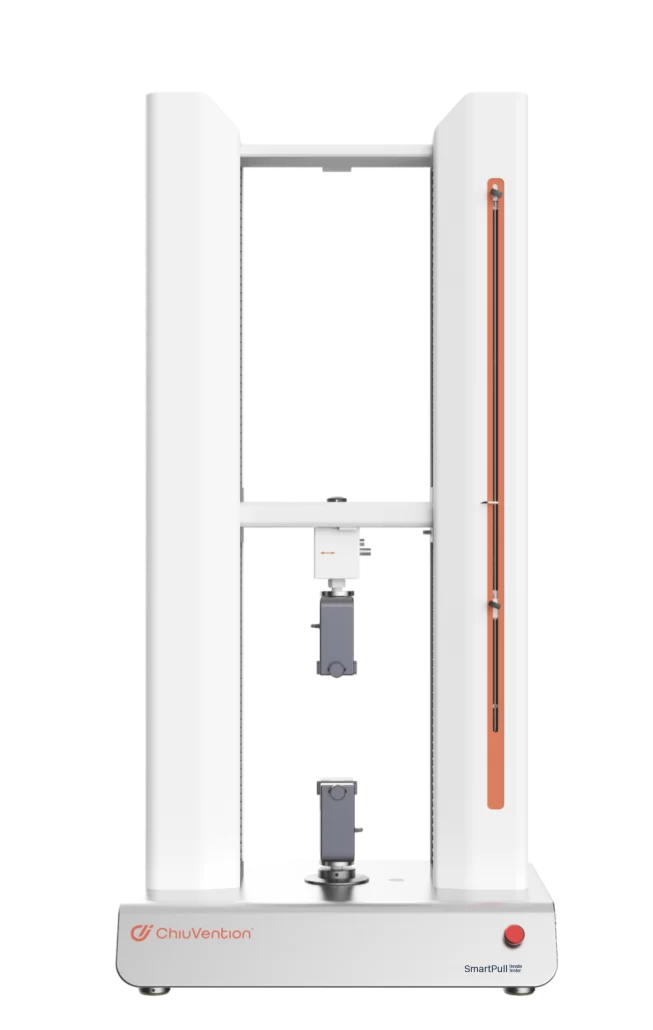

Higher Testing Accuracy and Reliability

The AC servo drive and ball screw make this Fabric Tensile Strength Tester stable. They provide a steady pulling force. It has 1% force accuracy. That ensures reliable and repeatable tensile test results.

Powerful software

The test software of this fabric strength testing machine works in many languages. It shows the displacement, maximum force, elongation, and stress. It also shows the maximum and bending stress, speed, and other test results. That is, getting more comprehensive test indexes to evaluate the quality of textiles.

Safety guarantee for the whole testing process

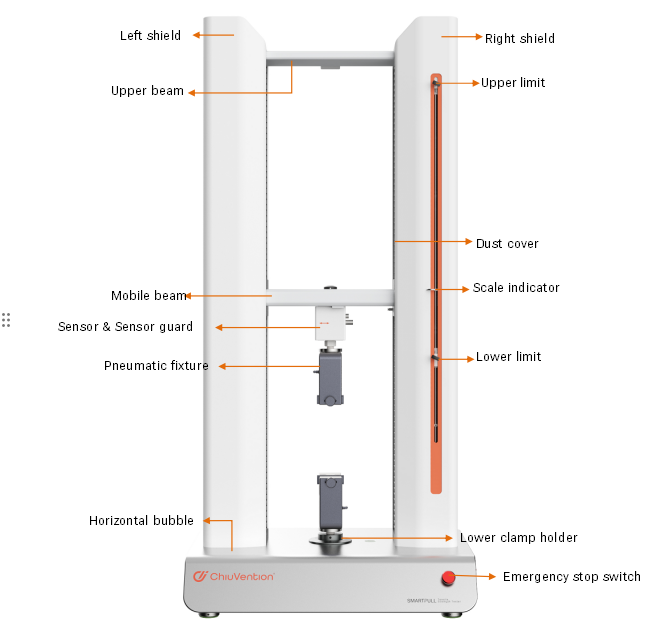

SmartPull fabric tensile testing machine has an intelligent and active alarm system. It has alarms for displacement and torque. It also has an overload and emergency stop device. And, it has an up-and-down travel limiting device. These features keep the testing process safe and stable.

You can customize it to suit your needs.

You can customize the S-type load cell that can measure 5-10KN of pulling force. It will perform more tests. You can also customize the testing software of this machine. It can do automatic repeated testing.

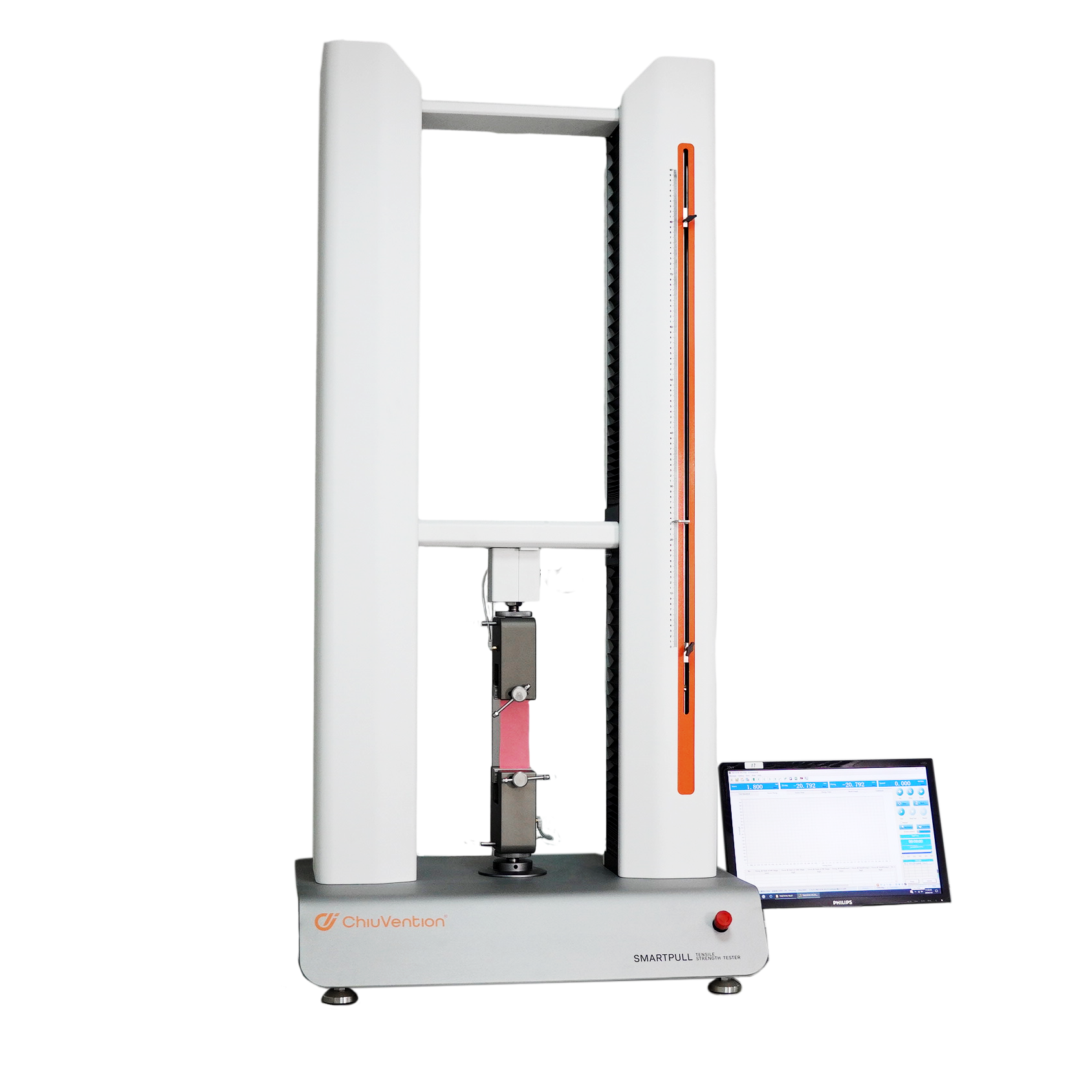

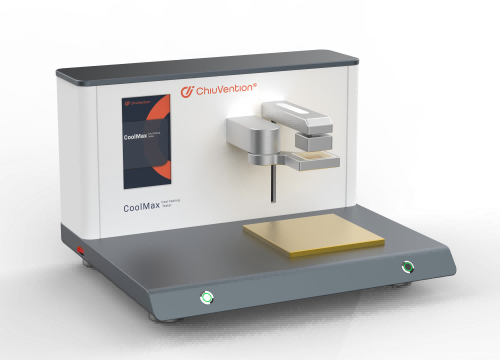

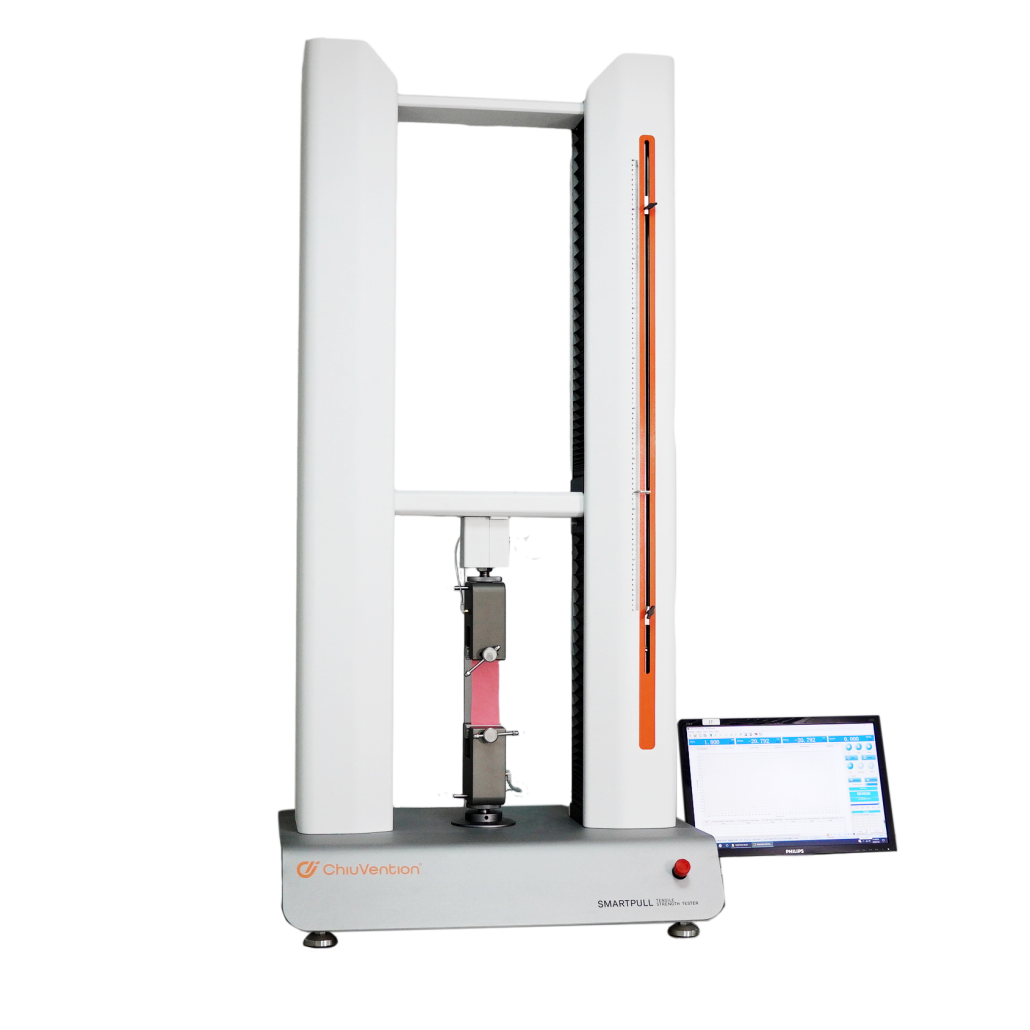

Light-Weight design

This Textile Tensile Strength Tester looks high-tech. It has rounded lines and a warm feeling. It has a trapezoidal base for stability.

Designed in Germany, quality is our life.

All our textile testing instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our textile testing instruments of outstanding quality. 100% source factory and factory price.

Customer Feedback

“This tensile strength machine has many uses and meets many standards. It is easy to use. Also, it is lighter and smaller than many machines with the same force range.”

“The tensile test results are reliable. This SmartPull Tensile Tester has a good safety design. So, we feel more confident when using it.”

The Specification of Tensile Strength Tester

Testing capacity 1000 kg

Test level class1

Max Travel 900mm (without fixture)

Travel accuracy ≤ 1%

Travel speed 1mm/min ~500mm/min

Speed accuracy ≤ 1%

Test force range 0.5 % ~ 100%FS

Test force value accuracy ±1%

Range of constant rate control 0.5%~100%FS

Software configuration (standard):

Version A of the test system, with a single-step test

Software configuration (optional):

Version C of the test system can achieve a multi-step test

Fixture and standards

Version A :

ISO 9073-3, ISO 13934-1, ISO 13934-2, ASTM D5034,

ASTM D5035, GB/T 3923.1, GB/T 3923.2

GB/T 13773.1, GB/T 13773.2, GB/T 24218.3

(The standards above are matched with clamps by 25×25 mm, 25×50 mm,

25×75 mm)

Optional Fixture and standards

Clamps by 25×100 mm: ISO 9073-4 GB/T 3917.3

Clamps by 50×75 mm : ASTM D5587

Leather tearing fixture: ISO 3377-2

Top breaking fixture: ASTM D6797 FZ/T 01030 GB/T 19976

Yarn fixture: ISO 2062

Version A+: ISO 13937-2 (Sample 50 mm wide)ISO 13937-3

GB/T 3917.2 (Sample 50 mm wide) GB/T 3917.5

Clams by 25×200 mm: ISO 13937-4 ISO 4674-1 GB/T 3917.4

Version C: ISO 13936-2, ASTM D4964 (U type fixture)

VersionC+: ASTM D434 ASTM D1683 ISO 13936-1

ISO 20932-1( with linear clamps, or choose other fixtures and replace the

clamps)

(The standards above should be programmed according to the test requirements provided by customers.)

Accessory

Standard accessories: pins, operation manuals, power cords, communication cords, control panels, fuses

Optional accessories: sampling plate

Computer Configuration of SmartPull Tensile Testing Machine For Fabric

CPU for the Intel Celeron (Celeron) 2GHz or more CPU

Memory at least 512MB, more than 1GB is better

Hard disk space of more than 2GB

Display resolution of 1024 × 768 or more.

If you need output reports, use a printer that is compatible with the operating system.

The system applies to Windows XP, Windows 7, Windows 8, and Windows 10.

You should install Microsoft Office 2003, 2007, or 2010. This will let you output the report in Word and Excel format.

Power 220 V 50/60 Hz Other voltages require an external transformer

Weight 160kg

Dimension 830*600*1730 mm (D*W*H)

ChiuVention provides more smart textile testing equipment for you. Contact us for details about textile testing machines.

Frequently Asked Questions of Tensile Strength Tester

What is tensile strength tester?

It is called a Tensile Strength Tester. We can also call it a tensile testing machine or a fabric strength tester. Its main purpose is to test the tensile strength of textile materials.

Tensile strength is the maximum stress a material can withstand. The material stretches or pulls. It’s before necking or breaking. For textile products, tensile strength affects its lifespan and quality.

This equipment tests tensile strength. Users can test fabrics or fibers. They measure strength under different stretches. The tester will stretch the test sample. They will record tensile values. This will make the tensile strength curve.

Tensile strength testing shows the quality of textile materials or products. It provides reference data for later production. This is significant for improving the level of products in textile enterprises.

What are the applications of a fabric tensile strength tester?

Here are some common applications of a fabric tensile strength tester:

- Quality control testing of woven, knitted, or nonwoven fabrics: Test fabric strength at various stages of production to ensure it meets specification requirements.

- Material development: Textile manufacturers use Tensile Machines to test new materials and blends during product development.

- Fiber and yarn testing: Tensile machines can test individual fibers, filaments, or entire yarns to determine tensile properties.

- Raw material inspection: Incoming raw materials like fibers, yarns, and fabrics are tested on receipt to verify strength matches the paperwork.

- Manufacturing process control: Fabric strength is monitored through processes like weaving, knitting, and dyeing/finishing to detect issues.

- Wear testing: Simulate effects of wear and laundering by repeated tensile tests to rate fabric durability.

- Finished product inspection: Final textile products are tested before release to avoid weakness failures in use.

- Military/industrial fabric certification: Strong fabrics for protective clothing, equipment, tarps, etc. require certification.

- Forensics: Determine if fabric failure was a product fault or caused by external factors in liability investigations.

- Research and development: Universities and textile labs use it for fabric improvement studies.

What are the key features to consider when selecting a Tensile Machine?

1. Range and precision

Range range: According to the nature of the test material, select the appropriate range of the tension machine. If the range is too small, it may lead to equipment overload; range is too large, it may reduce the test accuracy. Therefore, it is very important to choose a tension machine that can cover the required test force range.

Accuracy requirements: Different applications require different levels of accuracy. Ensure that the force measurement accuracy of the tension machine is in line with the test standards, the general requirements of the accuracy of ± 0.5% or ± 1% or less.

2. Test speed

Speed range: the adjustable speed range of the tension machine is very important, especially for different materials such as tensile, compression, peeling, and other tests. Select the speed range in line with the test requirements of the tension machine, such as the usual speed range should be between 0.01 mm/min to 1000 mm/min.

Speed accuracy: Speed accuracy is also important to ensure that the tension machine can maintain precise control at different speeds to avoid deviation during testing.

3. Fixtures and Accessories

Fixture type: Select the appropriate fixture according to the material to be tested. Different materials (fabrics, plastics, metals, etc.) and types of tests (tensile, compression, peeling, tearing, etc.) require different types of fixtures.

Interchangeability: Ensure that fixtures are easy to change and support future fixture changes or upgrades for different testing needs.

Fixture strength and durability: For high-strength material testing, fixture strength and durability are critical. Weak fixtures may slip off or damage samples during testing.

4. Force Transducers

Sensor accuracy: The accuracy of the force transducer directly affects the accuracy of the test results. Choose a force transducer with high accuracy, low drift, and stability.

Replaceable Sensors: Some tension machines support the replacement of sensors to meet the needs of different test ranges. Confirm whether the tension machine is compatible with sensors of different ranges.

5. Displacement accuracy and stroke

Displacement accuracy: The displacement measurement accuracy of the Tensile Strength Equipment is an important index of the test data. Select the machine with high high-precision displacement sensor to ensure accurate displacement data, especially in long-stroke tests.

Stroke range: According to the size of the sample and the test demand, choose the appropriate range of stroke of the Tensile Strength Equipment, to avoid insufficient equipment stroke can not complete the test.

6. Control system and software functions

User Interface: Ensure that the control system of the Tensile Strength Equipment is easy to operate, can intuitively set the test parameters, and monitor the test process in real time. Touch screen or PC-based software interface to improve operational efficiency.

Data Acquisition and Analysis: The Tensile Strength Equipment should be equipped with a powerful data acquisition system capable of capturing and storing data such as force-displacement curves and stress-strain curves.

Test Report Generation: Select equipment that can automatically generate and export test reports to help users analyze and store data, which helps subsequent test comparisons and results tracking.

7. Test standard compatibility

Compliance with industry standards: According to the requirements of the industry or test, the Tensile Strength Equipment needs to comply with the corresponding international or national standards (such as ISO, ASTM, GB, etc.). Confirm that the tension machine can meet the requirements of these standards for test force, accuracy, and performance.

Multiple test mode support: Select equipment that supports multiple test modes for different types of tests such as tensile, compression, bending, shear, peeling, etc.

8. Equipment stability and durability

Structural materials: The frame and structure of the Tensile Strength Equipment should be made of high-strength materials to ensure that the equipment will not be deformed or loosened in long-term use and maintain accuracy.

Durability: The durability of the Tensile Strength Equipment determines its life and maintenance cost. Choose equipment manufactured by reliable brands and proven in the market to ensure its durability.

9. After-sales service and support

Warranty: Understand the warranty period of the equipment and make sure that the manufacturer of the Tensile Strength Equipment provides adequate after-sales service support, such as installation and debugging, training, and maintenance.

Technical support: technical support may be required during the use of the Tensile Strength Equipment, especially in the testing software, sensors, accessories, etc. Ensure that the vendor provides timely technical support to help solve problems encountered in the operation of the equipment.

10. Price and cost-effective

Price range: according to the budget to choose the right Tensile Strength Equipment, not only considering the price of the equipment itself, but also considering the long-term use of maintenance costs, accessory costs, and so on.

Cost-effective: do not just pursue low-priced equipment, according to the test requirements, to find the best balance between performance and price, to ensure that the purchased Tensile Strength Equipment can be a long-term stable operation, to meet the test requirements.

11. Expandability and upgradability

Upgrade and expand functionality: Some tension machines can be upgraded through software or hardware to add new features or improve performance. Choose the equipment with scalability and upgradability to meet future changes in testing requirements.

12. Environmental Adaptability

Environmental conditions: Some Tensile Strength Equipment may need to operate in specific environmental conditions, such as temperature and humidity-controlled laboratories. Ensure that the tensile machine can function properly in the required environmental conditions.

What is the maximum load capacity of the Tensile Machine?

The largest load a Tensile Machine can hold varies. It depends on the specific model. Here are some typical greatest load capacities seen in commercial Tensile Machines:

-

Light duty lab testers: 1 kN to 5 kN

-

General purpose testers: 5 kN to 20 kN

-

Heavy duty testers: 20 kN to 50 kN

-

Very heavy-duty testers: Above 50 kN

The largest load capacity needs to match the intended testing applications. For example:

-

You can perform fabric and yarn testing using load cells that are under 20 kN.

-

Fiber testing may only need 1-5 kN loads.

-

Rubber, threads, and films can be 5-20 kN.

-

Steel wire rope and chains need 20-50 kN or higher loads.

Top models may offer load ranges. They use interchangeable load cells. This provides flexibility for different materials.

Load accuracy is also important, within +/-0.5% to 1% of the rating. Proper load cell selection ensures test results fall within the rated measurement range.

The largest load capacity depends on material strength and tester specifications. It ranges from 1 kN for delicate tests to over 50 kN for heavy materials.

What is the accuracy of the tensile strength tester?

The tester’s accuracy depends on the model. But, in general, tensile testers aim for high accuracy. Some key points about tensile tester accuracy:

-

Load measurement accuracy is within ±0.5% to 1% of the rated load capacity of the load cell. For example, a 20 kN load cell would have an accuracy of ±0.1-0.2 kN.

-

Displacement/extension accuracy is also very good, often ±0.5% or better of the full-scale range.

-

High-end systems can achieve even higher accuracy of ±0.25% for load and ±0.1% for displacement.

-

Factors like system calibration, the load cell type, and the data rate affect accuracy.

-

Accuracy is usually specified and guaranteed by manufacturers in technical specifications.

-

Industry standards like ASTM D638 prescribe the lowest accuracy level for reported values.

-

Calibration is important to maintain the rated level of accuracy over time.

In summary, a top Tensile Machine can provide load accuracy within ±0.5-1%. It can also provide displacement accuracy within ±0.5%. These accuracies depend on specific product capabilities. This level ensures reliable, reproducible test data. Proper use and calibration sustain the rated level of precision.

What is the testing speed range of the tensile strength tester?

A Tensile Machine can achieve the following range of testing speeds:

-

Low-speed range: 0.1 mm/min to 50 mm/min

This low-speed range is suitable for testing very thin and delicate fabrics or films. It allows the gradual application of force to prevent tearing.

-

Medium speed range: 50 mm/min to 500 mm/min

Researchers conduct most general-purpose fabric and material testing within this medium range. It’s fast enough but also prevents sudden failure of samples.

-

High-speed range: 500 mm/min to 2000 mm/min

used for testing plastics, composites, rubber, and other tough materials. Also useful for production line quality checks.

-

Very high speed: Above 2000 mm/min

Some advanced testers can achieve very high speeds. They use them for impact testing. They test ballistic materials and aviation composites.

The exact speed capabilities depend on the individual tensile tester model. Higher-rated loads generally mean more mechanical robustness for high speeds.

Can the tensile strength tester perform tests on different materials?

Yes, tensile strength testers are versatile machines. They can test many types of materials. Some common materials that researchers can test include:

-

Fabrics – Different types of woven, knitted, or nonwoven fabrics.

-

Yarns – Natural and man-made fibers, filaments, spun yarns, plied yarns.

-

Films and thin sheets – Plastic films, foil laminates, paper sheets.

-

Rubber and elastomers – Different grades of rubber, seals, o-rings, silicones.

-

Composites – Fiberglass, carbon fiber, Kevlar composites, laminates.

-

Plastics – Different polymer samples, injection molded parts.

-

Metals – Wires, cables, thin metal sheets, aluminum, mild steel.

-

Non-metals – Ceramics, concrete, wood, cork, leather, sealants.

-

Biological tissues – Tendons, cartilage, and skin tissues from animals/humans.

-

Paper and board – Cardboards, corrugated boxes, tissues.

What ASTM standards are suitable for tensile strength tester?

Tensile machines are common. Researchers use them to conduct tensile tests. These tests follow various ASTM standards. Here are some of the key ASTM standards related to tensile testing:

-

ASTM D638 – Standard test method for tensile properties of plastics. Researchers use most for testing plastics and polymers.

-

ASTM D882 – Standard test method for tensile properties of thin plastic sheeting. For films, foils, and other thin flexible plastic materials.

-

ASTM D5035 is the standard test for the breaking force and stretch of fabrics. Common for woven, knitted, or nonwoven fabrics.

-

ASTM D792 is the standard for testing the density and specific gravity of plastics. The test uses displacement. Calculates properties of polymer materials.

-

ASTM D822 – Standard practice for preparing cork composites for test purposes. For testing cork and cork composites.

-

ASTM D885 – Standard test method for tensile properties of fiber-reinforced plastics. Used for fiber-reinforced plastics like composites.

-

ASTM D2834 is the standard test method for the transition temperatures of fabrics.

-

ASTM D2240 – Standard test method for rubber property-durometer hardness. For characterizing the hardness of rubber materials.

Following standardized protocols ensures consistent testing methods and compatibility/comparison of data globally. Instrument calibration is also against reference standards.

It is called a Tensile Strength Tester. We can also call it a tensile testing machine or a fabric strength tester. Its main purpose is to test the tensile strength of textile materials.

Tensile strength is the maximum stress a material can withstand. The material stretches or pulls. It’s before necking or breaking. For textile products, tensile strength affects its lifespan and quality.

This equipment tests tensile strength. Users can test fabrics or fibers. They measure strength under different stretches. The tester will stretch the test sample. They will record tensile values. This will make the tensile strength curve.

Tensile strength testing shows the quality of textile materials or products. It provides reference data for later production. This is significant for improving the level of products in textile enterprises.

Here are some common applications of a fabric tensile strength tester:

- Quality control testing of woven, knitted, or nonwoven fabrics: Test fabric strength at various stages of production to ensure it meets specification requirements.

- Material development: Textile manufacturers use Tensile Machines to test new materials and blends during product development.

- Fiber and yarn testing: Tensile machines can test individual fibers, filaments, or entire yarns to determine tensile properties.

- Raw material inspection: Incoming raw materials like fibers, yarns, and fabrics are tested on receipt to verify strength matches the paperwork.

- Manufacturing process control: Fabric strength is monitored through processes like weaving, knitting, and dyeing/finishing to detect issues.

- Wear testing: Simulate effects of wear and laundering by repeated tensile tests to rate fabric durability.

- Finished product inspection: Final textile products are tested before release to avoid weakness failures in use.

- Military/industrial fabric certification: Strong fabrics for protective clothing, equipment, tarps, etc. require certification.

- Forensics: Determine if fabric failure was a product fault or caused by external factors in liability investigations.

- Research and development: Universities and textile labs use it for fabric improvement studies.

1. Range and precision

Range range: According to the nature of the test material, select the appropriate range of the tension machine. If the range is too small, it may lead to equipment overload; range is too large, it may reduce the test accuracy. Therefore, it is very important to choose a tension machine that can cover the required test force range.

Accuracy requirements: Different applications require different levels of accuracy. Ensure that the force measurement accuracy of the tension machine is in line with the test standards, the general requirements of the accuracy of ± 0.5% or ± 1% or less.

2. Test speed

Speed range: the adjustable speed range of the tension machine is very important, especially for different materials such as tensile, compression, peeling, and other tests. Select the speed range in line with the test requirements of the tension machine, such as the usual speed range should be between 0.01 mm/min to 1000 mm/min.

Speed accuracy: Speed accuracy is also important to ensure that the tension machine can maintain precise control at different speeds to avoid deviation during testing.

3. Fixtures and Accessories

Fixture type: Select the appropriate fixture according to the material to be tested. Different materials (fabrics, plastics, metals, etc.) and types of tests (tensile, compression, peeling, tearing, etc.) require different types of fixtures.

Interchangeability: Ensure that fixtures are easy to change and support future fixture changes or upgrades for different testing needs.

Fixture strength and durability: For high-strength material testing, fixture strength and durability are critical. Weak fixtures may slip off or damage samples during testing.

4. Force Transducers

Sensor accuracy: The accuracy of the force transducer directly affects the accuracy of the test results. Choose a force transducer with high accuracy, low drift, and stability.

Replaceable Sensors: Some tension machines support the replacement of sensors to meet the needs of different test ranges. Confirm whether the tension machine is compatible with sensors of different ranges.

5. Displacement accuracy and stroke

Displacement accuracy: The displacement measurement accuracy of the Tensile Strength Equipment is an important index of the test data. Select the machine with high high-precision displacement sensor to ensure accurate displacement data, especially in long-stroke tests.

Stroke range: According to the size of the sample and the test demand, choose the appropriate range of stroke of the Tensile Strength Equipment, to avoid insufficient equipment stroke can not complete the test.

6. Control system and software functions

User Interface: Ensure that the control system of the Tensile Strength Equipment is easy to operate, can intuitively set the test parameters, and monitor the test process in real time. Touch screen or PC-based software interface to improve operational efficiency.

Data Acquisition and Analysis: The Tensile Strength Equipment should be equipped with a powerful data acquisition system capable of capturing and storing data such as force-displacement curves and stress-strain curves.

Test Report Generation: Select equipment that can automatically generate and export test reports to help users analyze and store data, which helps subsequent test comparisons and results tracking.

7. Test standard compatibility

Compliance with industry standards: According to the requirements of the industry or test, the Tensile Strength Equipment needs to comply with the corresponding international or national standards (such as ISO, ASTM, GB, etc.). Confirm that the tension machine can meet the requirements of these standards for test force, accuracy, and performance.

Multiple test mode support: Select equipment that supports multiple test modes for different types of tests such as tensile, compression, bending, shear, peeling, etc.

8. Equipment stability and durability

Structural materials: The frame and structure of the Tensile Strength Equipment should be made of high-strength materials to ensure that the equipment will not be deformed or loosened in long-term use and maintain accuracy.

Durability: The durability of the Tensile Strength Equipment determines its life and maintenance cost. Choose equipment manufactured by reliable brands and proven in the market to ensure its durability.

9. After-sales service and support

Warranty: Understand the warranty period of the equipment and make sure that the manufacturer of the Tensile Strength Equipment provides adequate after-sales service support, such as installation and debugging, training, and maintenance.

Technical support: technical support may be required during the use of the Tensile Strength Equipment, especially in the testing software, sensors, accessories, etc. Ensure that the vendor provides timely technical support to help solve problems encountered in the operation of the equipment.

10. Price and cost-effective

Price range: according to the budget to choose the right Tensile Strength Equipment, not only considering the price of the equipment itself, but also considering the long-term use of maintenance costs, accessory costs, and so on.

Cost-effective: do not just pursue low-priced equipment, according to the test requirements, to find the best balance between performance and price, to ensure that the purchased Tensile Strength Equipment can be a long-term stable operation, to meet the test requirements.

11. Expandability and upgradability

Upgrade and expand functionality: Some tension machines can be upgraded through software or hardware to add new features or improve performance. Choose the equipment with scalability and upgradability to meet future changes in testing requirements.

12. Environmental Adaptability

Environmental conditions: Some Tensile Strength Equipment may need to operate in specific environmental conditions, such as temperature and humidity-controlled laboratories. Ensure that the tensile machine can function properly in the required environmental conditions.

The largest load a Tensile Machine can hold varies. It depends on the specific model. Here are some typical greatest load capacities seen in commercial Tensile Machines:

-

Light duty lab testers: 1 kN to 5 kN

-

General purpose testers: 5 kN to 20 kN

-

Heavy duty testers: 20 kN to 50 kN

-

Very heavy-duty testers: Above 50 kN

The largest load capacity needs to match the intended testing applications. For example:

-

You can perform fabric and yarn testing using load cells that are under 20 kN.

-

Fiber testing may only need 1-5 kN loads.

-

Rubber, threads, and films can be 5-20 kN.

-

Steel wire rope and chains need 20-50 kN or higher loads.

Top models may offer load ranges. They use interchangeable load cells. This provides flexibility for different materials.

Load accuracy is also important, within +/-0.5% to 1% of the rating. Proper load cell selection ensures test results fall within the rated measurement range.

The largest load capacity depends on material strength and tester specifications. It ranges from 1 kN for delicate tests to over 50 kN for heavy materials.

The tester’s accuracy depends on the model. But, in general, tensile testers aim for high accuracy. Some key points about tensile tester accuracy:

-

Load measurement accuracy is within ±0.5% to 1% of the rated load capacity of the load cell. For example, a 20 kN load cell would have an accuracy of ±0.1-0.2 kN.

-

Displacement/extension accuracy is also very good, often ±0.5% or better of the full-scale range.

-

High-end systems can achieve even higher accuracy of ±0.25% for load and ±0.1% for displacement.

-

Factors like system calibration, the load cell type, and the data rate affect accuracy.

-

Accuracy is usually specified and guaranteed by manufacturers in technical specifications.

-

Industry standards like ASTM D638 prescribe the lowest accuracy level for reported values.

-

Calibration is important to maintain the rated level of accuracy over time.

In summary, a top Tensile Machine can provide load accuracy within ±0.5-1%. It can also provide displacement accuracy within ±0.5%. These accuracies depend on specific product capabilities. This level ensures reliable, reproducible test data. Proper use and calibration sustain the rated level of precision.

A Tensile Machine can achieve the following range of testing speeds:

-

Low-speed range: 0.1 mm/min to 50 mm/min

This low-speed range is suitable for testing very thin and delicate fabrics or films. It allows the gradual application of force to prevent tearing.

-

Medium speed range: 50 mm/min to 500 mm/min

Researchers conduct most general-purpose fabric and material testing within this medium range. It’s fast enough but also prevents sudden failure of samples.

-

High-speed range: 500 mm/min to 2000 mm/min

used for testing plastics, composites, rubber, and other tough materials. Also useful for production line quality checks.

-

Very high speed: Above 2000 mm/min

Some advanced testers can achieve very high speeds. They use them for impact testing. They test ballistic materials and aviation composites.

The exact speed capabilities depend on the individual tensile tester model. Higher-rated loads generally mean more mechanical robustness for high speeds.

Yes, tensile strength testers are versatile machines. They can test many types of materials. Some common materials that researchers can test include:

-

Fabrics – Different types of woven, knitted, or nonwoven fabrics.

-

Yarns – Natural and man-made fibers, filaments, spun yarns, plied yarns.

-

Films and thin sheets – Plastic films, foil laminates, paper sheets.

-

Rubber and elastomers – Different grades of rubber, seals, o-rings, silicones.

-

Composites – Fiberglass, carbon fiber, Kevlar composites, laminates.

-

Plastics – Different polymer samples, injection molded parts.

-

Metals – Wires, cables, thin metal sheets, aluminum, mild steel.

-

Non-metals – Ceramics, concrete, wood, cork, leather, sealants.

-

Biological tissues – Tendons, cartilage, and skin tissues from animals/humans.

-

Paper and board – Cardboards, corrugated boxes, tissues.

Tensile machines are common. Researchers use them to conduct tensile tests. These tests follow various ASTM standards. Here are some of the key ASTM standards related to tensile testing:

-

ASTM D638 – Standard test method for tensile properties of plastics. Researchers use most for testing plastics and polymers.

-

ASTM D882 – Standard test method for tensile properties of thin plastic sheeting. For films, foils, and other thin flexible plastic materials.

-

ASTM D5035 is the standard test for the breaking force and stretch of fabrics. Common for woven, knitted, or nonwoven fabrics.

-

ASTM D792 is the standard for testing the density and specific gravity of plastics. The test uses displacement. Calculates properties of polymer materials.

-

ASTM D822 – Standard practice for preparing cork composites for test purposes. For testing cork and cork composites.

-

ASTM D885 – Standard test method for tensile properties of fiber-reinforced plastics. Used for fiber-reinforced plastics like composites.

-

ASTM D2834 is the standard test method for the transition temperatures of fabrics.

-

ASTM D2240 – Standard test method for rubber property-durometer hardness. For characterizing the hardness of rubber materials.

Following standardized protocols ensures consistent testing methods and compatibility/comparison of data globally. Instrument calibration is also against reference standards.

OUR BROCHURE

Working Principle

-

Preparation:

-

The specimen is made to standard dimensions. It is then mounted in a tensile tester between the upper and lower grips.

-

-

Initialization:

-

The system is set up with the test parameters. These include the speed, length, and max load. The system may also be calibrated to ensure accurate measurements.

-

-

Testing:

-

The test begins by moving the crosshead at a set speed. It applies force to the specimen.

-

As the crosshead moves, the specimen elongates. The load cell measures the force. The extensometer or displacement sensor measures the elongation.

-

-

Data Collection:

-

The force and elongation data are continuously recorded by the data acquisition system. This data is used to make a stress-strain curve. The curve shows the material’s mechanical properties. These include tensile strength, yield strength, and elongation at break.

-

-

Completion:

-

The test continues until the specimen breaks or reaches a predefined elongation limit. The machine then stops and records the final data.

-

-

Analysis:

-

We analyze the recorded data to determine the material’s mechanical properties. The stress-strain curve is plotted. It shows the link between the applied force (stress) and the elongation (strain).

-

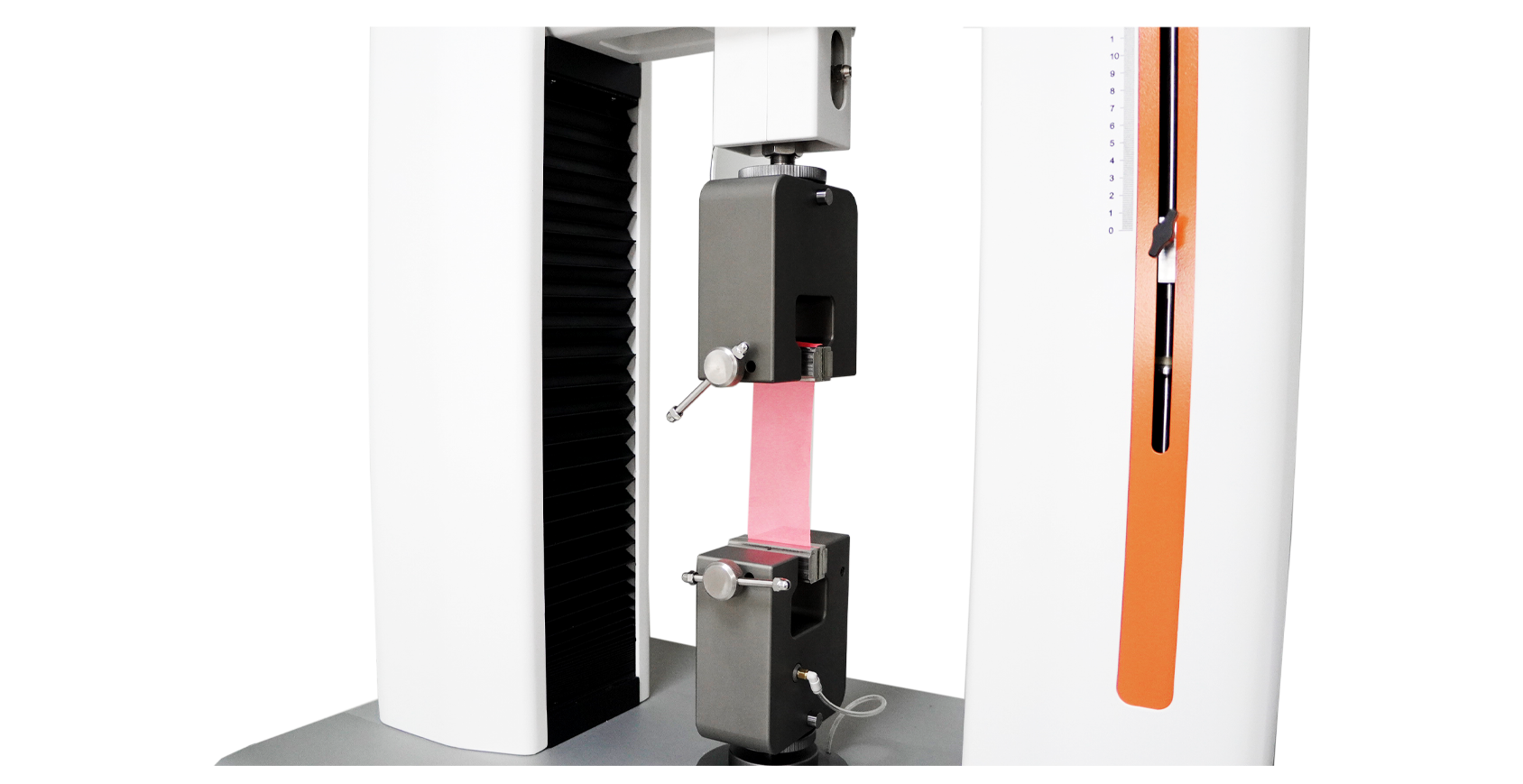

Components

-

Frame:

-

The double-column frame provides stability and rigidity to ensure accurate measurements. It consists of two vertical columns that support the crosshead and the load cell.

-

-

Crosshead:

-

The crosshead is the moving part of the machine that applies the tensile force to the specimen. It can move up and down along the columns.

-

-

Load Cell:

-

The load cell is a transducer that converts the applied force into an electrical signal. It is mounted on the crosshead or at the base of the machine.

-

-

Grips and Fixtures:

-

The specimen is held in place by grips or fixtures attached to the crosshead and the base of the machine. These grips ensure the specimen is securely held during testing.

-

-

Motor and Drive System:

-

A motor and a drive system control the crosshead’s movement. The drive system can be screw-driven or hydraulic.

-

-

Control and Data Acquisition System:

-

The control system allows the operator to set test parameters. For example, they can set the crosshead speed and maximum load. The data acquisition system records the force and elongation data during the test.

-

Test Method

-

Preparation:

-

Prepare the material specimen according to the relevant standards. For example, ASTM and ISO. Ensure the specimen’s dimensions, including length, width, and thickness, meet the specified requirements.

-

Equipment Check: Ensure the tensile tester is calibrated and in proper working condition. Check the load cell, grips, extensometer, and any other attachments.

-

-

Mounting the specimen:

-

Gripping the Specimen: Place the specimen between the upper and lower grips. Make sure the specimen is aligned and held securely. This prevents slippage during the test.

-

Set the initial gauge length of the specimen. This is the distance between the grips. This is an important parameter for calculating strain.

-

-

Setting Test Parameters:

-

Test Speed: Set the crosshead speed based on the material type and testing standard. The speed should be appropriate to ensure accurate results.

-

Set the largest load and elongation limits. This prevents machine damage and ensures the test stops if they are reached.

-

-

Initialization:

-

To zero the load cell, ensure it reads zero when no load is applied. This step is crucial for accurate force measurement.

-

Start Data Acquisition. Initialize the system to record force and displacement data.

-

-

Conducting the Test:

-

Starting the Test: Begin the test by starting the crosshead movement. The crosshead will move at the set speed, applying tensile force to the specimen.

-

Monitoring the Test: Continuously monitor the test to ensure everything is functioning correctly. Watch for any signs of specimen slippage or machine malfunction.

-

-

Recording Data:

-

Force and Elongation: The load cell measures the force on the specimen. The displacement sensor or extensometer measures the elongation. We’ve recorded these measurements in real time.

-

Stress-Strain Data: The data is used to make a curve. The curve shows the material’s mechanical properties.

-

-

Completion:

-

The test ends when the specimen breaks or reaches the set largest elongation or load limit.

-

Data Storage: Save the recorded data for further analysis.

-

-

Analysis:

-

Plotting the stress-strain curve: Use the recorded data to plot the stress-strain curve. The curve shows the relationship. It’s between the force (stress) and the resulting elongation (strain).

-

This involves analyzing the stress-strain curve. It helps determine key mechanical properties. These include tensile and yield strength, Young’s modulus, and elongation at break.

-

-

Reporting:

-

Generating a Test Report: Compile the test results into a detailed report. Include information about the specimen, test conditions, and measured mechanical properties.

-

Compliance with Standards is key. Ensure the test method and results meet the relevant standards and specs.

-

Tips for Accurate Testing

-

Align the specimen well. This prevents bending stress, which can affect the results.

-

Specimen Security: Clamp the specimen firmly into position. This prevents slipping during the test.

-

Calibration: Verify the tensile tester’s precision at routine intervals.

-

Environmental Conditions: Conduct tests in a controlled environment. This minimizes the effects of temperature and humidity on the results.

Calibration Process

-

Preparation

-

Review the SmartPull Tensile Tester Manual. Always refer to it for the specific calibration procedures and recommendations.

-

Gather Calibration Tools. You will need calibrated weights. You will also need a calibration rod or specimen. You will also need a calibration certificate. You will also need any other tools that ChiuVention recommends.

-

-

Environmental Conditions

-

Perform calibration in a stable environment. Control the temperature and humidity. They can affect measurement accuracy.

-

-

Load Cell Calibration

-

Zero the Load Cell: Before starting, make sure to zero the load cell. This means the load cell should read it’s zero when no force is applied.

-

Apply known weights: apply a series of known weights to the load cell. Begin with a light load and build up slowly. Record the readings at each weight.

-

Verify Accuracy: Compare the readings from the load cell with the known weights. The readings should match the weights. They must be within the allowable tolerance set by the manufacturer.

-

Adjust if needed. Adjust the load cell using ChiuVention’s instructions. Do this if the readings are outside the allowed range. This may involve using software to calibrate or physically adjust the load cell.

-

-

Displacement/Extension Calibration

-

Zero the Displacement Sensor. Make sure the sensor is zeroed when the crosshead is at the start.

-

Use a Calibration Rod: Place a calibration rod with a known length between the grips. Move the crosshead a set distance, then measure the actual displacement.

-

Verify Accuracy: Compare the measured displacement with the actual movement of the crosshead. The readings should match within the specified tolerance.

-

Adjust if needed. If there is a difference, fix the sensor or use the machine’s software to correct the measurements.

-

-

Software Calibration

-

Access Calibration Settings. Use the tester’s software to access them. Follow the software prompts to calibrate both the load cell and displacement sensor.

-

Input the calibration data. Enter the data from the known weights and displacements into the software. This will calibrate the machine.

-

-

Verification

-

Re-test the machine with the known weights and displacement. Do this to verify accuracy after calibration.

-

Check for Consistency: Ensure the machine gives consistent and accurate readings. They should span the full range of weights and displacements.

-

-

Documentation

-

Record Calibration Results. Write down all calibration data. Include the weights used, measured values, adjustments made, and final results.

-

Calibration Certificate: If an outside service provider does the calibration, get a certificate. It verifies the machine’s accuracy.

-

-

Regular Calibration Schedule

-

Set a Calibration Schedule. Base it on how often you use the tool, ChiuVention’s recommendations, and any industry standards.

-

Check often. This ensures the machine stays accurate between calibrations.

-

Need to clean up after each test. Keep the equipment clean.

After using the fixture, coat it with anti-rust oil for storage.

Replace the sensor or plug, and then unplug the cable after turning off the power.

If the sensor’s end is suspended, static can easily damage the amplifier. It can also damage the A/D converter.

The instrument needs to calibrate the load cell frequently. This is done to ensure the accuracy of the measured value.

Apply lubricant to moving parts at regular intervals.

If the instrument fails, professionals or the manufacturer should repair it. You must replace spare parts according to the original model.

The company is not responsible for all consequences. Not using the instrument as the manual says causes them.