Textile companies strive to maintain and improve the quality of their products. One crucial aspect of textile quality is its bursting strength. This parameter measures the material’s ability to withstand pressure before breaking. This discussion explores the importance of bursting strength tests. We’ll look at the standards for the tests and ways to increase bursting…

color fastness to washing is a critical attribute in the textile industry. It impacts consumer satisfaction and product durability. Understanding how to maintain vibrant colors through many washes is essential. In this discussion piece, we’ll explore color fastness to washing. We’ll also look at testing methods and relevant ISO standards. We will take practical steps…

When it comes to the world, textile manufacturing innovation grows into an ambitious force over grade and efficiency. One such creation that is creating ripples in the enterprise is the infrared dyeing machine. Modern technology delivers the most suitable change in sample dyeing, offering textile manufacturer’s different options and capabilities before being unavailable over traditional…

Did you ever note that certain clothes feel airy and cool while others make you feel as if one is in a suffocating house? But it is how air can freely pass through them. Yeah, these fabrics are endowed with this quality called air permeability which shows how easily air can travel through it. This…

What Does Abrasion Resistance Mean? A good Martindale score specifies strong abrasion resistance in a fabric. Abrasion resistance is the capability of fabric to endure damage. This is caused by scratching, rubbing, and friction over time. In textiles, needed materials are subject to repeated friction in daily usage. The Martindale tests are also known as…

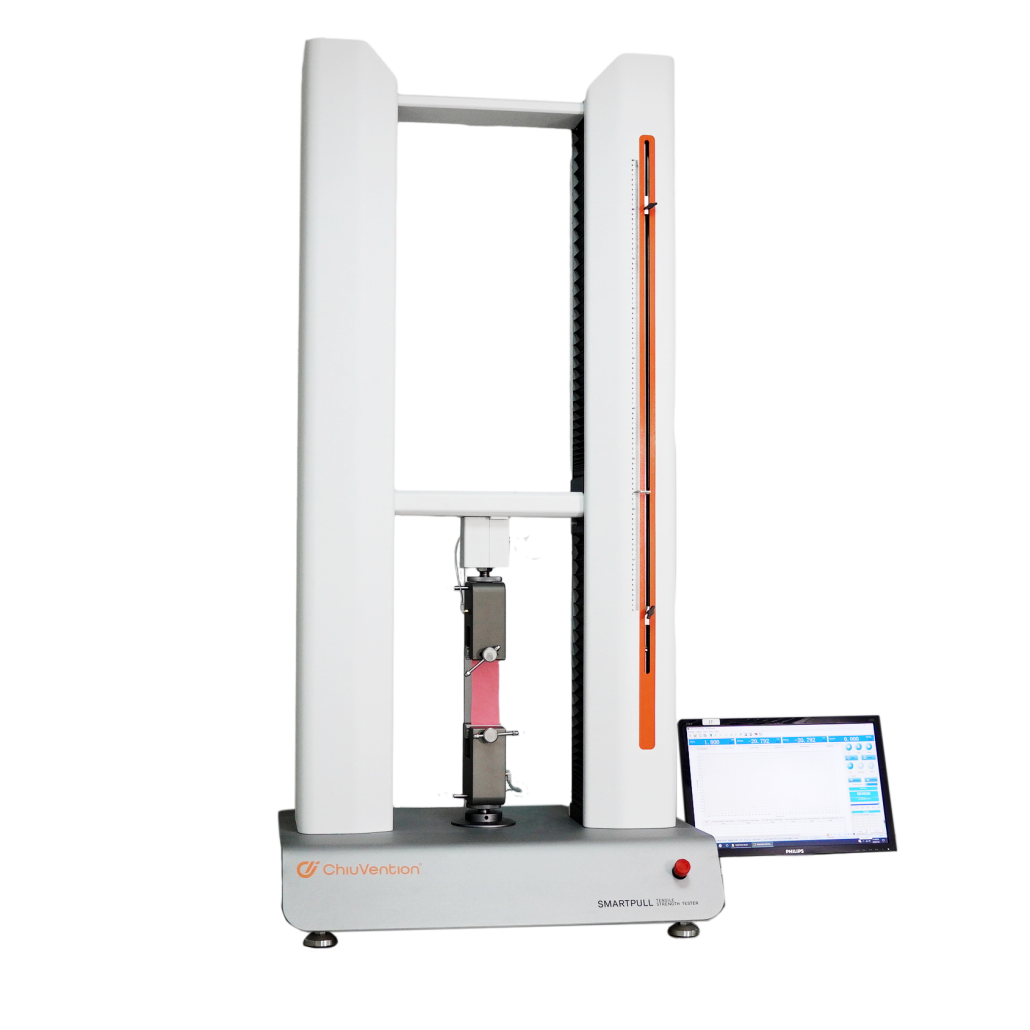

Ever wondered what a Dual Column Type Tensile Tester is all about? You’ve come to the right place! In this ultimate guide, you’ll learn: How do dual-column-type tensile testers work? Which industries use them? What makes them unique? That’s not it. You will also find out how choosing the right tester can make or break your…

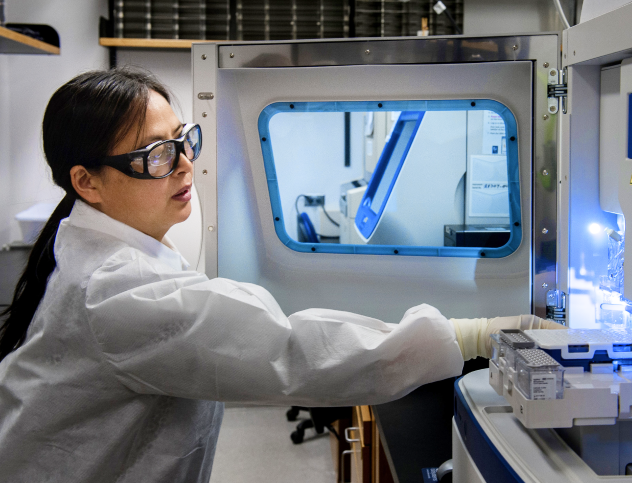

Introduction: Quality management is vital in the textile industry that we work in because of ensures the use of top-quality materials every day. It would be frustrating if your most loved t-shirt began to disintegrate after just a few washes or if the design on your favorite dress faded quickly. This is why we have…

This article delves deep into the pivotal role that constant temperature and humidity chambers play in enhancing the quality standards of textile production processes. From maintaining the integrity of delicate fibers to ensuring uniform dye absorption, the intricate dance between temperature and humidity profoundly influences every stage of textile manufacturing. Join us as we unravel…

Textiles are all around us, from the clothes we wear to the furniture we sit on. But have you ever considered how strong these fabrics need to be? In certain situations, fabrics must withstand pressure applied directly to their surface. This is especially important for products like airbags, tires, and upholstery. To guarantee the…

What is the ASTM D4966-22 Test Standard? ASTM D4966-22 is a standard test method developed by the American Society for Testing and Materials (ASTM) in order to assess the abrasion resistance of textiles. Of course, this Martindale test method is rapidly used in various industries, such as automotive, textiles, and aerospace, to assess the performance…