Textiles suffer many types of damage in daily use. Tensile, compression, bending, and friction cause the most important effects. These forces lead to fracture, tearing, and breaking. So, the textile’s tensile, tearing, and breaking properties directly affect the product’s durability. They also determine the textile’s quality. Tensile strength testing assesses the basic properties of textiles….

The test simulates how textiles keep their color. It does so under different conditions. Many types of colour fastness tests exist. These include soap, water, sweat, and light resistance. But, the tests differ in how they sample. Different staff take samples differently, even with the same test method. Habits, judgment, and other factors affect their…

“The Digital Future of Textile Testing”, “Start Smart Testing”, and “Designed in Germany, Manufactured in China” — If you have been following ChiuVention, you should be familiar with these slogans. Since the beginning of our smart transformation in 2020, ChiuVention has made some achievements in the field of smart textile testing over the past four years….

Functional clothing is increasingly popular. Cool textile technology has matured. So, the cool textile function is now practical. The relevant departments made two product standards. They aim to regulate the market and assess cool textiles. One is FZ/T 73067-2020 “contact cool knitted garments”. The other is FZ/T 62042-2020 “cool fabric bedding”. Both standards started on…

In life, you may find that some fabrics are warm to the touch and some are cool to the touch. The specific heat capacity of pure substances varies. This is understandable. But, some clothing fabrics are the same substance in a different form. Why do people feel such a big temperature difference? In terms of…

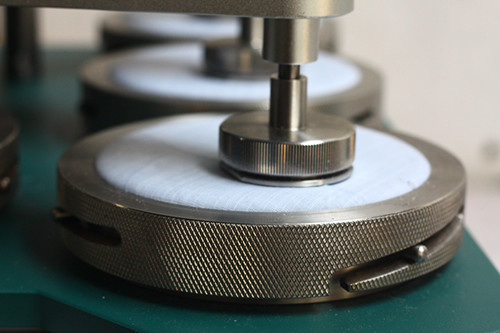

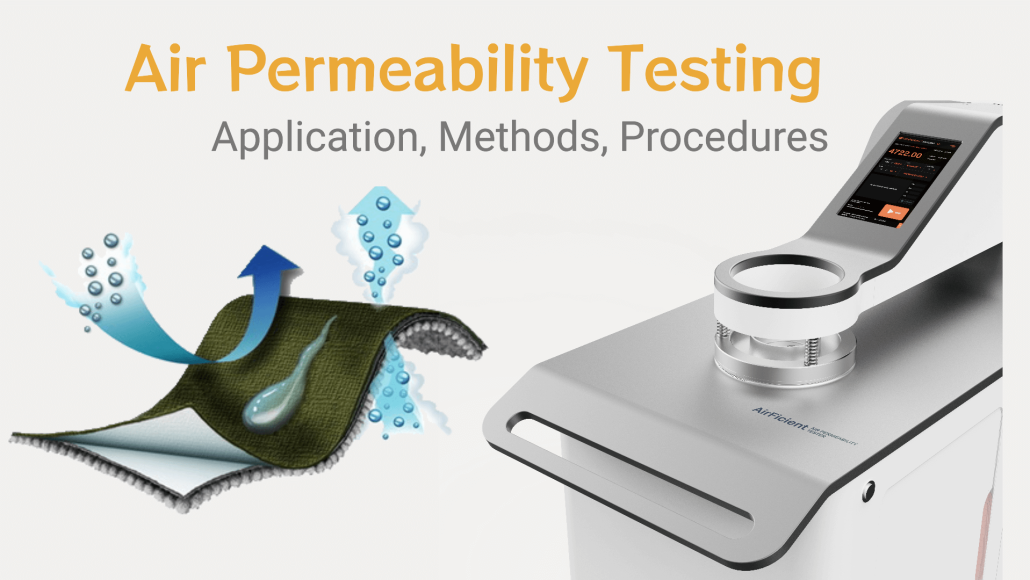

As the weather turns warmer, the temperature rises. People wear thinner clothes. They wear fewer of them. This makes air permeability especially important! Good, breathable clothes can evaporate body sweat. So, fabric breathability is key to fabric comfort. Application of air permeability in textile industry Garment industry: Air permeability is an important comfort indicator for…

Have you ever seen the scene pictured below while watching a sporting event? Isn’t it a great body? Isn’t it wild? Today, we’ll focus on the clothes, not the athletes’ looks. The clothes were “violently” torn during the game. This happens to us in our daily lives. It happens when we are driving or doing…

Imagine this: when you go out in summer, you can’t avoid sweating. Even with enough sun protection. If the sweat on your clothes can’t evaporate in time, your skin will be sticky and uncomfortable. No, if you wear a quick-drying T-shirt, sweat will evaporate right away. Then, you will be in a good mood! Therein…

The footwear industry occupies a pivotal position in the light industry sector. In 2017, the world made 23.5 billion pairs of shoes. China made 13.523 billion pairs, 57.5% of the total. Since 2012, Nike created Computerized Flat Knitting Upper. They named it the well-known Flyknit. The technology was first for knitting jumpers. It was quickly…

Air permeability is one of the fundamental requirements for comfort in clothing. Since the perception of air permeability is more subjective than rational, how can we effectively evaluate and test it? Introduction Have you ever wondered what makes your favorite sportswear so breathable or how medical masks manage to be both protective and comfortable? The…