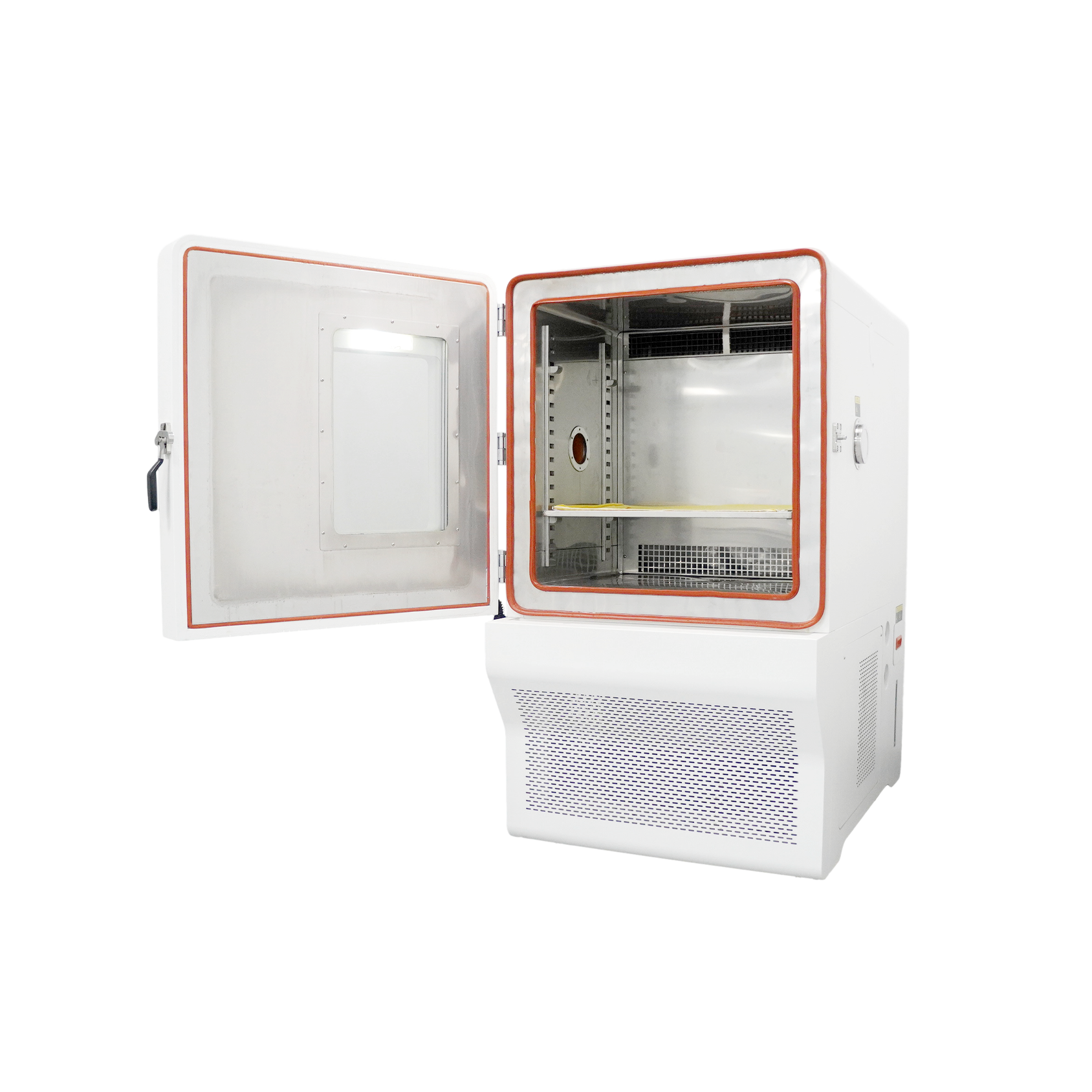

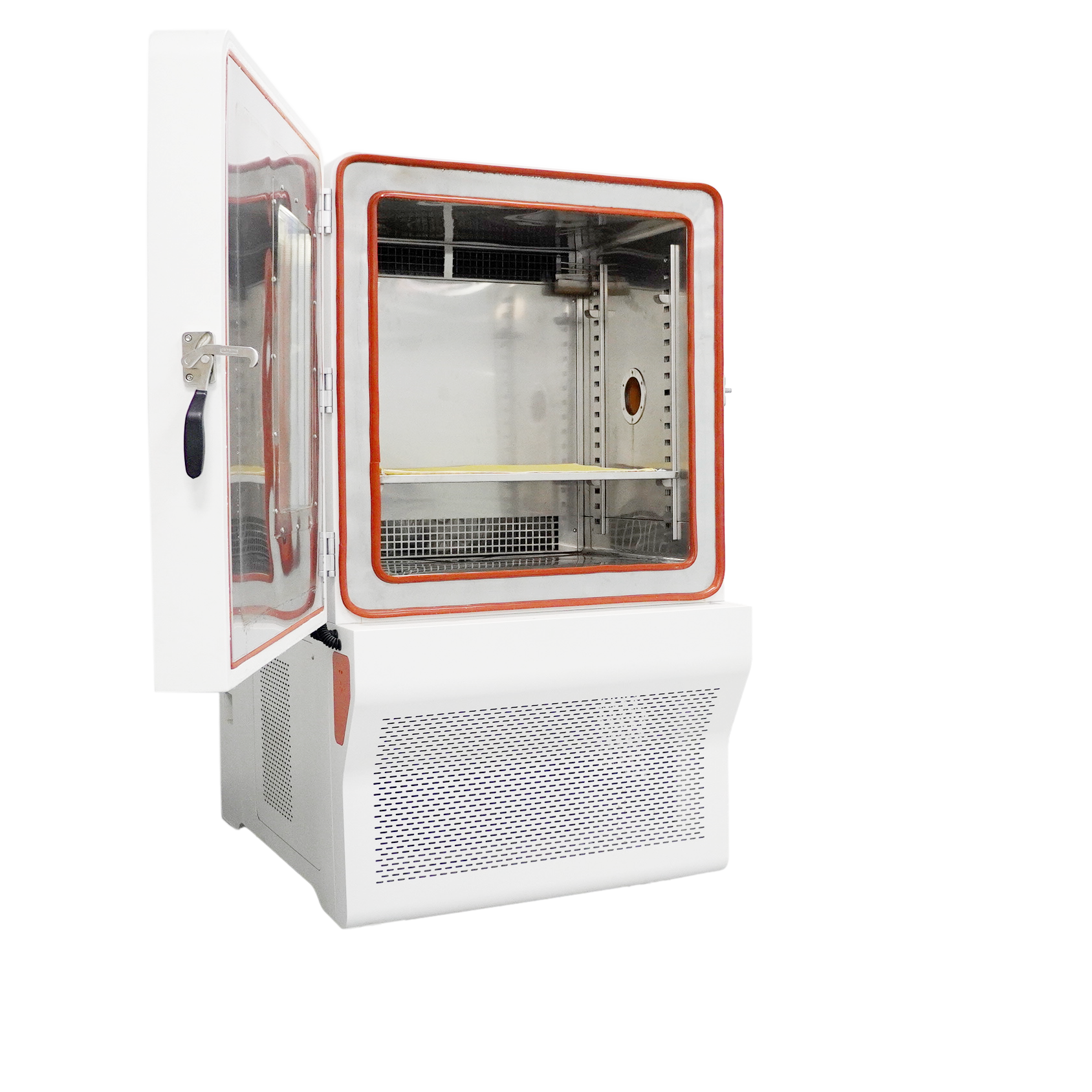

Wide range of applications

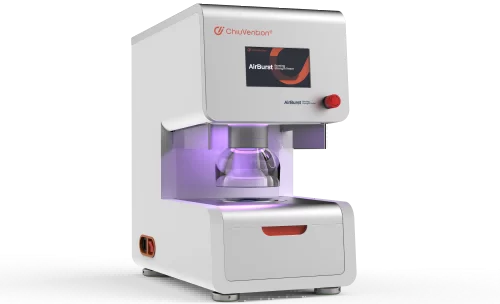

The AtmoExplorer Temperature and Humidity Chamber simulates high and low temperatures and humidity. It is used for testing needs in many fields. These include electronics, materials research, and medicine. It is also used in the automotive, food, and other industries. We also provide other climate chambers. These include the Thermal Shock Test Chamber, Hast Chamber, and Aging Test Chamber.

Excellent both in terms of precision, and uniformity of temperature and humidity.

Temperature and humidity control precision: ±0.5°C; ± 3%RH

Temperature and humidity uniformity: ± 2°C; ± 5.0% RH

Achieve heating and cooling quickly.

When empty, this Climate Chamber heats from room temperature to 100℃ in 30 minutes. It also cools from room temperature to -20℃ in 60 minutes.

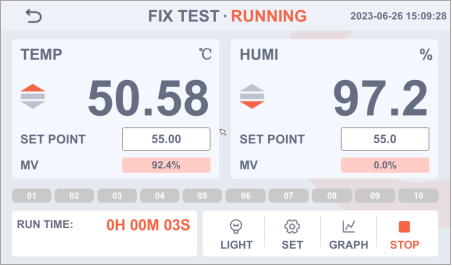

The intuitive and practical screens are easy to operate.

The Temperature and Humidity Test Chamber has a 7-inch touch screen. It displays information in Chinese and English. The display shows the set values (SV) and performs values (PV) for temperature and humidity. It also shows the current program number, segment, remaining time, and cycle count. It also has a separate program editing screen.

Stable operation originated from high-quality insulation materials and humidifiers.

Spring-type nickel-chromium wire makes up the temperature and humidity chamber’s heating element. Its humidifier is a stainless steel UL-shaped.

High-quality refrigeration system and refrigeration auxiliary parts

The Environmental Test Chamber has a Tecumseh compressor from France. It also has a solenoid valve from Japan. And it has a pressure controller. It also has an oil separator from a famous international brand. We provide you with a high-quality constant temperature and humidity chamber.

A variety of safety precautions

This temp and humidity chamber can run smoothly. It has dry-burning prevention. It also has high-pressure, overheating, and overcurrent protection for the compressor. It also has a no-fuse switch and a water shortage alarm. Besides, it has long-term water shortage shutdown protection.

We can customize various sizes.

such as 80L, 150L, 225L, 408L, 800L, 1000L

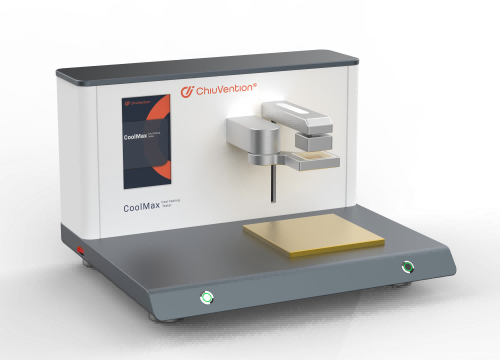

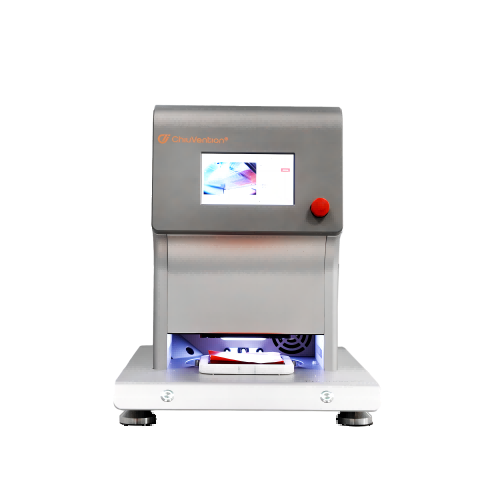

Designed in Germany, quality is our life.

All our lab instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our lab instruments of outstanding quality. 100% source factory and factory price.

Application Examples of Temperature and Humidity Chamber

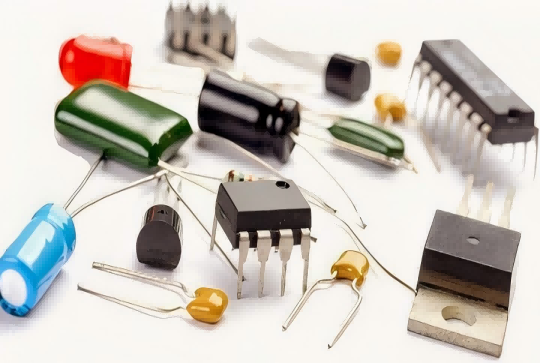

Electronics and Electrical Components

Textiles and Apparel

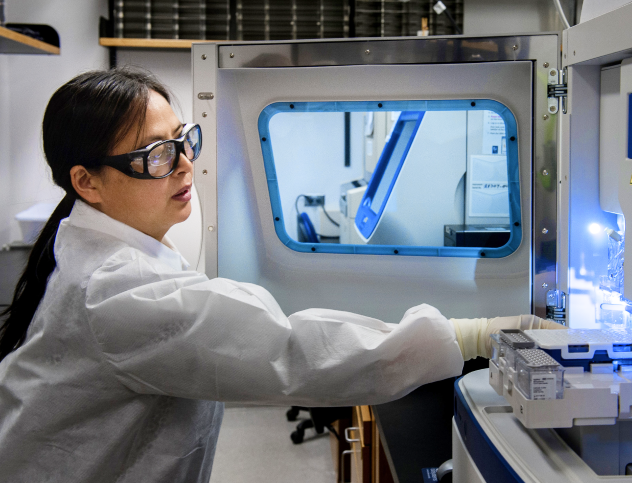

Pharmaceuticals and Biotechnology

Food and Beverage Industry

Customer Feedback

“We are in the automotive interior industry. This is the second time we’ve bought ChiuVention’s constant temperature and humidity test chamber. The constant temp and humidity chamber is durable, so we continue to choose it!”

“This environmental chamber can be customized. The temperature, humidity range, and volume can be made to fit our needs. ”

The Specification of AtmoExplorer Temperature and Humidity Chamber

Temperature range -20°C to +150°C

(-60°C to -40°C or +150°C Optional)

Humidity range: 20% to 98% relative humidity

Temperature and humidity control accuracy ±0.5°C; ±3% relative humidity

To achieve the same performance, measure it after 30 minutes of stable temperature.

Temperature and humidity distribution uniformity: ±2°C; ±5% relative humidity

To achieve the above performance, measure it at 1/6 distance from each wall of the test area. Measure it after the temperature has been stable for 30 minutes.

Heating time from room temperature to 100°C, within 30 minutes when no load.

Cooling time from room temperature down to -20°C, within 60 minutes when no load.

Testable area: 500 x 750 x 600 mm (D x W x H)

Controller specifications

Accuracy, Temperature ± 0.1°C ± 1 digit, humidity ± 1% relative humidity ± 1 digit.

Degree of Resolution: temperature ± 0.1 ℃, humidity ± 0.1 percent relative humidity.

Temperatures can be set from 0.1 to 9.9.

Show the current program number. Also, show the number of segments, the remaining time, and the number of laps.

A curve displays the setting value. It shows the temperature and humidity program. It also shows the current execution of the program.

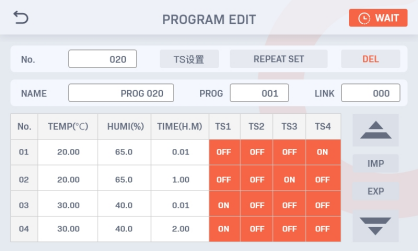

The program has a separate editing screen. On each page, you can input at least four temperature and time steps.

Model Power Weight Dimension

| Model | Measurable temperature range | Overall dimension D*H*W(mm) | Inner Box size D*H*W(mm) | Power(KW) | Voltage / Frequency | Number of phases | Gross weight (kg) |

| CV340-80L | -40℃~ 150℃

-20℃~ 150℃ |

1250*1510*700 | 400*500*400 | 5.0KW

4.5KW |

AC220V/50H | 1 phase/3 wire | 307 |

| CV340-150L | -40℃~ 150℃

-20℃~ 150℃ |

1350*1610*800 | 500*600*500 | 5.0KW

4.5KW |

AC220V/50H | 1 phase/3 wire | 367 |

| CV340-225L | -40℃~ 150℃

-20℃~ 150℃ |

1350*1720*970 | 500*750*600 | 7.0KW

6.0KW |

AC380V/50H | 3 phase/5 wire | 422 |

| CV340-408L | -40℃~ 150℃

-20℃~ 150℃ |

1450*1820*1080 | 600*850*800 | 8.0KW

7.0KW |

AC380V/50H | 3 phase/5 wire | 518 |

| CV340-1000L | -40℃~ 150℃

-20℃~ 150℃ |

1850*1970*1280 | 1000*1000*1000 | 14.0KW

12.0KW |

AC380V/50H | 3 phase/5 wire | 783 |

ChiuVention provides more smart textile testing equipment and please contact us for more details about textile testing machines.

OUR BROCHURE

Frequently Asked Questions

The environmental chambers have closed doors. You can set their temperature and humidity. When you put the products into it, the climate chamber can test them. It tests their durability, safety, and reliability. It also tests their performance in certain temperature and humidity conditions.

The components of the AtmoExplorer Temperature and Humidity Chamber are made from internationally recognized brands. Such as the Tecumseh compressor from France and the solenoid valve from Japan.

This ensures long-term stable operation and uniformity of temperature and humidity, which makes the climate test results more reliable and a reference value. The operation interface is simple and easy to understand, and supports segmented temperature and humidity control, allowing for more flexible and comprehensive testing of sample performance.

They use heating systems, such as electric heaters, to raise the temperature. They use cooling systems, such as refrigerators, to lower it. Humidifiers add moisture, and dehumidifiers lower humidity. Sensors check the conditions and provide feedback. The feedback allows the control systems to adjust. They do this to maintain the desired settings.

The AtmoExplorer chamber keeps a constant temperature and humidity. It can reach -20℃ to +150℃ (or -60℃/-40℃ to +150℃). It can also reach 20%R.H. to 98%R.H. Customized Temperature and Humidity Controlled Cabinets can provide specific ranges.

The Temperature Humidity Chamber can simulate real environmental conditions. It shows how products and parts will endure long-term stresses. These stresses relate to durability, safety, reliability, lifespan, and performance.

Aerospace, automotive, electronics, defense, and telecommunications industries use these climate chambers the most. They use them because vehicles, planes, and devices must work in all weather. They also rely on them for infrastructure. Pharmaceuticals and medical equipment also use humidity chambers. They use them to check stability and performance.

It improved quality control and lowered costs. It did this by finding flaws sooner. It ensured that products met industry and regulatory standards. It did this by using better materials and solutions. It also simplified global distribution and supply chains. It did this by conducting localized climate testing. In other words, various industries use a Constant Temperature and Humidity Chamber.

Choices include small benchtop chambers for experiments and samples. Floor-standing chambers support larger test setups. Walk-in room-sized chambers test entire vehicles and large configurations. Custom sizes suit unique test pieces. For example, the inner size (test size) of our Environmental Control Chamber can be:

| 400×500×400 mm |

| 500×600×500 mm |

| 500×750×600 mm |

| 600×850×800 mm |

| 1000×1000×1000 mm |

When empty, the AtmoExplorer can heat from room temperature to 100℃ in 30 minutes. It can also cool from room temperature to -20℃ in 60 minutes.

Potential electrical, fire, extreme heat/cold, mechanical, material handling dangers. Test samples may also pose explosion, toxicity, or combustion risks during experiments. Following proper operating, monitoring, and containment procedures is vital for safety.

Regular visual checks and compressor oil checks are important. The tasks include cleaning condensers and filters. They also include calibrating sensors and checking heating and cooling performance. Additionally, leak tests, wiring inspections, and general maintenance tasks. They help the Environmental Control Chambers run well.

Advanced computer systems check, control, and record data. They track temperature, humidity, ramp rates, dwell times, and stability. This data supports standards compliance and results analysis.

Experienced manufacturers, such as Chiuvention, can customize units for specific test space sizes. They can also handle extreme temperatures. They can also customize them for humidity levels. They can also customize them for instrumentation, software, data, and networking. We base the customizations on customer test requirements and budget.

Bare benchtop chambers for quality checks might cost a few thousand dollars. Rugged chambers for advanced, mission-critical aerospace/defense testing can exceed $100,000. Depending on capabilities, most technical-grade chambers fall between $20,000 and $80,000.

The ChiuVention AtmoExplorer Constant Temperature and Humidity Chamber wins. It has a good price and great performance. Want the quotation? Contact us right now!

For more about the temperature and humidity tests, or the chamber’s price, click the WhatsApp icon. It’s in the right corner now!

Working Principle of Temperature and Humidity Chamber

Temperature Control

Heating System: The chamber has electric heaters or other elements. They raise the internal temperature. A thermostat or a digital controller controls the heating system. It adjusts the power of the heaters to keep the temperature you want.

Cooling is typically achieved using a refrigeration system. The system includes a compressor, condenser, expansion valve, and evaporator. The refrigeration cycle removes heat from the chamber. The compressor and expansion valve control the temperature.

Temperature sensors track the chamber’s internal temperature. They can be either thermocouples or resistance temperature detectors (RTDs). The sensors provide feedback to the control system. They keep the set temperature accurate.

Humidity Control

Humidification System: Humidity is added to the chamber using a humidification system. This system may involve ultrasonic humidifiers, steam generators, or atomizers. These systems introduce water vapor into the air inside the chamber.

The chamber uses a dehumidification system to reduce humidity. The system is often part of the refrigeration system. The evaporator coil of the fridge cools the air below its dew point. This process condenses moisture and removes it from the air.

Humidity Sensors: Hygrometers or capacitive sensors measure the chamber’s humidity. The sensors provide feedback to the control system. We use this feedback to adjust the humidification and dehumidification processes. They’re adjusted to keep the humidity at the desired level.

Air Circulation

Fans and blowers help keep the chamber’s air at a uniform temperature and humidity. They do this by circulating the air continuously. This helps maintain consistent environmental conditions throughout the chamber space.

Control System

The chamber has a programmable controller. It is a PLC or a microprocessor-based controller. It lets users set and adjust the desired temperature and humidity levels. The controller processes inputs from temperature and humidity sensors. It makes precise adjustments to heating, cooling, humidification, and dehumidification systems.

A user interface is a digital display with buttons or a touchscreen. It lets users input setpoints. They can also create test profiles and track real-time conditions inside the chamber.

Operating a temperature and humidity chamber has two main modes. They are fixed mode and programming mode. Each mode allows for different levels of control and automation. It caters to various testing needs.

Fixed Mode

Overview

In fixed mode, the chamber operates at a single set temperature and humidity. It stays at that level until the user changes the settings or stops the operation. This mode is straightforward and is often used for simple, steady-state tests.

Steps to Operate in Fixed Mode

Power on the chamber:

Turn on the main power switch.

Allow the system to initialize.

Access the Control Panel:

Navigate to the main menu using the control panel’s interface.

Set Temperature:

Enter the desired temperature setpoint.

Please provide the input.

Set Humidity:

Enter the desired humidity setpoint.

Confirm the input.

Start Operation:

Press the start button to begin the operation.

Track the chamber as it stabilizes to its set conditions.

Watch Conditions:

Monitor temperature and humidity readings at all times.

Make adjustments if necessary.

Stop Operation:

Press the stop button to end the test.

Power down the chamber if needed.

Programming Mode

Overview

The chamber follows a pre-defined sequence in programming mode.

Each step has specific temperature and humidity settings and durations. This mode is great for complex tests. They need varied conditions over time.

Steps to Operate in Programming Mode

Power on the chamber.

Turn on the main power switch.

Allow the system to initialize.

Access the Control Panel:

Navigate to the programming menu using the control panel interface.

Create a program.

Step Definition: Define each step in the program with specific set points and durations.

Temperature: Set the desired temperature for each step.

Humidity: Set the desired humidity for each step.

Duration: Specify the duration for each step.

Define how the chamber should move between steps. For example, how quickly it ramps up or down.

Save the program.

Save the program to the chamber’s memory.

Assign a name or identifier to the program for easy retrieval.

Start the program.

Select the saved program from the menu.

Press the start button to begin the operation.

The chamber will automatically follow the defined steps.

Watch Conditions:

Observe the temperature and humidity readings as the program progresses through each step.

Ensure that the transitions and setpoints are being followed accurately.

Completion of Program:

The program will end automatically after the last step.

The chamber may return to a default state or power down, depending on the settings.

Manual Intervention:

If needed, you can pause, modify, or stop the program during its execution.

Advantages and Applications

Fixed Mode:

Advantages:

Simplicity and ease of use.

Suitable for tests requiring stable and constant conditions.

Applications:

Steady-state aging tests.

Simple material stability tests.

Programming Mode

Advantages:

Allows for complex testing protocols.

Can simulate real-world environmental conditions.

Reduces the need for constant monitoring and manual adjustments.

Applications:

Accelerated life testing.

Environmental stress screening.

Cyclic testing is done to simulate day-night temperature and humidity variations.

Calibration Tools and Equipment

Standard Thermometer: A calibrated and certified thermometer to measure temperature.

Hygrometer: A calibrated and certified hygrometer to measure humidity.

Data Logger: Optional, for continuous monitoring and recording of conditions.

The chamber manufacturer provides this software. It is for adjusting sensor readings if available.

Calibration Certificate: Check that the reference instruments are in their calibration period. They must have valid calibration certificates.

Calibration Steps

Preparation

Read the manual. It has the calibration instructions and safety rules.

Stabilize the Environment: Ensure the chamber and its surroundings are stable. Keep them free from big changes in temperature and humidity.

Clean the Chamber. Make sure it is free of any obstructions that could affect the readings.

Initial Check

Power On: Turn on the chamber and let it stabilize at a known setpoint.

Set the chamber to a known temperature and humidity. This is typically in the middle of the operating range.

Temperature Calibration

Place Standard Thermometer: Put the standard thermometer in the chamber. Put it in the center to avoid the wall’s effects.

Allow Stabilization. Let the chamber stabilize for long enough to ensure a steady temperature. This period is usually 30 minutes to 1 hour.

Record Readings. Compare the chamber’s display to the standard thermometer.

Adjust Calibration. If there is a discrepancy, adjust the chamber’s temperature sensor. Do this through the control panel or using calibration software. Follow the manufacturer’s procedure for making adjustments.

Repeat the process at multiple setpoints across the chamber’s range. This range includes low, medium, and high temperatures. This ensures accuracy across the whole range.

Humidity Calibration

Place the standard hygrometer in the chamber. Put it next to the standard thermometer.

Allow Stabilization: Let the chamber stabilize. Do this for a time long enough to ensure consistent humidity readings.

Record Readings. Compare the chamber’s humidity display with the standard hygrometer’s reading.

Adjust Calibration if there is a discrepancy. You can do this by adjusting the chamber’s humidity sensor calibration. You can do this through the control panel or using calibration software. Follow the manufacturer’s procedure for making adjustments.

Repeat the process at many setpoints across the chamber’s range. These include low, medium, and high humidity. This ensures accuracy across the whole range.

Validation

Check the readings:

after adjustments, check the readings at the setpoints. This confirms that the adjustments worked.

Document Results:

Record all calibration readings, adjustments, and results in a calibration log. This documentation should include the date, time, instrument serial numbers, and calibration certificates.

Final Steps

Save Calibration Settings. The chamber’s control system records all adjustments with complete accuracy.

Seal and Label: Seal the chamber if needed. Label it with a calibration sticker showing the date of calibration and the next due date.

Calibration Report: Make a report on the calibration process. Include the instruments used, readings taken, and any adjustments made.

1. Clean the heat sink (condenser) of the cooling unit often.

Dusty condensers cause false alarms from high-voltage switch trips. Maintain the condenser monthly. Vacuum the dust from the heat sink. Brush it with a stiff brush or blow it with a high-pressure air nozzle after the machine is turned on.

2. When opening and closing the door, or taking the test object from the furnace, do not let the items touch the rubber edge of the gate.

This will prevent the rubber edge from being damaged and will make it wear out faster.

3. Keep the ground around and at the bottom of the machine clean at all times.

This will prevent accidents and keep too much dust from getting sucked into the machine.

4. The cooling system is the core of the machine, so inspect all copper pipes once a year for leakage.

Notify the company or deal with it directly if there is a leak in an oil or loudspeaker joint or a welding port.

5. Clean and repair the high-current contacts of the switchboard at least once a year.

Loose contacts make the machine dangerous. They can burn the components or cause fire, alarm, or injury. Use the vacuum cleaner to suck out the dust inside.

6. Clean the humidifier and water trays often.

This prevents scale, which blocks the steam. Generally, clean after each test. Remove scale timely extends humidification tube life, and ensures smooth water flow. Use copper brushes with water.

7. Clean wet cloth frequently.

Hold on when the test cloth surface is not clean or hardened, or under the high heat above 85 ℃ control. Replace the cloth not absorb water. Do this once every three months. It will improve moisture measurement accuracy. Use a clean cloth to wipe the heat-measuring body using clean hands, and then clean the sink.

8. Inspect and adjust the wet bulb’s water level.

Keep the accumulation cylinder at the proper water level. Avoid too much or too little water. These can make the wet ball test cloth soak up water wrong and mess up the wet ball’s accuracy. Keep the water level at about the sixth scale. Adjust the screws on two sides of the water accumulation box to adjust its water level.

9. Do not debug the set values of two over-heat protectors in the distribution box at random.

The values have been adjusted before the factory. A switch protects the heating and humidification tube. It stops empty burning and water shortage. Set point = heat set point +20 ℃ ~ 30 ℃

When the machine is running, the set point of the overheat protector on the panel = heat set point +15℃~20℃. The heater stops as the chamber reaches the set temperature. Then, the “OVER HEAT” alarm turns on. If it runs long and unattended, make sure the over-heat protector is set. Do this before the operation.

10. Water line inspection and maintenance.

Water pipes are easy to plug and leak, so check regularly whether there is water leakage and plugging. If any, promptly eliminate or notify the company. Replace the humidifier’s water once a month. This ensures good water quality and flow.

11. To remove the product when the test is done, make sure the machine is off. Also, make sure the operators wear dry, electric, temperature-resistant gloves.

12. Internal and external cleaning and maintenance. Remove the internal impurities before operating the machine.

13. Clean the distribution room at least once a year using a vacuum cleaner to remove the dust inside. Wipe it externally at least once a year with soapy water.