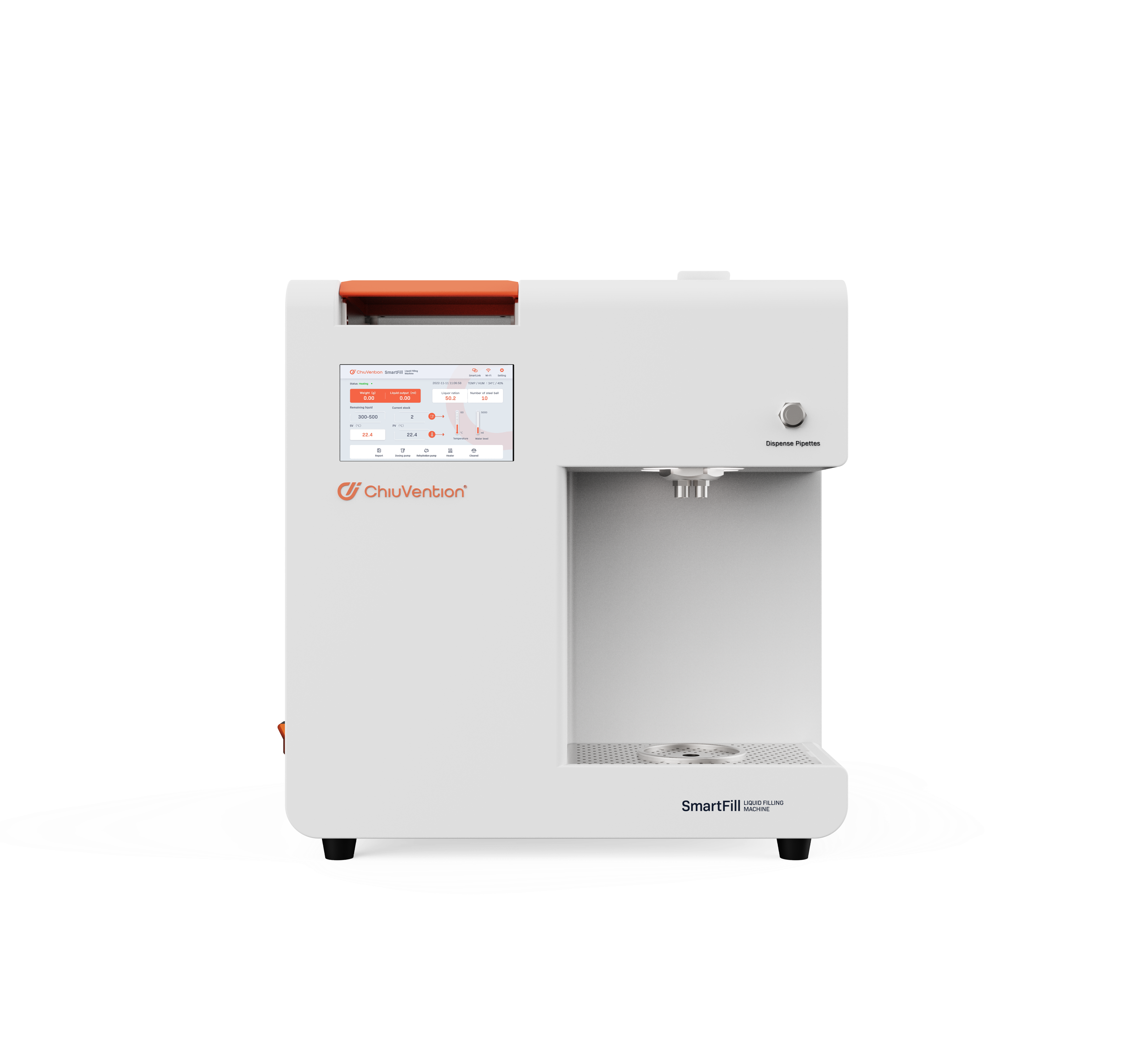

More accurate testing

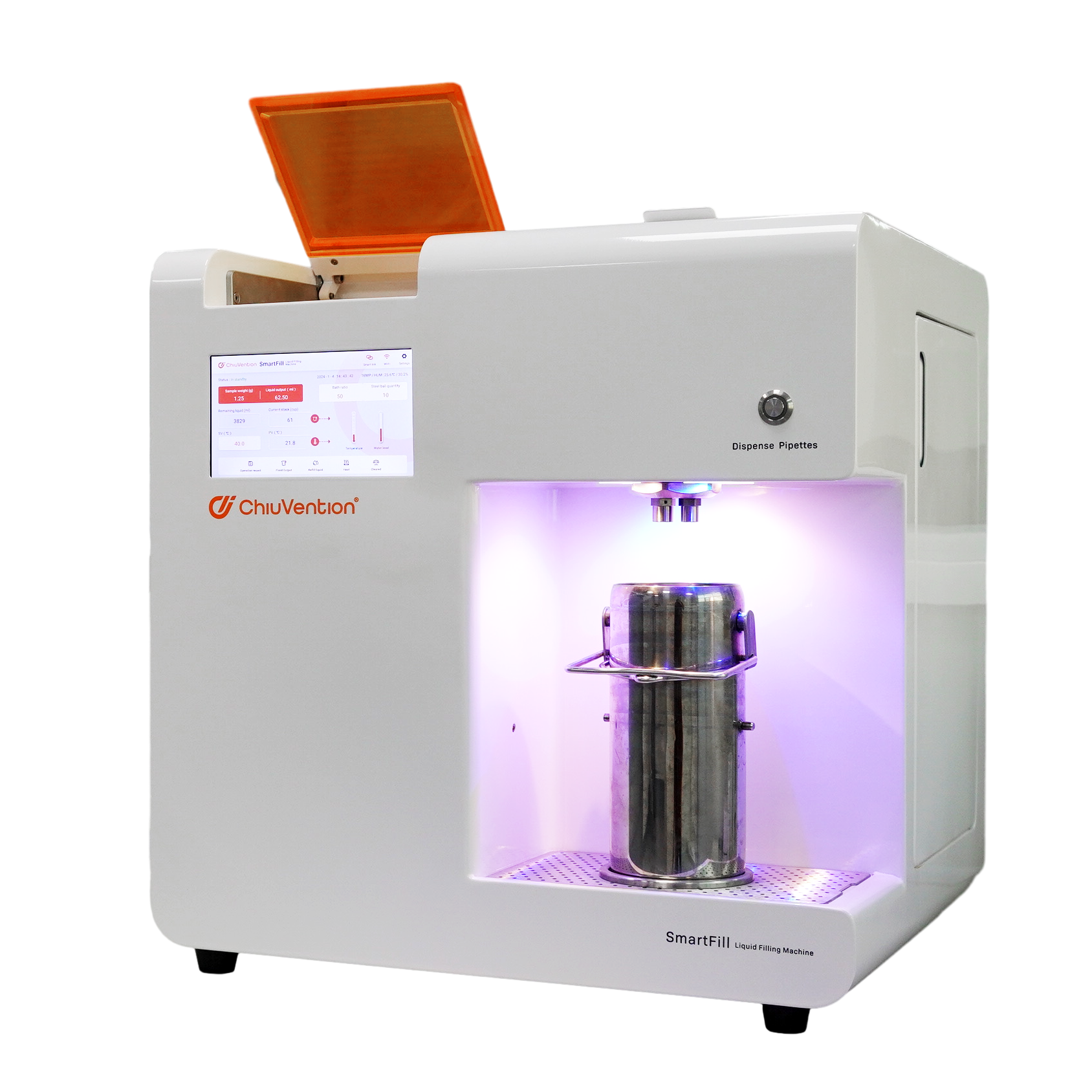

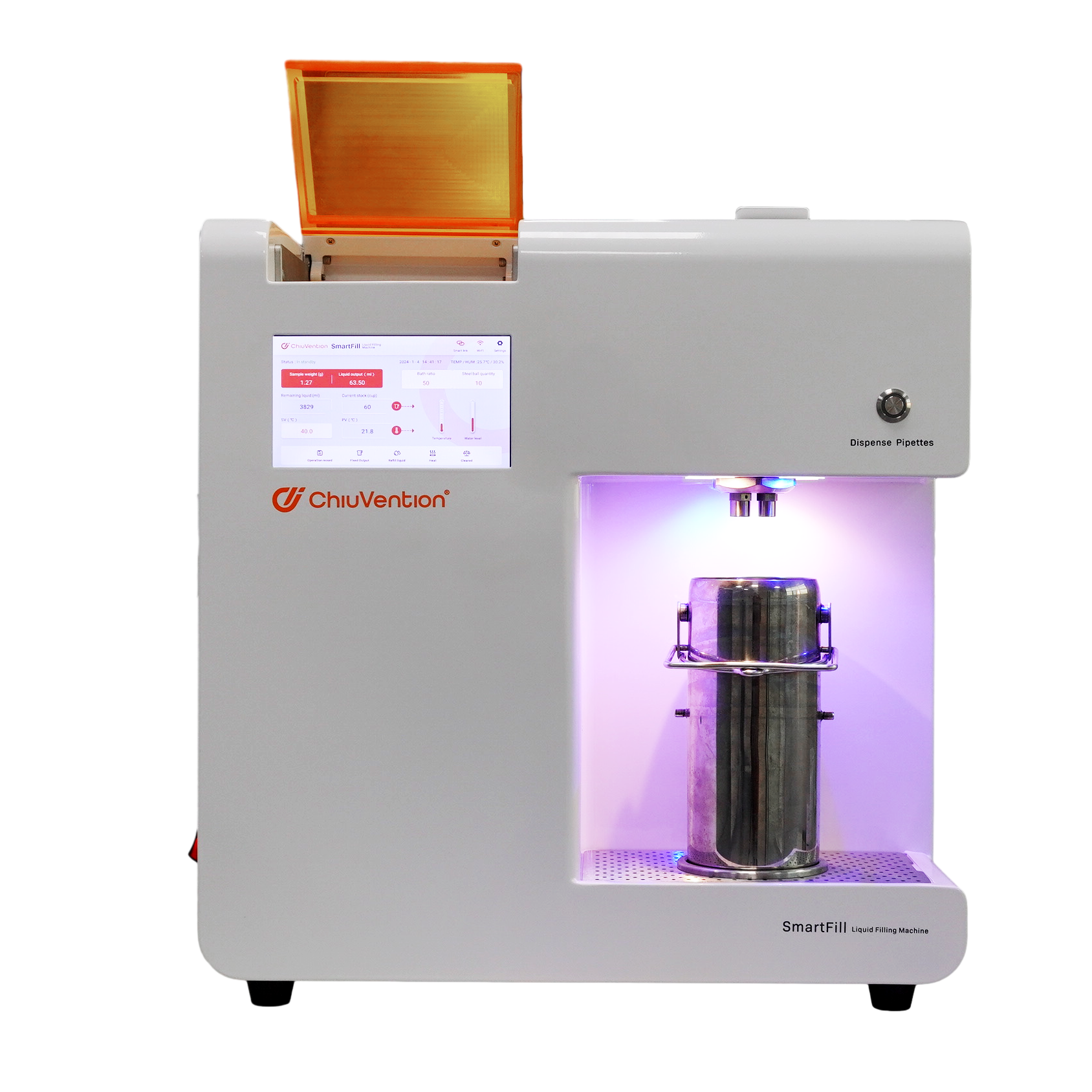

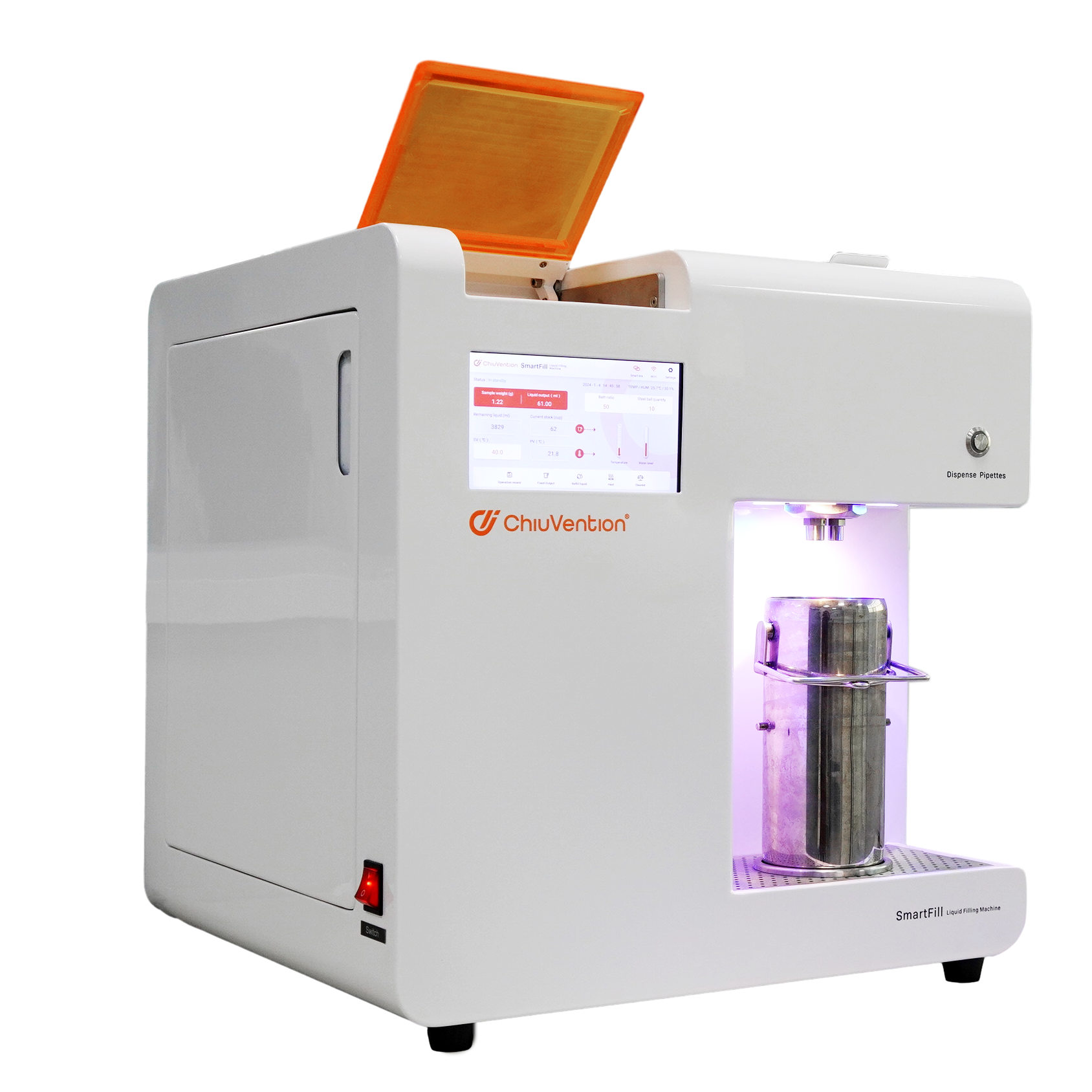

The high-precision balance weighs the sample. The soap dispenser gives the dosage-to-bath ratio, accurate to 1 milliliter. It does this with precise temperature control. It also does this by counting steel balls. This makes sample prep more accurate. This makes the washing color fastness test more reliable.

Testing is more efficient.

By choosing SmartFill, a 1-wash color fastness tester with 12 test cups, each test prep can save 10 minutes. This is true for 200 samples per day. Or, it can save 30% of labor costs for a year for a single worker.

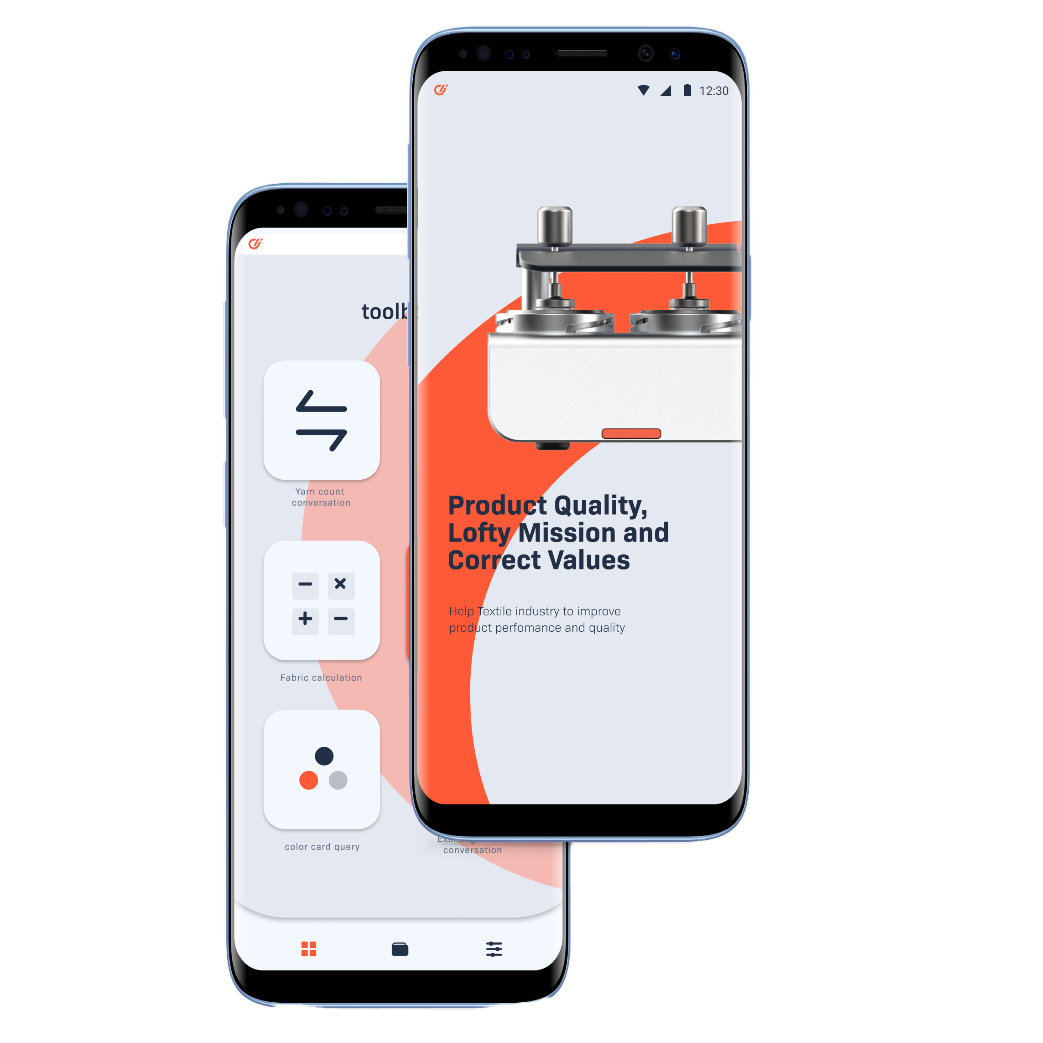

Smart Instrument

You can connect to the SmarTexLab App through Wi-Fi on smartphones. You can use it to set parameters and check the test’s status. It also sends equipment and replenishment reminders.

Well-known brands are using.

Anta supply chain chose SmartFill. It got the garment color fastness data faster and more efficiently. This made corporate brand and quality management more scientific.

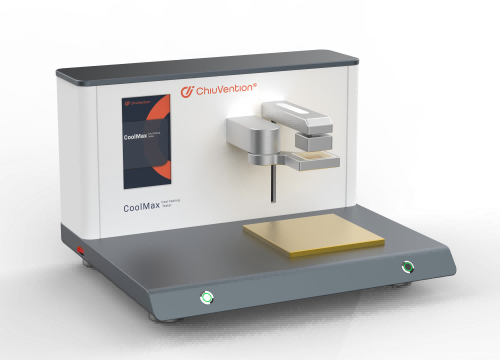

Designed in Germany, quality is our life.

All our textile lab instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our textile lab instruments of outstanding quality. 100% source factory and factory price.

The Specification of SmartFill Liquid Filling Machine

Balance: weighing limit 600g, accuracy ± 0.01g

Soap tank: working volume 6500ml

(Soap can be refilled automatically)

Single pumping volume of soap: 2.5~1000ml,

Liquid output accuracy: 1ml ± 5%

Soap pumping speed: ≤ 28ml / s (with steel balls)

Temperature control range: 0~65℃, precision ±1℃

Power 220V 50/60Hz Other voltages require an external transformer

Weight 45kg

Dimension 500*500*520 mm (L*W*H)

OUR BROCHURE

Frequently Asked Questions

What is the SmartFill Liquid Filling Machine, and what does it do?

The SmartFill Liquid Filling Machine is an automated solution. It’s for precise liquid filling in many industries. It uses modern and trending technology. This technology has flow meters, sensors, and logic controllers. They ensure accurate and efficient liquid filling. This machine tailors an array of liquids. Its scalability, adaptability, and interface are well-known.

How does SmartFill ensure accurate liquid filling?

SmartFill ensures accurate liquid filling. It does this via refined sensors and precise controls. The machine uses a flow meter and sensors. They often check and adjust the flow of liquid in real time. You may combine this with programmable logic controllers. They ensure precise timing and duration during filling. The result is consistent and efficient output, decreasing wastage and optimizing production efficiency.

What type of maintenance is needed for the SmartFill system, and is technical support offered?

SmartFill needs steady but easy maintenance. It mostly consists of routine checks, vacuuming, and adjustments. The expert manufacturers deliver full technical support. They keep strategies to ensure the system performs well and lasts. This facility may include remote aid and on-site upkeep. It’s also going to have standby parts that are easy to get.

What is The Specification of SmartFill Liquid Filling Machine?

1. Precision Weighing System

At the center of SmartFill’s capability is its precision weighing machine. With a sturdy weight of 600g and a majestic accuracy of ± 0.01g, the balance forms the foundation for meticulous dimension. This feature is precious in applications wherein the exact extent of liquid is critical, ensuring that each container gets the required quantity.

2. Soap Tank Innovation

SmartFill introduces a soap tank with a full-size running quantity of 6500ml. What sets it aside is the seamless refilling mechanism, improving operational efficiency by minimizing downtime. This design desire displays SmartFill’s dedication to supplying a non-stop, uninterrupted liquid filling process.

3. Versatility in pumping volume

SmartFill’s adaptability shines through its capability to address diverse liquid products. The machine supports a single pumping volume of soap from 2.5ml to 1000ml. This versatility caters to various product packaging requirements, making it the best solution for small-scale and large-scale manufacturing needs.

4. Steady Accuracy in Liquid Output

Retaining a liquid output accuracy of 1ml ± 5%, SmartFill ensures consistent and dependable effects. This level of precision is vital for industries in which product uniformity is paramount, instilling self-confidence in the reliability of the liquid filling technique.

5. Fast soap Pumping Speed

In industries where the pace is necessary, SmartFill excels with a soap pumping pace of ≤28ml/s, facilitated by the inclusion of metallic balls. This selection quickens the liquid filling process, contributing to average manufacturing speed and throughput.

6. Temperature control expertise

SmartFill doesn’t simply forestall at volume and speed; it also addresses the significance of temperature management. With a temperature control variety from 0 to 65℃ and an accuracy of ±1℃, the machine ensures the maintenance of the liquid’s integrity, contributing to the overall quality and toughness of the filled products.

How does the SmartFill Liquid Filling machine enhance the accuracy of washing coloration fastness tests?

The SmartFill Liquid Filling device is complementary to the washing coloration fastness tester. Incorporating weighing stability guarantees precise measurements of the sample. The device then readies the soap solution. It heats it based on the bath ratio. This ratio ensures consistency in test conditions. This careful method improves the accuracy of the washing color fastness test. It gives reliable and repeatable results.

What functions does the SmartFill Liquid Filling Machine carry out during testing?

The SmartFill Liquid Filling system streamlines the testing system. It does this by automating many vital steps. After weighing the sample, it makes and heats the soap solution. It does this according to the set bath ratio. The machine then outputs the soap at a set temperature. It also dispenses the set number of steel balls into the test cup. This automatic workflow ensures accuracy. It improves the washing shade fastness test. This makes it valuable for labs and quality control.

How do I connect the Smart Instrument to the SmarTexLab App on my smartphone?

To connect your innovative instrument to the SmarTexLab App:

- Ensure both the instrument and your smartphone have wireless capabilities.

- Follow the person’s manual commands furnished with the tool to establish a wireless connection.

- Once it connects, open the SmarTexLab App, go to the settings, and pick out the option to join a new tool.

- Select your innovative instrument from the available devices and follow the on-screen activities to complete the pairing process.

How does SmartFill contribute to progressed testing performance with the 1-Wash color Fastness Tester?

SmartFill is a function machine. It streamlines the procedure for the Wash Color Fastness Tester. This is especially true with twelve test cups. By selecting SmartFill, each test preparation can save up to 10 minutes. This results in significant time savings, especially for enterprises carrying out excessive tests. SmartFill helps users test better. They can achieve correct and reliable results faster.

How does the time-saving impact ordinary productiveness for enterprises when using the 1-Wash coloration Fastness Tester with SmartFill?

For organizations that do about 200 samples per day, the time saved per test with SmartFill adds up. This adds to big gains. In a year, using SmartFill can cut personal labor charges by 30%. This will make testing cheaper. It will boost the productivity of the testing.

Why did Anta supply Chain pick out SmartFill for their garment color fastness data needs?

Anta’s delivery chain chose SmartFill. They did so because it can quickly gather facts about garment color fastness. SmartFill’s technology permits faster data collection. It helps streamline the Anta supply chain’s best and brand control.

How has the adoption of SmartFill impacted the scientific method of company brand and first-rate management at Anta Supply Chain?

SmartFill helps Anta Supply Chain’s operations to make their brand management more scientific. It has also made their control better. SmartFill allows Anta to get coloration fastness facts better. This will let them make better decisions. It will ensure more precise and reliable quality control.

The SmartFill Liquid Filling Machine is an automated solution. It’s for precise liquid filling in many industries. It uses modern and trending technology. This technology has flow meters, sensors, and logic controllers. They ensure accurate and efficient liquid filling. This machine tailors an array of liquids. Its scalability, adaptability, and interface are well-known.

SmartFill ensures accurate liquid filling. It does this via refined sensors and precise controls. The machine uses a flow meter and sensors. They often check and adjust the flow of liquid in real time. You may combine this with programmable logic controllers. They ensure precise timing and duration during filling. The result is consistent and efficient output, decreasing wastage and optimizing production efficiency.

SmartFill needs steady but easy maintenance. It mostly consists of routine checks, vacuuming, and adjustments. The expert manufacturers deliver full technical support. They keep strategies to ensure the system performs well and lasts. This facility may include remote aid and on-site upkeep. It’s also going to have standby parts that are easy to get.

1. Precision Weighing System

At the center of SmartFill’s capability is its precision weighing machine. With a sturdy weight of 600g and a majestic accuracy of ± 0.01g, the balance forms the foundation for meticulous dimension. This feature is precious in applications wherein the exact extent of liquid is critical, ensuring that each container gets the required quantity.

2. Soap Tank Innovation

SmartFill introduces a soap tank with a full-size running quantity of 6500ml. What sets it aside is the seamless refilling mechanism, improving operational efficiency by minimizing downtime. This design desire displays SmartFill’s dedication to supplying a non-stop, uninterrupted liquid filling process.

3. Versatility in pumping volume

SmartFill’s adaptability shines through its capability to address diverse liquid products. The machine supports a single pumping volume of soap from 2.5ml to 1000ml. This versatility caters to various product packaging requirements, making it the best solution for small-scale and large-scale manufacturing needs.

4. Steady Accuracy in Liquid Output

Retaining a liquid output accuracy of 1ml ± 5%, SmartFill ensures consistent and dependable effects. This level of precision is vital for industries in which product uniformity is paramount, instilling self-confidence in the reliability of the liquid filling technique.

5. Fast soap Pumping Speed

In industries where the pace is necessary, SmartFill excels with a soap pumping pace of ≤28ml/s, facilitated by the inclusion of metallic balls. This selection quickens the liquid filling process, contributing to average manufacturing speed and throughput.

6. Temperature control expertise

SmartFill doesn’t simply forestall at volume and speed; it also addresses the significance of temperature management. With a temperature control variety from 0 to 65℃ and an accuracy of ±1℃, the machine ensures the maintenance of the liquid’s integrity, contributing to the overall quality and toughness of the filled products.

The SmartFill Liquid Filling device is complementary to the washing coloration fastness tester. Incorporating weighing stability guarantees precise measurements of the sample. The device then readies the soap solution. It heats it based on the bath ratio. This ratio ensures consistency in test conditions. This careful method improves the accuracy of the washing color fastness test. It gives reliable and repeatable results.

The SmartFill Liquid Filling system streamlines the testing system. It does this by automating many vital steps. After weighing the sample, it makes and heats the soap solution. It does this according to the set bath ratio. The machine then outputs the soap at a set temperature. It also dispenses the set number of steel balls into the test cup. This automatic workflow ensures accuracy. It improves the washing shade fastness test. This makes it valuable for labs and quality control.

To connect your innovative instrument to the SmarTexLab App:

- Ensure both the instrument and your smartphone have wireless capabilities.

- Follow the person’s manual commands furnished with the tool to establish a wireless connection.

- Once it connects, open the SmarTexLab App, go to the settings, and pick out the option to join a new tool.

- Select your innovative instrument from the available devices and follow the on-screen activities to complete the pairing process.

SmartFill is a function machine. It streamlines the procedure for the Wash Color Fastness Tester. This is especially true with twelve test cups. By selecting SmartFill, each test preparation can save up to 10 minutes. This results in significant time savings, especially for enterprises carrying out excessive tests. SmartFill helps users test better. They can achieve correct and reliable results faster.

For organizations that do about 200 samples per day, the time saved per test with SmartFill adds up. This adds to big gains. In a year, using SmartFill can cut personal labor charges by 30%. This will make testing cheaper. It will boost the productivity of the testing.

Anta’s delivery chain chose SmartFill. They did so because it can quickly gather facts about garment color fastness. SmartFill’s technology permits faster data collection. It helps streamline the Anta supply chain’s best and brand control.

SmartFill helps Anta Supply Chain’s operations to make their brand management more scientific. It has also made their control better. SmartFill allows Anta to get coloration fastness facts better. This will let them make better decisions. It will ensure more precise and reliable quality control.