What is the ASTM D4966-22 Test Standard?

ASTM D4966-22 is a standard test method developed by the American Society for Testing and Materials (ASTM) in order to assess the abrasion resistance of textiles. Of course, this Martindale test method is rapidly used in various industries, such as automotive, textiles, and aerospace, to assess the performance and durability of various materials under abrasive conditions. Now, we will share the complete guide of ASTM D4966-22 for the Abrasion Resistance Test.

The Martindale test method outlined in ASTM D4966-22 includes subjecting the test specimen to control mechanism abrasion using a specialized abrasive material and apparatus. The material is being tested, often placed on a rotating disc or drum, and then abrasive action is applied over the rotation of it. Well, the test specimen is mattered to be predetermined number of processes or else until a certain level of wear is reached.

Throughout the test, the amount of material lost because of abrasion is measured and recorded. This loss of material is indicative of the material’s resistance to wear and abrasion. In addition, the appearance of the test specimen beforehand and afterward testing may be improved to assess modification in surface characteristics such as color, texture, or gloss.

ASTM D4966-22 offers guidelines for the choice of test parameters that consist of abrasive material, test speed, and then the duration of the test, ensuring reproducibility and consistency of results over various testing labs. Of course, these standards also specify the strategies for conditioning test specimens before testing to ensure uniformity in the testing conditions.

Generally, ASTM D4966-22 acts as the best tool for researchers and manufacturers to objectively find out the abrasion resistance of textiles and various other materials that aid in the development of products, performance optimization, and quality management. Well, compliance with standards makes that materials meet the necessity of durability for their intended applications.

The Test Principle of ASTM D4966-22

The principle behind ASTM D4966-22 includes subjecting a test specimen to manage mechanical abrasion to stimulate wear and tear that experienced overuse. The test goal is to assess the resistance of the material to abrasion and then predict its durability in real-world applications.

The Martindale test specimen, often a textile fabric or else other material, is securely placed onto a rotating drum within a Martindale abrasion tester. An abrasive material consisting of emery cloth or sandpaper is then applied over the specimen surface with a specific force and then under controlled conditions. This specimen moves into several cycles and then until a specific level of wear is reached.

Over the test, the amount of material lost because of abrasion is quantified frequently by measuring the weight loss or thickness of the Martindale test specimen. In addition, the surface and appearance characteristics of the specimen evaluated include changes in color and texture.

By systematically evaluating the material to abrasion underneath normal conditions, ASTM D4966-22 lets manufacturers and researchers compare the abrasion resistance of various materials considerably. This data aids in selecting the materials for specialized applications and ensures the product is quality and longevity.

This article focuses on the details of ASTM D4966-22 standard testing for Martindale abrasion test method, if you want to learn more standards guide, please go to this page: Abrasion Testing: Summary Of National Standards, Fabric Types

The Application of ASTM D4966-22 Test Standard

The ASTM D4966-22 test holds great importance across various industries in which materials are concerned with abrasion in their applications. Its application spans from textiles to automobile and aerospace, wherein durability and performance below abrasive situations are indispensable elements. Let’s discover how this preferred is applied in special sectors:

- Textiles industry

In the fabric industry, ASTM D4966-22 is widely used to assess the abrasion resistance of fabric, along with apparel, upholstery, and technical textiles. For clothing manufacturers, it is crucial to ensure that fabrics can face up to repeated friction against surfaces without excessive wear, pilling, or tearing. This widespread lets in decide on suitable materials for various garment applications, along with workwear, sportswear, or outdoor tools.

- Automobile Sector

Abrasion resistance is critical for car textiles, consisting of seat covers, carpets, and interior trim substances. ASTM D4966-22 is employed to assess the sturdiness of these materials in opposition to abrasion attributable to elements like passenger motion, friction from objects, or contact with cleaning retailers. By way of testing automobile textiles in line with this general, producers can make sure that materials meet great requirements and maintain their look and capability over the car’s lifespan.

- Aerospace industry

In the aerospace industry, materials are regularly subjected to abrasive situations as a result of factors like friction throughout flight, maintenance activities, or exposure to harsh environments. ASTM D4966-22 is applied to evaluate the abrasion resistance of aerospace textiles, composites, and coatings utilized in components, which include seating, insulation, and cargo liners. Through testing materials towards this popular, aerospace producers can ensure the reliability and durability of aircraft interiors and outdoor additives.

- Sporting goods and outdoor equipment

Materials utilized in carrying items and outdoor equipment, along with tents, backpacks, and footwear, should withstand abrasive situations encountered throughout outside activities. ASTM D4966-22 helps manufacturers check the sturdiness of textiles, synthetic materials, and coatings utilized in this product. With the aid of engaging in abrasion tests consistent with this general, producers can develop high-overall performance gear that withstands wear and tear, improving user experience and product sturdiness.

- Medical Textiles and Personal Protective Equipment (PPE)

Abrasion resistance is vital for medical textiles utilized in healthcare settings and Personal Protective Equipment (PPE) worn by workers in numerous industries. ASTM D4966-22 is applied to assess the durability of fabrics utilized in surgical robes, drapes, and PPE, together with gloves, masks, and protective clothing. Ensuring ample abrasion resistance aids in keeping the integrity of those materials during use, decreasing the chance of contamination, injury, or premature failure.

- Production and Geotextiles

In the construction industry, materials which include geotextiles, membranes, and shielding covers, are exposed to abrasive conditions throughout set-up, management, and long-term exposure to environmental elements. ASTM D4966-22 is utilized to evaluate the abrasion resistance of those materials, ensuring their sturdiness and effectiveness in applications such as erosion drainage systems and the construction of roads.

- Furniture and fabric

Furnishing fabrics and upholstery materials are subjected to abrasion from each day of use, such as sitting, leaning, and cleaning. ASTM D4966-22 lets producers compare the abrasion resistance of these materials, ensuring that a fixture meets first-class requirements for durability and toughness. By checking out upholstery fabrics in keeping with this popular, furniture manufacturers can choose materials that face up to wear and hold their appearance over time, improving the lifespan of furnishings merchandise.

- Purchaser items and Electronics

Abrasion resistance is likewise vital for consumer items and electronics, composed of protective cases, covers, and digital tool coatings. ASTM D4966-22 is applied to evaluate the durability of those substances towards scrapes, scratches, and diverse varieties of abrasion faced throughout dealing with and normal use. By testing client goods and electronics in step with this trend, producers can make sure the product is excellent and purchaser gratification.

ASTM D4966-22 performs a critical function in various industries via the contribution of a standardized approach for evaluating the abrasion resistance of materials. Its application helps producers pick out suitable materials, ensure product quality, and enhance sturdiness and performance in a wide variety of packages, from textiles and automobiles to aerospace and client items. Compliance with this widespread ensures that substances meet the indispensable durability necessities for their supposed use, contributing to the reliability and toughness of products in various industries.

The Test Material and Test Equipment of ASTM D4966-22

The ASTM D4966-22 test trend specifies requirements for each test material and device used in comparing abrasion resistance. The selection of appropriate materials and equipment is crucial for acquiring correct and dependable take a look at outcomes. Let’s delve into the info on test substances and equipment:

Test materials:

- Specimen: The Martindale test specimen refers to the fabric being evaluated for abrasion resistance. It could be fabric, coatings, laminates, or another material subjected to abrasion in its meant application. Specimens should be consultants of the fabric’s composition, form, and floor end.

- Abrasive cloth: ASTM D4966-22 allows for numerous abrasive materials for use depending on the specific application and material being examined. Not unusual abrasive materials include emery cloth, sandpaper, or abrasive yarns. The choice of abrasive material needs to simulate the abrasive situations encountered by the test cloth in real-world applications.

- Backing material: In some cases, a backing fabric can be used to guide the test specimen for the duration of testing, especially for flexible substances like textiles. The backing fabric should be well-matched with the test specimen and offer enough help without influencing the test results.

Test Equipment:

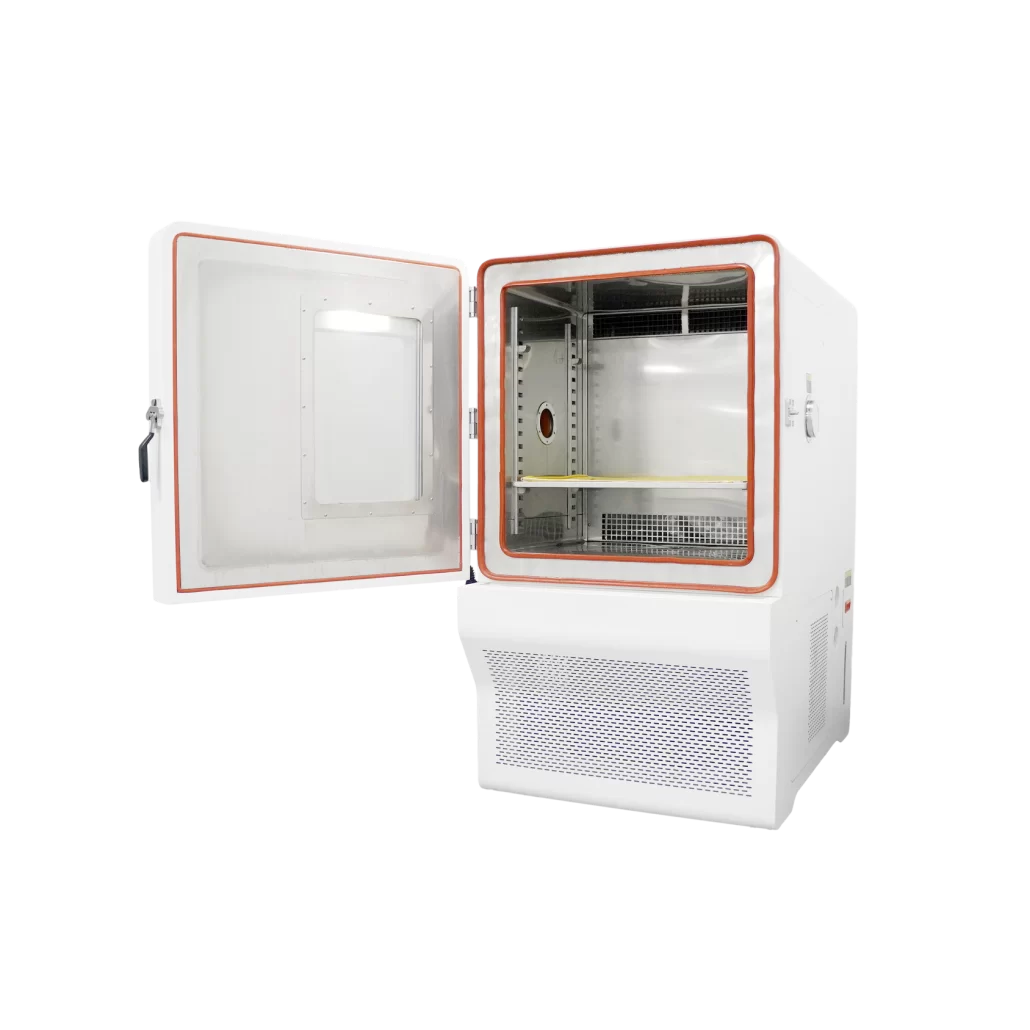

- Abrasion testing machine: The core factor of the test device is the Martindale Abrasion and Pilling Tester, which subjects the test specimen to managed mechanical abrasion. The Martindale machine typically includes a rotating drum or disc, where the check specimen is mounted, and an abrasive surface towards which the specimen is rubbed. Martindale abrasion tester for sale NOW! Get a quick quote below the picture.

- Specimen Holder: The specimen holder safeguards the test specimen onto the rotating drum or disc in the course of testing. It must provide uniform tension and guarantee the right touch between the specimen and the abrasive floor.

- Abrasive Wheel: The abrasive wheel is the thing liable for producing abrasion on the check specimen. It may consist of rough material followed by a rotating drum or disc, or it might be a separate thing that smears abrasive action to the specimen.

- Loading Weight: Some Martindale test equipment includes a loading weight to use a certain force or pressure on the test specimen in the course of testing. The loading weight assures regular contact between the specimen and the abrasive surface, simulating sensible abrasion conditions.

- Manipulate Panel: Current Martindale pilling tester machines are ready with a control panel or interface that lets users set test parameters such as test speed, number of cycles, and abrasive cloth type. The manage panel additionally presentations checks facts and lets in for tracking of test progress.

- Environmental Chamber (If needed): In certain applications, an environmental chamber can be used to manage temperature and humidity conditions during testing. This is particularly applicable for materials subjected to abrasive situations in unique environmental conditions, inclusive of outside textiles or car components.

- Calibration equipment: Everyday calibration of abrasion checking out machines is critical to ensure correct and regular test outcomes. Calibration tools, along with weights, gauges, or reference materials, are used to confirm the accuracy and performance of the Martindale abrasion tester.

Concerns for test materials and equipment choices:

- Material Compatibility: The test materials must be well matched with the abrasive materials and system utilized in trying out to make certain correct and reliable outcomes.

- Representativeness: The test specimens ought to correctly constitute the fabric’s composition, shape, and surface end encountered in real-world applications.

- Trendy Compliance: Well, the choice of test materials and devices needs to comply with the necessities specified in ASTM D4966-22 or other relevant requirements to make certain check validity and reproducibility.

- Precision and Accuracy: The pilling tester machine should be able to manage particular over-test parameters such as test speed, load, and range of cycles to ensure consistency and accuracy in test results.

- Durability and upkeep: Abrasion trying out machines ought to be robust, durable, and easy to keep, ensuring long-term reliability and performance.

In conclusion, you should prepare those for the ASTM D4966-22 Test

Martindale Tester by using a Lissajous figure of 60mm and having a 38 mm sample holder.

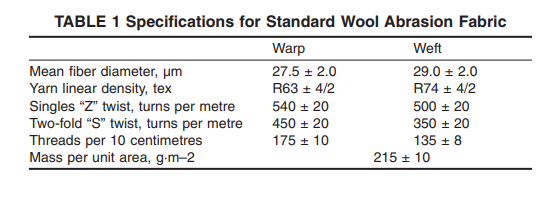

Standard Abradant Fabric, a plain weave, crossbred, worsted wool fabric described in the finished state as in Table 1.

Standard Felt, of mass 750 g ⁄m2 ±50 g/m2 (22 oz ⁄yd2±1.5 oz/yd2) and 3 mm ± 0.3 mm (0.12 in. ± 0.01 in.) thick.

Polyurethane Foam Backing, 3.00 mm ± 0.01 mm(0.12 in. ± 0.04 in.) thick, 29 kg ⁄m3 to 31 kg/m3 (1.81 lbf ⁄ft3to 1.94 lbf/ft3-) density, and 170 N to 210 N (38.23 lbf to 47.22lbf) hardness.

Fabric Punches or Press Cutters,4 38 mm (1.5 in.) and 140 mm (5.5 in.) in diameter.

AATCC Gray Scale for Color Change if needed.

ASTM D4966-22 specifies requirements for each test material and machine used in comparing abrasion resistance. Careful selection of suitable materials and systems is critical for obtaining accurate and dependable test results, ensuring that the examined substances meet the fundamental durability requirements for their intended application. Compliance with general procedures and best practices is essential to achieving constant and reproducible Martindale test results throughout extraordinary testing laboratories.

The Sampling Requirement of ASTM D4966-22

Sampling is a typical factor of any testing method, together with ASTM D4966-22 for abrasion resistance. Proper sampling assures that the test results correctly constitute the performance of the fabric being evaluated. Here, let’s discover the sampling necessities mentioned in ASTM D4966-22:

- Sample size:

ASTM D4966-22 guides the minimal sample size required for testing. The pattern size needs to be enough to yield statistically significant results.

The standard recommends the use of a couple of specimens for testing to account for variability in the cloth and make certain consultant results.

- Random Sampling:

Samples should be decided randomly from the fabric lot or production batch to make certain independent illustrations.

Random sampling limits the ability for sample selection bias and assures that the test results apply to the whole population of materials.

- Homogeneity:

Earlier than checking or testing, it is vital to ensure the homogeneity of the fabric batch. This includes verifying that the material homes are steady all through the batch.

If the material reveals variations in properties consisting of composition, thickness, or surface finish, suitable measures ought to be taken to address these versions or account for them at some stage in testing.

- Circumstance of Samples:

Samples must be in an appropriate situation for Martindale abrasion testing, free from any defects or infection that might affect the test outcomes.

Before testing, specimens may additionally go through conditioning to obtain standardized moisture content or environmental situations as targeted in general.

- Representative Sampling:

The samples selected for testing ought to be consultants of the fabric’s supposed use and alertness.

Factors along with material composition, shape, surface finish, and production variability should be considered while choosing samples to ensure that the test effects appropriately reflect real-world performance.

- Rejection standards:

ASTM D4966-22 may stipulate criteria for rejecting samples that do not meet certain quality or overall performance requirements.

Samples that showcase large defects, deviations from specifications, or other abnormalities can be rejected to ensure the integrity of the test results.

- Documentation:

Well, proper documentation of the sampling system is typical for traceability and quality guarantee.

Records need to include details including pattern identification, source, sampling method, sample size, and any applicable records about sample choice and handling.

- Storage and handling:

Samples have to be stored and handled in a system that prevents harm, contamination, or degradation.

Proper storage factors, consisting of temperature, humidity, and publicity to light, need to be maintained to hold the integrity of the samples until testing.

- Reproducibility:

To ensure the reproducibility of Martindale test results, samples ought to be handled and examined constantly throughout specific checking-out sessions or laboratories.

Standardized processes for sample practice, address, and testing assist in limiting variability and ensuring those results are similar and reliable.

Finally, sampling is an essential step within the ASTM D4966-22 testing system for abrasion resistance. Right sampling strategies help make sure that the Martindale abrasion and pilling test results correctly reflect the overall performance of the fabric being evaluated and are representative of its intended use and alertness. Compliance with standardized sampling protocols facilitates and improves the reliability, reproducibility, and validity of test results, supporting knowledgeable choice-making in fabric selection, product improvement, and quality assurance efforts.

The Test Procedure of ASTM D4966-22

The test technique outlined in ASTM D4966-22 provides a consistent technique for comparing the abrasion resistance of substances. Right here’s a top-level view of the important thing steps involved in accomplishing the test:

Preparation of test specimen:

- Reduce the test specimen into uniform pieces according to the size unique within the preferred.

- Make sure that the specimens are free from any defects, infections, or irregularities that might affect the test consequences.

- If vital, condition the specimens to reap standardized moisture content or environmental conditions as per the necessities of the same old.

Mounting of Specimen:

- Securely mount the fabric abrasion test specimen onto the rotating drum or disc of the abrasion trying-out machine.

- Ensure that the specimen is located flat and calmly on the surface of the drum or disc to facilitate uniform abrasion.

Choice of Abrasive fabric:

- Pick the ideal abrasive cloth based on the application and fabric being examined.

- Make sure that the abrasive material is well matched with the test specimen and may simulate the abrasive situations encountered in real-world use.

Utility of erosion:

- Begin the Martindale test machine and apply the abrasive material toward the surface of the test specimen.

- Manipulate the test parameters which include test speed, load, and quantity of cycles according to the necessities distinctive within the popular.

- Monitor the test progress to make certain consistent and uniform abrasion across the entire floor of the specimen.

Key Points:

On each testing table place a piece of felt, approximately 140 mm (5.5 in.), followed by a piece of the standard abradant fabric of the same size. Place the mounting weight on the table to flatten the fabric/felt pieces. Secure the fabric/felt to the table with the mounting weight in place then remove the weight and inspect for tucks or ridges. If necessary, repeat the mounting process.

Assemble the holder by placing the specimen face down into the specimen holder. For fabric having a mass/unit area less than 500 g/m(14.7 oz/yd2) place a 38 mm (1¼ in.) disk of polyurethane foam between the specimen and the metal insert. Assemble the holder according to the manufacturer’s instructions.

Place the assembled holder on the machine above the table with the fabric/felt pieces and add the required weight to give a pressure on each specimen of 9 kPa ±0.2 kPa (1.31 psi±0.03 psi) for apparel fabrics and 12 kPa±0.3 kPa(1.74 psi±0.04 psi) for upholstery fabrics.

Assessment of wear and tear:

- Periodically examine the test specimen for signs of damage and harm at some stage in testing.

- Measure the amount of material loss on account of abrasion, typically by means of weighing the specimen earlier than and after testing or measuring thickness reduction.

- Document the test records, together with the range of cycles completed and any observations concerning modifications in the advent or properties of the specimen.

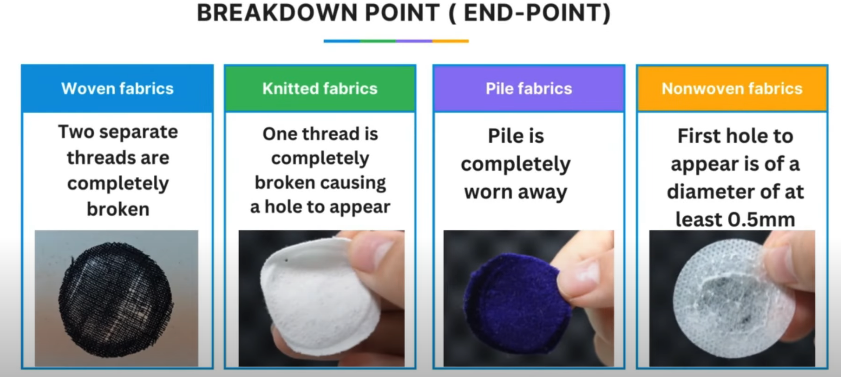

Endpoint standards:

- Determine the endpoint of the test based totally on predefined criteria, which include achieving a distinctive level of damage or finishing a predetermined quantity of cycles.

- If imperative, conduct extra testing or analysis to assess the performance of the fabric underneath different situations or examine precise homes of interest.

Reporting of effects:

- Assemble the test results, together with measurements of material loss, observations of specimen circumstance, and any other applicable data.

- Prepare test data documenting the Martindale test process, outcomes, and any deviations from the standard protocol.

- Consist of relevant info such as sample identity, testing conditions, device used, and any unique considerations or precautions taken all through testing.

By following the standardized test system outlined in ASTM D4966-22, manufacturers and researchers can appropriately compare the abrasion resistance of materials and make knowledgeable selections regarding cloth selection, product improvement, and satisfactory guarantee. Consistent adherence to the check protocol facilitates ensuring reproducible and reliable test results, assisting the development of durable and high-overall performance materials for various applications.

The Evaluation of Test Results

After engaging in the ASTM D4966-22 abrasion resistance test, the assessment of the test result is necessary to determine the fabric’s overall performance and suitability for its supposed application. Right here’s how the Martindale rub test results are commonly evaluated:

- Material Loss dimension: Calculate the amount of cloth misplaced on account of abrasion by evaluating the specimen’s weight or thickness before and after checking out. A better material loss suggests lower abrasion resistance.

- Visible Inspection: Check the test specimen for any visible signs of wear, including pilling, fraying, or surface damage. Note any changes in look or texture, as they will indicate the cloth’s capability to face up to abrasion.

- Assessment to acceptance standards: Compare the Martindale test results to acceptance standards targeted by relevant standards or industry specs. Determine whether or not the fabric meets the required overall performance standards for abrasion resistance.

- Statistical analysis: You have to conduct statistical evaluation, if relevant, to evaluate the variety of Martindale abrasion test results and decide the confidence level within the acquired records. Statistical techniques inclusive of calculating mean values, fashionable deviations, and confidence intervals can offer insights into the consistency and reliability of the test results.

- Interpretation and decision-making: Interpret the test results within the context of the material’s intended use and alertness necessities. Decide whether or not the material’s abrasion resistance meets the desired overall performance criteria and make choices concerning fabric choice, product design, or quality control measures primarily based on the evaluation.

Finally, the assessment of check consequences involves a comprehensive analysis of material loss, visible inspection, evaluation of reputation standards, and statistical analysis to evaluate the material’s abrasion resistance appropriately. This assessment procedure guides decision-making and helps make sure that materials meet the indispensable sturdiness requirements for their intended applications.

For more information on Martindale test methods/standards

or martindale abrasion tester price, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com