In today’s diverse fashion and industrial fields, textiles are everywhere. From the clothes we wear daily to high – end industrial materials, their quality and performance directly impact our lives and production. Textile finishing technology, as a crucial link in endowing textiles with unique charm and practical value, is playing an increasingly important role. It…

Category Archives: Textile Testing

When it comes to ensuring the durability of textile colors, color fastness is one of the most critical factors for both manufacturers and consumers. The ability of laboratory inspectors to visually evaluate color fastness can significantly impact the quality control processes of textile production. This article will explore methods to enhance inspectors’ skills in visually assessing color…

Are you ready to explore the future of textile testing technology? ChiuVention is thrilled to announce our participation in the EGYPT STITCH & TEX EXPO 2025, taking place from February 20th to 23rd at the Cairo International Convention Center (CICC), Nasr City. We invite you to visit us at Hall 5, Stand 5C24, where we will showcase our cutting-edge testing…

The air permeability test for fabric measures the ease with which air passes through a fabric. It is commonly used to assess the breathability of textiles. The air is passed through the fabric from a unit cross-sectional area by applying constant and different pressures. What is the Air Permeability of a Fabric? What is…

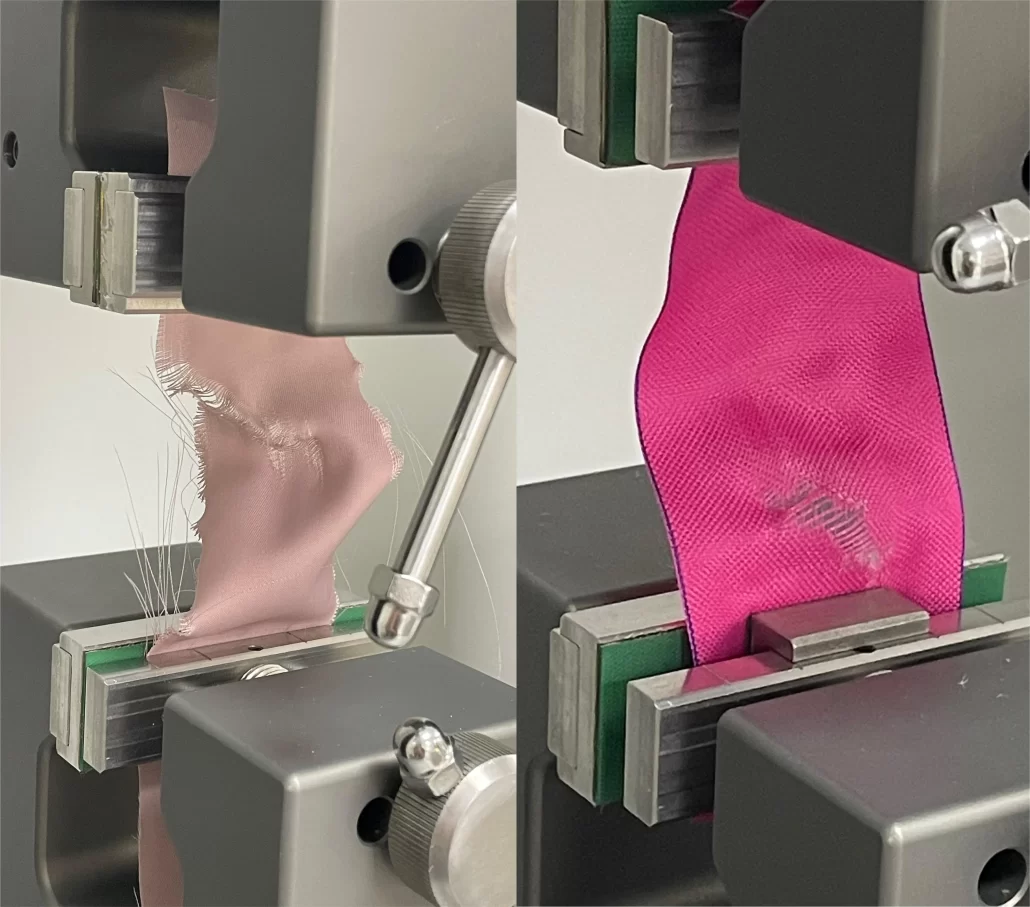

Introduction to Tensile Elasticity and Strength Testing The tensile elasticity of woven fabrics is a crucial property that impacts the performance, durability, and overall quality of textiles. The FZ/T 01034 test method specifies how to determine this property using a Constant Rate of Elongation (CRE) tester. Unlike knitted fabrics, which use a different approach, woven fabrics are…

Introduction Evaluating fabric quality is essential for manufacturers, suppliers, and quality control professionals to ensure consistent textile performance. Whether working with cotton, wool, silk, or synthetic blends, precise laboratory testing plays a crucial role in determining strength, durability, and appearance standards. This guide explores six essential testing methods, including color fastness, strength testing, and…

Introduction Accelerated Colorfastness Testing to Laundering, the AATCC TM61 – 2013E(2020) standard offers a detailed framework for conducting the Color Fastness to Washing Test under home and commercial laundering conditions. This test, an essential component of textile durability tests, evaluates fabric performance using an accelerated Washing Fastness Tester. By replicating multiple wash cycles, it provides…

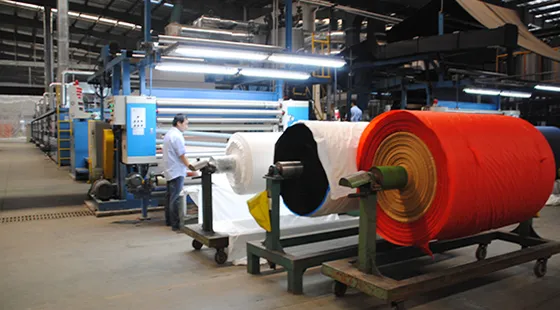

In the vibrant world of textiles, the dyeing and finishing process stands as the crucial bridge between raw fibers and the beautiful, functional fabrics we use in our daily lives. This comprehensive guide dives deep into the four essential steps of textile dyeing and finishing – pretreatment, dyeing, printing, and finishing – uncovering the specific…

Introduction Laboratory dyeing plays a pivotal role in ensuring the color accuracy of dyed polyester fabrics in textile factories. Proper sampling methods, accurate equipment usage, and precise dye preparation are essential for achieving consistent results in bulk production. This guide explores the importance of laboratory dyeing in textile dyeing processes, focusing on polyester fabric dyeing with disperse…

Winter are undeniably the “season of static electricity.” Dry air with low humidity, skin that has lost moisture, and an increase in clothing made from synthetic fibers all contribute to the accumulation of electric charges. There has been widespread complaining online, with many lamenting that they’ve been shocked by static electricity. “Opening a door gives…