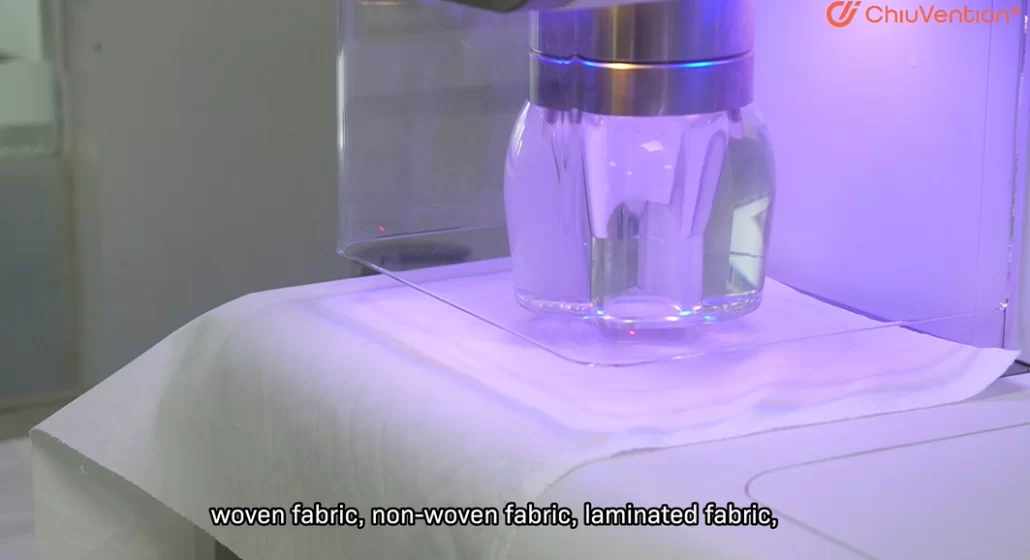

Textiles are all around us, from the clothes we wear to the furniture we sit on. But have you ever considered how strong these fabrics need to be? In certain situations, fabrics must withstand pressure applied directly to their surface. This is especially important for products like airbags, tires, and upholstery.

To guarantee the quality and safety of these textiles, a standardized testing method is essential. Have you ever wondered how strong a fabric is when pressure is applied directly to its surface? This is exactly what the ISO 13938-1:2019 test standard helps determine. It outlines a specific method for measuring the bursting strength of textile materials.

In this test, we want to see how much pressure a fabric can take before it breaks or bursts.

This blog post will break down this standard into easy-to-understand sections, explaining its purpose, how it’s applied, and what information it provides.

What is the Test Standard of ISO 13938-1:2019?

ISO 13938-1:2019 is a set of rules created by the International Organization for Standardization (ISO) for testing the bursting strength of materials. Think of it as a detailed instruction manual that tells us how to conduct a specific type of test – the bursting strength test. This standard ensures that the test is done consistently and reliably across different industries and countries.

The main goal of ISO 13938-1:2019 is to provide a common framework for evaluating the bursting strength of materials. Bursting strength is a critical factor in many industries, including textiles, packaging, and manufacturing. For example, in the textile industry, knowing the bursting strength of fabrics ensures that they can withstand the stresses of daily use without tearing or ripping.

ISO 13938-1:2019 covers various aspects of the bursting strength test, including the equipment used, the test procedure, and the evaluation of test results. By following this standard, companies can ensure that their materials meet certain quality requirements and perform as expected in real-world applications.

One important aspect of ISO 13938-1:2019 is its focus on standardization. Standardization means that everyone follows the same set of rules when conducting tests, regardless of where they are located or what industry they belong to. This consistency is essential for comparing test results between different laboratories and ensuring that products meet the same quality standards worldwide.

ISO 13938-1:2019 is updated periodically to reflect advances in testing technology and changes in industry practices. The 2019 version incorporates the latest developments in bursting strength testing and replaces previous versions of the standard. This ensures that the standard remains relevant and up-to-date with current industry requirements.

Importance of Bursting Strength Testing

The primary objective of ISO 13938-1:2019 is to establish a universal framework for evaluating the bursting strength of materials. Bursting strength is a critical parameter in numerous industries, including textiles, packaging, and manufacturing. For instance, in the textile industry, understanding the bursting strength of fabrics is essential to ensure their durability and performance in various applications.

Scope and Coverage of ISO 13938-1:2019:

ISO 13938-1:2019 encompasses various aspects of the bursting strength test, including the equipment utilized, the testing procedure, and the interpretation of test results. It provides detailed instructions and guidelines to ensure consistency and accuracy in the testing process.

The Test Principle of ISO 13938-1:2019 for Bursting Strength Test

The test principle of ISO 13938-1:2019 is fundamental to understanding how bursting strength testing is conducted for textiles. This standard provides comprehensive guidelines for determining the bursting strength of textiles, which is crucial for assessing their quality and performance. Bursting strength refers to the maximum force required to rupture a textile specimen when subjected to increasing hydraulic or pneumatic pressure.

To understand this test principle, let’s break it down step by step:

Maximum Force Requirement: ISO 13938-1:2019 focuses on measuring the maximum force necessary to burst a textile specimen. This force is a critical indicator of the fabric’s ability to withstand pressure without tearing. It is particularly important in applications where textiles are subjected to stress, such as in clothing, automotive interiors, and industrial materials.

Hydraulic or Pneumatic Pressure: The test involves applying pressure to the textile specimen using either hydraulic or pneumatic means. Hydraulic systems utilize fluids, typically oil or water, to generate pressure, while pneumatic systems use compressed air. Both methods are effective in exerting pressure on the fabric until it ruptures. The choice between hydraulic and pneumatic pressure depends on factors such as equipment availability and the specific requirements of the testing application.

Gradual Pressure Increase: During the test, pressure is applied gradually to the textile specimen until it reaches its breaking point. This gradual increase allows for accurate measurement of the fabric’s resistance to bursting. It also simulates the gradual stress that textiles may experience in real-world applications, ensuring that the test results are reflective of actual performance.

Rupture Point Determination: The point at which the textile specimen ruptures is carefully observed and recorded. This point represents the maximum force the fabric can withstand before failing. It is typically identified using visual or automated detection methods. By determining the rupture point, manufacturers can assess the fabric’s strength and durability, enabling them to make informed decisions regarding product design and material selection.

Repeatability and Reproducibility: ISO 13938-1:2019 emphasizes the importance of repeatability and reproducibility in testing. Repeatability ensures that the test results are consistent when the same sample is tested multiple times under the same conditions. Reproducibility ensures that the test results are consistent when different operators or testing equipment are used. Achieving repeatability and reproducibility requires careful control of testing parameters, such as pressure application rate and specimen preparation, as well as regular calibration of testing equipment.

Standardization: The standard provides specific guidelines for conducting the test, including equipment specifications, testing procedures, and data interpretation. Standardization ensures consistency and comparability of test results across different laboratories and manufacturers. It also facilitates regulatory compliance and quality assurance, enabling stakeholders to make informed decisions regarding product quality and safety.

Overall, the test principle of ISO 13938-1:2019 is focused on accurately assessing the bursting strength of textiles using hydraulic or pneumatic pressure. By following standardized procedures and guidelines, manufacturers can ensure the quality and performance of their textile products, meeting the expectations of consumers and regulatory requirements.

The Application of Test Standard ISO 13938-1:2019 for Bursting Strength Test

applications of test standard ISO 13938-1:2019 is widespread and crucial in various industries where textiles play a vital role. This standard provides guidelines for determining the bursting strength of textiles, which is essential for assessing their quality and performance. Let’s explore the applications of ISO 13938-1:2019 in detail:

Apparel Industry: In the apparel industry, textiles are used to manufacture clothing, including shirts, pants, dresses, and outerwear. The bursting strength of textiles is critical in ensuring that garments can withstand the stresses and strains of everyday wear. By adhering to ISO 13938-1:2019, clothing manufacturers can assess the durability of fabrics and ensure that their products meet quality standards.

Automotive Sector: Textiles are also widely used in the automotive sector for interior upholstery, seat covers, and trim components. The bursting strength of textiles is essential for ensuring the longevity and safety of automotive interiors. By testing textiles according to ISO 13938-1:2019, automotive manufacturers can verify the strength and durability of materials used in vehicle interiors, thereby enhancing passenger comfort and safety.

Home Furnishings: Textiles play a crucial role in home furnishings, including upholstery fabrics, curtains, and bedding materials. The bursting strength of textiles is important in ensuring the longevity and performance of these products. By following ISO 13938-1:2019, manufacturers of home furnishings can assess the quality of fabrics and ensure that their products meet the expectations of consumers.

Medical Textiles: Textiles are also used in various medical applications, including surgical gowns, drapes, and wound dressings. The bursting strength of medical textiles is critical for ensuring patient safety and comfort. By testing medical textiles according to ISO 13938-1:2019, manufacturers can verify the strength and integrity of materials used in medical applications, thereby ensuring the efficacy of medical products and devices.

Industrial Textiles: Industrial textiles are used in a wide range of applications, including filtration systems, conveyor belts, and protective clothing. The bursting strength of industrial textiles is essential for ensuring the reliability and performance of these products in demanding environments. By adhering to ISO 13938-1:2019, manufacturers of industrial textiles can assess the strength and durability of materials used in industrial applications, thereby enhancing product quality and safety.

Sporting Goods: Textiles are also used in the production of sporting goods, including athletic apparel, footwear, and equipment. The bursting strength of textiles is crucial for ensuring the performance and safety of sporting goods, especially in high-impact activities such as running, cycling, and weightlifting. By testing sporting goods textiles according to ISO 13938-1:2019, manufacturers can verify the strength and durability of materials used in athletic products, thereby enhancing athlete performance and reducing the risk of injury.

The Test Material and Test Equipment:

The test material and test equipment are essential components of conducting bursting strength tests according to ISO 13938-1:2019. Let’s delve into the details of each:

Test Material:

The test material refers to the textile specimen that undergoes bursting strength testing. The test material must be representative of the product being evaluated and free from any defects that could affect test results. Here are some key considerations regarding test materials:

Selection: The selection of test materials should be done carefully to ensure they accurately represent the textile product under evaluation. Samples should be taken from different areas of the product to account for variations in fabric quality.

Preparation: Before testing, test materials need to be prepared according to the specifications outlined in ISO 13938-1:2019. This may involve cutting samples to specific dimensions and removing any surface irregularities or imperfections.

Conditioning: Test materials should be conditioned to standardize environmental conditions, such as temperature and humidity, to ensure consistent test results. Conditioning helps minimize variations in test outcomes caused by environmental factors.

Verification: Before testing, it is essential to verify that the test materials meet the requirements specified in ISO 13938-1:2019. This may involve visual inspection, measurement of fabric weight and thickness, and other quality checks to ensure the integrity of the test materials.

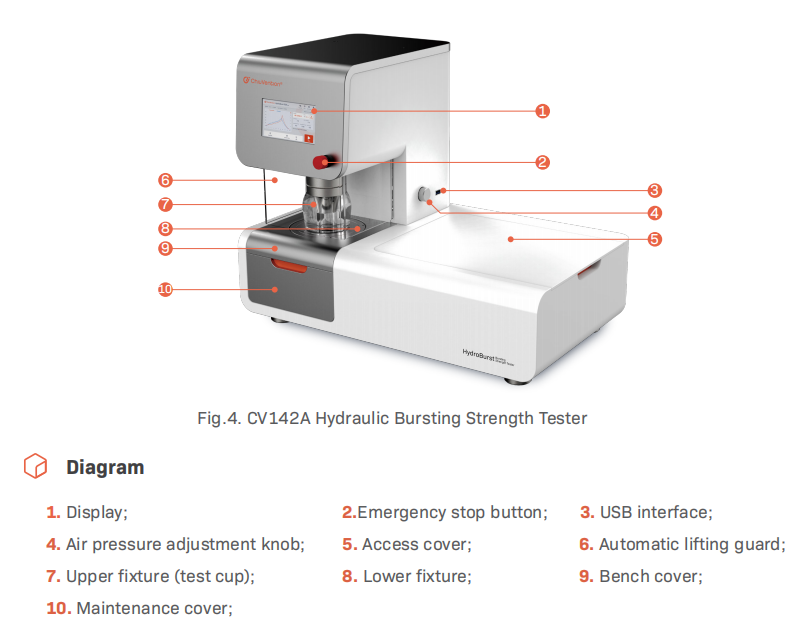

Test Equipment:

The test equipment used for bursting strength testing plays a critical role in ensuring the accuracy and reliability of test results. ISO 13938-1:2019 provides specific guidelines for the selection and calibration of test equipment. Here are the key components of test equipment:

Bursting Strength Tester: The primary piece of equipment used for bursting strength testing is the bursting strength tester. This device applies hydraulic or pneumatic pressure to the test material until it ruptures. Bursting strength testers come in various designs, including diaphragm-type and ball-type testers, each with its advantages and limitations.

Clamping Device: The clamping device holds the test material securely in place during testing. It ensures that the material remains flat and does not slip or distort under pressure. Proper alignment and positioning of the test material within the clamping device are essential to obtain accurate test results.

Pressure Measurement System: The pressure measurement system is responsible for applying and measuring the pressure exerted on the test material. It may consist of hydraulic or pneumatic components, such as cylinders, pistons, and pressure gauges, depending on the type of bursting strength tester used.

Control System: The control system regulates the rate at which pressure is applied to the test material and ensures that testing conditions remain consistent throughout the test. It may include manual or automated controls for adjusting pressure levels and monitoring test progress.

Calibration Equipment: Calibration equipment is used to verify the accuracy and precision of the bursting strength tester. Regular calibration ensures that the equipment performs reliably and produces consistent test results over time. Calibration procedures should comply with the requirements specified in ISO 13938-1:2019.

Proper selection, preparation, and verification of test materials, along with the use of calibrated and well-maintained test equipment, are essential for obtaining accurate and reliable test results. By adhering to the guidelines outlined in the standard, manufacturers can ensure the quality and performance of their textile products across various applications.

The Sampling Requirement of Test Standard ISO 13938-1:2019 for Bursting Strength Test:

The sampling requirement is a crucial aspect of conducting bursting strength tests according to ISO 13938-1:2019. Sampling involves selecting representative samples from a larger population of textile products for testing. Here’s an in-depth look at the sampling requirement:

Sampling Plan:

ISO 13938-1:2019 provides guidelines for developing a sampling plan based on the type of textile product being tested and the intended purpose of the testing. A sampling plan outlines the number of samples to be tested, as well as the criteria for sample selection. The goal of the sampling plan is to ensure that the test results are statistically meaningful and representative of the entire population of textile products.

Sample Size:

The sample size is determined based on factors such as the variability of the textile product, the desired level of confidence in the test results, and the acceptable margin of error. ISO 13938-1:2019 provides formulas and tables for calculating the appropriate sample size based on these factors. In general, larger sample sizes are required for products with greater variability or when higher levels of confidence are desired.

Random Sampling:

Random sampling is essential to ensure that the samples selected for testing are representative of the entire population of textile products. Random sampling involves selecting samples at random from the population without bias or preference. This helps minimize the risk of sampling errors and ensures that the test results accurately reflect the characteristics of the population.

Sample Selection Criteria:

The criteria for sample selection may vary depending on the specific requirements of the testing application. However, ISO 13938-1:2019 recommends selecting samples that are typical of the production batch and that cover a range of characteristics, such as fabric type, color, and manufacturing process. This ensures that the test results apply to a broad range of textile products.

Sampling Locations:

Samples should be taken from various locations within the production batch to account for potential variability in fabric quality. ISO 13938-1:2019 recommends sampling from different areas of the product, such as different rolls or batches, to ensure that the test results are representative of the entire production process.

Sampling Procedure:

The sampling procedure should be standardized and documented to ensure consistency and reproducibility. ISO 13938-1:2019 provides guidelines for collecting samples, including procedures for sample identification, handling, and storage. Samples should be handled carefully to avoid contamination or damage that could affect the test results.

Quality Control Measures:

Quality control measures should be implemented throughout the sampling process to verify the integrity of the samples and ensure that they meet the requirements of ISO 13938-1:2019. This may include visual inspection, measurement of sample dimensions and weight, and other quality checks to confirm that the samples are suitable for testing.

Here are Some Key Points of the Test Standard ISO 13938-1:2019 for the Bursting Strength Test

The BS Tester shall be capable of producing various constant rates of increase in volume per unit time between 100 cm3/min and 500 cm3/min to within ±10 % of the indicated value. If the BS Tester is not equipped to adjust fluid volume, a testing time to burst of (20 ± 5) s may be applied. This shall be

indicated in the test report.

Bursting pressure shall be indicated with an accuracy of ±2 % of the full-scale range above the first 20 % of the range.

Height at burst up to 70 mm shall be indicated with an accuracy of ±1 mm.

The zero position of the measuring gauge shall be adjustable to accommodate the thickness of the test specimen.

Means for indicating the volume at burst (if available) to within ±2 % of the indicated value.

A test area of 50cm2 (79,8 mm diameter) shall be used. Other test areas of 100 cm2(112,8 mm diameter) 10cm2 (35,7 mm diameter) or 7,3 cm2

(30,5 mm diameter) may be used, if the preferred test area is not applicable in the existing testing equipment, or due to high or low expansion of the fabric or other fabric requirements, or by mutual agreement.

The clamping device shall provide for the clamping of the test specimen securely without distortion or damage and prevent slippage during the test.

The clamping ring shall allow undisturbed vaulting of highly expansive fabrics (e.g. fabric test specimens whose height at burst is greater than half of the test

specimen diameter). All test specimen clamping ring inner diameters shall be accurate to ±0,2 mm.

To avoid test specimen damage, a small curvature at the inner edge of the clamping ring facing the test specimen is recommended.

A safety cover shall enclose the clamping device during the test when the expansion of the test specimen takes place. It shall allow clear observation of the expansion of the test specimen during the test.

The diaphragm shall meet the following requirements:

— thickness up to 2 mm;

— highly expansive;

— if the diaphragm is to be used several times, it shall be elastic within the range of height at burst

observed during the test;

— resistant against pressurizing fluids used.

Atmospheres for conditioning and testing

The atmospheres for preconditioning, conditioning, and testing shall be as specified in ISO 139.

Preconditioning and conditioning are not required for wet tests.

The Test Procedure of Test Standard ISO 13938-1:2019 for Bursting Strength Test

The test procedure outlined in ISO 13938-1:2019 is meticulous and precise, ensuring consistent and reliable results in bursting strength tests. Here’s an in-depth look at each step:

Preparation of Test Equipment: Before starting the test, ensure the bursting strength tester is properly set up and calibrated according to the manufacturer’s instructions and ISO 13938-1:2019 guidelines. This involves checking the calibration of pressure gauges, verifying the functionality of control systems, and confirming the alignment of the clamping device.

Preparation of Test Material: Prepare the textile specimen by cutting it to the specified dimensions, typically a circular shape with a defined diameter. Ensure that the specimen is free from wrinkles, folds, or any surface irregularities that could affect the test results. Handle the specimen with care to avoid introducing any damage or distortion.

Clamping of Test Material: Securely clamp the prepared test material in the clamping device of the bursting strength tester. Position the specimen centrally within the clamping device to ensure uniform pressure distribution. Adjust the clamping device tension to securely hold the specimen in place without causing any deformation.

Application of Pressure: Gradually apply hydraulic or pneumatic pressure to the test material using the bursting strength tester. Follow the prescribed rate of pressure increase specified in ISO 13938-1:2019, typically ranging from 50 to 100 kPa per second. Monitor the pressure levels continuously during the test to ensure uniform pressure application.

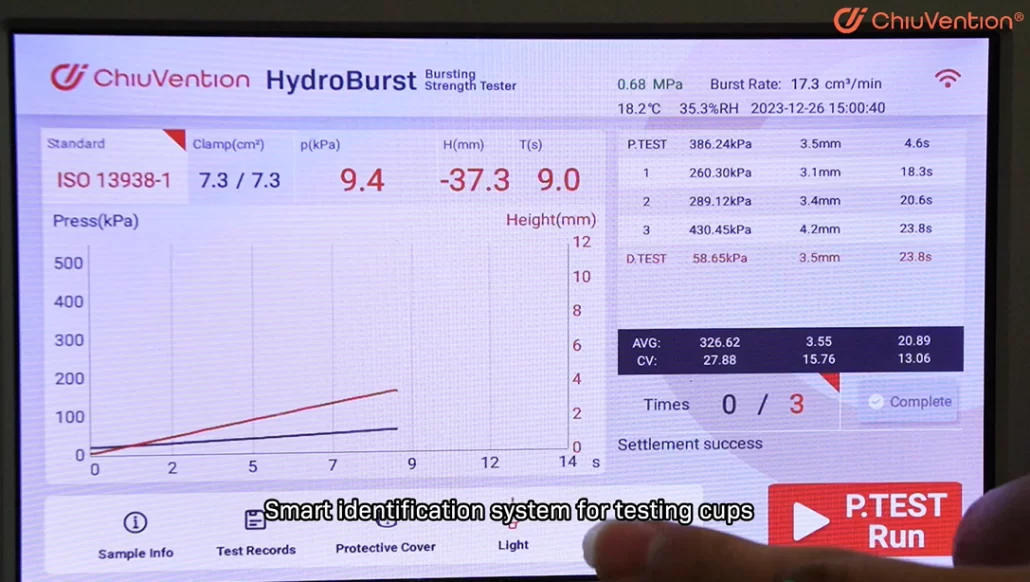

Detection of Rupture Point: Observe the test material closely as pressure is applied until it ruptures. The rupture point is indicated by a sudden drop in pressure or a visible tearing of the fabric. Use visual observation or automated detection systems to accurately identify the rupture point. Record the maximum pressure at the moment of rupture.

Data Recording and Analysis: Record all relevant test data, including the maximum pressure at rupture, the diameter of the specimen, and any observations related to the test procedure. Calculate the bursting strength of the test material using the formula specified in ISO 13938-1:2019, taking into account the area of the specimen and the maximum pressure applied.

Reporting of Test Results: Prepare a detailed test report documenting the test procedure, equipment used, test results, and any deviations from the standard procedure. Include all relevant information necessary for the interpretation and evaluation of the test results. Ensure that the test report complies with the reporting requirements specified in ISO 13938-1:2019.

By following the precise steps outlined in ISO 13938-1:2019, manufacturers can conduct bursting strength tests accurately and consistently, ensuring the quality and performance of their textile products.

The Evaluation of Test Results:

After conducting bursting strength tests according to ISO 13938-1:2019, the evaluation of test results is crucial for determining the quality and performance of textile materials. Here’s an accurate and detailed approach to evaluating test results:

Comparison with Requirements: Compare the bursting strength of the test material obtained from the test procedure with the minimum bursting strength requirements specified in ISO 13938-1:2019 or other applicable standards. Ensure that the test material meets or exceeds the specified requirements to ensure product quality and performance.

Statistical Analysis: Conduct statistical analysis of the test results to assess their variability and reliability. Calculate key statistical parameters such as the mean bursting strength, standard deviation, and coefficient of variation. Evaluate the consistency and repeatability of the test data to ensure its reliability.

Interpretation of Results: Interpret the test results in the context of the intended application and performance requirements of the test material. Consider factors such as the intended use of the textile product, the level of stress and strain it will be subjected to, and the consequences of failure in real-world scenarios.

Identification of Non-Conformities: Identify any non-conformities or deviations from the specified requirements observed in the test results. This may include instances where the bursting strength of the test material falls below the minimum requirement or exhibits unexpected variability. Investigate the root causes of non-conformities to determine corrective actions.

Root Cause Analysis: Conduct a thorough root cause analysis to determine the underlying factors contributing to any non-conformities observed in the test results. This may involve examining potential sources of variation in the test procedure, such as sample preparation, equipment calibration, or testing conditions.

Corrective Actions: Implement appropriate corrective actions to address any non-conformities identified in the test results. This may include adjusting the manufacturing process, modifying the design of the textile product, or selecting alternative materials to improve bursting strength and performance.

Documentation and Reporting: Document the evaluation of test results, including any non-conformities identified, corrective actions taken, and their effectiveness in addressing the issues. Prepare a comprehensive test report summarizing the findings of the evaluation and documenting any changes made to the manufacturing process or product design.

This rigorous evaluation process is essential for maintaining product quality and reliability in various applications.

Conclusion:

ISO 13938-1:2019 is instrumental in ensuring the quality and reliability of textile products through standardized bursting strength testing procedures. From understanding the test principle to evaluating results, each aspect of this standard plays a vital role.

This standard finds application across various industries, including apparel, automotive, medical, and industrial sectors, ensuring products meet stringent quality standards.

Meticulous preparation, calibration, and verification of test materials and equipment are essential for accurate testing. Sampling requirements dictate the selection of representative samples, while the test procedure outlines precise steps for conducting tests.

The evaluation of test results involves statistical analysis, interpretation, and identification of non-conformities. Root cause analysis and corrective actions address any deviations from requirements, ensuring continuous improvement in product quality and reliability.

In essence, ISO 13938-1:2019 provides a standardized framework for bursting strength testing, facilitating the production of high-quality textile products that meet consumer expectations and regulatory standards.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com