Introduction

Accelerated Colorfastness Testing to Laundering, the AATCC TM61 – 2013E(2020) standard offers a detailed framework for conducting the Color Fastness to Washing Test under home and commercial laundering conditions. This test, an essential component of textile durability tests, evaluates fabric performance using an accelerated Washing Fastness Tester. By replicating multiple wash cycles, it provides critical insights into color fastness to water and laundering processes. This guide highlights the principles, equipment, and steps for achieving consistent color fastness to laundering results, ensuring high-quality textiles for consumers.

This test can simulate the color and surface changes of textiles after multiple hand washes or home launderings. The test process takes about 45 minutes.

Test Principle and Scope

Test Purpose and Scope

The purpose of this Color Fastness to Washing Test is to simulate the effects of multiple home laundering cycles on textiles. Using a Washing Fastness Tester, the test evaluates how fabrics withstand washing conditions, including detergent and temperature variations. The results offer insights into color fastness and the fabric’s ability to resist fading during laundering. This accelerated method replicates five hand washes or home laundries, making it a critical aspect of textile durability tests.

However, the staining effects of five typical hand, home, and commercial launderings do not fully match the 45 – minute test results. This is because factors such as the fabric fiber content in the washing load, the proportion of color transferred to the adjacent fabric, and other end – use conditions vary.

Test Principle

The specimen is tested under appropriate temperature, detergent, bleach, and friction conditions, such that its color change is similar to that of five hand washes, home or commercial launderings. The color change can be easily measured in a short time. The friction behavior during washing involves the contact between the fabric and the steel cup, a low liquor ratio, and the impact of steel balls on the fabric.

Test Equipment and Consumables

The instruments and consumables used are as follows:

- Colorfastness to Washing Tester:

Washing Fastness Machine: It can rotate the sealed steel cup at a speed of 40 ± 2 rpm in a thermostatically controlled water bath.

Lockable Stainless Steel Cup on the Instrument: Model I: Volume: 500ml, Diameter: 75mm, Height: 125mm, Suitable for 1A.

Lockable Stainless Steel Cup on the Instrument: Model II: Volume: 1200ml, Diameter: 90mm, Height: 200mm, Suitable for 2A, 3A, 4AA, and 5A.

Metal Clamps to Fix the Stainless Steel Cup on the Washing Fastness Machine.

Stainless Steel Balls with a Diameter of 6mm and a Weight of 1g.

Teflon Sealing Rings.

Heating Plate.

2. Scales for Rating Test Results:

AATCC 9 – step Chromatic Transfer Scale (AATCC EP8)

Gray Scale for Color Change (AATCC EP1).

Gray Scale for Staining (AATCC EP2).

3. Multifiber Fabric:

No.1 Multifiber Fabric

Its fiber strips are composed of acetate, cotton, nylon, silk, viscose rayon, and wool.

No.10 Multifiber Fabric

Its fiber strips are composed of acetate, cotton, nylon, polyester, acrylic, and wool.

4. Bleached Cotton Test Fabric:

Density is 32×322 roots/cm, weight per unit area is 136 ± 10g/m, desized and free of fluorescent brighteners.

5. AATCC Standard Reference Detergent WOB (Free of Fluorescent Brighteners).

6. AATCC Standard Reference Detergent 1993 (Containing Fluorescent Brighteners).

7. Pure Water Machine: used to prepare deionized water.

8. Reagents:

Bleach NaOCl.

Na₂CO₃.

10% H₂SO₄.

10% KI.

0.1 N Na₂S₂O₃.

9. Square Friction White Cloth with a Length of 50mm

10. Sample Mounting White Card: The Y value in the tristimulus color solid diagram should be at least 85%.

11. Sample Preparation Device for Soap Washing Colorfastness Tester: SmartDispen Detergent Dispenser, used to automatically prepare soap solution.

Sampling Requirements

Specimen Size: 5.0cm×10.0cm (1A), 5.0cm×15.0cm (2A, 3A, 4A, and 5A). When sampling, sample along the inside of the marked line to ensure that the specimen has no pen marks.

Only one specimen can be placed in each steel cup.

For the staining assessment of options 1A and 2A, multifiber fabric can be used.

For the staining assessment of option 3A, either multifiber fabric or bleached cotton fabric can be used. If multifiber fabric is used for staining assessment, only the staining of cotton is evaluated, and the staining of other fibers is not evaluated. However, when the specimen or the final garment contains the above fibers, they need to be evaluated. To prevent fraying, it is recommended to use multifiber fabric with heat – sealed edges.

For options 4A and 5A, staining is not evaluated.

Specimen Preparation Requirements

Prepare bleached cotton fabric and multifiber fabric with each fiber strip 8mm wide. Both the multifiber fabric and the bleached cotton fabric are square samples with a length of 50mm. Sew them to the front of the test sample along the short side in an appropriate way. If multifiber fabric is used, place the multifiber fabric at the end 50mm away from the specimen, and sew the wool of the multifiber fabric on the right side of the specimen. At the same time, the directions of the six fiber strips should be parallel to the long side of the specimen.

For the preparation of multifiber fabric with a fiber strip width of 15mm, the multifiber fabric is a rectangular sample of 50×100mm. Place it along the long side of the specimen in an appropriate way with the front sides facing each other. The multiple fiber strips should be parallel to the short side of the specimen, and sew the half – wool part of the multifiber fabric to the short side of the specimen.

For knitted fabric test samples, it is recommended to first sew bleached cotton fabric of the same size as the specimen around the four sides of the knitted specimen to prevent curling of the knitted specimen and help the multifiber fabric achieve a uniform staining condition. Then sew the multifiber fabric to the front of the specimen.

For pile product specimens, sew the multifiber fabric to the end in the direction of the pile.

For yarn specimen test samples, the following two options can be used to prepare specimens.

- Option 1: Use an appropriate knitting machine to knit the yarn into knitted fabric to prepare the test sample. At the same time, for each test, keep an unwashed knitted fabric as a comparison sample.

- Option 2: For each specimen, take a 120y long yarn sample. Wind the yarn sample tightly and evenly along a template with a width of 50mm and a length according to the selected procedure (100 or 150mm). Keep an unwashed yarn sample. Remove the template, sew the yarn sample to a bleached cotton fabric of the same mass to prevent yarn from loosening, and then sew the multifiber fabric.

Test Procedure

Preparation

Set the temperature as specified.

Set the water bath temperature and washing time of the washing machine, and preheat it to reach the set temperature.

Prepare the washing solution: Prepare and stir thoroughly to dissolve according to the concentration specified above in the chapter Test Equipment and Consumables.

Operation

Add the specified number of steel balls and amount of water to the steel bottle. Place the steel bottle vertically in the washing test machine, ensuring that all four sides are balanced. After turning on the washing test machine, the motor rotates at 40 ± 2 rpm until the required time is reached. When the time is up, take out the test piece.

When the set time is reached, take out the specimen and pour it into a beaker. Note that each specimen should be placed in a separate beaker. Wash each specimen 3 times with deionized water at 40 ± 3°C in the beaker for 1 minute each time. Stir continuously during washing and squeeze out the water by hand. A centrifuge or wringing machine can be used to remove excess water.

Dry the specimen in an oven at a temperature not exceeding 71°C. It can also be placed in a nylon bag and dried in a tumble dryer. Note that the exhaust temperature should be between 60 – 70°C. Alternatively, it can be air – dried.

Before rating, condition the specimen in an environment with a temperature of 21 ± 1°C and a relative humidity of 65 ± 2% for 1 hour.

Before rating, trim the washed specimen and the adjacent multifiber fabric, such as loose yarns or loose fibers on the specimen surface, long fluff. For pile specimens, use a brush to comb the direction of the pile to be similar to that of the unwashed specimen. If the specimen wrinkles due to washing and drying, flatten the specimen first. To facilitate rating, the specimen can be bound on a card. The card is usually white, firm, and does not affect the rating.

For yarn samples, comb them neatly first. To make the rating comparable to the unwashed sample, treat the unwashed sample and the test sample in the same way.

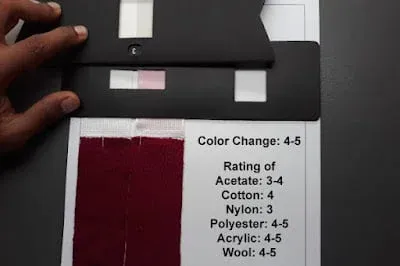

Rating

Evaluation of Color Change

The color change of the specimen can be directly evaluated using the Gray Scale for Color Change with reference to Rating Procedure 1. To increase the accuracy of the rating, several people can jointly evaluate.

Grade 5: Negligible or no staining.

Grade 4.5: The color change is equivalent to Grade 4 – 5 of the Gray Scale for Color Change.

Grade 4.0: The color change is equivalent to Grade 4 of the Gray Scale for Color Change.

Grade 3.5: The color change is equivalent to Grade 3 – 4 of the Gray Scale for Color Change.

Grade 3.0: The color change is equivalent to Grade 3 of the Gray Scale for Color Change.

Grade 2.5: The color change is equivalent to Grade 2 – 3 of the Gray Scale for Color Change.

Grade 2.0: The color change is equivalent to Grade 2 of the Gray Scale for Color Change.

Grade 1.5: The color change is equivalent to Grade 1 – 2 of the Gray Scale for Color Change.

Grade 1.0: The color change is equivalent to Grade 1 of the Gray Scale for Color Change.

The color change can also be measured by a colorimeter. For the color matching software, refer to AATCC Rating Procedure 7.

Evaluation of Staining

The staining of the multifiber fabric can be evaluated using the Gray Scale for Staining with reference to Rating Procedure 2 or the Staining Color Card with reference to Rating Procedure 8. The report should indicate whether the Gray Scale for Staining or the Staining Color Card is used.

Grade 5: Negligible or no staining.

Grade 4.5: The staining condition is equivalent to Grade 4 – 5 of the Gray Scale for Staining or Grade 4.5 of the 9 – step AATCC Staining Color Card.

Grade 4.0: The staining condition is equivalent to Grade 4 – 5 of the Gray Scale for Staining or Grade 4.0 of the 9 – step AATCC Staining Color Card.

Grade 3.5: The staining condition is equivalent to Grade 3 – 4 of the Gray Scale for Staining or Grade 3.5 of the 9 – step AATCC Staining Color Card.

Grade 3.0: The staining condition is equivalent to Grade 3 of the Gray Scale for Staining or Grade 3.0 of the 9 – step AATCC Staining Color Card.

Grade 2.5: The staining condition is equivalent to Grade 2 – 3 of the Gray Scale for Staining or Grade 2.5 of the 9 – step AATCC Staining Color Card.

Grade 2.0: The staining condition is equivalent to Grade 2 of the Gray Scale for Staining or Grade 2.0 of the 9 – step AATCC Staining Color Card.

Grade 1.5: The staining condition is equivalent to Grade 1 – 2 of the Gray Scale for Staining or Grade 1.5 of the 9 – step AATCC Staining Color Card.

Grade 1.0: The staining condition is equivalent to Grade 1 of the Gray Scale for Staining or Grade 1.0 of the 9 – step AATCC Staining Color Card.

The degree of color transfer from the specimen to the multifiber fabric or bleached cotton fabric can be determined by comparing it with the unwashed multifiber fabric or bleached fabric. If multifiber fabric No. 10A or FAA is used, and the width of its fiber strip is wider than the aperture of the colorimeter, the staining of this multifiber fabric can be measured by a tester.

Precautions

The aim is to improve the accuracy and reliability of test results. This article will analyze and explore aspects such as the preparation of combined specimens, operation procedures, rating, and report issuance, and systematically and comprehensively propose precautions for testing the colorfastness to soaping of textiles.

Precautions for Preparing Combined Specimens

To avoid the impact of improper sampling and differences in the number of specimens on the test results of the colorfastness to soaping of textiles and to standardize the preparation of combined specimens, the following precautions for preparing combined specimens are proposed: During the preparation of combined specimens, representative parts (avoiding wrinkles and defects) should be selected from the samples provided by the inspection applicant, and specimens of the specified size should be cut from them. When the sample contains patterns or multiple colors, a sufficient number of specimens should be taken for separate tests to ensure that all colors are included in the tested area of the specimen. To prevent the specimen from curling during the test, it is recommended to sew the four sides of the specimen to bleached cotton fabric of the same size to obtain a smooth fabric surface, and attach standard multifiber fabric to the front of the knitted specimen.

Precautions for Operation Procedures

To prevent errors in the actual operation procedures from affecting the test results of the colorfastness to soaping of textiles and to standardize relevant operations, the following precautions for operation procedures are proposed: In the test operation procedures, the corresponding test conditions should be selected according to the relevant information of the product to be tested and the product standards it complies with, so as to accurately prepare the soap solution required for the test and preheat it to the corresponding test temperature. During this process, avoid the formation of bubbles in the prepared soap solution that may affect the accurate measurement of the solution. In addition, it is necessary to verify whether steel balls need to be added to the stainless – steel container according to the corresponding test conditions and the relevant requirements of the inspection applicant, and ensure the airtightness of the stainless – steel container. Before starting the washing machine, check the initial state of the colorfastness to washing tester and set parameters (such as the corresponding test temperature and test time). During the washing process, pay attention to whether the colorfastness to washing tester is operating normally. When taking out the machine, check whether the stainless – steel container has water entering in the colorfastness to washing tester. If water enters the stainless – steel container in the colorfastness to washing tester, re – sample and test to ensure the accuracy of the results.

When taking out the combined specimen, remove all the stitches on the thick and severely fading combined specimen, and hang the sample and its adjacent fabric separately for drying to avoid uneven staining of the adjacent fabric after drying due to dye migration. Also, record the details. During the rinsing process of the combined specimen, rinse it thoroughly until clean to minimize the impact of soap scale spots remaining on the fabric surface on the rating results. After squeezing out the excess water from the combined specimen, place the specimen between two filter papers and squeeze to remove the remaining water to reduce the possibility of dye thermal migration as much as possible. When hanging the specimen for drying with clips, the clips should avoid the pattern part of the specimen to prevent the clip marks left on the specimen from affecting the rating results. If there is a power outage or the colorfastness to washing tester malfunctions during the test, re – sample and test.

Precautions for Rating

The Color Fastness to Washing Rating is determined using AATCC-approved scales, such as the Gray Scale for Color Change. These ratings assess the degree of fading and staining after testing with the Washing Fastness Tester. Manufacturers rely on this metric to evaluate compliance with color fastness to water and laundering standards, ensuring their products meet consumer expectations.

During the rating process, visual rating should be carried out in a standard light box using AATCC gray cards (Gray Scale for Color Change, Gray Scale for Staining, 9 – step Chromatic Transfer Scale), or instrument rating should be carried out using a spectrophotometer that meets the standard requirements. When using visual rating, the rating personnel should wear neutral gray gowns and strictly rate the color change grade of the specimen and the staining grade of the adjacent fabric according to AATCC Evaluation Procedure 7. For samples that are at the qualified critical value, unqualified, have uneven color change after the test, or have uneven staining of the adjacent fabric, re – sample and retest, and conduct multi – person rating. All abnormal phenomena and test details should also be described and recorded.

Precautions for Issuing Test Reports

In the process of issuing the test report, the data obtained from the test should be accurately recorded as well as entered into the standard requirements of the report include the relevant content and information, in particular, attention should be paid to and record the details of deviation from the standard AATCC 61, “Colorfastness of Textiles to Soaping: Accelerated Method” as well as abnormal phenomena during the test to ensure the accuracy of the data in each test report, the completeness of the content.

Conclusion

The AATCC TM61 – 2013E(2020) standard is a crucial tool for ensuring textile quality and durability through accelerated colorfastness testing. By simulating multiple laundering cycles, it helps manufacturers maintain high-quality standards while ensuring customer satisfaction. Adhering to this standard promotes consistent testing outcomes, improving textile performance and reliability in both home and commercial applications.

The Color Fastness to Washing Test, as outlined in AATCC TM61 – 2013E(2020), is a cornerstone of textile durability tests. Employing a WashTrue Washing Colour Fastness Tester ensures manufacturers meet industry standards for color fastness to water and laundering. Proper adherence to this standard not only evaluates the color fastness to washing rating but also supports sustainable practices by enhancing textile longevity. By integrating reliable washing fastness test methods, companies can deliver superior products that excel in color fastness to laundering under various conditions.

For more valuable insights on textile testing, we encourage you to subscribe to our website or reach out to us using the following contact information:

Email: sales@chivention.com

WhatsApp: +86 180 2511 4082

Linkedin: Chiuvention