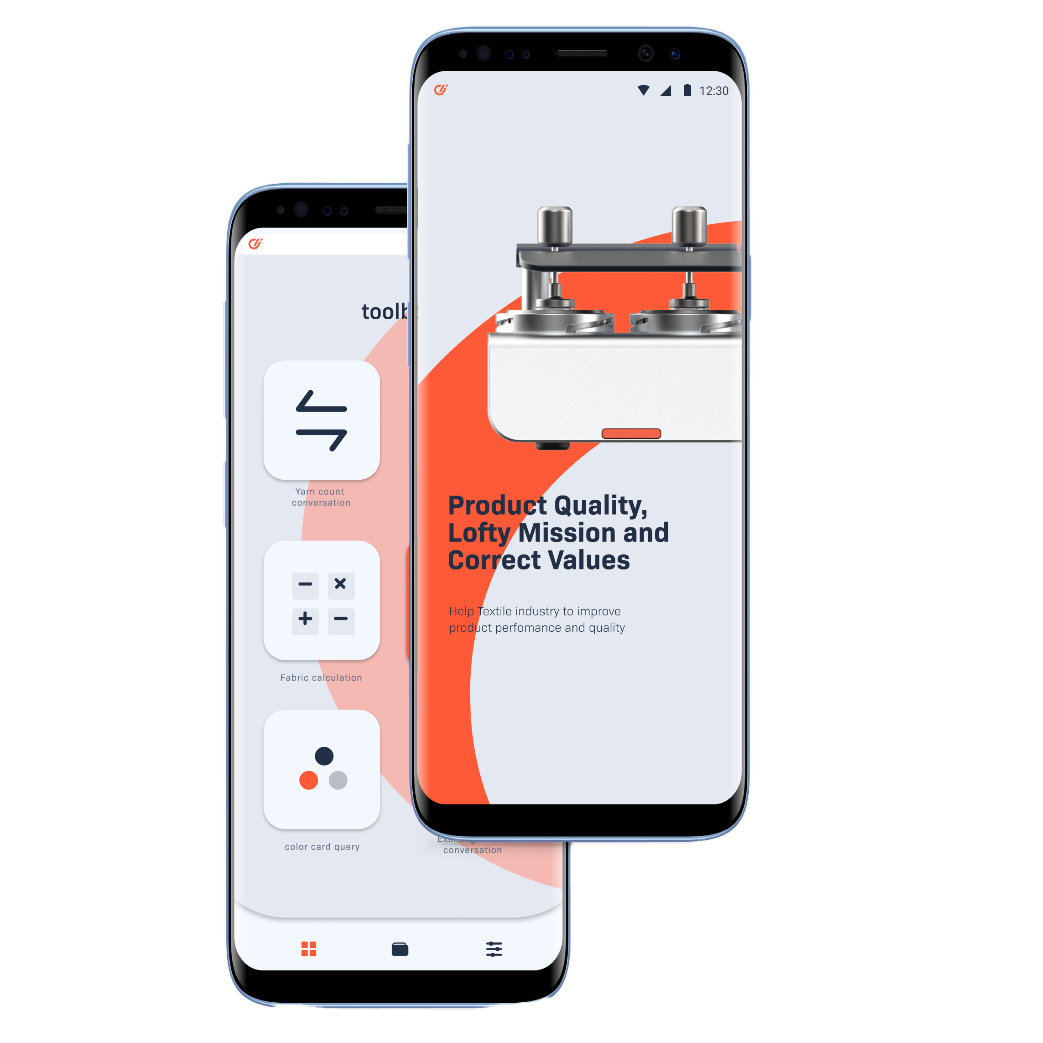

Smart Air Permeability Testing

The AirFicient Air Permeability Tester connects to your smartphone or computer. It also links to the ERP/LIMS. So the instrument can receive test orders and standards. You can also present the sample information on this Air Permeability Test Apparatus. After the air permeability testing, we will create a digital raw record. It will include the test process, air permeability value, temperature, and humidity. You can view the air permeability test report on your smartphone or computer. You can also share it with everyone who needs it. You can also chat online for fast help from ChiuVention customer service. Also, receive reminders to calibrate, maintain, and replace consumables on the instrument. Lastly, perform OTA remote upgrades regularly.

This AirFicient Air Permeability Tester can also be operated by a ChiuVention app named SmarTexLab, you can chat with ChiuVention staff for quick support there. You’ll get reminders that the air permeability tester needs calibration, maintenance, and new consumables. Regular OTA remote upgrades are available.

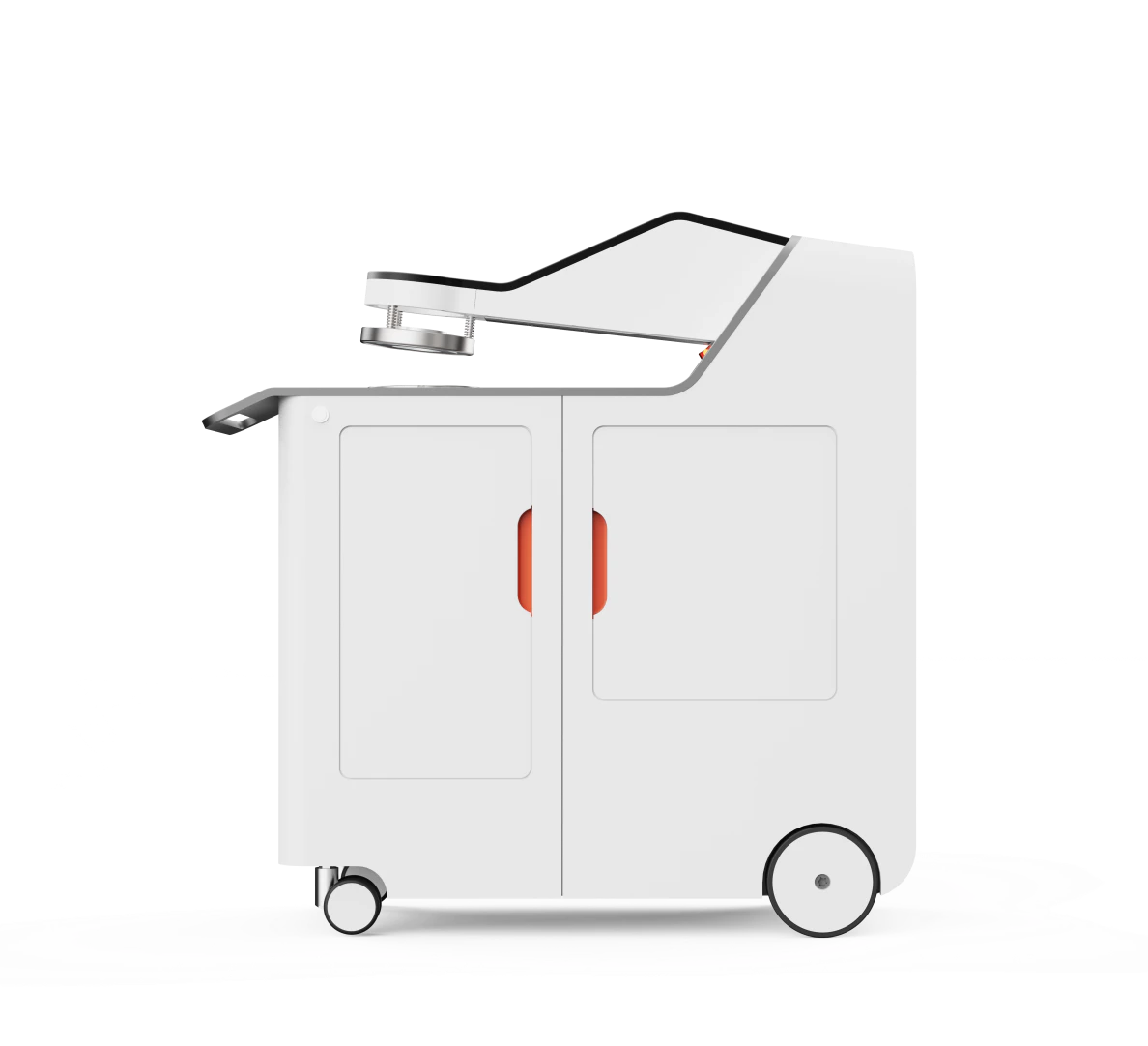

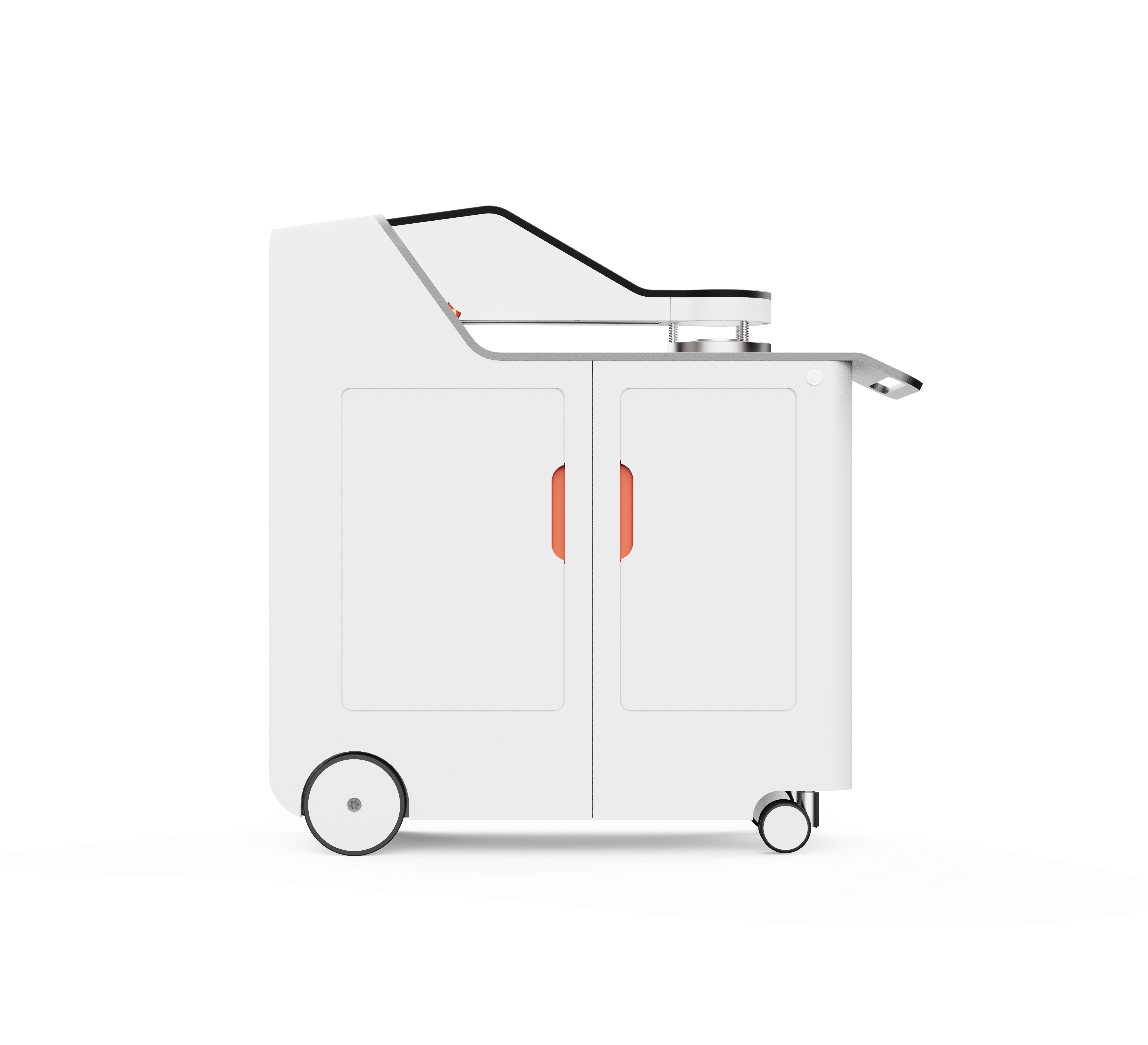

Designed in Germany, quality is our life.

This air permeability tester is designed by a German Team. It has high-quality parts that ensure long-lasting durability. ChiuVention is dedicated to high-quality textile testing equipment. We offer efficient and reliable testing solutions.

Technical Specifications

Measurement units

mm/s, m/s, l/m²/s, ft³/min/ft², cfm

cm³/s/cm², l/s/cm², l/m²/min

1/dm²/min, l/min, m³/min, dm³/s

m³/s/m², m³/min/m², m³/h/m², ft³/s/ft²

Test Mode Automatic

Test head 20 cm2 (standard)

Test pressure 10 ~ 2,500 Pa

Air velocity 0.6 ~ 10,000 mm/s (20 cm2)

The sample thickness range is 0 to 10 mm. You can customize other thicknesses and fixtures.

Testing Accuracy <+/-2%

Optional test heads 5 cm2, 25 cm2, 38 cm2, 50 cm2, 100 cm2

Power 220V 50/60Hz Other voltages require an external transformer

Weight 125kg

Dimension

970*400*970 mm (L*W*H)

Testing Standard Of AirFicient

| Standard | Explanation |

| ISO 9237 | Determines the air permeability of textile fabrics using a constant differential pressure method. |

| ISO 9073:15 | Specifies the test method for measuring the air permeability of nonwoven materials. |

| GB/T 5453 | Chinese standard for measuring air permeability of textile fabrics under specific pressure conditions. |

| GB/T 24218.15 | A method for evaluating the breathability of textiles using a pressure differential. |

| BS 3424-16 | British standard for determining the air permeability of coated fabrics. |

| BS 6F 100 3.13 | Aerospace industry standard for testing the permeability of aircraft textiles. |

| NWSP 070.1.RO(15) | Nonwoven industry standard for assessing air permeability of nonwoven fabrics. |

| JIS L1096 Item 8.26 Method C | Japanese standard for measuring fabric breathability using a constant air pressure method. |

| ASTM D737 | American standard test method for air permeability of textile fabrics. |

Application Examples of AirFicient Air Permeability Tester

Sports Fabric

Outdoor Gear

Medical Mask

Home Textiles

Customer Success Stories

“I learned about this instrument at the ITMA 2023 Exhibition in Milan and was impressed by some of the features on site. It was particularly easy to operate and the test results were quickly available. So we purchased it in 2024.”

“The air permeability test results are reliable. And the German-engineered precision Air Permeability Test Apparatus is easy to use and not too big. We are in the down apparel business and there is a high demand for it.”

OUR BROCHURE

FLYER

The test measures the rate at which air passes through a material. Here’s a detailed explanation of how the test works:

The Test Principle of Air Permeability Test Apparatus

Sample Preparation:

The team will test the material sample. It is firmly mounted in the test apparatus to prevent air from bypassing.

Controlled Airflow:

A pump or blower drives air through the sample.

The team precisely controls and measures the airflow rate and pressure differential.

Pressure Differential (ΔP):

The experiment applies a known and constant pressure difference across the material.

This air permeability test simulates real conditions.

They are the ones the material will face. We measure the pressure differential in pascals (Pa) and inches of water column (inH2O).

Measurement of Airflow Rate:

The volume of air passing through the material per unit of time is measured. This is the core measurement in an air permeability test.

Most cases measure the airflow rate in cubic centimeters per second (cm³/s) or cubic feet per minute (CFM).

Air Permeability Calculation:

To calculate air permeability, divide the airflow rate by the sample area.

This gives an air permeability value, usually in cm³/s/cm² or CFM/ft². It measures the material’s air permeability.

Air Permeability Test Method or Air Permeability Test Procedure

Sample Preparation:

Cut a sample of the material to the needed size. The size is set by the testing standard.

Ensure the sample is clean, dry, and free from any defects affecting the test results.

Calibrate the equipment.

Calibrate the air permeability tester based on our instructions. Also, follow the relevant testing standard. Ensure that the pressure gauges and flow meters are accurate.

Mount the Sample:

Secure the sample in the test chamber of the air permeability tester. To prevent any air leakage around the edges, clamp the sample tightly.

Set the pressure differential.

Set up the air permeability test device. It should create a specific pressure difference across the sample. The pressure difference is usually chosen based on the material and its use. Testing standards specify common values.

Initiate Airflow:

Start the airflow through the material. The air permeability tester will draw air through the sample or blow air through it.

Measure airflow rate:

Measure the rate of air passing through the sample. The flow rate is often recorded using built-in sensors. It is then shown on the equipment’s readout panel. Ensure that someone measures after the airflow has stabilized.

Record Environmental Conditions (Optional):

Record the temperature and humidity if the test standard requires it. These can affect the air permeability of some materials.

Calculate Air Permeability:

The test results for air permeability will express units such as cm³/s/cm², CFM/ft², or other types. (You can select the Air Permeability Units from the operation screen)

Repeat the test (optional):

Test several samples or various spots on one sample. Then, find the average air permeability.

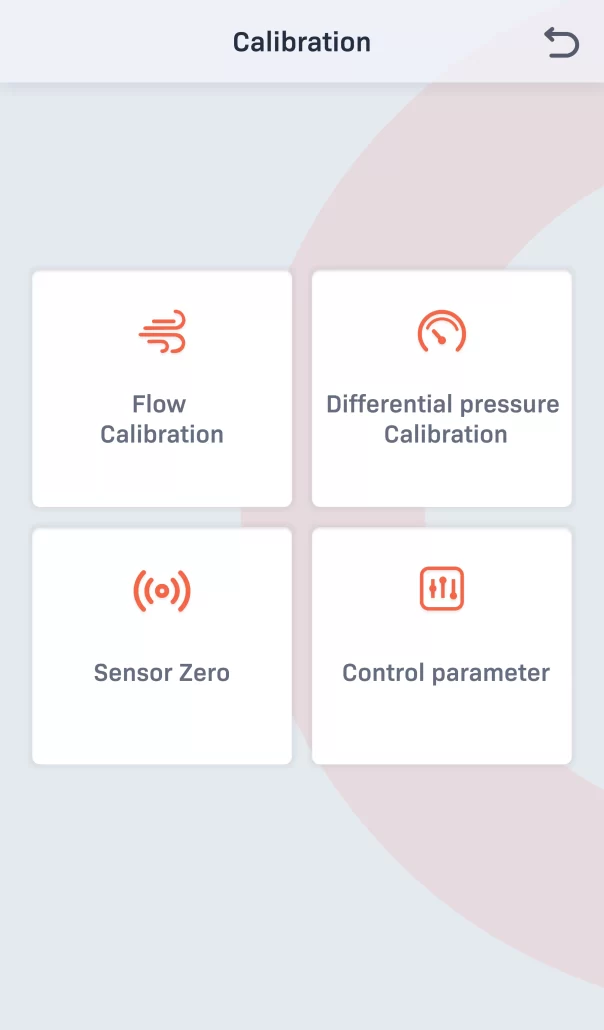

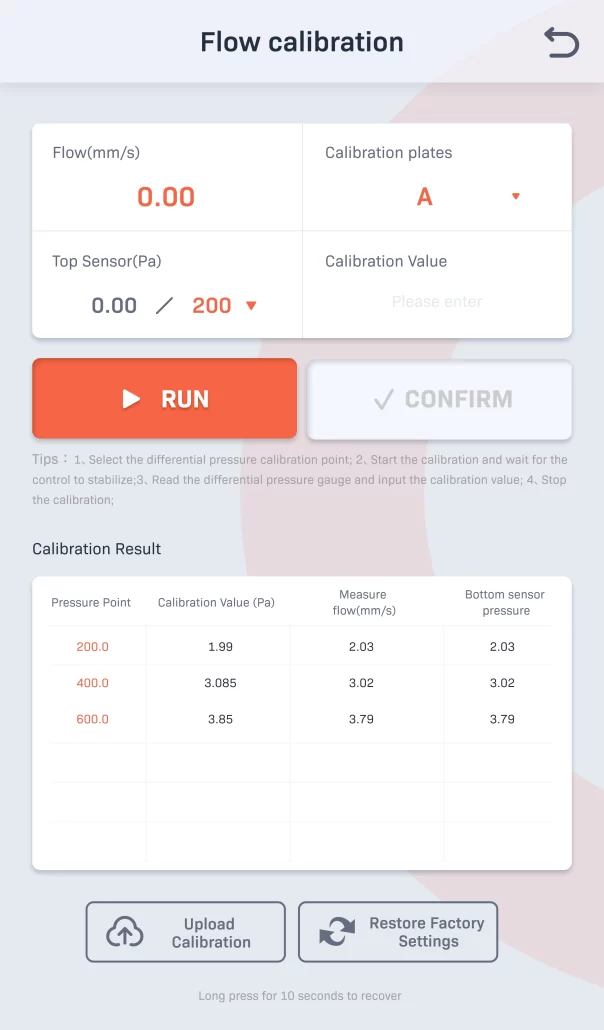

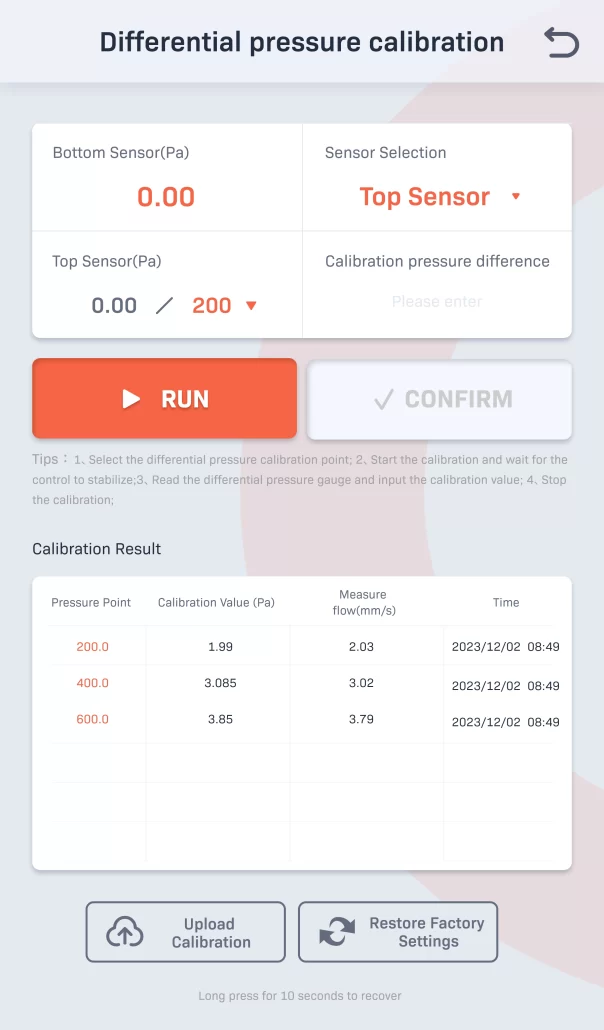

Calibration is performed using 20cm2 upper and lower fixtures, with units selected in mm/s. And you can enter the calibration mode on this Air Permeability Tester operation screen. You can calibrate the air flow and differential pressure.

Please view the air permeability tester operation manual for the detailed calibration steps or contact us.

You should ground the instrument shell reliably. Its grounding resistance should be ≤ 1Ω.

Clean the filtering steel mesh once a month. The mesh is stainless steel. It is best to blow it with high-pressure gas or wash it with water. To wash with water, put it into the instrument after drying. Place the mesh in the designated location.

Take out the lower fixture and see the filtering stencil.

You can use the sealing rubber sheet, supplied as an accessory, to test the airtightness of the device. Contact ChiuVention to replace the rubber sheet when it wears out.

GET A QUOTE

Frequently Asked Questions of Air Permeability Tester

What is an air permeability tester?An Air Permeability Tester measures the air permeability of textiles. It is also known as a Permeability Tester or Air Permeability Testing Machine. This equipment tests industrial fabrics, nonwovens, and other breathable materials. It’s also good for testing the air permeability of breathable materials. These materials include paper.

What are the unique points of this AirFicient air permeability tester?This Air Permeability Test Apparatus can be directly connected to smartphones, computers, and enterprise ERP or laboratory LIMS systems, can directly transmit air permeability test reports, and related parties can view the test situation and air permeability test results, and it is also very convenient since you can select the Air Permeability Test Standards and Air Permeability Units from the screen. If you want to know more about air permeability testing or air permeability tester prices, please contact us now.

How to ensure better Air Permeability Test results for your samples?To ensure better air permeability test results for your fabric samples, consider the following best practices based on the information from various sources:

1. Sample Preparation

Select Representative Samples: Choose samples that accurately represent the fabric type and structure you want to test. Ensure they are free from defects.

Proper Cutting: Cut samples to the required dimensions specified by the testing standards (e.g., ISO 9073:15). Avoid wrinkles, folds, or creases that could affect airflow.

Conditioning: Precondition samples in a controlled environment (typically at 20°C and 65% relative humidity) for at least 24 hours to stabilize moisture content and temperature.

2. Standardized Testing Conditions

Temperature and Humidity Control: Maintain consistent temperature and humidity during testing to eliminate variations in fabric properties that could influence results

Edge Treatment: Trim edges neatly to prevent fraying and ensure a proper seal during testing. Use sealing materials if necessary to minimize edge leakage.

3. Equipment Calibration

Regular Calibration: Ensure that the air permeability testing apparatus is calibrated according to manufacturer guidelines or industry standards. Regular checks help maintain the accuracy and reliability of the results

4. Proper Setup and Clamping

Secure Mounting: Affix samples securely in the test apparatus, ensuring they are flat and centered without any gaps around the edges. This prevents air leakage that could skew results

Pressure Differential Management: Set the specified pressure differential accurately before starting the test. Follow recommended pressure levels (e.g., typically around 125 Pa) to avoid distortion or turbulence in airflow

5. Conduct Multiple Tests

Replicate Testing: Perform multiple tests on different samples or locations within the same sample to account for variability. Average the results for a more reliable measurement

Documentation: Maintain detailed records of each test, including conditions, sample details, and any deviations from standard procedures.

6. Data Interpretation

Understand Standards: Familiarize yourself with relevant testing standards (e.g., ASTM D737, ISO 9073) to ensure compliance and accurate interpretation of results

Analyze Results Thoroughly: Compare results against established benchmarks for air permeability to assess performance effectively.

By implementing these practices, you can enhance the accuracy and reliability of air permeability testing for your fabric samples, leading to better insights into their performance characteristics in real-world applications.

What is a good score on the air permeability test?A “good” air permeability score depends on the application and material. Different applications and industries have varying requirements for air permeability. Here are some general guidelines. They show what might be good air permeability in various contexts.

Textiles (Apparel and Technical Fabrics):

Breathable Fabrics (e.g., sportswear, outdoor clothing): 10-50 cm³/s/cm². Higher values may be desirable for increased breathability.

Windproof Fabrics: 0-10 cm³/s/cm². Lower values say better wind resistance.

Geotextiles:

General Purpose Geotextiles: 100-300 cm³/s/cm². Values within this range usually or show good drainage properties.

Filter Fabrics: 50-200 cm³/s/cm². The exact need depends on the specific filtration application.

Nonwoven Fabrics (e.g., medical textiles, hygiene products):

Medical Textiles: 10-100 cm³/s/cm². Lower values are often better for barriers. Higher values may be preferred for breathability.

Hygiene Products (e.g., diapers): 100-300 cm³/s/cm². This range generally indicates a good balance between absorbency and breathability.

Building Materials (e.g., house wraps, insulation):

House Wraps: 5-60 cm³/s/cm². Lower values are better for water and air barriers. Higher values improve vapor permeability.

Insulation Materials: Variable. Specific requirements depend on the insulation type and intended use.

Filters (e.g., HVAC filters, industrial filters):

High-Efficiency Filters: 10-100 cm³/s/cm². Lower values typically indicate higher filtration efficiency.

General Purpose Filters: 100-500 cm³/s/cm². Higher values may be acceptable where less stringent filtration is needed.

The ranges are approximate. The standards vary. They depend on the needs of different groups and industries. The best air permeability for an application depends on breathability, barriers, and strength. It’s based on the material’s intended use.

What parameters does an air permeability tester measure?An air permeability tester typically measures the following parameters:

Air Permeability is the primary measurement. It shows the amount of air that passes through a material over time. People often express it in units such as cubic centimeters per second per square centimeter (cm³/s/cm²). Or, they use cubic feet per minute per square foot (CFM/ft²).

The pressure differential (ΔP) is the difference in air pressure. It’s between the two sides of the material being tested. The differential is usually kept constant during the test. This standardizes the measurement of air permeability. Common units are pascals (Pa) or inches of water column (inH2O).

Sample Area: The area of the material sample through which the air is passing. This ensures that the air permeability is calculated per unit area. It is generally measured in square centimeters (cm²) or square inches (in²).

What is the Air Permeability Method and how is it used to evaluate the porosity of materials?The Air Permeability Tester for fabric utilizes the following air permeability test methods:

ISO 9237 is the international standard for finding the air permeability of fabrics. It uses a constant airflow. It measures air permeability as the volume of air passing through a known area of fabric per unit of time.

ASTM D737 is the American Society for Testing and Materials standard. It tests the air permeability of textile fabrics. It measures the rate of airflow passing through the fabric. The airflow is passing through a known area.

DIN 53887 is a German standard. It determines the air permeability of textile fabrics using constant airflow. It’s like ISO 9237 and provides a measure of the air permeability in liters per square meter per second.

JIS L 1096 is a Japanese Industrial Standard (JIS). It measures the air permeability of woven and knitted fabrics. It measures the volume of air passing through a set area of the fabric. The test has specific conditions.

What are typical applications for air permeability testers?Air permeability testing is important for textile manufacturers. It’s a key part of quality control. It ensures that fabrics meet standards and performance requirements. These include breathability, comfort, and function.

The permeability meter is used in fabric development and research. It evaluates how different fabric structures, compositions, and finishes impact air permeability. This helps in the development of new fabrics with desired properties

Performance Evaluation

The air test assesses fabric performance in many uses. For example, in sportswear or activewear, high breathability and moisture management are important. They affect comfort and performance. The Shirley air permeability tester can measure the air permeability. It does this to find out if the fabric is suitable for such uses.

Air permeability testing is crucial in the filtration industry. Fabrics are used as filter media there. It helps determine the filtration efficiency and airflow of filter fabrics. These fabrics are for air filters, liquid filters, and dust collections.

Medical Textiles

Air permeability testing is used in medical textiles. It tests how breathable the fabrics are. They are used in surgical gowns, masks, and other healthcare products. It ensures that the fabrics allow proper airflow and reduce the risk of moisture buildup.

Comfort Evaluation

Air permeability is closely related to the comfort of textiles. The machine measures air permeability. It helps assess the breathability of fabrics. This includes their ventilation and thermal comfort. They are used in clothing, bedding, and upholstery.

Many industries have specific regulations and standards related to air permeability. These industries include automotive, aerospace, and personal protective equipment. The permeability tester enables manufacturers to ensure compliance with these standards.

Why is the air permeability testing for textiles and fabrics important ?For textiles, air permeability testing determines breathability, which is critical for comfort in clothing, particularly in sportswear, protective gear, and outdoor apparel. It also impacts performance in filtration systems and insulation materials.

What standards are used for air permeability testing?Common standards include:

- ASTM D737 for textiles

- ISO 9237 for textiles and fabrics

- DIN 53887 for nonwoven fabrics

- BS EN 12114 for building materials

- ISO 5636 for paper and packaging materials, Different industries follow specific standards based on their requirements.

What is the difference between air permeability and breathability?While often used interchangeably, air permeability specifically refers to the rate of airflow through a material under a defined pressure difference. Breathability generally refers to the overall comfort of material in allowing air and moisture vapor to escape, which is a broader concept that may include other factors like moisture-wicking properties and heat dissipation.

Can air permeability be controlled or adjusted in materials?Yes, textile manufacturers can control air permeability through material design choices, such as adjusting fiber density, weave patterns, material thickness, and surface treatments. Coatings or membranes may also be applied to reduce air permeability.

How do I choose the right level of air permeability for my product?The ideal level of air permeability depends on the application. For example, high air permeability is preferred in sportswear for breathability, while lower permeability is desirable in windproof jackets, insulation materials, and some filtration applications. Consulting industry standards and understanding the product’s end use will guide the selection.

Can air permeability testing be conducted in different environmental conditions?Yes, air permeability testing can account for different environmental conditions like temperature and humidity. These factors can influence the material’s performance, so testing under real-world conditions may be necessary to ensure accuracy for specific applications.

How much does an industrial air permeability tester cost?The cost of an industrial air permeability tester can vary widely based on factors such as the brand, features, and specifications. Generally, you can expect prices to range from:

- Basic models: $1,000 to $5,000

- Mid-range models: $5,000 to $15,000

- High-end models: $15,000 and above

If you want to know our air permeability tester price, please feel free to contact us now.

An Air Permeability Tester measures the air permeability of textiles. It is also known as a Permeability Tester or Air Permeability Testing Machine. This equipment tests industrial fabrics, nonwovens, and other breathable materials. It’s also good for testing the air permeability of breathable materials. These materials include paper.

This Air Permeability Test Apparatus can be directly connected to smartphones, computers, and enterprise ERP or laboratory LIMS systems, can directly transmit air permeability test reports, and related parties can view the test situation and air permeability test results, and it is also very convenient since you can select the Air Permeability Test Standards and Air Permeability Units from the screen. If you want to know more about air permeability testing or air permeability tester prices, please contact us now.

To ensure better air permeability test results for your fabric samples, consider the following best practices based on the information from various sources:

1. Sample Preparation

Select Representative Samples: Choose samples that accurately represent the fabric type and structure you want to test. Ensure they are free from defects.

Proper Cutting: Cut samples to the required dimensions specified by the testing standards (e.g., ISO 9073:15). Avoid wrinkles, folds, or creases that could affect airflow.

Conditioning: Precondition samples in a controlled environment (typically at 20°C and 65% relative humidity) for at least 24 hours to stabilize moisture content and temperature.

2. Standardized Testing Conditions

Temperature and Humidity Control: Maintain consistent temperature and humidity during testing to eliminate variations in fabric properties that could influence results

Edge Treatment: Trim edges neatly to prevent fraying and ensure a proper seal during testing. Use sealing materials if necessary to minimize edge leakage.

3. Equipment Calibration

Regular Calibration: Ensure that the air permeability testing apparatus is calibrated according to manufacturer guidelines or industry standards. Regular checks help maintain the accuracy and reliability of the results

4. Proper Setup and Clamping

Secure Mounting: Affix samples securely in the test apparatus, ensuring they are flat and centered without any gaps around the edges. This prevents air leakage that could skew results

Pressure Differential Management: Set the specified pressure differential accurately before starting the test. Follow recommended pressure levels (e.g., typically around 125 Pa) to avoid distortion or turbulence in airflow

5. Conduct Multiple Tests

Replicate Testing: Perform multiple tests on different samples or locations within the same sample to account for variability. Average the results for a more reliable measurement

Documentation: Maintain detailed records of each test, including conditions, sample details, and any deviations from standard procedures.

6. Data Interpretation

Understand Standards: Familiarize yourself with relevant testing standards (e.g., ASTM D737, ISO 9073) to ensure compliance and accurate interpretation of results

Analyze Results Thoroughly: Compare results against established benchmarks for air permeability to assess performance effectively.

By implementing these practices, you can enhance the accuracy and reliability of air permeability testing for your fabric samples, leading to better insights into their performance characteristics in real-world applications.

A “good” air permeability score depends on the application and material. Different applications and industries have varying requirements for air permeability. Here are some general guidelines. They show what might be good air permeability in various contexts.

Textiles (Apparel and Technical Fabrics):

Breathable Fabrics (e.g., sportswear, outdoor clothing): 10-50 cm³/s/cm². Higher values may be desirable for increased breathability.

Windproof Fabrics: 0-10 cm³/s/cm². Lower values say better wind resistance.

Geotextiles:

General Purpose Geotextiles: 100-300 cm³/s/cm². Values within this range usually or show good drainage properties.

Filter Fabrics: 50-200 cm³/s/cm². The exact need depends on the specific filtration application.

Nonwoven Fabrics (e.g., medical textiles, hygiene products):

Medical Textiles: 10-100 cm³/s/cm². Lower values are often better for barriers. Higher values may be preferred for breathability.

Hygiene Products (e.g., diapers): 100-300 cm³/s/cm². This range generally indicates a good balance between absorbency and breathability.

Building Materials (e.g., house wraps, insulation):

House Wraps: 5-60 cm³/s/cm². Lower values are better for water and air barriers. Higher values improve vapor permeability.

Insulation Materials: Variable. Specific requirements depend on the insulation type and intended use.

Filters (e.g., HVAC filters, industrial filters):

High-Efficiency Filters: 10-100 cm³/s/cm². Lower values typically indicate higher filtration efficiency.

General Purpose Filters: 100-500 cm³/s/cm². Higher values may be acceptable where less stringent filtration is needed.

The ranges are approximate. The standards vary. They depend on the needs of different groups and industries. The best air permeability for an application depends on breathability, barriers, and strength. It’s based on the material’s intended use.

An air permeability tester typically measures the following parameters:

Air Permeability is the primary measurement. It shows the amount of air that passes through a material over time. People often express it in units such as cubic centimeters per second per square centimeter (cm³/s/cm²). Or, they use cubic feet per minute per square foot (CFM/ft²).

The pressure differential (ΔP) is the difference in air pressure. It’s between the two sides of the material being tested. The differential is usually kept constant during the test. This standardizes the measurement of air permeability. Common units are pascals (Pa) or inches of water column (inH2O).

Sample Area: The area of the material sample through which the air is passing. This ensures that the air permeability is calculated per unit area. It is generally measured in square centimeters (cm²) or square inches (in²).

The Air Permeability Tester for fabric utilizes the following air permeability test methods:

ISO 9237 is the international standard for finding the air permeability of fabrics. It uses a constant airflow. It measures air permeability as the volume of air passing through a known area of fabric per unit of time.

ASTM D737 is the American Society for Testing and Materials standard. It tests the air permeability of textile fabrics. It measures the rate of airflow passing through the fabric. The airflow is passing through a known area.

DIN 53887 is a German standard. It determines the air permeability of textile fabrics using constant airflow. It’s like ISO 9237 and provides a measure of the air permeability in liters per square meter per second.

JIS L 1096 is a Japanese Industrial Standard (JIS). It measures the air permeability of woven and knitted fabrics. It measures the volume of air passing through a set area of the fabric. The test has specific conditions.

Air permeability testing is important for textile manufacturers. It’s a key part of quality control. It ensures that fabrics meet standards and performance requirements. These include breathability, comfort, and function.

The permeability meter is used in fabric development and research. It evaluates how different fabric structures, compositions, and finishes impact air permeability. This helps in the development of new fabrics with desired properties

Performance Evaluation

The air test assesses fabric performance in many uses. For example, in sportswear or activewear, high breathability and moisture management are important. They affect comfort and performance. The Shirley air permeability tester can measure the air permeability. It does this to find out if the fabric is suitable for such uses.

Air permeability testing is crucial in the filtration industry. Fabrics are used as filter media there. It helps determine the filtration efficiency and airflow of filter fabrics. These fabrics are for air filters, liquid filters, and dust collections.

Medical Textiles

Air permeability testing is used in medical textiles. It tests how breathable the fabrics are. They are used in surgical gowns, masks, and other healthcare products. It ensures that the fabrics allow proper airflow and reduce the risk of moisture buildup.

Comfort Evaluation

Air permeability is closely related to the comfort of textiles. The machine measures air permeability. It helps assess the breathability of fabrics. This includes their ventilation and thermal comfort. They are used in clothing, bedding, and upholstery.

Many industries have specific regulations and standards related to air permeability. These industries include automotive, aerospace, and personal protective equipment. The permeability tester enables manufacturers to ensure compliance with these standards.

For textiles, air permeability testing determines breathability, which is critical for comfort in clothing, particularly in sportswear, protective gear, and outdoor apparel. It also impacts performance in filtration systems and insulation materials.

Common standards include:

- ASTM D737 for textiles

- ISO 9237 for textiles and fabrics

- DIN 53887 for nonwoven fabrics

- BS EN 12114 for building materials

- ISO 5636 for paper and packaging materials, Different industries follow specific standards based on their requirements.

While often used interchangeably, air permeability specifically refers to the rate of airflow through a material under a defined pressure difference. Breathability generally refers to the overall comfort of material in allowing air and moisture vapor to escape, which is a broader concept that may include other factors like moisture-wicking properties and heat dissipation.

Yes, textile manufacturers can control air permeability through material design choices, such as adjusting fiber density, weave patterns, material thickness, and surface treatments. Coatings or membranes may also be applied to reduce air permeability.

The ideal level of air permeability depends on the application. For example, high air permeability is preferred in sportswear for breathability, while lower permeability is desirable in windproof jackets, insulation materials, and some filtration applications. Consulting industry standards and understanding the product’s end use will guide the selection.

Yes, air permeability testing can account for different environmental conditions like temperature and humidity. These factors can influence the material’s performance, so testing under real-world conditions may be necessary to ensure accuracy for specific applications.

The cost of an industrial air permeability tester can vary widely based on factors such as the brand, features, and specifications. Generally, you can expect prices to range from:

- Basic models: $1,000 to $5,000

- Mid-range models: $5,000 to $15,000

- High-end models: $15,000 and above

If you want to know our air permeability tester price, please feel free to contact us now.