In life, you may find that some fabrics are warm to the touch and some are cool to the touch. The specific heat capacity of pure substances varies. This is understandable. But, some clothing fabrics are the same substance in a different form. Why do people feel such a big temperature difference? In terms of heat and humidity comfort, it is the fabric’s “contact warmth and coldness” that matters.

About contact warmth and coldness of fabrics

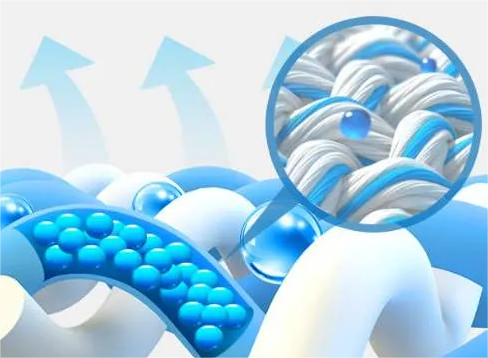

When skin touches fabrics of different temperatures, they quickly exchange heat. This creates a temperature difference on the skin. Nerves carry this difference to the brain. It makes people feel the fabric as cold or warm.

Skin temperature is usually higher than the air temperature. It’s lower than the fabric temperature. So, the skin loses heat and cools. Then, skin nerves send the temperature info to the brain, making us feel cold and warm. In terms of touch, fabric and the body’s contact with it guide away heat. The strength of the warmth or cold feeling depends on the fabric and the body.

In general, the reason is the fabric’s surface state. It affects how warm or cold fabric feels. The smoother the surface, the cooler the feeling, while the plush feeling warm.

This is because the plush surface has more air. The air is still and does not convect. Also, air has low thermal conductivity. This is why thick fur on an animal’s body is an insulator. The air in the middle of the fur is still. This insulates it from convective heat transfer inside and outside.

How to evaluate the contact warmth and coldness?

Now, methods for testing warmth and coldness focus on heat flow and absorption. They mainly focus on transient heat.

Maximum heat flow method

The max heat flow method is the earliest method. It comes from the Japanese scholar Kawabata. He based it on the transient heat conduction theory. He proposed a fabric contact warmth testing and evaluation method. The method simulates the heat transfer to human skin from fabric. It measures the heat flow curve in real time.

Now, people use the instrument at home and abroad. It measures the warmth of fabrics. It does so using contact cooling and warming sense analysis. The tester only considers cases where the hot plate is hotter than the sample. The maximum heat flow it measures is relative warmth and coldness. Higher heat flow values mean coldness and lower ones mean warmth.

The Contact Warmth and Cooling Tester has three basic parts and a control system. It has three basic testing abilities:

You can test the evaluation value q max of cold and warm sensations within 1 point.

Thermal conductivity and thermal diffusion coefficient test (within 2 to 3 points)

Thermal insulation test (within 2 to 5 points)

q max test (cold and warm feeling test)

The researcher places the sample on the constant temperature table. We place the heat storage plate on the heat source table for storing heat. When the plate touches the sample, the stored heat moves to the sample’s cold side. At this time, the peak of the tested heat flow is the q max value. q max is the larger the colder, the smaller the warmer.

The principle of testing warmth and coldness is to use pressure to contact the specimen. It is the heat detection plate. This simulates human touch design. The body will touch an object when the heat detection plate measures the weight and area of contact. It is possible to measure the heat transfer process that is as close as possible to the human body’s senses.

Thermal Conductivity and Thermal Diffusion Coefficient Test

The thermostat is set to room temperature. Place the sample on it. Then, position the hot plate near the specimen on the heat source table. After the heat source table and the ring guard stabilize. Then, we can find the steady-state thermal conductivity. We do this by measuring the steady-state heat flow. You can also find the diffusion coefficient from the heat and temperature profiles. Do this before they stabilize. To do this, we use specific boundary conditions.

Thermal insulation test

Tests fix the specimen to a 10 x 10 cm heat source table. Fix the specimen to the table using the specimen mounting frame. Normally, the wind tunnel’s air is the same temperature as the room. The heat source table is set to 10°C above room temperature. When the heat source table and heat flow stabilize, measure the heat flow. Then, use it to calculate the insulation performance.

Heat absorption coefficient method

Czech scholar Hes proposed another way to describe how warm or cold fabrics feel. He called it the heat absorption coefficient. The skin is in contact with the fabric during heat transfer. The fabric’s conductivity, capacity, and density affect the heat transfer. The absorption coefficient shows how well the fabric absorbs heat. It does this from the body when in contact with the skin. In 2016, the United States introduced the ASTM D7984. It is the “Standard Test Method for Measurement of Fabrics. It uses the Improved Transient Plane Heat Source (MTPS) Instrument.” ASTM D7984 is the “Standard Test Method. It measures the Heat Absorption Coefficient of Fabrics. It uses a Modified Transient Planar Heat Source (MTPS) Instrument.

The classic MTPS method serves as the basis. In this method, the test structure changes. It changes from the two-sample probe of the MTPS method to a single-sample format. The new format replaces the second sample. A material with a known property replaces it. The thin-film probe integrates this material as a single test probe. It can do most of the test functions of the transient plane heat source method. It can measure the thermal absorption coefficient and thermal conductivity. But, it cannot directly measure the maximum heat flow density.

Typical test instruments that implement the ASTM D7984 standard are thermal conductivity analysers.

The instrument applies a fixed amount of thermal energy (a known current) to a heating element in a probe. The element provides a small amount of heat to the sample under test. This heat raises the sample’s surface temperature by 1 to 1.5°C. It then changes the sensor’s voltage. We measure heat absorption and thermal conductivity. We measure them based on how much and how quickly the temperature rises.

Relevant Standards

ASTM D7984-21 is the Standard Test Method. It measures the Thermal Efficiency of Fabrics. It uses an Improved Transient Plane Source (MTPS) Instrument.

GB/T 35263-2017 is called “Detection and Evaluation of Cool Feeling Performance of Textiles on Contact Instant.”

FTTS-TA-019 “Specification for Verification of Instantaneous Cool Feeling of Fabric

Summary

The coolness of fabric is a subjective feeling. It depends on a person’s sensitivity to temperature. It’s also greatly influenced by the evaluator’s condition. It’s also influenced by the environment they are in. The test is objective. It’s based on a result relative to each test parameter. Different people feel the warmth and coldness differently. So, each method only gives a reference to the fabric’s warmth and coldness.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com