The Mullen burst test measures the strength of paper, cardboard, and corrugated boxes. This test is performed especially for packaging material to ensure its quality. Can it withstand the product load?

The Mullen test is not used for high-strength materials because it is designed to evaluate the strength of packaging materials, where we require not too much strength and not too little, which cannot withstand the product inside the box.

Significance of Burst Testing

Significance of Burst Testing

The bursting strength is evaluated to know the material resistance to rupture. It is an important factor in the packaging industry for the safe delivery and shipment of products and sensitive instruments. It ensures the material’s strength and whether it can hold the product’s weight.

The results of the bursting strength test for packaging materials are measured in lb/inc2. The resulting values tell us how much force a corrugated box can bear during shipment.

Packaging materials like corrugated boxes, thermal insulation, and foam should withstand forces up to a certain level for the safety of the product.

It is just like your product is important for you, similarly, its safe delivery is also important, which cannot be done without using durable packaging materials.

For example, if you are shipping any product, then you should ensure that your packaging box is strong enough to bear external forces like dropping, pulling, pushing, and environmental and human handling impacts during cargo.

What the Mullen Burst Test Really Measures?

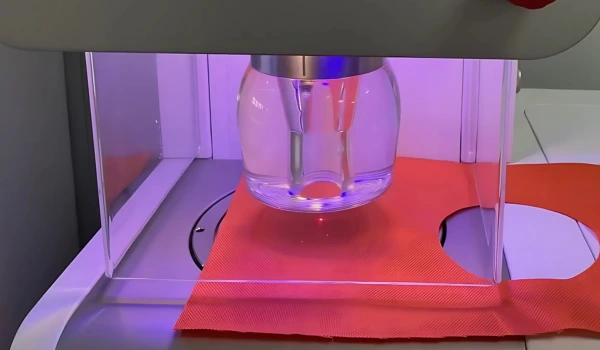

The Mullen burst strength test measures the durability of packaging material like paper, cardboard, and corrugated box. The material’s resistance to rupture is noticed by applying hydraulic pressure using the diaphragm.

A hydraulic burst test is performed to know how much rough handling a packing material can bear because during shipping, this type of material has to face rough handling. So the durability of such material is essential for safe delivery of products.

To perform this test, we need an instrument that is called a Bursting Strength Tester and a material specimen that has to be tested. It is performed by following the guidelines of standard ASTM D 3786.

Let us see how to perform the Mullen bursting test. We will see which types of testing equipment are required for performing it.

Testing Equipment

Mullen Bursting Tester

We will use this instrument to determine the bursting strength of the packaging material.

Sample Cutter Blade

A sample cutter blade is used to cut the specimen properly.

Calibration

The instrument should be calibrated before performing the test. It is recommended to do calibration after every 100 results. An aluminum foil is used to check the tester’s accuracy. The diaphragm should be replaced after every 500 readings.

The diaphragm performance depends upon its usage and time after installation. If we have to replace on the basis of usage then it should be changed after 500 readings, or if the usage is less, then it should be replaced after 06 months.

Sampling

The materials sampling should be done on the basis of lot size. If your lot size is too big, then you must take multiple samples from different positions. It will help you to get more precise and accurate results.

Here we are performing the test for paper. The ASTM D 774 and TAPI T 403 are the standards for determining the bursting strength of a paper.

Conditioning

The specimen should be conditioned before performing the test. The sample is kept at 27° C and 65% relative humidity for 08 hours.

Test Procedure

The specimen is placed over the testing head and the clamping plate by pressing the button down. The first test for a new sample should always be done with a greater range, 0 to 120 lb per Square.

The bursting pressure is indicated on the digital display of the instrument which is noted during the test. After that, push the button to move the clamp upward. Now, the instrument is ready for the next test.

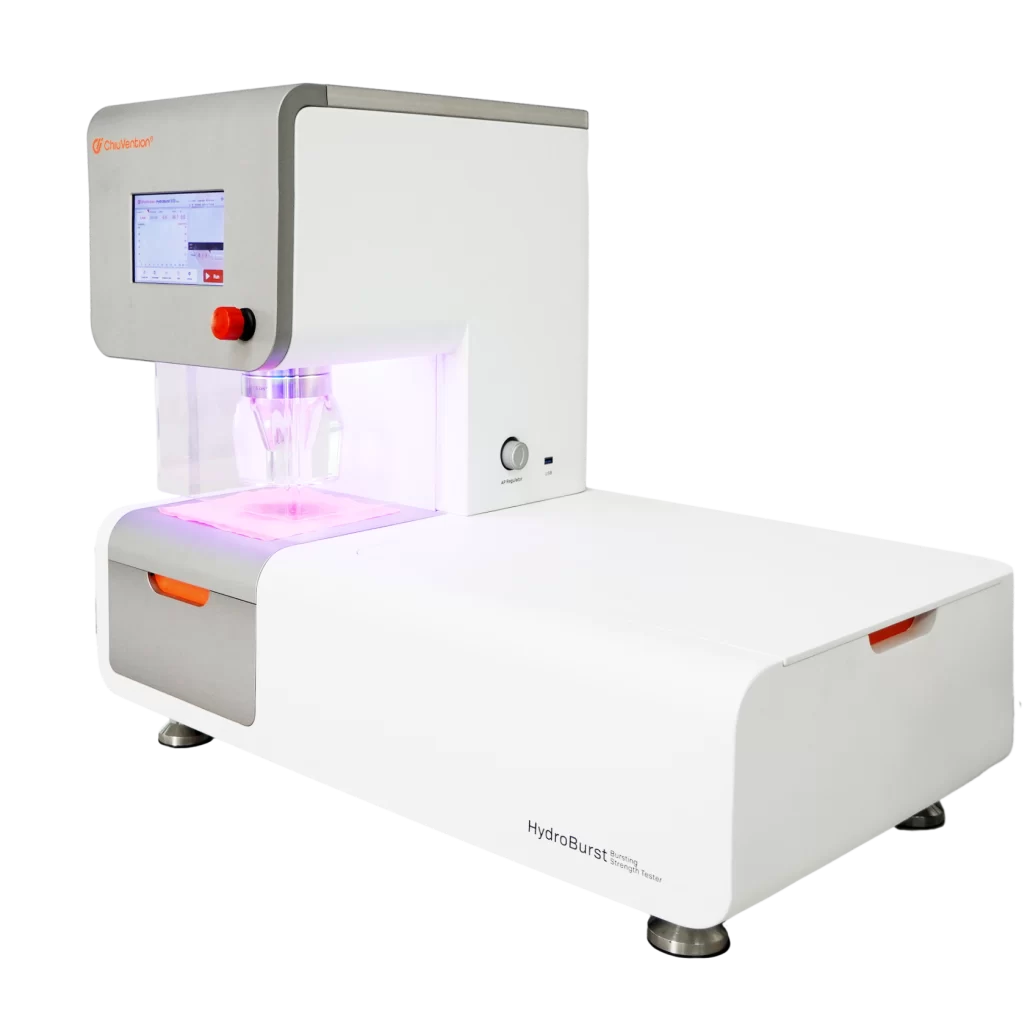

ChiuVention bursting strength tester gives results automatically; you do not need to calculate the readings. Once the specimen is placed on the top head of the testing area, the holding cup moves downward, and it holds the specimen firmly.

When you start the button, the diaphragm will move upward and exert pressure from inside of specimen to the outer side, until the material ruptures. The high-precision sensors measured the value of pressure that was required to rupture the specimen.

Formulas

The ChiuVention bursting strength tester is automatic in doing calculations for test results. Let’s see how the important formulas are involved in the calculation of bursting strength.

The bursting factor can be easily calculated though this formula.

Bursting Factor = (Bursting Strength × 100) ÷ g/m2

The bursting factor is a proportionality constant and has the same value for a material. It has no unit, while bursting strength result is written in kilogram per square cm, or kilopascal, or in pound per square inches. Either of these units can be selected.

Burst Ratio = Bursting Strength (lb/inch2) ÷ Basis Weight (lbs/ream)

Burst Index = Bursting Strength (Kpa) ÷ Grammage (g/m2)

Take the average result of all readings. It helps to get take best possible result.

BS Tester Vs Other Strength Testing Machines

The bursting strength tester measures the resistance of a material to rupture, while other strength testing machines, like tensile testers, determine the material’s resistance to elongation and breakage.

Bursting Strength Tester

These testers are used to determine the material’s durability and find how much force a material can bear before to bursts. BS testers are used for packaging material like paper, card board, corrugated box, textile, foam, and sheets.

This tester applies a hydraulic or pneumatic pressure on the specimen to move its surface outward, and keeps exerting pressure until the specimen bursts.

The pneumatic testers are more affordable, and easy to perform the test. Hydraulic testers give more accurate results as compared to pneumatic testers.

Other Strength Testing Machines

Tensile Testing Machine

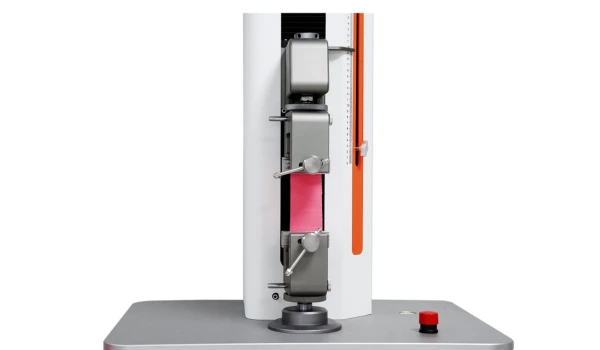

Other strength testing machines, like tensile testers, are used to measure the tensile strength of a material. It determines the material’s resistance to tension. It evaluates the material elongation behavior and breaking point.

The universal tensile tester

This is used in the textile and automotive industries to measure the material’s elongation and resistance to tension.

The universal tensile tester applies a tensile force on the specimen by pulling from one end, and the second end is clamped in the static jaw. In this way pulling causes elongation and keeps on applying tensile force until the specimen breaks.

The tester measures the elongation length, and tensile force to break the specimen. UTM tester also has two types of versions. One is electro electro-mechanical machine in which force is applied through an electric motor.

The second is the Servo-hydraulic machines, which use a hydraulic system to pull the specimen. UTM testers are more costly than BS testers, but it also give more accurate and precise results.

Avoiding Common Mistakes

The packaging in our daily items has become a basic need. We cannot store, hold, and ship our products without packaging. So it has a very important role for delivering the products and items.

The bursting strength is the parameter that ensures the standard durability of packaging material according to their use. What will happen if our testing is doubted? Obviously, we could not be able to certify the material.

That is why standard testing of packing material is essential. Now, let’s see what the common mistakes that can happen during the burst strength testing are and how to avoid them.

It might happen during testing that the socket might spark or not work consistently.

So the technician should plug in the socket properly and check the main supply. He can call the electrical department to ensure a consistent electric supply without short circuits.

If you are using a hydraulic bursting tester, then there might be a possible leakage of glycerin.

In this case, the exact pressure will not be developed according to the screen display, which will lead to false results, so fix this issue through the mechanical department or supplier.

The pneumatic tester is more sensitive to air leakage, so proper checking and balancing are mandatory before performing the bursting test. To solve this issue technician should inform the manager or call the relevant department.

The next issue that you may face is not evenly bursting of specimen.

It happens when the diaphragm is not exerting equal force in all directions. It may be due to excessive usage, so you can eliminate this issue by replacing it with a new diaphragm.

Sometimes, you will see that the tester is reading beyond the material’s limit.

It happens when the specimen is not placed properly on the testing head. So place the sample as according to standard testing procedure.

The slippage of the sample might have taken place during the testing due to loose clamping.

So you must ensure that the specimen is tightly clamped on the testing head.

Machine calibration is very important.

It assures you that the instrument is in the right working conditions. Sometimes technicians forget to do this task, which leads to improper results.

You may face a very important issue: the machine is making too much noise.

It means that there is a problem inside the tester. In this case, turn off the machine promptly and then check out the reason for the noise, which may be due to a loose part. Find it and fix it.

The Future of Burst Testing Machines

The bursting strength machines play an important role in determining the material durability like for packing industry, textile and automotive. Firstly, the bursting strength tester was operated manually.

For example, paper strength was measured through a paper bursting strength tester. This instrument applies force on the paper to rupture it. The technician has to stand on the machine to note the reading at what point the paper bursts.

So in manual testing, there was a chance of human error in taking the reading because we can measure the real-time data. We could not express the material behavior to bursting through a scientific computer report.

With the passage of time, industry revolutionized. Textile testing instruments also upgraded. Now, ChiuVention bursting testing machines are fully automated with high-precision load cells and pressure sensors, which give us real-time data.

ChiuVention Bursting strength tester also shows the materials bursting behavior through a graph. This scientific computer report helps the manufacturer and technician to understand the material’s durability and lifespan.

BS testers are now equipped with the latest high-speed cameras that capture the material’s bursting moment from different angles, which gives a clear understanding of the material’s performance. This helps the material manufacturers to further enhance its quality.

The material could be paper, foam, cardboard, corrugated box, textile, woven fabric, and sheets. These all types of materials are checked on bursting strength testers.

There is further classification of bursting tester on the basis of getting more accurate results for a specific product. For example, bursting strength testers are hydraulic, pneumatic, manual, and automatic.

The future of burst testing machines is bright. Scientists are working to develop machines more user and environment-friendly and monitor real-time data.

How AI and Digital Advancements are shaping the Industry?

Artificial intelligence and digital advancement are helping the industrial sectors to reduce the production mistakes and helping to take the right actions which saves industry cost and time. It helps to increase the production within the same resources.

AI in textile testing instruments is helping to take real time data and monitor the quality of a product more precisely. AI with machine learning is now becoming capable of doing predictive analysis about the material life span and durable longevity.

The combination of cloud computing and artificial intelligence is helping the technicians to manufacturers to control their system remotely. AI is definitely playing an important role in shaping the future of the textile industry and testing instruments.

Bursting Strength Tester Manufacturers

Bursting Strength Tester Manufacturers

There are several bursting strength manufacturers in the market. Let’s have a look at it.

ChiuVention

ChiuVention is leading among all of other manufacturers due to its latest technology, integration of SmarTex lab app, ERP/LIMS systems, remote monitoring and precise measurements system.

ChiuVention offers hydraulic and pneumatic bursting strength testers. Its testers are used in packaging, textile, and automotive industries. It is the technicians’ most preferred due to its user-friendly interface and wide application.

TESTEX

It is the sister company of ChiuVention and the manufacturer of the BS tester. TESTEX also offers hydraulic and pneumatic bursting testers.

Presto Group

This group is the manufacturer of bursting strength tester for packaging industry uses neoprene diaphragm.

TESTRONIX

TESTRONIX is the providing BS tester for the packaging industry. It manufactures analogue and computerized tester.

QUALITEST

This manufacturer provides Mullen burst testers for the packaging industry.

Who is leading the Market?

ChiuVention is the leading manufacturer due to its smart technology and multiple options for testing using the same tester. It was established in 2010, a head headquarters is in China. This group is famous due to his highly quality testing instruments and has a good reputation in the market.

How Much Should a Bursting Strength Tester Cost?

The bursting strength tester costs vary on its model, functionality, automation, pressure range and testing requirements. There are different types of testers available in the market, from friendly budget ones to expensive ones.

The range of bursting strength tester is from $1500 to $5000. It all depends upon functionalities and requirements. Analogue has lower prices, while the latest computerized models with AI integration have higher prices.

Cost-Effective Solutions

The purchasing of the most suitable instrument for the laboratory is a decision that has to be made wisely. You should not rush to buy any brand without getting quotations from all over the market and other competitors.

The best strategy to buy the most suitable instrument in a low budget is to take quotations of the same requirement tester from all other manufacturers and vendors.

Then, analyze the testing requirements, machine durability, and supplier market reputation, because the company that is supplying out of the country would be more professional as compared to others which is giving services within the country.

You have to define your testing requirements, analyze the manual and automatic model. Decide whether you can work on manual or automatic is mandatory for the testing. You should ensure company policies regarding after sale services.

Finally, figure out the cost of the instrument including shipping and installation. Now you will have a clear idea which manufacturer will suit you.

Conclusion

The bursting strength is evaluated to know the material resistance to rupture. It is an important factor in the packaging industry for the safe delivery and shipment of products and sensitive instruments. It ensures the material’s strength and whether it can hold the product’s weight.

The Mullen burst test measures the strength of paper, cardboard, and corrugated boxes. This test is performed especially for packaging material to ensure its quality. Can it withstand the product load?

The best strategy to purchase the bursting strength tester in a low budget is to take quotations of the same requirement tester from all other manufacturers and vendors. Then, analyze machine durability, supplier market reputation, and cost, including shipping and installation.