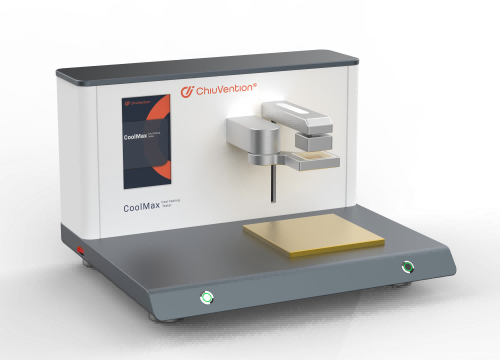

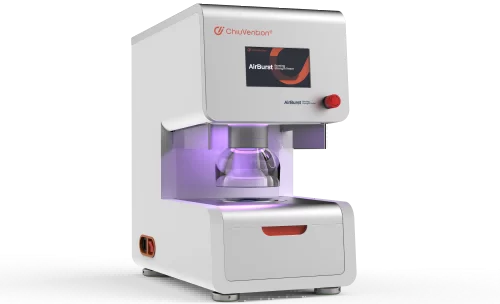

Overview of Cool Feeling Tester

A Cool Feeling Tester, also known as a Cool-Lite Tester, is an essential tool for monitoring the development progress of eggs without the need for direct handling. This lightweight, easy-to-use device provides accurate readings, allowing users to identify infertile or dead eggs for timely removal. Commonly used in incubators, the Cool Feeling Tester ensures a healthy hatch by providing real-time insights into egg development.

There are various types of Cool Feeling Testers available on the market, each with unique features and specifications. For instance, the GQF Manufacturing Cool-Lite Tester is renowned for its precision and ease of use, while the Thexton Manufacturing TH100 Propylene Glycol Antifreeze and Cool Tester is celebrated for its robust design and reliability. Despite their differences, all Cool Feeling Testers share the common goal of delivering accurate readings to help users monitor the progress and development of eggs effectively.

More reliable test results.

Rapidly heats the heat detection board to 35°C and responds with a Q-max value in seconds. So it minimizes the temperature loss of samples for accurate tests.

Precise control of temperature deviation

Suppose the ambient temperature in the laboratory deviates due to the location of the instrument or other reasons. In that case, the built-in temperature sensor can record that deviation and you can trace it. Besides, the instrument ensures that the deviation between the detection board and the sample is controlled.

More reliable test results

Samples tested by one third-party organization are re-tested by our CoolMax and the results match the third-party data.

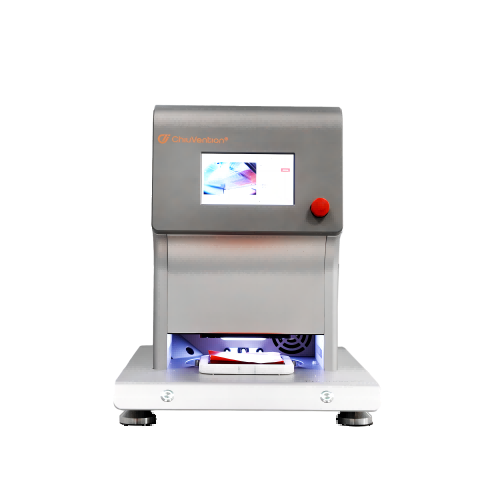

Smart Cool Feeling Test

At SmarTexLab App, you can set up a program to start or stop the instrument remotely; and you can schedule a test or remotely reheat the detection board to make testing more efficient.

Application Examples of CoolMax Cool Feeling Tester

Tencel Fabric

Bamboo Fabric

Modal Fabric

Linen Fabric

Client Success Stories

“Cool Machine! I heard it recently and will experience it at the ITMA Asia 2024.”

“ChiuVention is a reliable textile testing machine brand and we are using some its machines, so I also have interest to purchase this new machine in 2025.”

OUR BROCHURE

FLYER

The Specification of CoolMax Cool Feeling Tester

Heat detection plate temperature 35+/-0.5°C, adjustable from 20°C to 40°C

Cold plate 1 Polyester foam plate, Size 220mm * 220mm

Cold plate 2 Copper plate temperature 15℃-25℃, Size 200mm * 200mm, Precise temperature control

Temperature display resolution of 0.01℃ for thermal test plate and sample carrier.

Response time of thermal inspection plate<0.2s

Test time 1~99s adjustable

Testing mode manual/automatic

Test sample area 200*200 mm

A real-time test control system developed based on the Android system, which can display the test curve in real time.

With two USB-A interfaces, you can directly export the test report or connect other supporting equipment.

Light flashes when the test is complete.

Power 220V 50 / 60 Hz Other voltages require an extemal transformer

Weight about 30 Kg

Dimension 435*545*315 mm(D*W*H)

The Test Standards of CoolMax Cool Feeling Tester

JIS L1927

FTTS-FA-019

GB/T 35263-2017

CNS 15687-2013

GET A QUOTE

Frequently Asked Questions of Fabric Coolness Tester

- Synthetic Cool-Feeling Fabrics

Coolmax®: Engineered to enhance moisture management and evaporation, providing a cooling effect through its hydrophilic properties.

Polyester is often treated to improve moisture-wicking capabilities, allowing sweat to evaporate quickly and create a cooling sensation.

- Natural Fibers

Cotton: Known for its breathability and moisture absorption, cotton can provide a comfortable cooling effect, especially in lightweight forms.

Linen: Highly breathable and moisture-wicking, linen is ideal for hot weather and offers a natural cooling sensation.

Bamboo: This fabric is known for its excellent moisture-wicking properties and breathability, contributing to a cool feeling against the skin.

- Specialty Fabrics

Jade-infused Fabrics: Incorporating jade powder into the fibers enhances thermal conductivity, allowing for better heat dissipation and a cooler feel.

Graphene-infused Fabrics: Graphene can improve heat dissipation in lightweight fabrics, providing a cooling effect by balancing body heat with the surrounding environment.

- Performance Fabrics

Activewear Fabrics: Many sportswear materials are specifically designed to wick moisture away from the body and promote evaporation, enhancing the cooling effect during physical activity.

Cooling Technology Fabrics: Fabrics that incorporate phase change materials (PCMs) or other cooling technologies are engineered to provide an immediate cooling sensation upon contact with skin.

These fabrics are commonly used in various applications such as sportswear, summer clothing, home textiles (sheets and pillowcases), and outdoor gear. Conducting cool feeling tests on these materials helps manufacturers ensure that their products meet consumer expectations for comfort in warm conditions.

Step-by-Step Guide to Using a Cool Feeling Tester

Preparation

- Sample Preparation: Cut fabric samples to specified sizes (180 × 180 mm for KES-QM or 200 × 200 mm for GB/T 35263). Ensure they are wrinkle-free, without defects or contaminants.

- Instrument Check: Ensure the tester’s components (heat detection plate, temperature sensors) are clean and functional. Confirm the thermo-cool system is active for temperature stabilization.

Calibration

- Calibrate using reference materials or manufacturer guidelines. The CoolMax tester requires the heat plate set at 35°C with a temperature control precision of ±0.1°C. Ambient conditions should meet testing standards (20°C ± 2°C and 65% ± 5% RH).

Setting Parameters

- Temperature Difference (ΔT): Maintain a 15°C difference (e.g., heat plate at 35°C, sample platform at 20°C). Adjustable ranges may vary by device, such as 25–45°C for RF4008CF.

- Contact Pressure: Apply standardized pressure with the copper plate (e.g., 0.1 N/cm²).

Testing Procedure

- Place the sample with the skin-contact side up on the platform.

- Activate the heat plate and wait for stabilization. For automated testers like KES-QM, start the 10-consecutive-measurement mode.

- Lower the heat plate onto the sample. The instrument will record the qmax value (peak heat flux in J/(cm²·s)), indicating the cooling sensation.

Data Analysis

- Calculate the average qmax from multiple measurements (e.g., five samples); higher values indicate greater coolness. Use software like the SmarTexLab App to generate reports or compare with standards such as JIS L1927 or FTTS-FA-019.

Yes, the fabric coolness tester can also measure the warmth of the fabric. The underlying principle involves assessing the thermal effusivity of the fabric, which indicates how a material feels upon initial contact with the skin.

Thermal Effusivity Measurement: The tester measures the rate of thermal transport between a heating element and the fabric specimen. Lower thermal effusivity values are associated with sensations of warmth, while higher values indicate sensations of coolness.

ASTM D7984 Standard: This standard outlines a method for measuring thermal effusivity, which correlates with how warm or cool a fabric feels when it first touches the skin. It provides valuable data for product developers regarding fabric selection based on comfort properties.

Instantaneous Sensation: The tester can simulate real-life scenarios by measuring how quickly a fabric can absorb heat from the skin, thus determining both its cooling and warming sensations. This is particularly useful in evaluating fabrics designed for varying environmental conditions.

Applications: Fabrics used in activewear, bedding, and other clothing types can benefit from this testing to ensure they provide the desired thermal comfort, whether that be a cooling effect in hot conditions or warmth in cooler environments. In summary, while primarily used for assessing coolness, fabric coolness testers are versatile tools that can effectively evaluate both cooling and warming sensations of textiles based on their thermal properties.

GB/T 35263-2017

This is a Chinese national standard titled “Testing and Evaluation of Instantaneous Coolness Performance in Contact.” It outlines a method to evaluate the coolness of textiles when they touch the skin, measuring the temperature change of a hot plate in contact with the fabric to calculate the contact coolness coefficient (q max).

FZ/T 62042-2020

This standard pertains to “Cool Feeling Fabrics for Beddings,” defining criteria for coolness based on contact coolness coefficients with three grades of coolness performance.

FZ/T 73067-2020

Known as “Contact Cool Feeling Knitted Garments,” this standard categorizes garments into three levels of coolness based on their contact cool feeling coefficient, with specific numerical thresholds for each grade.

ASTM D7984

This American standard measures thermal effusivity and conductivity in fabrics, providing insights into how warm or cool a fabric feels upon initial contact. It employs a modified transient planar heat source method to quantify thermal properties.

JIS L 1927

A Japanese Industrial Standard evaluates the measurement method of cool touch feeling properties in textiles, focusing on how fabrics feel against the skin.

CNS 15687 / L3272

This standard outlines methods for testing the instantaneous cool feeling performance of fabrics, similar to other standards but tailored for specific regional requirements.

ASTM F3628

This test method measures evaporative cooling efficiency by evaluating how well clothing materials can release cooling energy back to the skin during the sweating and drying phases.

These standards collectively provide a comprehensive framework for evaluating the cooling performance of fabrics, helping manufacturers ensure that their products meet consumer expectations for comfort in cooling or warm conditions.

To determine the cooling effect of fabrics, different test standards provide various data results that indicate how desirable the cooling effect is. Here are the key metrics from several standards that reflect this performance:

Contact Coolness Coefficient (Qmax)

GB/T 35263-2017: This standard defines the cooling effect using the contact coolness coefficient (Qmax). A Qmax value of ≥0.15 W/cm² indicates good contact coolness. Higher values are more desirable, with superior fabrics achieving Qmax values of ≥0.25 W/cm² as per FZ/T 73067-2020.

Thermal Absorption Coefficient

Thermal Absorption Levels: According to certain studies, fabrics with a thermal absorption coefficient of:

≥340 Ws1/21/2/(m²·°C) are classified as having obvious coolness.

200 to 300 Ws1/21/2/(m²·°C) indicate slight coolness.

Lower values (e.g., below 100 Ws1/21/2/(m²·°C)) suggest no coolness, making higher coefficients more desirable for effective cooling.

Instantaneous Heat Loss Measurement

Qmax Measurement: The Qmax value represents the maximum instantaneous heat loss from the skin when in contact with the fabric. A higher Qmax value indicates a greater ability to absorb heat from the body, resulting in a cooler sensation. For example, a Qmax value of ≥0.140 W/cm² is considered a baseline for instant cooling performance.

Evaluation Criteria Across Standards

Different standards categorize fabrics based on their performance:

FZ/T 62042-2020 sets thresholds for bedding fabrics with grades requiring Qmax values of at least 0.20, 0.25, and 0.30 for different quality levels.

JIS L 1927 evaluates fabrics based on similar principles, focusing on initial cool sensations upon contact.