Winter are undeniably the “season of static electricity.” Dry air with low humidity, skin that has lost moisture, and an increase in clothing made from synthetic fibers all contribute to the accumulation of electric charges.

There has been widespread complaining online, with many lamenting that they’ve been shocked by static electricity. “Opening a door gives me a shock, washing my hands gives me a shock, especially when taking off clothes — it’s like a thunderstorm with crackling and popping sounds…”

Many netizens have even shared, “I’ve been defeated, turns out static electricity only shocks the poor,” and “The winter of the poor is all about crackling static electricity…”

So, does static electricity really only affect the poor? Actually, no. This is just a marketing ploy by capitalists, attempting to “brainwash” consumers into purchasing more expensive clothing and anti-static devices.

Here’s the preview conclusion — let’s clarify the rumors:

The formation of static electricity is closely related to air humidity, fabric material, processing methods, and the skin’s moisture level, with no direct relationship to the price of the clothing. (Even an expensive cashmere sweater can still generate static electricity!)

How is static electricity produced?

According to the Institute of Physics at the Chinese Academy of Sciences, static electricity mainly forms due to the transfer of electrons in processes like friction, contact, or induction. When two objects rub or come into contact, electrons move from one object to the other, causing them to carry different charges. When the charged objects separate, the charges do not easily transfer through the air, causing a difference in charge on their surfaces. That is how static electricity is produced and how static electricity works.

When static electricity accumulates to a certain level, it breaks through the air, forming an electric spark (similar to how lightning is created). At this moment, the current passing through the air excites its molecules, releasing energy in the form of light, which is the glow we see.

The light emitted by static electricity is mostly blue, primarily because of the excitation spectra of nitrogen and oxygen in the air. As the current passes through the air, it excites nitrogen and oxygen molecules, causing their electrons to jump to higher energy levels. When these electrons return to lower levels, they release photons, and the frequency of the photons corresponds to blue (or violet) light. That’s why we often see blue light. In addition, some energy from static discharge is also transmitted as sound, which is why we hear the “crackling” sound.

Other colors of static electricity are usually related to the voltage level, the discharge contacts, and the humidity and temperature of the air.

Is Polyester Fabric Most Prone to Static Electricity?

Yes, traditional polyester fibers are more likely to generate static electricity than natural fibers.

The fabrics most prone to static electricity, ranked from highest to lowest:

Polyester fiber > Acrylic > Nylon (Polyamide) and Spandex > Silk > Wool & Cashmere > Cotton & Linen.

Cotton exhibits better resistance to static electricity than polyester does. There are anti-static polyester options available, including regenerated cellulose fibers like Lyocell and Modal, which are more moisture-absorbent and therefore less likely to generate static.

Do Natural Fibers (Wool, Cashmere) Resist Static More Effectively?

Cotton and linen do have an advantage, but not all natural fibers are resistant to static. Cashmere static electricity property may be lower than other types of fabrics. For instance, wool and silk can also generate static in dry environments, especially 100% pure wool, which can discharge quite strongly when rubbed with other clothes in particularly dry winters. Additionally, silk is also prone to static in dry winter conditions.

No fabric is completely immune to static. Under very dry and cold conditions, even cotton and linen can generate static. The most important factor in static electricity is the humidity in the air. Also, while cotton and linen perform better with static, they also have their own drawbacks.

Should You Avoid Polyester (Polyester Fiber) in Winter?

Not necessarily! While polyester is prone to static shock, its production process can be improved to make it “less static-prone.” Modified polyester fibers can overcome many of polyester’s drawbacks, and many high-tech polyester blends, such as some types of “science cotton,” are actually less likely to generate static.

What are Anti-static Fabrics?

- Anti-static silk: Made from polyester and used in the production of dustproof clothing and anti-static workwear. It can come in stripe or mesh forms.

- 100% cotton anti-static fabrics: Made from cotton and woven with conductive fibers, these fabrics are moisture-absorbent, heat-resistant, alkali-resistant, and hygienic. Typically, cotton fabrics have good moisture absorption and heat resistance, making them comfortable to wear.

- Anti-static ultra-clean fabric: Made from special polyester filaments woven with conductive fibers using a special process. These fabrics offer excellent anti-static properties and can also prevent fiber shedding and the leakage of small dust particles. They are heat-resistant and washable, suitable for dust-free rooms ranging from class 10 to class 100.

- TR anti-static fabric – Polyester andViscose: This blend fabric is smooth, clean, vibrant in color, offers good elasticity, moisture absorption, but poor resistance to wrinkles.

- TC anti-static fabric – Polyester andCotton: This fabric is woven with a blend of polyester and cotton fibers along with embedded conductive fibers. It comes in plain weave, fine twill, and coarse twill styles.

- Wool anti-static fabric: A wool blend fabric that feels and performs similarly to regular wool, mainly used for professional clothing.

These are all examples of anti static fabrics and anti static clothing material that can help combat static electricity.

How Does the Textile Industry Deal with Static Electricity?

There are two main methods:

Adding conductive fibers

Advantages: Conductive fibers, being metallic, can quickly release accumulated static charges from the fabric, effectively reducing static.

Disadvantages: Conductive fibers are typically dark in color, limiting the range of colors in the final product.

Adding anti-static agents

Special additives are incorporated into the fabric during or after weaving to impart certain properties, such as making shirts stiffer or preventing static.

Advantages: This method is generally less expensive than the first.

Disadvantages: The effectiveness of anti-static agents decreases with repeated washing.

Both methods aim to “minimize the generation of static electricity” but cannot completely eliminate it. From this perspective, claims like “static-free” on e-commerce sites are not entirely accurate.

Textile Testing Methods on Preventing Static Electricity

Rotary Static Voltage Measurement

Principle: Under a certain tension, the sample is rubbed with a standard fabric, and the highest and average voltage generated is evaluated. If there is a significant difference between the front and back of the sample, both sides should be measured.

Friction Charge Quantity Measurement

After rubbing the sample to build static, it is placed into a Faraday cage to measure the total charge it carries.

Impedance Measurement

Electrodes are placed a certain distance apart on the surface of the sample, and the resistance between the electrodes is measured. This method is commonly used to evaluate the anti-static properties of dust-free clothing and carpets.

Human Body Voltage Measurement

Used to test the anti-static properties of decorative textiles, such as carpets and automotive fabrics.

Static Adsorption Test (Cling)

The fabric is rubbed to generate static, and the time it takes for the fabric to adhere to a metal plate under gravity is measured.

Charge Decay Time Measurement

A sample is charged to a certain voltage (usually 5000V), and the time required for the charge to decay by half is measured.

Walking (Simulated Walking) Test

Simulates walking, with friction between shoes and the sample creating static. The voltage generated in the human body is then tested.

Half-life Measurement

After charging a sample in a high-voltage static field until stable, the power is cut off, and the time it takes for the voltage to decay to half of its original value is measured.

Ash Test

The sample, charged with static, is brought near dust to determine the extent of dust adsorption.

Friction Charge Decay Test

A standard method for testing anti-static textiles in Japan. The sample is rubbed with cotton or wool and measured for voltage and decay curves.

How to Prevent Static Shock During Winter in Daily Life?

Increase Humidity

Use humidifiers, anti-static sprays, or even a bowl of water in the room to increase moisture levels. You can also moisten your hands with water or a damp towel, or wipe your clothes with a wet wipe to release static.

Choose Clothes That Are Less Prone to Static

Wear cotton clothes: Natural fibers like cotton and linen are better at absorbing moisture, reducing static.

Avoid full synthetic fabrics like polyester and nylon, which are more likely to generate static.

Here’s a summary of key winter dressing tips:

- Sweaters are prone to static, but pure wool sweaters have less static.

- Layering cotton helps prevent static, but polyester plus cotton is a static magnet.

- Down jackets generate a lot of static, and you can’t take them off for warmth.

- Wool coats with sweaters can generate a lot of static — it’s a real “static storm.”

- Pairing with cotton sweatshirts really helps prevent static.

Release Static through Other Objects

Touch a wall: The wall can discharge the static electricity from your body, allowing you to “ground” yourself.

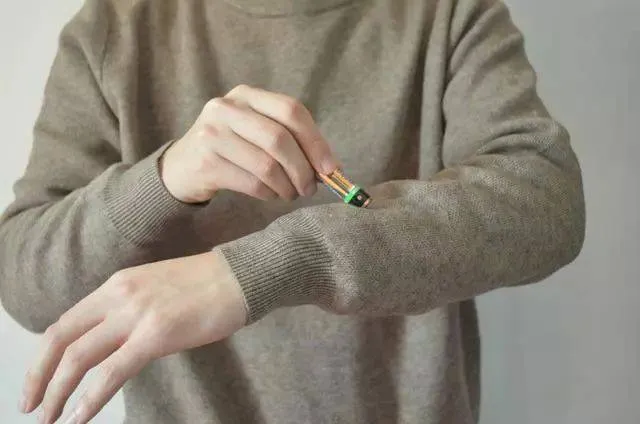

Hold a metal key: Carrying a metal key in your hand can help discharge static electricity.

Use Anti-static Sprays and Products

Commercial anti-static sprays can help reduce static, and there are also anti-static devices that can be clipped to your clothes or shoes.

FAQs on Fabric Static Electricity

What causes static electricity in winter?

Dry air, low humidity, and synthetic fabrics all contribute to the accumulation of static electricity during winter.

How to avoid static shock in winter?

Increase humidity, choose anti-static fabrics, and use anti-static products to reduce the buildup of static.

Can polyester fabric generate static electricity?

Yes, polyester is more prone to static due to its synthetic nature.

Are there any specific treatments for cashmere to prevent static electricity?

Yes, there are several ways to reduce cashmere static electricity:

- Condition your cashmere with fabric softeners to maintain its natural moisture content and reduce static buildup.

- Increase humidity in your home, as dry conditions exacerbate static problems in cashmere.

- Use anti-static sprays specifically designed for delicate fabrics like cashmere.

- Avoid over-drying cashmere garments in the dryer, as this can increase static electricity.

How does anti-static polyester work to reduce fabric static electricity?

Manufacturers treat anti-static polyester with a special coating or additive that helps it dissipate electrical charges quickly, preventing fabric static electricity buildup. This is particularly useful in environments where static discharge can damage sensitive electronics or cause discomfort. Engineers design anti-static fabrics to absorb moisture or incorporate conductive fibers that dissipate charges, reducing the likelihood of static shocks.

Why does fabric static electricity occur, and which materials are most affected?

Fabric static electricity occurs when certain materials, particularly synthetic fibers, rub against each other, causing an imbalance in electrical charge. Anti-static fabrics like anti-static polyester reduce static buildup, but natural fibers such as cashmere and cotton can still experience static under dry conditions. Synthetics like nylon and polyester are more prone to static because they don’t conduct moisture as well as natural fibers, making them more likely to hold a charge.

What are the main types of static electricity in textiles?

There are two primary types of static electricity in textiles: contact and triboelectric static electricity. Contact static electricity occurs when two different materials come into contact, exchanging electrons and creating a charge imbalance. Friction between fabrics causes triboelectric static electricity, where one material loses electrons and the other gains them, leading to static buildup. Both types can affect fabrics, including anti-static polyester and natural fibers like cotton and cashmere.

Conclusion

While static electricity might feel like an unavoidable winter annoyance, it’s not just a problem for the “poor.” Understanding its causes and how it interacts with different fabrics can help you make smarter choices when dressing for the season. Whether you’re using anti-static sprays, choosing the right fabrics, or keeping your environment humidified, there are plenty of ways to keep static shocks at bay. Stay comfortable and shock-free this winter!

For more valuable insights on textile testing, we encourage you to subscribe to our website or reach out to us using the following contact information:

Email: sales@chivention.com

WhatsApp: +86 180 2511 4082

Linkedin: Chiuvention