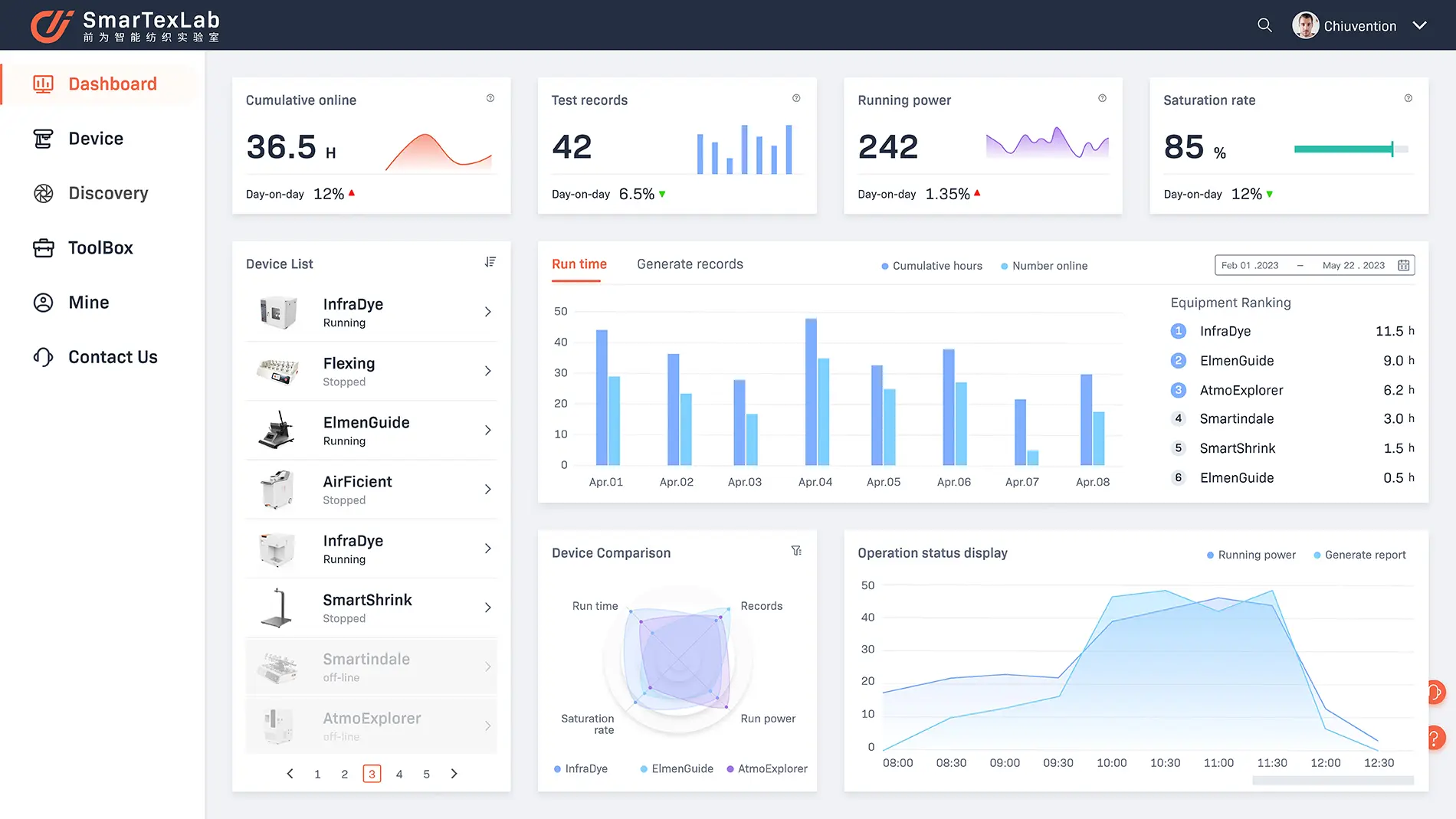

Link the textile testing instruments to smartphone/PC and ERP or LIMS

Faster, Reliable and Transparent

The textile instruments are connected via IoT to the SmarTexLab APP in the phone/PC. And The app can connect to ERP/LIMS via an API. Or, the textile testing instruments can connect directly to ERP/LIMS.

There are textile test orders and sample information in the system, and the textile testing instrument can start the test and record the sample info, test process, and test or rating results. The system will then summarize these into a textile test report. The textile testing report can be sent to SmarTexLab or ERP/LIMS. The relevant parties can view the report in real-time.

Test men can monitor textile tests for many instruments at once. They can also change textile test requirements, get alerts before tests end, and stop or repeat tests remotely.

In SmarTexLab, you can set up programs to start or stop the textile testing instruments. You can chat with ChiuVention service staff for quick support. You’ll get reminders that textile instruments need calibration, maintenance, and new consumables. Regular OTA remote upgrades are available.

Welcome to download SmarTexLab and dive into our Smart Textile Testing Now!

What are the differences between SmarTexLab Textile Testing and Conventional Textile Testing?

SmarTexLab Textile Testing

V S

Conventional Textile Testing

The test requirements are all collected online and received by the smart

cutting machine.

The collection of test

Fill out the test requirements manually, input them into the computer, and then print out some forms and corresponding labels.

The cutting machine automatically cuts the fabric into samples of

different sizes and put them into the

RFID basket that can identify and track the samples.

Cutting and

identiication of

Several samples were manually cut and labeled separately for differentiation.

By scanning the sample bar code or

placing an RFID basket in the induction

area, all information are automatically identiied and recorded, then the

instruments will be automatically set according to the test requirements.

Recording of

test elements

You need to manually record the test elements, such as environment, temperature and humidity, test material information, test method, etc., and set the instruments according to the test requirements, start the test.

Start test and just leave, the operator can monitor the test from app, until

mobile phone alarms to re-test or stop the tests.

Monitoring of

the testing process

The operators have to stay with the instruments to monitor the test status and wait for the ending of tests.

The system automatically calculates the test results, just confirm them.

Calculation of

test results

Manually record and calculate the test results.

Only need to confirm the report results and share them to all parties concerned in 1 minute.

Summary of test results and sharing

1 person is in charge of grouping a series of test reports and the other needs to input all the info into computer and print out them, then send to all parties concerned. Time:20 minutes

All the test results and pictures even videos are saved in the computer that eases the big data analysis.

Analysis of big data

The test results are recorded on the papers. It is very hard to do big data analysis.

What’s more, you can get the instrument calibration guide and maintenance service, consumable supply, as well as massive testing knowledge only by one-click on SmarTexLab. Test Smart Now!