When it comes to ensuring the durability of textile colors, color fastness is one of the most critical factors for both manufacturers and consumers. The ability of laboratory inspectors to visually evaluate color fastness can significantly impact the quality control processes of textile production. This article will explore methods to enhance inspectors’ skills in visually assessing color fastness, the various color fastness tests, and how a better understanding of color fastness rating and color fastness grade scale can lead to more accurate evaluations.

In the textile and apparel industry, the accurate assessment of color fastness is of paramount importance as it directly impacts product quality and consumer satisfaction. Color fastness evaluation relies heavily on the visual inspection skills of laboratory inspectors. However, this process is fraught with challenges due to various factors that can introduce errors. This article delves into the key aspects of improving the ability of laboratory inspectors to visually evaluate color fastness, offering practical insights and solutions.

Understanding Color Fastness Testing

Color fastness testing is a crucial part of evaluating how well a fabric holds its color under different conditions. One of the most common tests is the color fastness to rubbing test, which measures how well a fabric resists color transfer when rubbed, either under dry or wet conditions. This is also known as color fastness to crocking, and it’s a fundamental aspect of laboratory color fastness testing.

The color fastness to crocking test evaluates the risk of color transfer from one surface to another, such as from the fabric to another garment or to a person’s skin. A color fastness rating system is typically used to assign a score to how well the fabric performs under these tests. The ratings usually range from 1 (poor) to 5 (excellent), with intermediate values indicating varying degrees of color retention.

Understanding color fastness rating

The color fastness rating of clothing and textiles belongs to sensory inspection. Inspectors must visually observe the color change of the sample and then compare it with the standard color card to obtain information in the brain and draw an evaluation result after comprehensive analysis.

Sensory inspection is qualitatively different from instrumental inspection. The result measured by the instrument is an absolute value, while the sensory inspection gives a comprehensive conclusion relatively close to the correct value, so it is easily affected by objective and subjective factors, resulting in errors in the evaluation results.

To eliminate and reduce errors, laboratories use proficiency testing, inter-laboratory comparisons, and internal personnel visual comparisons to ensure the accuracy and stability of the color fastness inspectors’ rating vision. Although these measures are necessary, color fastness inspectors perform repetitive color fastness evaluations every day.

The factors causing errors are not only diverse but also unpredictable, and it is difficult to achieve only by a few comparisons. The author believes that in addition to the technical level of the raters, the inspector’s treatment of samples, the selection of rating environmental conditions, the observation and analysis during the evaluation process, and the inspector’s emotions and states should be concerned.

Mastering Sample Treatment for Accurate Color Fastness Evaluation

The sample treatment mentioned here is the pasting process of the samples after testing, which is also the preparation before rating. Generally, most laboratories cut and paste the samples and then rate them under the specified environmental conditions. This method is more conducive to observation. The cutting and pasting of samples seem simple, but in fact, it is a key link no less important than the previous test process and is also the most easily overlooked link in our daily inspection. The errors brought by this link are often large, so the sample treatment will directly affect the evaluation results.

The following points are recommended to be noted during sample treatment:

1. Proper Sample Preparation for Accurate Color Fastness Testing

The original color fastness records usually use white paper. Therefore, the samples should be cut neatly and the size should meet the requirements of the color card. Avoid the stitches of the seams. Especially when using GB250 “Grey Scale for Assessing Change in Colour” to assess the color change of the original sample, there should be no gap between the original sample and the test sample. The size should be slightly larger than the square hole of the covering blackboard of the GB250 color card, so that only the original sample and the test sample are visible through the square hole of the covering blackboard, and the original record paper cannot be seen. White will affect vision to a certain extent.

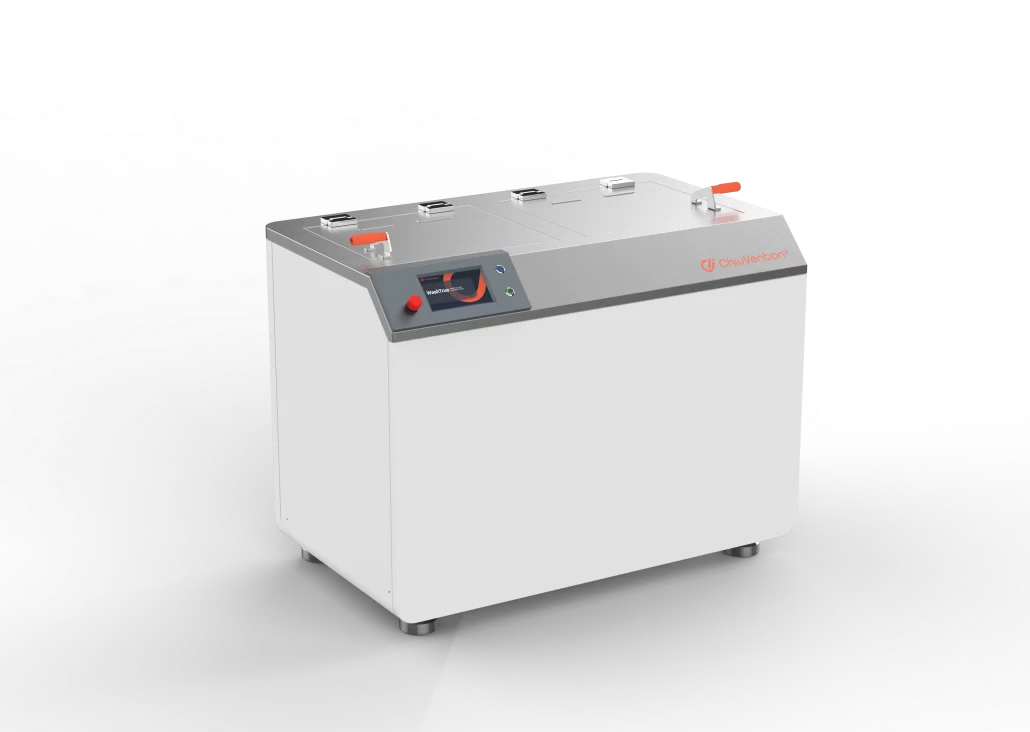

SmartDispen is a sample preparation device for washing color fastness tests.

2. Ensuring Consistency in Sample Orientation and Fabric Directions

Pay attention to the front and back sides and warp and weft directions of the sample. Generally, take the front side of the sample, and the side of the lining fabric in contact with the sample is the rating side. The up-down direction during rating observation is exactly the warp direction of the sample, and the yarn direction should be vertical without skew.

Pay attention to the consistency of the warp and weft directions, grain directions, and pattern positions of the original sample and the test sample. For example, for printed fabrics, the same pattern unit must be taken. When the colors are different, they can be pasted separately. For jacquard fabrics, the parts with the same color and texture should be taken. Otherwise, large rating deviations will occur due to the inconsistency of the warp and weft directions, grain directions, and pattern positions.

3. Handling Special Fabric Types and Testing Conditions for Reliable Results

Treat samples by category. For example, for pile fabrics, special attention should be paid to the consistency of the pile direction, and it is better to have the pile facing up. If necessary, the pile of the sample should be sorted out to make it as close as possible to the state before the test, and eliminate the grade difference caused by the opposite pile direction or the change of the pile state of the original sample and the test sample.

When doing the rubbing color fastness test, if there are loose fibers on the cotton lining cloth after the test, carefully remove them without rubbing hard to avoid destroying the original state of the sample and causing rating differences. If there is a dark edge in a linear shape on the cotton lining cloth of the rubbing color fastness test, it is best to repeat the test. If it still cannot be eliminated, do not be affected by it during rating. It is recommended to consider it outside the effective area.

For some pure cotton samples that have been calendered, sized, and have a large shrinkage rate, due to the elimination of gloss, removal of sizing agents, and the change of warp and weft density caused by excessive shrinkage rate after the test, the color difference from the original sample increases, and the color fastness rating result is likely to be low. Therefore, some laboratories spray distilled water on the original sample to make it wet without dripping, and then dry it naturally in the air not exceeding 60°C together with the test sample before comparison and rating to eliminate the errors caused by the variation of the textile surface and the migration of finishing agents. However, this operation must be indicated in the inspection report.

For sparse fabrics, to eliminate the influence of the background color of the record paper, the original sample and the test sample are preferably pasted in multiple layers.

Optimal Environmental Conditions: Key to Precise Color Fastness Rating

FZ/T 01047 “Standard Illuminant Conditions for Visual Assessment of Color Fastness of Textiles” stipulates that artificial D65 illuminant and natural daylight (clear day north-facing daylight: 9:00 am – 3:00 pm) are the light sources for color fastness assessment of textiles. Arbitration tests must be carried out under the D65 illuminant.

During the assessment, the influence of reflected light from external environmental substances should be avoided. At the same time, the standard also stipulates the environmental color for rating. The environmental color for box observation is Munsell neutral grey without gloss (Grade 1: N5 – N6; Grade 2: N5 – N7); the environmental color for non-box observation is Munsell N5 neutral grey, which is equivalent to Grades 1 – 2 of the grey scale for assessing change in colour.

Color Fastness Evaluation

In the inspection, the standard regulations must be strictly implemented. However, by rating under the conditions of box D65 illuminant, non-box D65 illuminant, and natural daylight respectively, feeling the differences, and summarizing the differences in the results, it is also helpful for the determination and stability of the rating.

During the observation and analysis process of color fastness rating, the color change of the sample after the test and the staining of the lining fabric are compared with the standard color cards GB 250 and GB251 “Grey Scale for Assessing Staining” respectively to evaluate the color difference between the original sample and the test sample, and between the stained lining fabric and the original lining fabric.

Factors influencing color difference in fabric

The color difference is caused by the fading of the original sample and the staining of the lining fabric, and is also caused by one or more changes in hue, brightness, and chroma. Therefore, the total color difference should be considered during the assessment.

When a special sample cannot be fully described by a numerical grade, it is recommended to add appropriate grade terms in the numerical rating to describe the color change characteristics and ensure the accuracy of the evaluation result. This requires the inspector to make careful observations and comprehensive analyses during the rating process. When observing general samples, the illumination of the light source is usually at an angle of about 45° to the sample surface, and the observation direction is close to perpendicular to the sample surface, that is, corresponding to the 45/0 illumination and observation conditions, and the observation distance is 30 cm to 40 cm.

However, when observing special samples, in order to ensure the accuracy of the evaluation result, the illumination and observation conditions should be selected according to the gloss degree of the sample. FZ/T 01047 – 1997 stipulates three types:

- When visually inspecting the color fastness of non-glossy textiles, it should be 45/0.

- When visually inspecting the color fastness of slightly glossy textiles, it should be 0/45.

- When visually inspecting the color fastness of highly glossy textiles, if the color of the sample changes with the illumination and visual angles, the observer should also visually inspect at various angles. In actual rating, it is best to use multiple angles for observation. Especially for fabrics with special cross-sectional fibers, due to different reflections and refractions, the gloss of jacquard fabrics, and the differences in fabric textures, great attention should be paid.

Systematic Evaluation Order: Enhancing Color Fastness Assessment

Color fastness inspectors need to complete multiple batches of inspections every day, and the inspected samples are often colorful. Due to the different degrees of stimulation of the visual sense by different colors of light, there must be a color order during the rating process. If there are dark, light, red, yellow, and blue colors in the rating samples, it is recommended to rate the light colors first, then the dark colors, and finally the red colors, to avoid rating deviations caused by the stimulation of the eyes by the color light. After a batch of samples is rated, it is best to re-evaluate them once and compare the samples of the same grade to ensure good consistency of the evaluation results.

Inspector’s Emotional and Physical Well-being: Impact on Color Fastness Rating

The key to the accuracy and stability of color fastness rating depends on the technical level of the inspector. However, for a high-level inspector, his own emotions and states will determine the exertion and stability of the technical level. It is recommended that the inspector should not perform color fastness rating when he is sleep-deprived, in a bad mood, or when his eyes feel tired after operating the computer. Because the deviation caused in this situation may be large and will seriously affect the accuracy of the result.

Decoding the Role of Light Sources in Color Fastness Evaluation

The strict regulations on environmental conditions in the standard originate from the relationship between light and color. Color is a feeling caused by the human visual sense being stimulated by light and making the brain respond. The physical basis of color vision is light, and light is a kind of electromagnetic radiation within a certain wavelength range, with the duality of wave and particle. Visible light is a kind of electromagnetic radiation with a wavelength range of 380nm – 780nm.

Besides visible light, there are also infrared light, ultraviolet light, X-rays, etc. However, only visible light can cause human visual perception. The change of the wavelength and quantity of light can make people have different color sensations.

The object color we usually observe is the feeling caused by the light reflected or transmitted by the non-luminous body after being irradiated by light stimulating the human eyes. Therefore, under different light sources, the color of the object will be different.

For example, a bright red garment in the sunlight during the day will turn black under a mercury lamp at night. This is because the red garment absorbs all the light other than red, and the red garment will not reflect light under a mercury lamp without red components, so we see it as black.

This shows that the relationship between light and color is very close. The color of the light source is primary, and the color of the object is secondary. When the irradiation light source is not white, generally, the color of the object under white light irradiation will not be presented. Therefore, we must carry out the color fastness rating under the light source conditions required by the standard.

(Author’s unit: Wei Jinyu: Baoding Fiber Inspection Institute; Shang Suping: Baoding Product Quality Supervision and Inspection Institute)

Key Factors in Improving Visual Color Matching

One of the most challenging aspects of color fastness inspection is the ability to visually match the colors of a tested sample to a standard or reference sample. Visual color matching is subjective and requires inspectors to have a keen eye for detecting slight variations in color that may not be immediately obvious.

To improve the ability of laboratory inspectors to visually evaluate color fastness, the following steps can be taken:

Training in Color Perception: Inspectors should be trained in recognizing the subtle differences in color that affect color fastness ratings. This includes learning how light, temperature, and humidity can affect the way color appears on different fabrics.

Using Standardized Lighting: The lighting under which color fastness inspection is performed plays a significant role in the accuracy of the results. Using a color fastness grade scale and ensuring consistent lighting conditions, such as using a D65 illuminant, helps reduce errors caused by environmental variables.

Regular Calibration of Equipment: For laboratory inspectors, it’s essential that any tools or systems used for color fastness testing are regularly calibrated. This includes color fastness test instruments and visual color matching aids, ensuring they provide reliable and consistent results.

Understanding the Color Fastness Scale: Familiarity with the color fastness grade scale helps inspectors better interpret the results from color fastness tests. This scale provides a clear framework for understanding whether a fabric’s color is resistant enough for its intended use.

Relevant Standards

- GB/T 251 – 2008 Grey Scale for Assessing Staining in Colour Fastness Tests of Textiles

- GB/T 250 – 2008 Grey Scale for Assessing Change in Colour in Colour Fastness Tests of Textiles

- GB/T 6151 – 2016 General Principles of Colour Fastness Tests of Textiles FZ/T 01047 – 1997 Standard Illuminant Conditions for Visual Assessment of Color Fastness of Textiles

Conclusion: Enhancing the Accuracy of Visual Color Fastness Evaluation

In conclusion, improving the ability of laboratory inspectors to visually evaluate color fastness is essential for maintaining high-quality standards in textile manufacturing. By meticulously handling samples, strictly adhering to proper environmental conditions, following a rational evaluation order, and taking into account the inspectors’ emotional and physical states, we can significantly reduce errors and enhance the accuracy and stability of color fastness ratings. Continuous training and improvement are essential for inspectors to maintain and refine their skills in this crucial area.Additionally, understanding the nuances of color fastness to rubbing tests, color fastness to crocking, and color fastness inspection will lead to more reliable results that can be trusted across the textile industry.

ChiuVention focuses on smart textile testing instruments. For more information about laboratory testers or to obtain professional testing solutions, please contact us!

Email: sales@chivention.com

WhatsApp: +86 180 2511 4082

Linkedin: Chiuvention