Textiles suffer many types of damage in daily use. Tensile, compression, bending, and friction cause the most important effects. These forces lead to fracture, tearing, and breaking. So, the textile’s tensile, tearing, and breaking properties directly affect the product’s durability. They also determine the textile’s quality.

Tensile strength testing assesses the basic properties of textiles. These indicators mainly include the fabric’s breaking strength, tearing strength, and seam performance. In this issue, we mainly share the content about testing fabric strength.

Basic Concept

Textile’s breaking strength is its tensile strength. It is the force needed for it to break when stretched. It is an indicator of the absolute value of the tensile force, and the legal unit is Niu (N). Breaking strength in textiles is the peak force that tears the sample apart. This happens in a tensile test conducted under set conditions. The breaking strength index measures the effect of sunlight, washing, abrasion, and finishes. It measures their effect on fabric quality. So, test textiles with anisotropic strength and low stretch.

Test criteria

Listed below are the relevant standards for determining the breaking strength of textiles.

| Test methods | Domestic standards | Foreign standards |

| Strip method | GB/T 3923.1-1997,FZ/T 60026-1999 | IS0 13934-1:1999,IS0 13935-1,1999,IS0 4606,1995,ASTM D5035(1995),BS 2576-86(95),DIN 53857.1-1979,DIN EN ISO 13934-1:1994,DIN EN ISO 13934-2:1994,NFG 07-001-1973,EN IS0 13934-1:1999 etc. |

| Grab method | GB/T 3923.2-1998 | IS0 13934-2:1999,IS0 13935-2,1999,IS0 4606,1995, ASTM D5034(1995),BS 2576-86(95),DIN 53858-1979,NFG 07-120-1973,EN IS0 13934-2:1999 etc. |

Test Principle

The yarn in the tension system straightens. The yarn in the non-tension system becomes more curved. The force at the point of interweaving increases and the tangential resistance increases.

At first, yarn bending reduces fabric stretch. Later, fiber and yarn stretching thin the fabric.

The girdle effect happens because yarn bending increases when not stretched. The length shortens. The deformation at the nip is small, but larger in the middle. The specimen gradually shrinks.

Test method

In tensile testing, the strip method and the grab method are two common sampling methods. Obtain test samples using them. The choice depends on the test’s needs and the textile’s type. When doing textile tensile tests, you must ensure the sample and test meet the standards. This ensures the accuracy and comparison of the results.

1 Strip method

In the strip method, the sample is a narrow strip cut along the long axis of the textile. This test measures how well textiles stretch and hold up when pulled lengthwise. The strip method is better for testing the strength of textiles. This is because the shape and orientation of the sample match the textile’s structure. The strip method test’s main technical parameters vary between national and international standards. The table below shows the differences.

| Project | GB/T 3923.1-1997 | IS0 13934-1 | ASTM D5035 |

| Test Range | Suitable for woven fabrics, knitted fabrics, coated fabrics and other types of textile fabrics. | Suitable for woven fabrics, but also for fabrics produced by other technologies. | Suitable for woven fabrics, not for knitted fabrics and high elasticity fabrics (more than 11%). |

| Equipment | Tensile Strength Tester | ||

| Upper and lower fixture spacing | 100mm or 200mmm with 1mm accuracy | 100mm or 200mm (depending on elongation value) | 75mm |

| Tensile rate | 20mm/min or 100mm/min with an accuracy of 10%. | 20mm/min, or 100mm/min (depending on elongation value) | 300mm/min |

| Environmental conditions | Temperature (20°C), Relative Humidity (65±2%) | Temperature (20±2)℃, relative humidity (65±2)%. | Temperature (21±1)°C, Relative humidity (65±2)%. |

| Humidification time | At least 4h | 24h | At least 4h |

| Specimen size | Length at least 200mm or 100mm, width (50±2)mm (trimmed selvedge layer) | Length 300mm, Width 50mm | Length 250mm or 150mm, width 25mm |

| Number of specimens | 5 pieces in warp direction, 5 pieces in weft direction | Warp direction 5 pieces, Weft direction 5 pieces | Warp direction 5 pieces, Weft direction 8 pieces |

Scope of application

It is mainly for woven fabrics. But, it also works for fabrics made by other technologies. It usually does not work for elastic fabrics, geotextiles, or glass fiber. It also does not work for carbon fiber and polyolefin flat yarn fabrics.

Test procedure

The following are GB/T3923.1-1997 testing methods and steps.

(1) Sample preparation

Cut two groups of specimens at least 150mm from the edge of the fabric. One group is for the warp specimen, the other for the weft specimen.

Each group has 5 pieces. The effective width of each is 50mm (excluding raw edges). The length should meet the 200mm spacing. But, if the specimen’s elongation at break is over 75%, it should meet a 100mm spacing.

The specimen should be evenly distributed on the sample. It does not contain the same warp and weft yarns. The length runs parallel to the measured direction.

Take the specimen and put it in the constant temperature and humidity lab. Before testing, we will adjust it for humidity.

(2) After checking and calibrating the tensile strength testing machine ,set the test parameters

If the fabric’s breaking elongation is <8%, the spacing length is set to 200mm. The stretching rate is set to 20mm/min.

The fabric’s elongation at break is 8% to 75%. In this case, the spacing length is set to 200mm and the stretching rate is set to 100mm/min.

If the fabric’s elongation at break is over 75%, the spacing is set to 100mm. The stretching rate is set to 100mm/min.

Before setting the parameters, test the elongation at break of the specimen. Measure how much the material stretches before breaking under tensile load. Also, measure the ratio of the original length. This ratio is usually given by the formula for the elongation at break. It is the distance the break shortened divided by the original distance. Then, you multiply by 100%. After obtaining the elongation at break, set the spacing length and tensile rate.)

(3) Clamping the specimen

Center the specimen in the clamp. This ensures the tension’s center line passes through the clamp’s midpoint. You can clamp the specimen under top tension or with loose clamping. Determine the value of the applied top tension based on the mass per unit area of the fabric. For fabric with mass <200g/m², the pre-tension is 2N. For fabric with mass 200-500g/m², the pre-tension is 5N. For fabric with mass >500g/m², the pre-tension is 10N.

(4) Start the tensile tester for tensile strength determination

Stretch the specimen to break it and record the breaking strength. Record the breaking elongation or elongation. Test at least 5 pieces in each direction.

If the specimen breaks within 5mm from the jaws, it a jaw break. After conducting 5 tests, we keep the jaw fracture value if it is higher than the smallest ‘normal value’. Discard anything below the ‘normal value’. Then, we conduct additional tests to obtain 5 ‘normal’ fracture values. ‘normal’ fracture values. If all the test results are jaw breaks, or can not get 5 ‘normal values’, should report a single value.

(5) Calculation results

Find the average warp and weft breaking strength. Refer to N for the average warp and weft breaking elongation if necessary.

2 Grab sample method

The grab method takes a wide, irregular sample from the textile’s center. This method examines the fabric’s performance in the width. It better reflects the fabric’s strength. The grab sample method is usually better for non-woven textiles. Textiles that require assessment of performance in the width also benefit from it. The main technical parameters of the grab method vary by country. The table below shows the differences from international standards.

| Project | GB/T 3923.2-1997 | IS0 13934-2 | ASTM D5034 |

| Test Range | Suitable for woven fabrics, knitted fabrics, coated fabrics and other types of textile fabrics. | Suitable for woven fabrics, but also for fabrics produced by other technologies. | Suitable for strength testing of almost all organic fabrics, high elasticity fabrics (>11%) are not recommended. |

| Equipment | Tensile Strength Tester | ||

| Upper and lower fixture spacing | 100±1mm | 100±1mm or 75±1mm | 75±1mm |

| Tensile rate | 50±5mm/min | 50mm/min, | 300mm/min |

| Environmental conditions | Temperature (20±2)℃,Relative Humidity (65±2)% | Temperature (20±2)℃, relative humidity (65±2)%. | Temperature (21±1)°C, Relative humidity (65±2)%. |

| Humidification time | At least 4h | 24h | At least 4h |

| Specimen size | Length at least 150mm, width (100±2)mm | Length 200mm, Width 100mm | Length 250mm or 150mm, width 100mm |

| Number of specimens | 5 pieces in warp direction, 5 pieces in weft direction | Warp direction 5 pieces, Weft direction 5 pieces | Warp direction 5 pieces, Weft direction 8 pieces |

Scope of application

It is mainly for woven fabrics, but also for other fabric types. It is not for elastic fabrics, geotextiles, and glass or carbon fiber fabrics.

Test procedure

The following are GB/T3923.2-1997 testing methods and operation steps.

(1) Sample preparation

Cut two groups of specimens above 150mm from the fabric. One is for the warp specimen, the other for the weft specimen. Each group of 5 pieces, each piece of specimen length of at least 150mm, width (100 ± 2) mm. They put the specimens into the lab. The lab has constant temperature and humidity. This is for humidity treatment after the test.

(2) Check and calibrate the tensile machine, set the test parameters

The spacing length is (100±1)mm and the tensile rate is (50±5)mm/min.

(3) Clamping specimen

When clamping the sample, focus on the middle part of the sample. This is to ensure that the sample’s center line goes through the clamp’s center line. It should also be perpendicular to the clamp’s jaw line. Do not tilt the specimen and ensure that the upper and lower exposed parts are the same.

(4) Determination of tensile strength

Start the tensile tester. Stretch the specimen until it breaks. Record the breaking strength. When stretching, watch the yarn. If part breaks, stop the test.

If the specimen breaks within 5mm from the jaws, we consider it a jaw break. After testing 5 specimens, we keep the jaw fracture value if it is above the minimum ‘normal’ value. If it’s below the minimum, it’s discarded. Then, conduct additional testing to obtain 5 ‘normal’ values. ‘normal’ fracture values. If the test results do not show any jaw breaks or 5 ‘normal’ breaks, report a single value.

(5) Calculation results

Find the average breaking strength for the warp and weft. This is in Newtons. The warp is the longitudinal direction and the weft is the transverse.

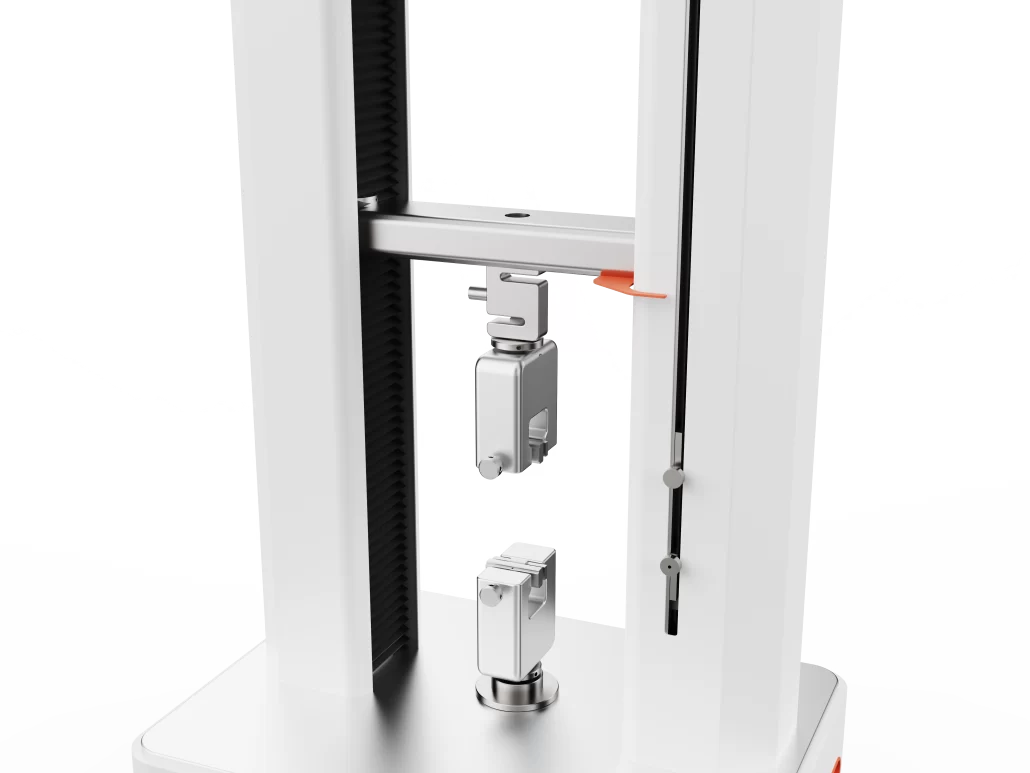

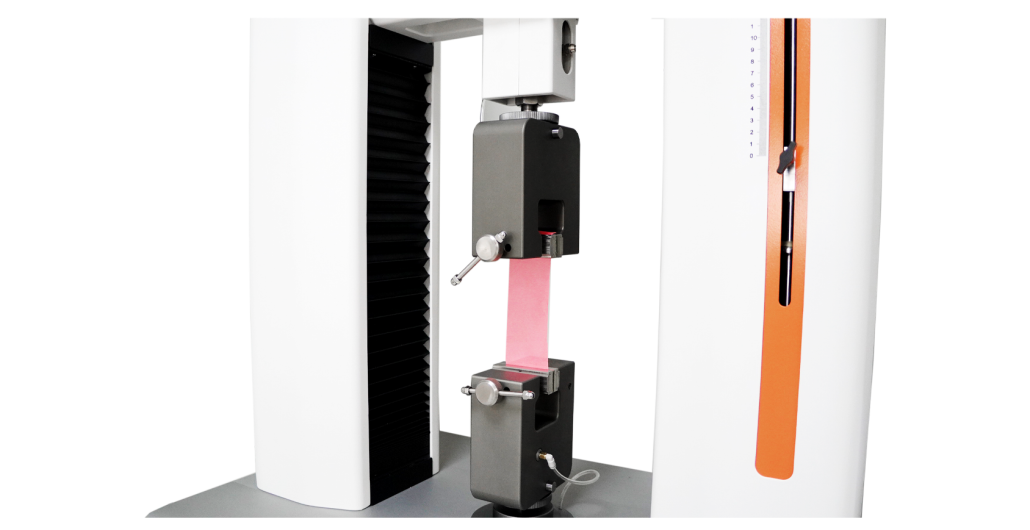

Test Equipment

The SmartPull Tensile Testing Machine can do two kinds of tensile strength tests. These are the strip method and grip method. It is a universal tensile testing machine. It is for textiles, leather, and footwear, among other things. And it can do tests for tension, compression, bending, tearing, shearing, peeling, and breaking. It applies to many standards, such as ISO9073-3, ISO13934-1/2, ASTMD5034, and ASTMD5035. It also applies to ISO3377-2, ISO13937-3, FZ/T01030, GB/T19976, and more.

SmartPull tensile testing machines come in single-arm and double-arm models. The double-arm ones can carry larger tensile force. Most products below 5KN use single arm. Most above 5KN use double arm.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com