The introduction of cool fabrics

Summer clothing’s moisture absorption and quick-drying functions are lacking. They do not meet people’s needs, especially after intense exercise and sweating. The existing fabrics have limited moisture transfer and thermal conductivity. Developers created moisture-conducting and cool-sensitive fabrics that are unidirectional. The development of cool-sensitive fabrics focuses on two things. First, it aims to improve their thermal conductivity. Second, it seeks to increase the coolness of the initial contact. There is a micro-environment between the body and clothing. The skin produces water vapor and liquid. They move through this micro-environment into the fabric, then to the outside. In hot summer or during intense sports, the skin sweats more. If sweat can’t escape, it will cause a stuffy, uncomfortable feeling. The instant coolness of fabrics is short-lived. Only continuous coolness is worth researching. It has more practical use.

Existing cool fabric development and testing focus on several aspects. They will add a high thermal conductivity nano-mineral powder to the original spinning liquid made of cool fibers. Also, they will change the shape of the spinneret holes in the spinning process. This will produce cool jade fibers with a shaped cross-section. The resulting fabrics must have both high thermal conductivity and quick-drying, moisture-absorbing properties. This will greatly improve the fabrics’ coolness. However, this method is complex. It requires high equipment and process condition standards, and spinning is difficult. However, using this method requires complex and challenging spinning. It requires high-end equipment and precise process conditions. Also, adding ore particles will reduce the fibre’s mechanical properties. The use of highly hygroscopic fibers can make cool fabrics. They can absorb moisture and dry quickly. Their coolness has limitations. It only works with a small amount of sweat. With too much sweat, the fabric can’t release it. The fabric clings to the body, causing stuffiness. Also, existing cool fabrics have poorly designed structures. They lack guides to their one-sided, water-locking features. After the fabric absorbs the sweat, it is inside and outside the fabric. There is no difference.

Definition of instantaneous coolness on contact

‘Instantaneous coolness on contact’ means an instant touch. The skin and the fabrics below their temperature. This causes rapid heat loss from the skin and a drop in temperature. The skin’s temperature-sensitive nerves send this to the brain. It creates a cool sensation.

‘Contact coolness coefficient Qmax’ refers to the temperature higher than the specimen. It is the maximum heat flow density after a heat transfer process. This occurs after a heat detection plate, at a certain pressure, contacts the specimen. The heat detection plate has a specified temperature difference from the specimen.

A larger Qmax means a stronger coolness felt by the skin. A smaller Qmax means a weaker coolness felt by the skin.

Background of Cool Feeling Fabrics:

Cool-sensitive fabrics originated in Japan. The goal was to save energy and slow global warming. So, wear cool-sensitive clothing. Next, the U.S. built on this by developing new, patented, cool-sensitive fabrics. These fabrics can quickly conduct heat away from the skin. They also wick away moisture and disperse sweat. This keeps the wearer dry and comfortable in the heat.

In order to achieve these properties, cool-sensing fibres have been developed using a variety of technologies and methods. For example, we use extraction and nanotech to process natural minerals, like jade, shell, and mica, into nanoscale particles. Then, hydrophilic slices combine with them to create fibers through spinning. These fibres have a special cross-section. It boosts their heat dissipation and ‘capillary effect’.

Application of cool-sensitive fabrics

Cooling fabric can help summer clothes, sportswear, and outdoor gear. It can also enhance home furnishings and any fabric. They need better comfort and heat control.

Specific products, such as: sportswear, sunwear, towels, and cool-sensitive home wear. This includes half-sleeve T-shirts, men’s and women’s shorts, and women’s tanks and camis. Also, home furnishings like cool-sensitive mattresses, sheet covers, pillows, and slippers. Plus, cool-soft quilt sets, gel mattresses, woven blankets, and indoor and outdoor slippers.

Test basis:

The instant coolness on contact test relies on a fact. When a fabric first touches the skin, it rapidly absorbs heat. This creates a cooling sensation. This sensation is due to the fabric’s surface and heat transfer properties. The test aims to simulate and measure the cooling effect on first contact.

Cool Feeling Fabric Design

1. Weaving process

1.1 One-sided cool feeling thin road terry weaving process

The organisation uses 20.0 tex indigo selvage compact-spinning yarn and 8.3 tex spandex yarn. The terry is 33.3 tex/(96f) cool-feeling polyethylene filament. The interweaving ratio is 60.7:19:20.3. The knitting machine used is a three-needle, single-face weft-knitting machine. It has a knitting number of 20 stitches/(25.4 mm). Its diameter is 863 mm.

1.2 One-side cool textured terry weaving process

20.0 tex indigo selvage compact spinning yarn, 8.3 tex spandex yarn, and 33.3 tex/(96f) cool feeling polyethylene filament are woven together for terry. The interweaving ratio is 50.4:15.8:33.8. The knitting machine is a three-needleway, single-face weft-knitting machine. It has a gauge of 20 stitches/(25.4 mm) and a diameter of 863 mm.

Sensory description of Super Cool

Summer is here, and there are many products on the market that claim to have cool sensory properties. The descriptions say Qmax equals a certain amount. How many consumers know this?) or provide a super-cool sensory description. Or they provide sensory descriptions of super coolness.

There are different ways to achieve cool sensation in textiles. One is from the textile fibre, or the textile’s own properties. The other is to finish with some phase-change materials or add other traits to the material. These two ways provide different mechanisms for the two senses. So, we should treat the test methods differently.

The fabric has a coolness. Its name is ‘Instant cooling on contact’ (or Immediate cool touch). Contact cooling fabric cools by heat conduction. It transfers heat from a high to a low temperature. This achieves the purpose of cooling. It is believed that the Japanese market first developed this type of cool touch fabric and its test method, JIS L 1927.

Cool Feeling Test Principle

The coolness test is to place a fabric on the instrument’s cold plate. When the fabric and cold plate are at the same temperature, quickly place the hot plate on the fabric. The heat from the hot plate will pass through the fabric to the cold plate. At the moment of contact, we can measure the fabric’s maximum heat loss. This value is the Q-max. It is the fabric’s instantaneous coolness, in heat flux (W/cm2). A greater Q-max means the fabric can remove more heat.

Related test standards:

GB/T 35263-2017 Textiles Testing and evaluation of instantaneous coolness performance in contact

FZ/T 62042-2020 Cool feeling fabrics for beddings

FZ/T 50048-2020. Test methods for the instant coolness of chemical fibre filaments in contact.

CNS15687, L3272 Test Method for Instantaneous Cool Feeling Performance of Fabrics

FZ/T 73067-2020 Contact cool feeling knitted garments

JIS L 1927 Evaluation method for contact coolness performance

FTTS-FA-019 Verification Specification for Instantaneous Cool Feeling of Fabrics

The 2017 national standard GBT 35263-2017 defines a cooling effect. It requires a Qmax of 0.15 or more under a 15℃ temperature difference.

Correspondingly, the corresponding evaluation standards have certain limitations. For example, the Qmax value will depend on the fabric’s style and weave. There is no data on the range of the effect.

FZ/T 73067 ‘Contact Cool Feeling Knitted Garments’ has three levels of coolness. The contact cool feeling coefficient of superior garments is not less than 0.25. For first-grade garments, it is not less than 0.20. For qualified garments, it is not less than 0.18. These are all better than the GB/T 35263-2017 standard. That standard is for testing and evaluating the contact cool feeling of textiles. This exceeds the GB/T 35263-2017 requirement of 0.15 for testing the cool feeling of textiles.

The product’s contact coolness coefficient is the basis for FZ/T 62042. It covers ‘cool fabric bedding’. It has three grades. Grade A must be at least 0.20. And grade AA must be at least 0.25. Grade AAA must be at least 0.30. So, the bedding’s coolness is even higher than that of clothing.

The above is the Chinese national and textile industry standards. They are based on the Qmax value from a test at a 15℃ temperature difference.

Related Terms:

Instantaneous coolness on contact

Contact with fabrics colder than the skin causes rapid heat loss. It cools the skin. It sends a signal to the brain via temperature-sensitive nerves. This creates a cool sensation.

Contact coolness coefficient

qmax

The maximum heat flow density, after contact, is at a certain pressure. This is after contact between the heat detection plate and the specimen. The heat detection plate must be hotter than a specified temperature of the specimen.

Note: The unit of qmax is Joule per square centimetre second [J/(cm²-s)].

Qmax value

Some products in the shipment will have labels that say “cooling” or similar. If they do not use phase change material (PCM, in microcapsules) to cool, the Qmax method will test them. Current market test reports vary in temperature settings. They are roughly divided into Δ10 ℃, Δ15 ℃, and Δ20 ℃. Δ15℃, Δ20℃. The Qmax values for the same specimen can vary greatly with different temperature differences.

Temperature difference ΔT = sensor temperature ℃ – sample temperature ℃.

To simulate human contact with the product, set a sensor temperature of 30°C (the temperature of human skin) and a sample temperature of 20°C (the temperature of air-exposed textiles). So, ΔT is 10°C.

Δ10°C is generally chosen for Japanese standards, Δ15°C for Chinese standards, and Δ20°C for some research cases.

If the customer has no test temperature difference, the Qmax is not comparable. If tests with varying temperature differences determine the Qmax, it is accurate. We can analyze and convert the Qmax data. This will let us compare it at different temperature differences.

q = ΔT x (sensor temperature characteristic, time derivative, etc.)

Increasing ΔT by a factor of xx when testing the same sample will also increase the result q (Qma) by that factor.

In this case, there are two samples, A and B, and the results of the respective tests are

A Qmax=1.50, ΔT=10°C

B Qmax=2.00, ΔT=20°C

Which product has the better coolness performance?

To make the temperature difference the same as A (ΔT=10°C) for product B, multiply it by a factor of 0.5. So, B has Qmax’ = 2.00 x 0.5 = 1.00 for a 10°C difference.

In this case, the coolness performance is A > B.

Finally, the Qmax test does not apply to fabric tests. This includes fabrics finished with PCM or xylitol for coolness.

Researchers developed two types of knitted denim to enhance fabric coolness. They used high-density polyethylene fibre for the loop tissue. They used cotton indigo yarn for the ground tissue.

We tested the new fabrics for coolness, moisture absorption, quick-drying, and UV resistance. A visual platform tested fabric coolness. Water droplets of a certain temperature replaced sweat in the tests.

We set up a test platform for fabric coolness. We used water droplets of a certain temperature instead of sweat. This was to study how fabric coolness changed after absorbing moisture.

The results show that:

Moisture absorption significantly improves the thermal conductivity of fabrics.

The cooling effect is obvious, and the steady state coolness of fabrics improves.

Moisture has a greater effect on the fabrics’ coolness than the fibres’ conductivity.

The better the moisture absorption of fabrics, the better their steady state coolness.

The fabrics will absorb water droplets. They will then diffuse into the cooler area on their surface.

There are many ways for fabrics to achieve rapid heat conduction and cooling:

1. When drawing chemical fibre, add ore or jade powder. Smartkool® fabrics use this to speed up heat transfer by blending jade into the yarn. So, the skin’s temperature exchanges heat with the air faster. This makes it feel cooler on contact. smartkool® fabrics also have a quick-drying effect.

2. Hydrophilic modification of fabrics (e.g., Coolmax®) gives a cool feel. This is due to their moisture-absorbing, quick-drying properties. The modification uses agents, bamboo carbon fibre, viscose, or cupra rayon. Coolmax’s operation can be summed up in three points: it helps skin remove moisture. It absorbs and spreads moisture to enhance evaporation. Coolmax® works in three ways. It removes moisture from the body. It absorbs and spreads moisture, helping it to evaporate and dry. And, it lets air flow through to keep the body cool and dry.

3. The fabric adopts three-dimensional weaving method;

4. Paraffin microcapsules absorb heat. They take a lot of work to make. They have a limited effect. Few exist on the market.

5. Use of contact coolness finishing agent

Specification for Verification of Instant Cooling of Textile (FTTS-FA-019)

01 Scope This standard applies to testing textile products with instant cooling. It is to judge their heat dissipation and cooling effect. It also applies to their semi-finished products. The goal is to assess if they meet cooling quality standards. This test is applicable to knitted and woven fabrics.

02 term interpretation instant contact coolness (Touch: Warmth or Coolness/Q-max): a test of contact with the fabric, the skin. It is the maximum value of the instantaneous heat loss. That is, for the fabric, the instantaneous maximum heat flow per unit area in Watts (W/cm2).

03 standard of this specification of the assessment of the qualifying standards:

Fabric instantaneous cool sensation heat flow (W/cm2)≧0.140

3.1 General Requirements

Please test it, per customer needs, in addition to the three water resistance levels.

04Test Method

4.1 Test sample:

The test specimen is 20 x 20 cm2 (measured area: 5 x 5 cm2). It must be at 20±2°C and 65±2% RH for 24 hours before testing.

4.2 Test environment:

Turn on the programmable constant temperature and humidity machine. Set the temperature to 25±2℃ and humidity to 65±5% RH. Wait at least 1 hour. This will ensure a constant environment before testing.

4.3 Test equipment:

Thermal effect tester KES-F7 THERMO LABO II, or the same level of test equipment.

4.4 Test steps:

4.4.1 Power up the ThermoLabo II device, confirm the parameters and warm up for about 15 minutes.

4.4.2 Cut the main hot plate heater (Heater) switch to ON. Set the hot plate temperature (Temperature-Box) to 35±0.1℃. When it reaches 35℃, cut the guard ring heater (Guard Heater) switch to ON.

4.4.3 Set the cold plate (Water-Box) to 25 ℃. This simulates the external environment. Wait until the temperature reaches 25 ℃. Then, place the sample fabric on the cold plate, fabric side up. When the hot plate (Temperature-Box) reaches 35 ℃, press the qm key. Quickly, and at a vertical angle, place the hot plate on the sample fabric. Record the qm value on the display. This value is the maximum heat loss, in W/cm². It is the result of the experiment.

4.5 Test results:

4.5.1 The test result is the average value of 5 times test data.

We average the valid data for the test report to the third decimal place.

Analyses

1. Fabric moisture absorption performance analysis

The main factors affecting fabric moisture absorption are:

Whether the fibre contains hydrophilic groups.

The fibre’s cross-sectional shape.

The fibre’s linear density.

The yarn structure.

The fibre’s surface structure.

The fabric’s weave.

The finishing process.

This paper’s two fabrics use the same yarn, weaving, and finishing processes. The only difference is the fabric’s organization and terry density. This shows a difference in moisture absorption between the two fabrics. The different fabric structures caused this difference.

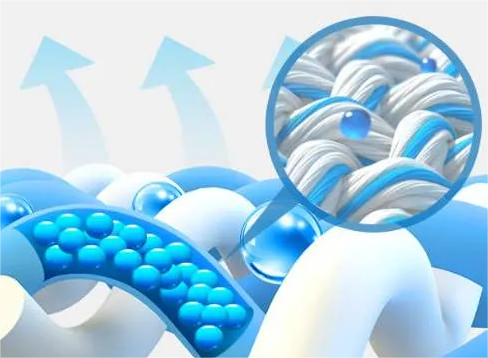

The fabrics have a unique structure. One side has a terry texture that flatters the skin. The other side has fine capillaries from indigo selvage compact spun cotton yarns. Between the layers are spandex filaments that create thicker capillaries for moisture transfer. The terry layer is less absorbent and has coarser capillaries. The fabric’s structure creates two gradients. One is a gap gradient from large to small. The other is a moisture absorption gradient from small to large. These gradients create a pressure difference between the fabric’s inner and outer surfaces. Due to this, moisture absorbed by the inner surface will flow to the outer surface. However, it’s very difficult for liquid water on the outer surface to flow to the inner surface.

A drop of water on the fabric shows that the initial droplets are spherical. Then, they spread out at high speed, forming an almost circular area on the fabric’s reverse side. Also, the cotton yarns of the fabric absorb the water. It then expands to the backside in the space between the fabrics. The polyethylene terry channels the water to the cotton yarns. Enlarging the observation area shows that the brighter threads are polyethylene filament bundles. The darker ones are cotton yarns. Thus, after the fabric absorbs moisture, water is mainly between the cotton yarns. The polyethylene yarns contain very little water. The tests show that the fabric can move moisture in one direction and lock out water.

2. Analysis of fabric’s quick-drying performance

The fabric’s moisture-absorption and quick-drying indices meet the standard. Both are excellent for quick-drying. After 40 min drying time, the residual water rate of all fabrics is lower than 13% of the standard. The evaporation rate is over 0.18 g/h. The fabrics’ moisture absorption and quick drying after washing improved. The residual water rate is 4%, and the evaporation rate is over 1.57 g/h. Moreover, the washing tends to improve the evaporation rate of the fabric. It is a sweatshirt made of denim yarn, polyethylene filament, and spandex. It is cool-sensation, moisture-absorbent, quick-drying, and anti-ultraviolet. Fabrics dry faster for two reasons. One is the material and structure. The other is that cotton yarn absorbs moisture on its outer surface. This moisture will concentrate there. As some of it evaporates, it helps the small amount of water inside transfer to the outer surface. This increases the area for evaporation, which speeds it up. The spandex silk inside the fabric acts as a moisture channel. It has a moisture absorption gradient. So, moisture can only move from the inner to the outer surface. This speeds up the evaporation of moisture inside the fabric.

3. Fabric cool-feeling performance

The coolness test results show that the two fabrics have a good coolness effect. Their qmax values are greater than the standard (0.15 W/cm²), whether washed or not. After washing, the qmax values of the fabrics were 0.162 W/cm² and 0.181 W/cm². These were higher than the original coolness values. This shows that washing affected the fabrics’ instant coolness. The fabrics’ quick-drying test showed that washing improved their moisture-absorbent properties. One can deduce that they increased their coolness value. Water conducts heat much better than ordinary fibres. Under the same test conditions, moisture-absorbing samples will soak up more water from the air. The fabrics’ thermal conductivity will greatly improve with higher water content. This will show as a higher coolness value in the coolness test results.

When the fabric touches the skin, it is cooler. The skin will feel a sudden coolness. After a time, the fabric in contact with the skin will be the same temperature as the skin. However, the fabric’s outer surface is not in contact with the skin. It is in contact with the external environment. The body transfers heat to the environment. The polyethylene fibres conduct heat better than cotton and spandex. This process is the same as that of fabric moisture conductivity. The human body sweats with some heat. Moisture transfer will cause heat transfer, resulting in a continuous cooling sensation. These 2 fabrics are good at transferring water and heat. This is mainly due to their fibre type and structure.

Conclusion

1.The fabric is a cool, knitted, denim jersey. It used: 20.0 tex indigo selvage compact-spun cotton yarn, 33.3 tex/(96 f) cool polyethylene filament, and 8.3 tex spandex. A 20-needle/(25.4 mm) circular knitting machine made it. It has excellent moisture absorption, quick-drying, and contact-cool properties.

2. The tests show that the two cool knitted fabrics can move moisture in one direction and lock water.

3. After the fabrics absorb moisture, their thermal conductivity improves. The cooling effect is obvious. So, the fabrics are cooler. To design cool-feeling fabrics, choose fibres that absorb and conduct moisture. This will improve the cool feeling effect.

4. Moisture affects how cool fabrics feel more than their fibres’ thermal conductivity. The more a fabric absorbs moisture, the cooler it will be. When designing cool fabrics, use a mix of cool and high-moisture-absorbing fibers. This will improve both the contact and steady coolness of the fabrics.

5. The water droplets will spread on the fabric after it absorbs them. They will reach a uniform temperature area on the surface. Reasonably set up the structure of the cool-sensitive fabric. Increase its moisture absorption and dissipation. This will improve the fabric’s heat conduction. It will enhance its steady-state cool-sensitive effect.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com