What Are the Common Cotton Testing Items and Test Instruments?

Cotton testing is a crucial part of the textile industry that ensures the quality and performance of cotton fibers. Various parameters are assessed to determine the suitability of cotton for multiple applications from fiber strength to length. Here are some of the common testing items and then instruments used in cotton testing.

Fiber Length and Length Uniformity

One of the crucial parameters in cotton testing is fiber length and its uniformity. Well, various instruments like the High Volume Instrument (HVI) and the Advanced Fiber Information System (AFIS) are frequently used for this purpose. Well, the HVI instruments measure fiber length, length uniformity, and then various other important characteristics consisting of micronaire, color grade, maturity ratio and so more. AFIS is another important instrument that offers detailed information regards fiber length distribution, fineness and maturity, and then short fiber content.

Fiber Strength

Fiber strength is another crucial aspect of cotton quality. Instruments such as the single fiber strength tester and the Stelometer are employed to gauge fiber strength. These instruments apply tension to individual fibers as they break offering valuable information into the strength properties of cotton.

Micronaire

Micronaire is known to be the fineness and maturity of cotton fibers and is a needed parameter for assessing spinning performance. It is measured using instruments like the Micronaire meter that determines the air permeability of a sample of cotton. It helps in classifying cotton fibers into various quality grades regarding their fineness.

Moisture Content

Moisture content expressively affects the processing and storage of cotton fibers. The instruments consisting of the moisture meter are used to measure moisture content samples accurately. Well, maintaining the correct level is needed to prevent mold growth, lessen fiber breakage, and then ensure the fineness of the fiber textile products.

Trash Content

It is known to be non-lint materials available in cotton that consist of stem, leaf, seed coat fragments, and then various other impurities. Thus, a high amount of trash content can adversely affect the quality of yarn and processing efficiency. Instruments such as the Shirley analyzer and the HVI are most commonly used to determine the trash in the cotton samples.

Color Grade

It is a highly crucial quality parameter in cotton, specifically for applications wherein color consistency is crucial, like the production of dyed textiles. Colorimeters or color vision systems are common instruments used to measure the grade of color accurately. These instruments quantify the color elements such as hue, saturation, and brightness and enable precise color grading.

Fiber Fineness

Fiber fineness also refers to being micronaire. It influences the spinning process and the quality of the final yarn. Various instruments like Fibograoph and AFIS measure the fineness of fiber by analyzing the fiber diameter and cross-sectional area. Thus, correct assessment of fiber quality helps in selecting the appropriate cotton types for specific textile applications.

Foreign Matter

Foreign matter in cotton refers to any minor material present in the fiber sample like grease, dirt, or else. Shirley Analyzer and the High Volume Instrument (HVI) is a common instrument used to measure the foreign matter content in cotton samples. Lessening foreign matter is needed in order to ensure the quality and purity of the products.

Finally, cotton testing includes various kinds of parameters needed for evaluating the quality and performance of cotton fibers. Well, different testing items and instruments are used to assess multiple aspects of cotton quality reliably, from length and strength to micronaire and then color grade. By using these tools easily, the textile manufacturer can ensure the production of high-quality textiles that meet the needs of consumers and then industry standards.

What Are the Common Fiber Testing Items and Test Instruments?

Within the textile industry, fiber testing is essential to ensure the excellent, performance, and suitability of fibers for various applications. There is no matter whether it is natural or artificial, fibers undergo rigorous trying out to assess parameters together with strength, fineness, elongation, and purity. Let’s explore the common fiber testing items and contraptions used in textile manufacturing:

Fiber Length and Diameter

Fiber term and diameter are imperative parameters influencing yarn power and cloth appearance. Longer fibers usually produce smoother and more potent yarns, even as finer fibers contribute to cloth softness and drape. The testing method includes the usage of fiber period and diameter analyzers, microscopic evaluation, and guiding measurement strategies.

Tenacity and Elongation

Fiber tenacity refers to its most tensile power, measured in force per unit cross-sectional area. Elongation represents the proportion increase in fiber length before breaking under tension. Those parameters decide the fiber’s capability to face up to stress at some point of processing and cease use. Tensile testing machines are commonly used to measure fiber tenacity and elongation as they should be.

Fiber Fineness

Fiber fineness, frequently expressed in denier or tex, indicates the thickness or diameter of individual fibers. Finer fibers contribute to smoother and extra costly fabrics, while coarser fibers are used for heavier textiles. Contraptions along with fineness testers or microscopes are employed to measure fiber fineness correctly.

Fiber Crimp

Fiber crimp refers back to the natural waviness or curliness of fibers, which influences yarn elasticity and fabric texture. Crimped fibers tend to lure air, presenting insulation and loftiness to textiles. Crimp testers determine the frequency and amplitude of fiber crimp, necessary for predicting material properties.

Fiber Purity

Fiber purity denotes the absence of contaminants or impurities within the fiber cloth. Impurities can negatively affect yarn fantastic, leading to defects and processing difficulties. Purity testing involves visual inspection, microscopic evaluation, and chemical exams to pick out the foreign matter in fibers.

Common Fiber Testing Instruments

Fiber Length and Diameter Analyzer

Those instruments gauge the length and diameter of individual fibers using image evaluation or optical strategies. Automated fiber analyzers provide accurate and speedy effects, facilitating quality management in fiber processing.

Tensile Testing Machine

Tensile testers observe managed tension to fibers till they smash, measuring parameters that include tenacity, elongation, and modulus. Those machines are quintessential for comparing fiber power and overall performance in diverse textile applications.

Fineness Tester

Fineness testers decide the linear density of fibers by measuring mass in step with unit duration. Instruments just like the microscope or airflow resistance testers are commonly used for fiber fineness evaluation.

Crimp Tester

Crimp testers verify the crimp frequency, amplitude, and form of fibers. They utilize specialized mechanisms to simulate fiber bending and degree crimp characteristics correctly.

Fiber Purity Analyzer

Purity analyzers rent strategies which include spectroscopy, microscopy, and chemical analysis to come across impurities in fibers. Those devices assist ensure the integrity and best of raw materials used in fabric manufacturing.

Fiber testing is essential to the textile industry, allowing producers to supply outstanding and performance-driven textiles. By evaluating parameters consisting of fiber length, power, fineness, crimp, and purity, manufacturers can optimize processing strategies and enhance product traits. Using superior checking devices guarantees accuracy, reliability, and consistency in fiber assessment, in the end contributing to the fulfillment and competitiveness of fabric groups. In the ever-evolving landscape of fabric production, investing in complete fiber checking-out methodologies remains imperative for assembly customer expectancies and industry standards.

What Are the Common Yarn Testing Items and Test Instruments?

In the textile industry, yarn testing serves as a top for ensuring the quality, overall performance, and suitability of yarns across numerous applications. Yarns, which are the building blocks of fabrics, must go through rigorous testing to meet stringent industry standards and customer needs. From assessing strength and evenness to evaluating twists and counting, comprehensive yarn testing is essential for fabric producers to produce top-notch textiles. Let’s delve into the common yarn-testing devices and instruments utilized in textile manufacturing.

Yarn Strength

Yarn strengths are a fundamental parameter that regulates its ability to resist mechanical pressure at some stage in numerous production procedures and end-use applications. Yarns with inadequate power can also damage all through weaving, knitting, or garment production, leading to defects and reduced product sturdiness.

Yarn Evenness

Evenness refers to the uniformity of yarn thickness along its duration. Irregularities in yarn evenness can bring about cloth defects such as streaks, slubs, or variations in texture. Considering regular yarn evenness is vital for generating tremendous fabrics with uniform look and performance.

Yarn Twist

Yarn twist performs an indispensable role in figuring out material traits together with strength, drape, and texture. Different types and degrees of twist are suitable for diverse yarns and fabrics. Assessing yarn twists should enable manufacturers to reap favored material homes and make certain consistency in product quality or fineness.

Yarn Matter

Yarn count, additionally known as linear density, suggests the mass in keeping with a unit duration of yarn. It directly influences fabric weight, thickness, and appearance. Constant yarn count is vital for producing textiles with uniform characteristics and assembly of exact material necessities.

Yarn Hairiness

It refers back to the presence of protruding fibers or fuzz on the floor of the yarn. Excessive yarn hairiness can affect material appearance, texture, and processing performance. Minimizing yarn hairiness is necessary for producing high-quality fabric with easy surfaces and top-of-the-line overall performance.

Common Yarn Testing Instruments

Tensile Testing Machine

Tensile trying-out machines follow managed tension to yarn samples till they damage, making an allowance for the dimension of braking pressure, elongation, and modulus. Those machines offer treasured statistics on yarn strength and performance, permitting producers to optimize yarn choice and processing parameters.

Evenness Tester

It measures the variant in yarn diameter or mass at one-of-a-kind factors along its length. These devices assist in quantifying yarn evenness and identify irregularities that could affect material fineness. Advanced evenness testers offer particular measurements, facilitating fantastic control in yarn production.

Twist Tester

Twist testers quantify the twist stage of yarn by way of counting the wide variety of twists in keeping with unit length. Those devices ensure consistency in yarn twist, which directly impacts fabric traits such as electricity, drape, and texture. Correct twist testing permits producers to produce textiles with preferred properties and overall performance.

Wrap Reel or Electronic Yarn Tester

Wrap reels or Electronic yarn testers’ degree yarn count with the aid of winding a precise length of yarn and weighing it. Those instruments provide unique measurements of yarn count, permitting manufacturers to produce textiles with consistent fineness and unique material traits.

Hairiness Tester

Hairiness testers measure the range and length of sticking-out fibers on the yarn surface. Through quantifying yarn hairiness, those devices assist producers in optimizing spinning procedures and limiting defects in finished fabrics. Reduced yarn hairiness contributes to step-forward material first-rate and processing efficiency.

Yarn testing is fundamental for ensuring the quality, performance, and consistency of textiles in the textile industry. By employing complete checking of objects and instruments, manufacturers can produce extremely good yarns that meet stringent industry requirements and consumer necessities. Investing in advanced testing technologies and methodologies enables fabric organizations to enhance product fantastic, optimize manufacturing techniques, and keep competitiveness within the worldwide marketplace.

What Are the Common Fabric Testing Items and Test Instruments?

Fabric testing is fundamental in the textile industry to ensure the quality, performance, and durability of fabric for numerous applications. From assessing physical properties like tensile strength and abrasion resistance to evaluating colorfastness and dimensional balance, complete fabric testing helps producers meet industry requirements and purchaser expectations. Let’s discover the not unusual material testing items and instruments utilized in textile production:

Tensile Strength

Tensile strength measures the maximum force a fabric can withstand earlier than breaking or tearing. It is critical for assessing fabric sturdiness and suitability for particular applications, including garb, home textiles, and technical textiles.

Tear Strength

Tear strength evaluates a fabric’s resistance to tearing or propagation of a tear. It is essential for assessing cloth performance in programs in which tear resistance is necessary, which includes shielding apparel and outside equipment.

Abrasion Resistance

Abrasion resistance measures a fabric’s capability to endure surface wear and damage on account of rubbing, friction, or repeated use. It is far particularly essential for fabrics used in upholstery, car interiors, and outdoor programs.

Colorfastness

Colorfastness refers to a fabric’s potential to retain its color while exposed to various external factors such as light, washing, and rubbing. Assessing colorfastness ensures that fabrics hold their look and shade intensity through the years.

Dimensional Stability

Dimensional balance evaluates a fabric’s ability to keep its authentic shape and length all through use and laundering. It is essential for preventing shrinkage, stretching, or distortion of fabric after washing or exposure to moisture.

Pilling Resistance

Pilling resistance measures a material’s resistance to the formation of drugs or small balls of fibers on its floor. It is fundamental for maintaining cloth appearance and texture through the years, in particular in garments and upholstery fabrics.

Water Repellency and Breathability

Water repellency assesses a material’s ability to withstand the penetration of water, at the same time as breathability measures its capability to allow moisture vapor to get away. These residences are imperative for outside and performance fabric utilized in rainwear, sportswear, and activewear.

Common Fabric Testing Instruments

Tensile Testing Machine

Tensile Testing Machines practice managed anxiety to fabric samples to degree tensile power and elongation. These machines offer precious facts on fabric performance and durability, enabling producers to ensure product fantastic and consistency.

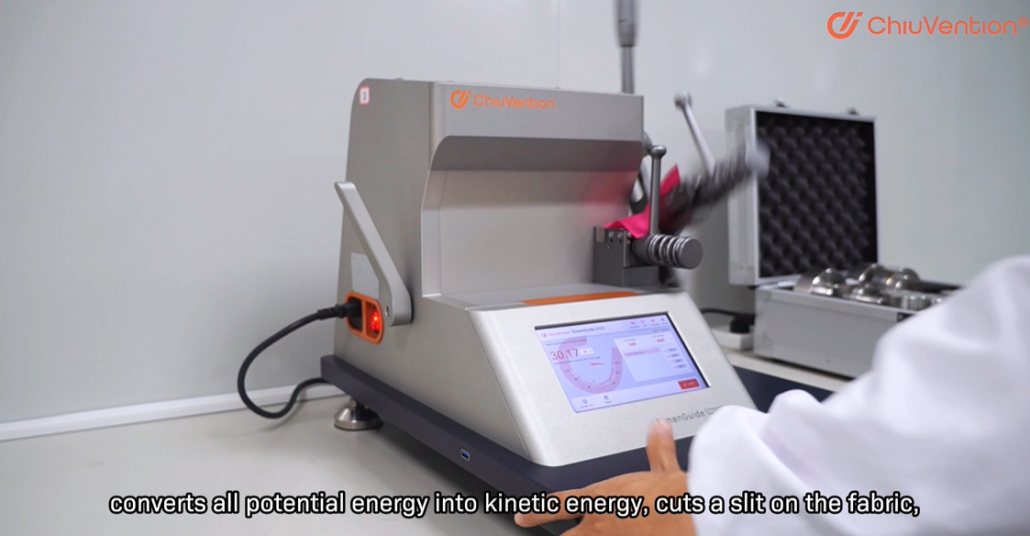

Tear Power Tester

Tear Power testers measure the pressure required to rip a cloth specimen. These instruments evaluate material tear resistance and assist manufacturers assess cloth suitability for particular applications.

Martindale Abrasion Tester

Martindale abrasion testers simulate floor wear and abrasion by rubbing fabric specimens against a preferred abrasive floor. Those instruments quantify fabric abrasion resistance and assist manufacturers in determining product sturdiness and lifespan.

Colorfastness Tester

Colorfastness Testers examine fabric colorfastness to different factors such as mild, washing, and rubbing. These contraptions use standardized take a look at strategies to evaluate color retention and ensure fabric quality and appearance over time.

Dimensional Stability Tester

Dimensional stability tester gauges adjustments in fabric dimensions after washing or exposure to moisture. These devices help producers investigate material shrinkage, stretching, or distortion and make sure the product is good and consistent.

Pilling Tester

Pilling testers simulate cloth pilling by subjecting specimens to friction and abrasion. Those devices or instruments quantify fabric pilling resistance and help manufacturers expand fabric with an advanced look and durability.

Hydrostatic Head Tester and Moisture Vapor Transmission Rate (MVTR) Tester:

Hydrostatic head testers measure the resistance of a fabric to water penetration, whilst MVTR testers verify their breathability by gauging moisture vapor transmission rate. Those contraptions are integral for evaluating the overall performance of waterproof and breathable fabrics utilized in outside and overall performance clothing.

The fabric trying out is indispensable for ensuring the quality, overall performance, and sturdiness of textiles in the fabric industry. By completely trying out gadgets and instruments, producers can determine fabric properties as they should be and ensure compliance with industry requirements and consumer necessities. Of course, investing in superior testing technology and methodologies allows textile businesses to enhance products best, optimize production methods, and hold competitiveness in the international marketplace.

What Are the Common Garment Testing Items and Test Instruments?

In the garment industry, testing plays a vital role in making sure the exceptional, safety, and performance of garments. From assessing physical properties like seam strength and material composition to comparing consolation and safety components which include flammability and chemical content material, comprehensive garment checking out allows manufacturers to meet regulatory necessities and patron expectancies. Let’s explore the common garment testing objects and testing instruments used in the clothing industry:

Seam Strength

Seam strength testing evaluates the strength of seams in garments, ensuring that they can resist pressure all through wear and laundering. Strong seams are crucial for preventing seam failures and keeping garment integrity.

Fabric Composition

Fabric composition checking out determines the materials used in garment construction, verifying the presence and proportions of fibres and blends specified in garment labeling. Correct fabric composition information is imperative for ensuring product excellence and compliance with labeling guidelines.

Dimensional Stability

Dimensional balance testing assesses the ability of clothes to hold their unique shape and size after laundering or sporting. It guarantees that clothes keep their health and look over the years, minimizing problems such as shrinkage or stretching.

Colorfastness

Colorfastness testing evaluates the colorfastness of garment fabrics to different factors such as mild, washing, and rubbing. It guarantees that garments preserve their coloration intensity and look in the course of their lifespan, assembly consumer expectancies for long-lasting color retention.

Fastener power

Fastener power testing assesses the power and durability of zippers, buttons, snaps, and different fasteners utilized in clothes. It guarantees that fasteners can face up to repeated use and laundering besides failure, contributing to garment safety and capability.

Flammability

Flammability testing evaluates the flammability of garment fabrics and additives, making sure compliance with protection standards and rules. It assesses the ignition and flame spread properties of materials in order to minimize fire hazards and enhance garment safety.

Chemical Material

Chemical content testing detects harmful materials in garment fabrics and dyes, ensuring compliance with regulatory restrictions and consumer protection standards. It lets pick out potentially unsafe chemical compounds that could pose risks to human health and the environment.

Common Garment Testing Instruments

Tensile Strength Tester

Tensile strength testers assess the strength of garment fabric and seams by using controlled tension till failure occurs. These instruments measure breaking force, elongation, and modulus, imparting valuable records for comparing cloth and seam overall performance.

Fabric Composition Analyzer

Fabric Composition Analyzers decide the fiber content and composition of garment fabric using strategies that include spectroscopy or microscopy. These instruments help affirm fabric composition facts provided with the aid of providers and ensure compliance with labeling requirements.

Dimensional Stability Chamber

Dimensional stability chambers simulate laundering or sporting conditions to assess garment dimensional adjustments over the years. Those chambers degree material shrinkage, stretching, or distortion, helping manufacturers become aware of ability health problems and improve product quality.

Colorfastness Tester

Colorfastness testers evaluate the colorfastness of garment fabric to light, wash, and rub the usage of standardized test methods. These instruments measure color modifications and marking to evaluate material coloration retention and ensure product satisfaction and durability.

Fastener Strength Tester

Fastener strength testers assess the energy and sturdiness of garment fasteners by considering tension or pressure till failure occurs. These contraptions degree fastener breaking pressure and deformation, supporting manufacturers pick out durable fasteners for their products.

Flammability Trying Out Chamber

Flammability testing chambers assess the flammability of garment fabric and additives with the aid of exposing them to managed ignition sources. Those chambers degree flame spread, burning rate, and after-flame time, ensuring compliance with safety standards and guidelines.

Chemical Analysis Device

Chemical analysis device detects dangerous materials in garment materials and dyes the usage of techniques together with chromatography or spectroscopy. These instruments assist manufacturers in being aware of and quantifying unsafe chemical compounds, ensuring product protection and regulatory compliance.

For more information on textile testing methods/standards

or textile testing machines, please contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com