Ever wondered what a Dual Column Type Tensile Tester is all about? You’ve come to the right place! In this ultimate guide, you’ll learn:

- How do dual-column-type tensile testers work?

- Which industries use them?

- What makes them unique?

That’s not it.

You will also find out how choosing the right tester can make or break your testing success. Keep reading to become a tensile tester expert!

Key Takeaways

- Dual column-type tensile testers can perform many tests, including tensile, compression, and bending tests.

- These testers are essential for those industries that require rigorous material testing. Examples are aerospace, automotive, and construction.

- Dual-column testers offer greater stability and capacity for higher loads compared to single-column testers.

- Choosing the right tester involves considering load capacity, material type, budget, and the manufacturer’s reputation.

- Investing in a high-quality dual-column tensile tester is a strategic decision ensuring long-term reliability and material testing accuracy.

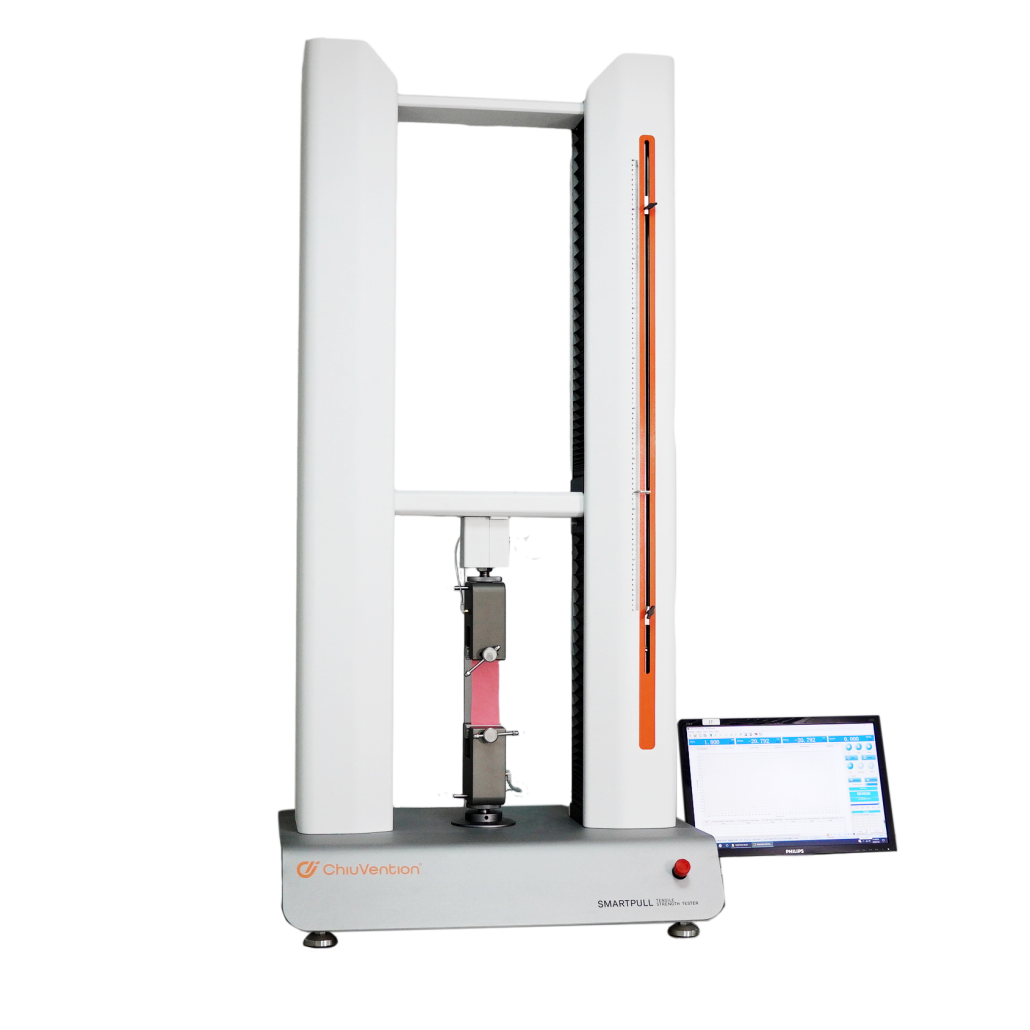

What is a Dual Column Type Tensile Tester?

A Dual Column Type Tensile Tester is a machine that we use to evaluate the tensile strength of various materials. It operates by pulling these materials in opposite directions until they break.

Tensile testing is crucial for engineers and material scientists as it helps determine a material’s:

- Strength

- Ductility

According to experts, these insights are critical for designing products that meet safety and performance standards.

Components of a Dual Column Type Tensile Tester

A dual-column type tensile tester has several key components. Here’s a table:

| Component | Function |

| Dual Columns | ● Provide stability and support for the testing process ● Ensures precise application of forces. |

| Load Cell | ● Measures the force applied to the material ● Essential for accurate force data recording. |

| Crosshead | ● Applies the tensile force to the material ● Crucial for conducting the stretch or pull tests. |

| Grips or Fixtures | ● Secure the material being tested to the machine ● Prevent slippage and ensure consistent tests. |

| Control System | ● Allows operators to set test parameters and monitor results ● Facilitates controlled experiments. |

| Data Acquisition System | ● Records and analyzes test data ● Provides valuable insights into the material’s behavior (under tension). |

Tensile testers are getting more advanced with time. A study from the Journal of Materials Processing Technology explains testers can now use special cameras to watch how materials stretch and change in real time. This is helpful for engineers, especially when working on important projects like making cars and airplanes.

Differences between Single Column and Dual Column Type Tensile Tester

There are two common types of tensile testers – Single Column and Dual Column Type Tensile Testers. Each type has its specific uses and advantages. Check out the key differences between them:

Structure and Stability

The biggest difference between single-column and dual-column type tensile testers is their structure. As the name suggests, a single-column tensile tester has one vertical support column. On the other hand, a dual-column tester has two.

Due to this structural difference, dual-column testers are more stable and can handle higher loads. That’s why they are ideal for testing larger or more rigid materials.

Single-column testers are often used for smaller, lighter samples.

Load Capacity and Testing Range

As discussed above, dual-column testers can manage heavier loads, which is why they are suitable for a wider range of materials and test types.

In comparison, single-column testers have a more compact design. You should use them for lower-load applications, such as:

- Testing plastics

- Textiles

- Other lightweight materials.

Footprint and Space Requirements

Single-column testers are compact, which is why they should be your first choice if you have limited space. Their smaller footprint allows them to fit into tighter spaces without any hassle.

Dual-column testers, on the other hand, require more room. The reason? Well, because of their larger structure. They are best suited for:

- Larger labs

- Industrial settings

Versatility and Application

Dual-column testers are more versatile because of their higher load capacity. This allows them to test a broader range of materials (from metals to composites).

In our opinion, this versatility is highly useful in research and development. You can easily test a variety of materials without any worry.

Contrarily, single-column testers are more specialized. You can only use them for specific applications (with lower force requirements).

Cost and Maintenance

Single-column testers are generally less expensive. Therefore, they are a cost-effective option for smaller labs or those organizations with budget constraints. Moreover, they also require less maintenance due to their simpler design.

In comparison, dual-column testers can be more costly. They also usually require more frequent maintenance to ensure optimal performance.

Overall, the choice between single-column and dual-column tensile testers depends on the following:

- The specific testing needs

- Available space

Note that single-column testers are ideal for smaller applications, while dual-column testers are better suited for heavy-duty testing.

Which Industries Need Dual Column Type Tensile Testers?

Dual column-type tensile testers are essential in many industries. Experts and researchers use it to test the strength and durability of materials used in critical applications. Let’s look at which industries use it the most:

Aerospace Industry

The aerospace industry relies heavily on Dual column-type tensile testers to ensure the materials used in aircraft and spacecraft can withstand extreme conditions. These testers check the strength of materials like:

- Aluminum

- Titanium

- Composite materials.

The data from these tests help engineers make smart choices about which materials to use and how to improve their designs.

Automotive Industry

Dual column-type tensile testers are also important for automotive industries. They check how strong and stretchy materials like metals and plastics are. Remember that these materials are now used in everything (from car frames to dashboards).

Because of these tests, companies are now making lighter and stronger cars.

Construction and Civil Engineering

Dual column-type tensile testers are also a big part of the construction and civil engineering sectors. They test the strength of materials used in bridges and buildings. Examples are:

- Steel rebar

- Concrete

These tests make sure the materials can handle the weight and stress they’ll face during and after the construction. This helps prevent building failures and ensures the safety of structures.

Textile and Apparel Industry

In the textile and apparel industry, dual column testers are used for high-strength materials like:

- Industrial fabrics

- Webbings

Remember that these materials need thorough testing to ensure they can handle tough conditions. For example, if a company sells camping gear, it first uses dual-column testers to see whether it can tolerate harsh conditions.

Medical Device Manufacturing

Dual column-type tensile testers are super important in the medical device manufacturing industry. They ensure the safety and reliability of biomaterials and medical textiles used in products like:

- Surgical sutures

Energy and Utilities

In the energy and utilities industry, dual-column tensile testers are essential for testing the strength of materials used in power plants and pipelines. These tests help ensure that components like pipes and cables can withstand high pressures and temperatures.

It’s crucial in preventing accidents and ensuring a safe energy supply.

Packaging Industry

Packaging industries rely on Dual column-type tensile testers to test the elasticity of “packaging” materials. You can use them to evaluate the durability of:

- Shipping containers

- Industrial bags

- Different packaging types.

During the tests, experts check whether the materials withstand the stresses of transportation and handling.

Keep in mind that ensuring the integrity of these materials is vital to prevent product damage and loss during shipping.

What Types of Tests Can Dual Column Type Tensile Testers Do?

Dual column-type tensile testers are versatile tools that can perform many tests, including tensile strength, compression, bending, and shear tests. These tests help determine how materials behave under different forces.

Let’s see the details.

Tensile Tests

Dual-column type tensile testers can do various types of tensile tests. The purpose is to:

- Assess the strength

- Check the flexibility of materials under tension.

It’s simple – You pull a sample apart. This helps figure out how much force it takes to break a material and how far it can stretch.

How do Tensile Tests work?

In a tensile test, a material is held by two grips that pull it from both ends. The machine measures:

- How much force is used?

- How much does the material stretch?

The test goes on until the material breaks or changes shape. This helps engineers and scientists understand how strong the material is and how much it can handle before it breaks.

Operation Key Points

- Sample Preparation: It’s important to prepare the sample correctly by making sure it’s the right size and shape. This helps get accurate and reliable results.

- Setting Test Parameters: The machine settings, like speed and force, need to be adjusted based on the type of material being tested.

- Data Collection: The machine measures how much force is applied and how much the material stretches until it breaks.

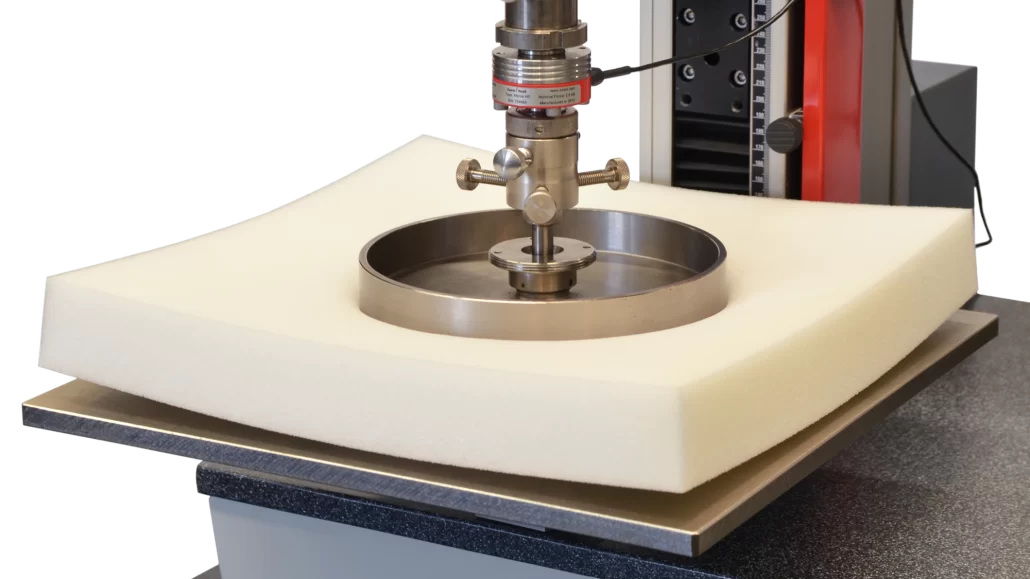

Compression Tests

Compression tests are another common type of test performed by dual-column tensile testers. You simply press a material to measure how much pressure it can withstand before it compresses. It’s suitable to evaluate materials like:

- Foam

- Concrete

- Metals

How do Compression Tests work?

In compression tests, a sample is placed between two plates. The plates then apply pressure and squeeze the material. Then, it measures its resistance to compression.

The data from this test helps engineers design materials that can bear heavy loads without deforming or breaking.

Operation Key Points

- Adjusting Plates: The plates are set based on the size of the sample to make sure the test is done correctly.

- Load Application: The pressure is increased slowly, and the machine notes the highest amount of force the material can handle without changing shape.

- Result Analysis: The results from the test tell us about the material’s strength and how much it can stretch.

Flexural Tests

Flexural tests, also called bend tests, check how well materials like plastics, composites, and metals can handle being bent. These tests are important for materials used in building to see how they hold up under bending pressures.

How Do Flexural Tests Work?

In a flexural test, a sample material is laid horizontally first. Then, a force is applied right in the middle, pushing it down to see how it bends. The test finds out how much force it takes to bend the material. Experts also check if the sample breaks from this stress.

This information helps engineers figure out if the material is good for construction or not.

Operation Key Points

- Fixture Setup: The material is placed on two supports, and the force is applied to the middle.

- Load Application: The force is slowly increased until the material either bends or breaks.

- Observations Recorded: The test measures how far the material bends under the load, helping to understand its strength and stiffness.

Shear Tests

Shear tests are done to check the strength and durability of joints and bonds. You do them to measure how well a material can handle forces that try to slide its layers apart.

How do Shear Tests Work?

During a shear test, a tester applies force to a material and tries to slide its layers horizontally. The test measures the amount of force needed to initiate this sliding. This data is essential for designing durable and reliable joints and adhesives.

Operation Key Points

- Sample Orientation: The material is positioned so the force hits it sideways.

- Force Application: Force is applied until the material either breaks or changes shape significantly.

- Data Interpretation: The strength of the material against shearing is calculated from the force applied and the stressed area.

Note that every test ensures our safety. Therefore, we should thank Dual column-type tensile testers.

Famous Dual Column Type Tensile Testing Machine Manufacturers

Top brands like Instron make some of the best dual-column tensile testers out there. These companies are known for their reliable and powerful machines that help ensure materials are strong and safe.

Let’s take a look at some of the most reputable manufacturers in the industry:

| Company | Founded | Key Features | Industries Served |

| Instron | 1946 | ● Cutting-edge technology ● Customizable solutions ● Comprehensive after-sales support | Aerospace, Automotive |

| ChiuVention | 2012 | ● Exceptionally user-friendly ● Durable, smart design ● Continual technological innovation | Textiles, Plastics, Metals |

| ZwickRoell | 1854 | ● Extensive range of machines ● High precision | Textiles, Plastics, Metals |

| MTS Systems | 1966 | ● Versatile testing capabilities ● Advanced features like high-resolution load cells ● Global customer support | Engineering Research, Material Development |

| Tinius Olsen | 1880 | ● Over 140 years of expertise ● Versatile application range ● Innovative technology and client-focused solutions | Aerospace, Electronics, Construction |

The Average Price of a Dual Column Type Tensile Tester

When you’re looking to buy a dual-column type tensile tester, you’ll notice the prices can be quite different depending on what you need. Don’t worry; we’re here to help. Check out this table:

| User Type | Price Range | Features | Suitable For |

| Beginners/Basic Needs | $10,000 – $20,000 | Basic models | Small labs, Schools |

| Intermediate Needs | $20,000 – $50,000 | Handles more weight | Larger labs, Versatile companies |

| High-End Industrial | $50,000 – $100,000+ | Handles heavy loads, automated testing, precision measurements | Aerospace, Automotive, Major Research Labs |

So, when you’re choosing a dual-column type tensile tester, think about what you’ll be using it for. A basic model is right for you if you don’t need anything fancy.

How Can You Select the Appropriate Dual Column Type Tensile Testing Machine?

You can select the right dual-column type tensile testing machine by understanding your specific testing requirements. It’s super easy. Here’s how to do it:

Assess Your Material Testing Needs

The first step is all about asking yourself questions. The top ones are:

- What types of materials you will be testing

- What kind of tests do you need to perform?

Note: Each material has different strength and flexibility requirements, so the machine you choose needs to match these.

Evaluate Machine Specifications

Once you know what you need from a tensile testing machine, the next thing to do is get the machine. For this, it’s better to compare the specifications of various models to find one that matches your requirements.

Consider Additional Features and Technology

It’s always a good idea to purchase a tester that has additional features. Here’s what we suggest:

| Technology Feature | Description |

| Automated Testing Capabilities | Machines with automated options save time and reduce errors during testing. |

| Data Management and Analysis Tools | Look for machines with integrated software to manage and analyze test data effectively. |

| Customization Options | Some machines can be customized to meet specific testing requirements or adapted for various tests. |

Budget and After-Sales Support

Your budget is important. If you have limited funds, look for affordable testers. Remember to compare prices across different brands.

Also, remember that the cost isn’t just about buying the machine. Maintenance, calibration, and technical support can add up. Therefore, we suggest thinking about these long-term costs too.

That’s all. Now, you can make better decisions and get the right tester for yourself.

Final Thoughts

In conclusion, Dual-column type tensile testers are versatile machines that test the strength and flexibility of different materials. Here’s what you should remember about dual-column type tensile testers:

- Versatile Uses: They can perform various tests, including tensile, compression, and peel tests.

- Essential for Safety: These machines ensure products meet safety standards.

- Range of Prices: They can cost from $10,000 to over $100,000, depending on the features and capacity.

- Important for Many Industries: Used in aerospace, automotive, construction, and more.

- Choosing the Right One: When selecting a tester, consider your testing needs, load capacity, features, space, budget, and manufacturer reputation.

Now, you have a complete guide to dual-column type tensile testers. Remember all the crucial points and get a tester that suits you best.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com