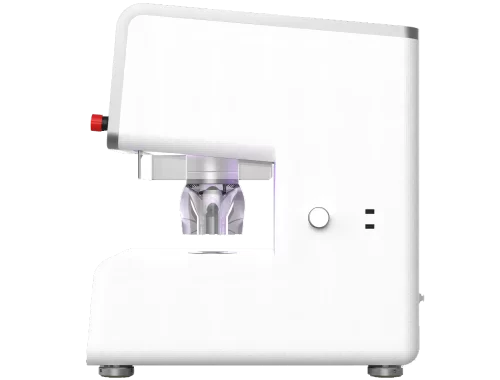

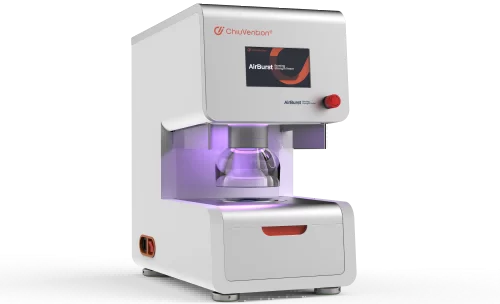

One pre-test can accurately control the bursting speed

The full servo-pneumatic system is controlled by an AI algorithm, together with a precise screw drive, only by one pre-test, the machine can reach the expansion speed within the standard requirements of the 20s.

Precise and reliable testing

The pressure measurement section uses a high-precision laser sensor. It has an accuracy of up to 0.2 degrees. This means the error is 0.2% of the maximum range.

Accurate measurement of expansion height

The micron-polar laser sensor goes right to the test sample, and the high-speed response makes testing faster and more accurate.

Longer sensor life

The Panasonic laser displacement sensor is also used. It has no rod, so changing the test cup is easier and harder to damage.

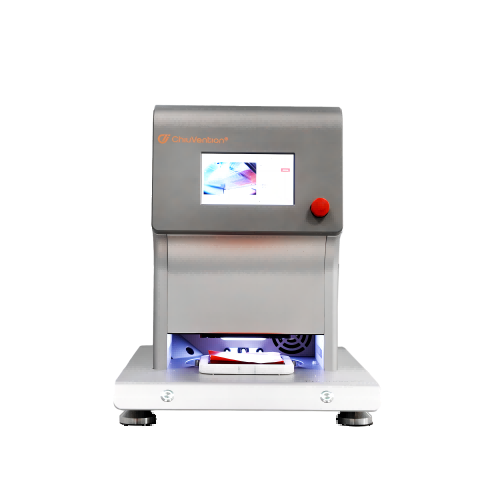

Test results can be uploaded to ERP or LIMS when connected to SmarTexLab.

The AirBurst can connect to the SmarTexLab App made by ChiuVention via Wi-Fi. This connection allows you to set parameters or watch the test from your phone. The burst strength test results will also be sent to SmarTexLab and you can export them to a computer or print them. Also, it can link to an organization’s ERP or LIMS to enable paperless and smart testing. All these things improve the textile laboratory’s quality management.

The Bursting Strength Tester is connected via IoT to the SmarTexLab APP in the phone/PC. And the app can connect to ERP/LIMS via an API. Or, the BS Tester can connect directly to ERP/LIMS.

There are test orders and sample information in the system, and the bursting strength tester can record all related information, including test results. The system will then summarize these into a test report. The relevant parties can view the burst strength report in real-time. In SmarTexLab, you can chat with ChiuVention staff for quick support. You’ll get reminders that the Burst Testing Machine needs calibration, maintenance, and new consumables. Regular OTA remote upgrades are available.

Intelligent Recognition System for Test Cups

When replacing the test cup for Bursting Strength Testing, the system will recognize the model of the current test cup. It will then switch the test parameters without manual input. This greatly improves work efficiency.

Eco-friendly and easy to maintain

Using air as the pressure medium makes it eco-friendly and harmless.

The pneumatic burst tester has a simple structure. It’s easier to maintain and service than the hydraulic type.

Wide range of applications

It applies to the textile industry. This includes many common fabrics and non-woven fabrics. It also applies to packaging materials, such as film, paper, and foam.

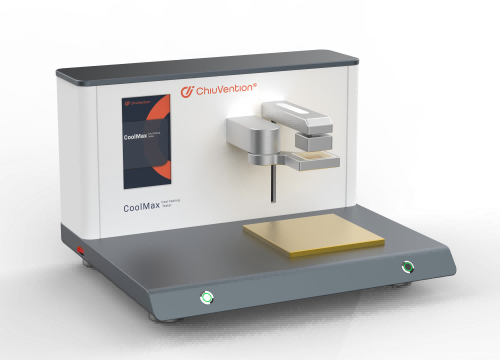

Designed in Germany, quality is our life.

All our textile testing instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our instruments of outstanding quality. 100% source factory and factory price.

Application Examples of AirBurst Bursting Strength Tester

Non-woven Fabric

Paper Board

Plastic Film

Waterproof Fabric

Customer Feedback

“We purchased this fabric bursting strength tester for teaching. It is small and easy to place. The machine runs automatically and it has a protective cover. It is very safe!”

“The test of this instrument is very accurate and helpful for us when selecting the fabrics. It is also very stable and easy to collect and transfer the test results.”

OUR BROCHURE

AirBurst Fabric BS Tester Standards

ISO 13938-2

GB/T 7742.2

ASTM D3786

|

Standard / Specification |

GB/T 7742.2-2015 | ISO 13938-2-2019 | ASTM D3786/3786M-18(2023) | |

| Test

Fixture |

7.3cm2 (φ30.5mm) |

√ | √ | √ |

|

7.55cm2(φ31±0.75mm) |

– | – |

√ |

|

|

10cm2 (φ35.7±0.5mm) |

√ | √ |

– |

|

|

50cm2 (φ79.8mm) |

√ | √ | – | |

| 100cm2

(φ113±1mm) |

√ | √ |

– |

|

The Specification of AirBurst Burst Strength Tester

Maximum air pressure 1.4MPa

Measurement accuracy ±2% FS

Measuring range 0.01~1.4 Mpa

Maximum expansion height 70±1mm

Test cup mode, Fixture mode, and related dimensions

Test Cup 1(Standard) 2.Z.CV.142.01 7.3cm²(Dia.30.5mm±0.2mm)

Lower fixture base 1(Standard) 2.Z.CV.142.11 7.3cm²(Dia.30.5mm±0.2mm)

Test Cup 5 (Standard) 2.Z.CV.142.05 50cm² (Dia. 79.8mm±0.2mm

Lower fixture base 5(Standard) 2.Z.CV.142.15 50cm² (Dia. 79.8mm±0.2mm)

Test Cup 2 (Optional) 2.Z.CV.142.02 7.55cm² (Dia. 31mm±0.2mm)

Lower fixture base 2(Optional) 2.Z.CV.142.12 7.55cm² (Dia. 31mm±0.2mm)

Test Cup 4 (Optional) 2.Z.CV.142.04 10cm² (Dia. 35.7mm±0.2mm)

Lower fixture base 4(Optional) 2.Z.CV.142.14 10cm² (Dia. 35.7mm±0.2mm)

Test Cup 6(Optional) 2.Z.CV.142.06 100cm² (Dia. 113 mm±0.2mm)

Lower fixture base 6(Optional) 2.Z.CV.142.16 100cm² (Dia. 113 mm±0.2mm)

Test diaphragm (optional) 4.M.020 Dia. 148 mm * 1.6 mm (10pcs/box)

Operating System Android

IoT (Internet of Things ) configuration is required

Power 220V 50 Hz Other voltages require an extemal transformer

Weight 120 Kg

Dimension 600 *360*660 mm (L*W*H)

Frequently Asked Questions

Hydraulic Bursting Strength Tester or Pneumatic Bursting Strength Tester? How to select?

When choosing a textile bursting tester, hydraulic and pneumatic bursting each has its application scenarios, depending on the specific needs of your test, the material properties, and the accuracy requirements of the test. Below is a comparison of the two methods to help you make a better choice:

- Hydraulic Bursting Strength Tester: The Hydraulic Burst Tester uses hydraulic pressure to push a diaphragm or apply pressure directly to the material. It is suitable for thicker, harder, or impermeable materials. Key features include: the Fabric Hydraulic Bursting Strength Tester is, therefore, the more appropriate choice when testing heavy technical textiles, functional outdoor fabrics, or other textiles where accurate results are required.

- Wide range of applications: It is particularly suitable for testing dense woven fabrics, industrial fabrics (e.g. tents, automotive fabrics), and other materials that require a high level of pressure.

- High testing accuracy: Hydraulic bursting strength testing is more stable during the pressurization process, and the measured data is more accurate, which is suitable for testing that requires high-precision results.

- Operation and maintenance: the hydraulic system is relatively complex, routine maintenance needs to be more detailed, and the use of environmental cleanliness requirements are higher.

- Pneumatic Bursting Strength Testers: Pneumatic Fabric Burst Testers use air pressure to propel them and are typically used for thinner, more breathable materials. Key features include: If your main test object is thin, lightweight textiles for apparel (e.g. knitted fabrics, more breathable fabrics), and test efficiency and ease of operation are more important, then a pneumatic burst tester may be more suitable.

- Faster: Pneumatic testing is faster for better gas compression and faster pressurization, which suits scenarios requiring higher testing efficiency.

- Suitable for breathable materials: Pneumatic bursting is ideal for breathable fabrics, such as knitted fabrics and some light clothing fabrics.

- Simple maintenance: the structure of pneumatic equipment is relatively simple, easy to maintain, and suitable for the medium precision requirements of the test.

Summary

- Precision and thick materials: choose a hydraulic bursting strength tester.

- Efficiency and light materials: choose pneumatic bursting testers.

If possible, test the material characteristics before choosing the appropriate type of equipment.

What test standards are applied to pneumatic bursting strength testing?

The main fabric test standards related to pneumatic bursting strength tests are ASTM D3786, ISO 13938.2, AATCC127, and GB/T 7742.2. These standards ensure consistency of test methods and comparability of results.

What is the principle of Fabric Pneumatic Bursting Strength Tester?

The Pneumatic Bursting Strength Tester uses an air compressor to apply pressure to a test sample at a constant rate until the sample bursts. The instrument records the pressure and height at which the sample ruptures and this data is used to assess the resistance of the material to bursting.

What should be kept in mind when purchasing a Textile Pneumatic Bursting Strength Tester?

1. Testing accuracy and range

It is important to select a fabric burst strength tester with a high-precision pressure sensor to ensure the accuracy of the test results. In addition, the pressure range of the tester should meet the required application standards, for example, the maximum pressure can be up to 6000 kPa, which can cover a wide range of material testing needs.

2. Software functionality and data processing

Modern pneumatic burst testers are usually equipped with advanced software systems, such as SmarTexLab, to receive and process test data in real-time. These software programs support data export, report generation, and connection to computers to improve efficiency and ease of data management. Users should choose software that provides an intuitive interface and a variety of functions to facilitate operation and analysis.

3. Ease of operation and safety of the equipment

The design of the equipment should take into account the user’s ease of operation, such as pneumatic control for quick sample clamping and touch-screen operation. In addition, safety is also an important factor to ensure that the equipment has good safety measures to prevent accidents when operating under high pressure.

When choosing a textile bursting tester, hydraulic and pneumatic bursting each has its application scenarios, depending on the specific needs of your test, the material properties, and the accuracy requirements of the test. Below is a comparison of the two methods to help you make a better choice:

- Hydraulic Bursting Strength Tester: The Hydraulic Burst Tester uses hydraulic pressure to push a diaphragm or apply pressure directly to the material. It is suitable for thicker, harder, or impermeable materials. Key features include: the Fabric Hydraulic Bursting Strength Tester is, therefore, the more appropriate choice when testing heavy technical textiles, functional outdoor fabrics, or other textiles where accurate results are required.

- Wide range of applications: It is particularly suitable for testing dense woven fabrics, industrial fabrics (e.g. tents, automotive fabrics), and other materials that require a high level of pressure.

- High testing accuracy: Hydraulic bursting strength testing is more stable during the pressurization process, and the measured data is more accurate, which is suitable for testing that requires high-precision results.

- Operation and maintenance: the hydraulic system is relatively complex, routine maintenance needs to be more detailed, and the use of environmental cleanliness requirements are higher.

- Pneumatic Bursting Strength Testers: Pneumatic Fabric Burst Testers use air pressure to propel them and are typically used for thinner, more breathable materials. Key features include: If your main test object is thin, lightweight textiles for apparel (e.g. knitted fabrics, more breathable fabrics), and test efficiency and ease of operation are more important, then a pneumatic burst tester may be more suitable.

- Faster: Pneumatic testing is faster for better gas compression and faster pressurization, which suits scenarios requiring higher testing efficiency.

- Suitable for breathable materials: Pneumatic bursting is ideal for breathable fabrics, such as knitted fabrics and some light clothing fabrics.

- Simple maintenance: the structure of pneumatic equipment is relatively simple, easy to maintain, and suitable for the medium precision requirements of the test.

Summary

- Precision and thick materials: choose a hydraulic bursting strength tester.

- Efficiency and light materials: choose pneumatic bursting testers.

If possible, test the material characteristics before choosing the appropriate type of equipment.

The main fabric test standards related to pneumatic bursting strength tests are ASTM D3786, ISO 13938.2, AATCC127, and GB/T 7742.2. These standards ensure consistency of test methods and comparability of results.

The Pneumatic Bursting Strength Tester uses an air compressor to apply pressure to a test sample at a constant rate until the sample bursts. The instrument records the pressure and height at which the sample ruptures and this data is used to assess the resistance of the material to bursting.