The performance and testing of materials are fundamental pillars in the development of the textile industry. From fiber selection to the final formation of fabrics, every step requires precise control over material properties and rigorous testing validation. With the rapid advancement of textile technology, new materials and processes continually emerge, leading to updates in performance indicators and testing methods.

The scope of textile material performance and testing has expanded significantly, encompassing both traditional natural fibers and modern high-performance synthetic fibers, as well as a wide range of physical and chemical testing methods. However, these terms are often highly specialized and complex, making them challenging for industry newcomers, students, and general readers interested in textiles to understand.

This article provides a systematic and comprehensive explanation of textile material properties and testing terms in an accessible manner. It covers various aspects such as fiber fineness and strength, fabric permeability and moisture absorption, and complex testing methods like tensile testing and abrasion resistance testing.

Related Terms and Requirements

Abrasion Resistance

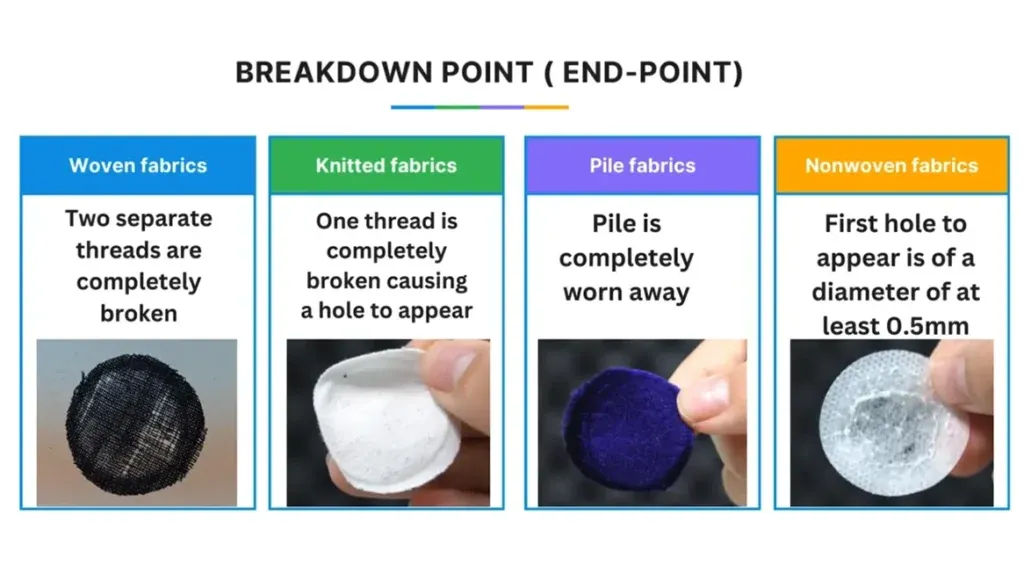

The ability of a material to withstand wear. It is typically measured by the number of friction cycles required to cause a certain degree of wear on a sample or by assessing changes in the sample’s appearance, strength, thickness, and weight after a specific number of friction cycles.

Relevant Standards

- GB/T 21196.1 – 2007 Textiles – Determination of the abrasion resistance of fabrics by the Martindale method – Part 1: Martindale abrasion tester

- GB/T 30314 – 2021 Rubber – or plastics – coated fabrics – Determination of abrasion resistance – Taber method

- GB/T 42942 – 2023 Textile materials for automotive interiors – Schopper abrasion test method

- GB/T 19089 – 2012 Rubber – or plastics – coated fabrics – Determination of abrasion resistance – Martindale method

- GB/T 43818.1 – 2024 Leather – Determination of abrasion resistance – Part 1: Taber method

- GB/T 39507 – 2020 Leather – Physical and mechanical tests – Determination of abrasion resistance: Martindale ball – disc method

- GB/T 21196.4 – 2007 Textiles – Determination of the abrasion resistance of fabrics by the Martindale method – Part 4: Evaluation of appearance change

- GB/T 21196.3 – 2007 Textiles – Determination of the abrasion resistance of fabrics by the Martindale method – Part 3: Determination of mass loss

- GB/T 21196.2 – 2007 Textiles – Determination of the abrasion resistance of fabrics by the Martindale method – Part 2: Determination of sample breakage

- FZ/T 90113 – 2023 Textile needles – Test method for abrasion resistance

- FZ/T 50063 – 2023 Test method for abrasion resistance of chemical fiber filaments for mooring ropes – Yarn – to – yarn friction

- FZ/T 60049—2022 Determination of abrasion resistance of fiber ropes – Drum friction method

- FZ/T 01151 – 2019 Textiles – Test method for fabric abrasion resistance – Accelerated friction method

- FZ/T 98014 – 2016 Martindale abrasion and pilling performance tester

- FZ/T 01128 – 2014 Textiles – Determination of abrasion resistance – Double – wheel abrasion method

- FZ/T 50025 – 2014 Test method for abrasion resistance of ultra – high – molecular – weight polyethylene filaments

- FZ/T 01122 – 2014 Textiles – Abrasion resistance test – Flex abrasion method

- FZ/T 01121 – 2014 Textiles – Abrasion resistance test – Flat abrasion method

- FZ/T 01123 – 2014 Textiles – Abrasion resistance test – Edge – fold abrasion method

- FZ/T 60012 – 1993 Determination of abrasion fastness of coatings on metallized textiles

- FZ/T 01011 – 1991 Coated fabrics – Determination method for abrasion resistance

Surface Abrasion

A flat abrasion test method where the sample undergoes surface friction under specified conditions. This includes the Martindale abrasion test and other flat abrasion test methods.

Relevant Standards

- FZ/T 01157-2021: Textile Color Fastness Test to Flat Abrasion (Metal Mesh Method)

- FZ/T 01156-2021: Textile Color Fastness Test to Flat Abrasion (Emery Method)

- FZ/T 01121-2014: Textile Abrasion Resistance Test (Flat Abrasion Method)

Flex Abrasion

A test method where the sample undergoes repeated bending and friction with an abrasive surface under specified conditions.

Fold Abrasion

A test method where the folded edge of a sample undergoes friction against an abrasive surface under specified conditions.

Relevant Standard

FZ/T 01123-2014: Textile Abrasion Resistance Test (Fold Abrasion Method)

Dynamic Abrasion

A test method where the sample undergoes repeated stretching and bending while in friction with an abrasive surface under specified conditions.

Relevant Standards

- GB/T 4802.4 – 2020 Textiles – Determination of fabric pilling and fuzzing properties – Part 4: Random tumble method

- ASTM D 3512 – 02 Tumble pilling test

- JIS L1076:2012 Testing methods for pilling of woven and knitted fabrics

- ISO 12945 – 3:2020 Textiles — Determination of fabric propensity to surface pilling, fuzzing or matting — Part 3: Random tumble pilling method

Pressing-in Crease

A process where fabric is subjected to pressure, heat, and moisture to create a sharp fold.

Relevant Standards

- GB/T 8438-1998: Color Fastness Test to Creasing (Steam Creasing)

- GB/T 13770-2009: Evaluation of Crease Appearance After Washing

- GB/T 11045.13-2005: Color Fastness of Dyed Wool Textiles to Chemical Creasing and Finishing

- FZ/T 20022-2010: Fabric Crease Retention Test Method

Crease Retention

The ability of a fabric to retain a crease.

Wrinkle

Unwanted, irregular, short-shaped creases in fabric.

Relevant Standards

- GB/T 29257-2012: Evaluation of Fabric Wrinkle Recovery by Appearance Method

- GB/T 43016-2023: Measurement and Evaluation of Wrinkles on Synthetic Leather

Wrinkle Resistance

The ability of a fabric to resist the formation of wrinkles.

Crease Recovery

The ability of a fabric to return to its flat state after being creased.

Relevant Standard

GB/T 3819-1997: Measurement of Fabric Crease Recovery by Recovery Angle Method

Crease Recover Angle

The angle formed between the two folded surfaces of a fabric sample that has been folded under stress under specified conditions, after the pressure is removed and the sample is allowed to stand for a certain period of time.

Stiffness

The property of a material to resist bending deformation, usually indicated by the bending length.

Relevant Standard:

GB/T 41567 – 2022 Textiles – Determination of fabric stiffness – Slot – seam method

- GB/T 7689.4 – 2013 Reinforcements – Test methods for woven fabrics – Part 4: Determination of bending stiffness

- GB/T 7690.4 – 2013 Reinforcements – Test methods for yarns – Part 4: Determination of stiffness

- GB/T 18318.5 – 2009 Textiles – Determination of bending properties – Part 5: Pure bending method

- GB/T 18426 – 2021 Rubber – or plastics – coated fabrics – Low – temperature bending test

- GB/T 39368 – 2020 Leather – Physical and mechanical tests – Determination of folding fastness: Footwear upper bending method

- GB/T 18318.6 – 2017 Textiles – Determination of bending properties – Part 6: Saddle method

- GB/T 18318.1 – 2009 Textiles – Determination of bending properties – Part 1: Inclined – plane method

- GB/T 18318.3 – 2009 Textiles – Determination of bending properties – Part 3: Glaize method

- GB/T 18318.4 – 2009 Textiles – Determination of bending properties – Part 4: Cantilever method

- GB/T 18318.2 – 2009 Textiles – Determination of bending properties – Part 2: Heart – shaped method

- GB/T 33621 – 2017 Test method for bending properties of 3D – braided fabrics and their resin – matrix composites

- GB/T 7689.4 – 2013 Reinforcements – Test methods for woven fabrics – Part 4: Determination of bending stiffness

- GB/T 31295 – 2014 Core materials for wind turbine blades – Determination of high – temperature dimensional stability under bending and compressive loads

Bending Length

The length at which a horizontally placed fabric strip bends to a specified angle under its own weight.

Flexural Rigidity

The ratio of a material’s minute bending moment change to the corresponding curvature change per unit width, calculated based on bending length.

Drape

The deformation ability of fabric when suspended under specified conditions.

Relevant Standards

FZ/T 01045-1996: Fabric Drape Test Method

GB/T 23329-2009: Measurement of Fabric Drape

Drape Coefficient

An index characterizing the drape of a fabric, expressed as the percentage of the projected area of the sagging part of the sample to its original area.

Hand Feel

The tactile sensation of fabric when touched, pressed, or rubbed by hand.

Relevant Standards

- FZ/T 01171-2023: Textile Fabric Hand Feel Detection and Evaluation (Three-Point Beam Method)

- FZ/T 01166-2022: Textile Fabric Hand Feel Detection and Evaluation (Multi-Indicator Integration Method)

- SN/T 3779-2014: Measurement of Fabric Hand Feel Changes Under Low Temperature

Snagging

The phenomenon where yarns or fibers are pulled out or broken by sharp objects, forming loops or broken strands on the fabric surface.

Relevant Standards

- GB/T 11047-2008: Textile Fabric Snagging Performance Assessment (Needle Hammer Method)

- GB/T 11047.3-2024: Textile Fabric Snagging Performance Testing and Evaluation (Pin Roll Drum Method)

- GB/T 11047.2-2022: Textile Fabric Snagging Performance Testing and Evaluation (Rolling Box Method)

Pilling and Fuzzing

The formation of fuzz or pills on fabric surfaces due to friction.

Relevant Standards:

- GB/T 4802.1-2008: Textile Fabric Pilling and Fuzzing Test (Circular Locus Method)

- GB/T 4802.3-2008: Textile Fabric Pilling and Fuzzing Test (Pilling Box Method)

- GB/T 4802.4-2020: Textile Fabric Pilling and Fuzzing Test (Random Tumble Method)

- GB/T 4802.2-2008: Textile Fabric Pilling and Fuzzing Test (Modified Martindale Method)

Martindale Abrasion Test Method System

Determination of Sample Breakage

Test Principle

A circular sample installed in the sample fixture of a Martindale abrasion tester undergoes planar motion with a Lissajous – shaped trajectory and rubs against the abrasive (i.e., standard fabric) under a specified load. The sample fixture can rotate freely around an axis perpendicular to the horizontal plane. The abrasion resistance of the fabric is determined based on the total number of friction cycles when the sample breaks.

Related Test Standards

EU Standard: ISO 12947 – 2

Chinese Standard: GB/T 21196.2

US Standard: ASTM D4966

Related Product Standards

Denim Clothing (FZ/T 81006 – 2017, FZ/T 73032 – 2017)

Laundered Finished Clothing (GB/T 22700 – 2016, FZ/T 73052 – 2015

Determination of Mass Loss

Test Principle

Circular samples are weighed at intervals during friction cycles to assess mass loss, indicating fabric abrasion resistance.

Relevant Standards

ISO 12947-3, GB/T 21196.3, ASTM D4966

Evaluation of Appearance Change

Test Principle

A circular sample installed in the sample fixture of a Martindale abrasion tester moves in a planar motion with a Lissajous – shaped trajectory and rubs against the abrasive (i.e., standard fabric) under a specified load. The sample fixture with the abrasive can rotate freely around an axis perpendicular to the horizontal plane. The abrasion resistance of the fabric is determined based on the changes in the appearance of the sample.

Related Test Standards

International Standard: ISO 12947 – 4

Chinese Standard: GB/T 21196.4

US Standard: ASTM D4966

More detailed explanation on these three determination methods, please check this article:

Selection and Application Scenarios of Test Methods

| Test Method | Core Indicator | Applicable Scenarios |

| Damage Cycle Measurement | Number of cycles to wear failure | Evaluating extreme wear resistance (e.g., outdoor apparel, denim clothing) |

| Mass Loss Measurement | Mass loss | Quantifying material abrasion loss (e.g., laboratory research, quality control) |

| Appearance Change Evaluation | Surface appearance change rating | Appearance-sensitive products (e.g., automotive interiors, high-end apparel) |

Industry Application Cases

Apparel and Outdoor Clothing:

The determination of the number of breakage cycles is used to assess the durability of items likehard-shell jackets and ski suits in high – friction environments.

Automotive Interiors:

The appearance change evaluation is used to assess the appearance retention ability of seat fabrics.

Industrial Conveyor Belts:

A combination of the determination of the number of breakage cycles and the determination of mass loss tests is used to verify the performance stability of materials under long – term friction.

Factors Affecting the Abrasion Resistance of Fabrics

Characteristics of Fibers

Geometric Features

(1) Generally, the longer the fiber, the better the abrasion resistance.

(2) A moderate fiber fineness is beneficial for abrasion resistance. If the fiber is too fine, the stress is high. If it is too coarse, the number of fibers is small, the cohesion is weak, and the bending resistance is poor.

(3) In terms of cross – sectional shape, fabrics made of profiled fibers have worse flex abrasion resistance and edge – fold abrasion resistance compared to those made of circular fibers.

Mechanical Properties

Fabrics with high breaking elongation, high elastic recovery rate, and high breaking specific work generally have good abrasion resistance.

Structure of Yarns

- Twist

The twist should be moderate. If the twist is too high, the mobility of fiber segments is small, the yarn is stiff, and the contact area is small. If the twist is too low, the yarn structure is loose, and fibers are likely to be pulled out. - Fineness

The coarser the yarn, the better the abrasion resistance, especially in flat abrasion. - Yarn Evenness

Yarns with good evenness are more abrasion – resistant. (The thick places are loose, and fibers are easy to be pulled out.) - Single Yarn and Plied Yarn

Fabrics made of plied yarns have better flat abrasion resistance than those made of single yarns, but they are worse in flex abrasion and edge – fold abrasion. - Radial Distribution of Blended Yarns

Fibers with good abrasion resistance are required to be distributed on the outer layer of the yarn.

Fabric Structure

- Weight per Square Meter

The higher the weight per square meter, the better the abrasion resistance. - Structure Phase and Support Surface

Near the fifth structure phase, with a large support surface, the abrasion resistance is good. - Fabric Density

A moderate fabric density results in better abrasion resistance. - Fabric Weave

The fabric density and weave should be considered comprehensively. When the warp and weft densities are low, plain weave is more abrasion – resistant. When the warp and weft densities are high, satin weave is more abrasion – resistant.

Test Conditions

- The selected abrasive.

- Tension and pressure.

- Temperature and humidity in the test environment.

- The direction of friction, especially for satin – weave fabrics.

Post – Treatment

The abrasion resistance of cotton and viscose fabrics shows different results under different pressures during testing. For example, when the pressure is high, the abrasion resistance decreases, and when the pressure is low, the abrasion resistance increases.

For more information on smart textile testing instruments, or to obtain professional testing solutions, please contact us!

Email: sales@chivention.com

WhatsApp: +86 180 2511 4082

Linkedin: Chiuvention