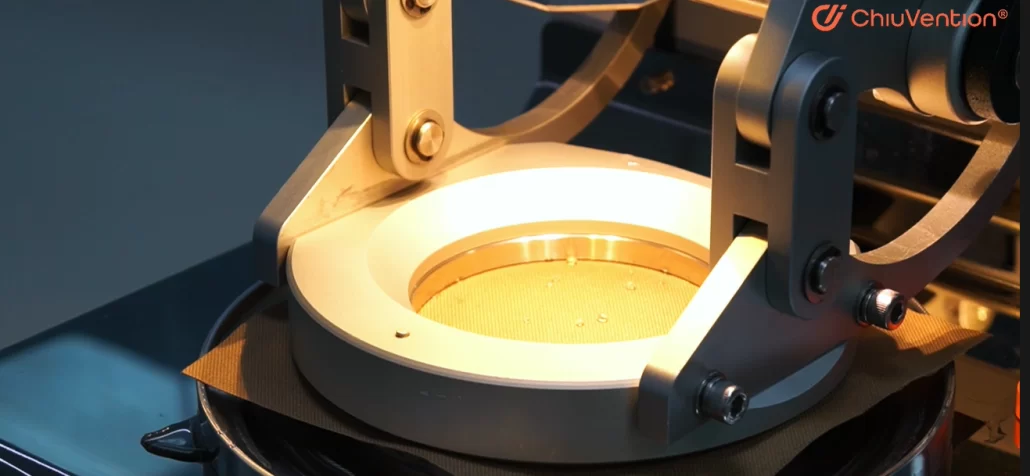

Troubleshooting and Calibration of Air Permeability Testers What is air permeability? What measures do we use to test air permeability? Which type of instrument measures air permeability? How do you Troubleshoot and Calibrate air permeability testers? In this article, we will examine air permeability and testers. Air Permeability of Fabric Air Permeability of Fabric “The…

Category Archives: Textile Testing

The rapid tech transformation is changing how we test. AI is now becoming part of traditional testing methods. AI empowerment technologies are making a big impact. They automate data collection and analysis for fabric testing around the world. They also offer smarter control of testing equipment. Plus, machine learning helps predict outcomes and find defects…

Introduction to Hydrostatic Head Testing Hydrostatic head testing is a vital method used to evaluate how well water-resistant or waterproof fabrics can withstand water pressure. This test determines the pressure level at which water begins to penetrate the fabric, which is crucial for applications in outdoor gear, tents, rainwear, and protective coverings. What Is…

The Martindale test method focuses on the pilling resistance of textiles.The Martindale pilling test methods differ significantly between American and Chinese standards. The American standard uses a 38 mm sample. It has a friction path of 60 mm and a load of 198 g, which is the weight of the abrasion head. The Chinese standard…

Pilling is a common problem in knitted fabrics. It affects how they look and traps dirt. This reduces wear performance and leads to a bad experience for consumers. The ICI pilling box method tests how well wool and other knitted fabrics resist pilling. In the ICI pilling test method, the specimen goes into a polyurethane…

The Mullen burst test measures the strength of paper, cardboard, and corrugated boxes. This test is performed especially for packaging material to ensure its quality. Can it withstand the product load? The Mullen test is not used for high-strength materials because it is designed to evaluate the strength of packaging materials, where we require…

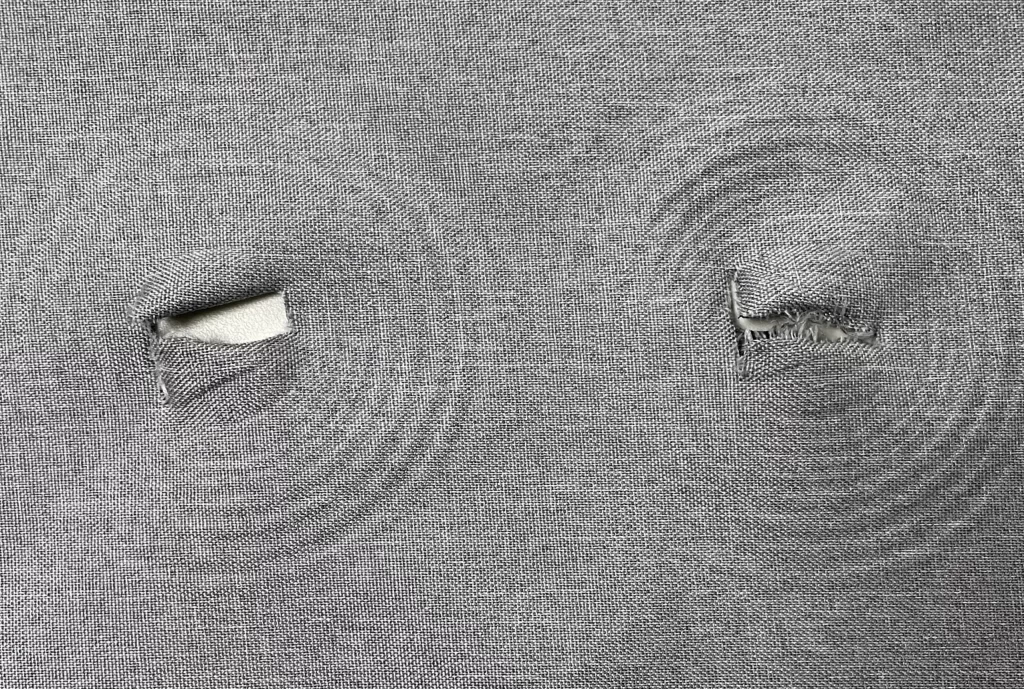

The Martindale abrasion tester is used to measure the abrasion resistance of home textiles and upholstery. It is the simulation of seat cover wear where the fabric undergoes rubbing on a daily basis use. The standard for abrasion resistance is ISO 12 947. Let’s start with what is Martindale Test. Martindale Test The specimen…

Fabric bursting strength testing is of great importace for our daily outfit. We often notice that the elbows of sweaters easily deform, the knees of knitted pants are the first to wear out, and socks frequently develop holes in the toe area. Consumers may wonder: Is this a quality issue or an inherent characteristic of…

The performance and testing of materials are the core foundation for the development of the textile industry. From the selection of fibers to the final formation of fabrics, every link relies on precise control of material properties and rigorous experimental verification. With the rapid development of textile technology, new materials and processes are emerging in…

The performance and testing of materials are fundamental pillars in the development of the textile industry. From fiber selection to the final formation of fabrics, every step requires precise control over material properties and rigorous testing validation. With the rapid advancement of textile technology, new materials and processes continually emerge, leading to updates in performance…