color fastness to washing is a critical attribute in the textile industry. It impacts consumer satisfaction and product durability. Understanding how to maintain vibrant colors through many washes is essential. In this discussion piece, we’ll explore color fastness to washing. We’ll also look at testing methods and relevant ISO standards. We will take practical steps to enhance color retention in fabrics. Keep reading.

What is the Color Fastness to Washing Test Method?

color fastness to washing refers to a fabric’s resistance to fading after washing. It’s a measure of how a fabric can maintain its original color after washing without running. The evaluation of color fastness involves subjecting the fabric to specific laundering conditions. The next step is to assess the extent of color loss and stain on other fabrics.

The test method involves washing the fabric sample in a controlled environment. Then you must add standardised detergents and apply specific temperature and agitation conditions. After washing, dry the fabric and assess the change in color. You’ll need to use a gray scale for color change and staining.

How to Test the Color Fastness of Fabrics to Washing?

Testing the color fastness of fabrics to washing is a critical step. It ensures that textiles meet consumer expectations for durability and quality. The process simulates normal household washing conditions. It assesses how well the fabric retains its color and doesn’t stain other materials.

Selection of Samples

Diverse Color Range

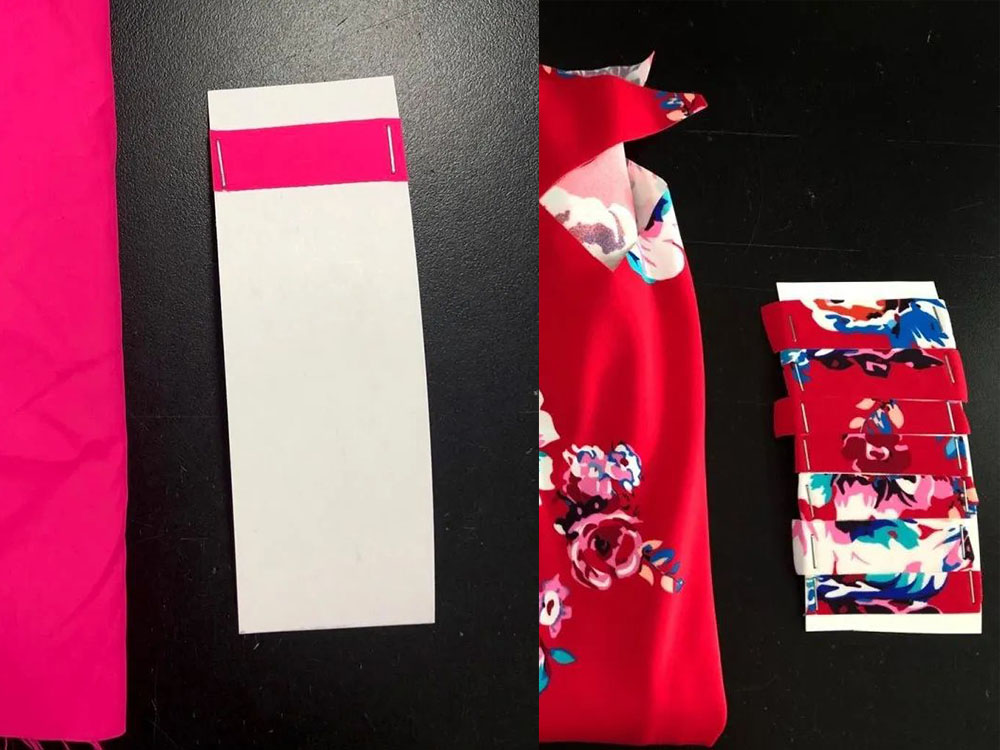

When choosing fabric samples, include a variety of colors. You should consider those that are sensitive to washing like deep reds, navies, and blacks. These colors show more significant changes in tests. They can or show how well a dye holds up in typical laundering conditions.

Material Types

The selection should include different material types such as cotton, polyester and silk. This is because the final product may include a range of fabrics. Different materials react to washing, and their color fastness can vary.

Real-World Representation

Samples must represent the end product in color, material, texture and weight. These factors can influence how the fabric interacts with water and detergent. Hence, it can affect the test outcome.

Cutting and Marking

Standard Specifications

The next step is to cut samples according to ISO 105-C06 or AATCC Test Method 61 standards. This ensures consistency across tests. The size must be large enough to allow for an accurate assessment of color change and staining. Also, it should fit testing equipment.

Precision in Cutting

The cutting process should be precise, ensuring clean edges that do not fray. Fraying edges affect the absorption of water and detergent during the washing process. This impacts the test results.

Marking for Identification

Each sample needs discrete markings for identification throughout the testing process. This is crucial for tracking the performance of individual samples. More so, when conducting many tests at the same time. You should mark in a manner that does not interfere with the test itself. Use small, washable labels or special non-fade ink for effectiveness.

Recording Details

It’s essential to keep detailed records of each sample’s characteristics. This includes fabric type, color, and any pretreatment the fabric has undergone. This information is vital for analyzing the test results and for future reference.

Considerations for Enhanced Reliability

Enhanced reliability can impact the accuracy and trustworthiness of the test outcomes.

Environmental Conditions

Climate Control

Maintaining a controlled storage environment is vital. You need to keep samples at consistent temperatures and humidity levels. Testing standards or best practices recommend this for textile preservation. Sudden changes in these conditions can start chemical reactions within the fabric. This changes its original state before testing.

Light Exposure

Direct sunlight or strong artificial light can cause premature fading or color alteration. You must store samples in dark and UV-protected areas to preserve their original colors. This is especially crucial for materials sensitive to photodegradation.

Cleanliness

The storage area must be free from dust, dirt, and other contaminants. These substances could settle on the samples and affect water absorption during washing. It can lead to skewed results.

Pre-Test Inspection

Systematic Examination

A detailed checklist for inspection helps ensure you don’t miss any defects. Look for color inconsistencies, material damage, or any treatment signs. These elements could influence the washing outcome. It might include pre-existing stains. These could spread or alter the perceived level of color bleeding or fading.

Documentation

Documenting the initial condition of each sample with high-resolution photographs is vital. It can provide a valuable point of reference. This visual record allows for a more fair comparison before and after washing. This is particularly useful when assessing subtle changes in color or texture.

Expert Assessment

Employing experienced personnel to perform the inspections is vital. It improves the identification of potential issues. Trained eyes can detect minor imperfections that untrained individuals might overlook.

Many Samples

Consistency Across Replicates

When preparing many samples, it’s critical to ensure that they are as identical as possible. These aspects include size, fabric composition, and color shade. This uniformity is essential for drawing reliable conclusions from repeated tests.

Randomization

To mitigate any bias or systematic error, randomize the order in which samples are tested. This ensures that any variability in the washing process affects all samples.

Statistical Significance

Using many samples increases the statistical power of the test results. Analyzing the variance within the results of these samples is important for researchers. They can attribute observed changes to the washing process. They don’t focus on anomalies in individual samples.

Control Groups

Including control samples, provides a baseline for comparison. This helps in quantifying the degree of color change or staining. It also assists in assessing the performance of the fabric relative to benchmarks.

Washing Procedure

Standardised Detergent and Conditions

Selection of Detergent

The choice of detergent is important. It should lack any added components like fabric softeners, bleach, or optical brighteners. These substances could influence the test outcomes. The concentration of the detergent is a vital consideration. It must replicate typical usage conditions in a household setting.

Water Temperature Control

Water temperature is a critical factor that can affect the test results. Different standards may specify different temperatures to simulate various washing scenarios. For example cold wash or warm wash conditions. The testing equipment must maintain the set temperature within a narrow margin. It ensures consistency.

Agitation and Washing Cycle

The mechanical action during the washing process requires control. It stimulates the tumbling and agitation of a domestic washing machine. This includes setting the washing machine to a specific cycle matching the requirements. You must also include duration. The amount of mechanical action can influence the degree of color loss. It also affects fabric wear. Thus, adhere to standardized conditions.

Rinse and Spin Cycles

Following the washing, a standardized rinse and spin cycle is vital. It ensures the removal of all detergent residues from the fabric. The number of rinses and the spin speed are available in the testing protocols. It mirrors common laundering practices.

Use of Control Samples

Purpose and Selection

Control samples are integral to the testing process. They serve as benchmarks for evaluating the color transfer from the test fabric. These comprise a material with known high color fastness qualities. It also includes a specific fabric designated by the testing standard.

Preparation of Control Samples

Prepare the samples by following the same guidelines as the test samples. It includes cutting to the correct size and marking for identification. Wash the control samples alongside the test samples under identical conditions.

Evaluation of Color Transfer

After washing, examine the control samples for color staining from the test fabric. This assessment provides a direct measure of the color fastness of the test fabric. This is its potential to bleed color onto other fabrics.

Ensuring Reproducibility

Replication of Home Laundering

The entire procedure aims to replicate typical home laundering conditions. It provides relevant and practical results. It also includes everything from the type and amount of detergent you use in washing.

Standardisation Across Tests

Standardize the washing procedure aspects to make the results meaningful and comparable. Adhere to set procedures. This applies across different locations. It allows for the comparison of results on a global scale.

Documentation

Detailed records of each step of the procedure are crucial. These include the detergent type and amount. It also includes water temperature, cycle times, and deviations from the standard protocol. This documentation ensures transparency. It allows other researchers or manufacturers to replicate the testing conditions if needed.

Drying

The drying phase in the testing of color fastness to washing is as critical as the washing procedure. The method of drying influences the final assessment of the fabric’s color retention. It also enables for evaluation of the fabric’s resistance to staining.

Drying Methods

Line Drying

Line drying involves hanging the fabric samples out to dry. It exposes samples to air without direct heat. This is ideal for fabrics sensitive to high temperatures. It’s important to avoid direct sunlight during line drying to prevent any fading or color change.

Tumble Drying

Some standards allow tumble drying to simulate common household laundry practices. Tumble drying introduces heat and mechanical action on fabric. It may affect some fabrics more than others, causing shrinkage or color fading. The temperature and duration ensure uniformity in the testing protocol.

Flat Drying

Hanging or subjecting fabric to excessive stress can deform delicate fabric. Flat drying is often the recommended method. It involves laying the samples out on a clean and flat surface. The place must be well-ventilated. This ensures dryness without direct exposure to heat or sunlight.

Consistency

Uniform Drying Conditions

Dry the samples under identical conditions within a single test series. This ensures that the drying process doesn’t introduce variability in the results. It includes using the same drying cycles, temperatures, and durations for all samples.

Controlled Environment

Control the environment for line and flat drying. This means avoiding areas with high humidity or significant air pollutants. This could affect the drying process and alter the fabric’s appearance.

Repeatability

The process should be repeatable in the same laboratories and different testing sessions. Detailed documentation of the drying conditions helps achieve this consistency. It also ensures that results are comparable over time and across different locations.

Post-Drying Conditioning

Samples need conditioning in a controlled environment before the assessment. This ensures that any temporary effects don’t influence the evaluation of color fastness.

Evaluation

Using Gray Scales

After drying, compare the washed samples against gray scales. The gray scale for color change has shades ranging from unchanged to faded. For staining, the scale assesses the amount of color transferred to adjacent fabrics.

Assessment Process

You must do an evaluation under standardized lighting conditions to ensure accuracy. It might involve many evaluators. These experts account for subjective interpretations of color change and staining.

Rating

Scoring System

The test results are rated on a scale from 1 to 5. 1 represents severe color change or staining, and 5 indicates no noticeable change. This rating system helps in quantifying the color fastness.

Documentation

Document detailed records of the test conditions, processes, and outcomes. It includes information about the fabric and detergent. It also includes washing and drying conditions, and the evaluation results.

Analysis and Implications

Interpreting Results

Analyze the ratings to understand the fabric’s performance. A high score suggests good color fastness, while a low score indicates a need for improvement.

Quality Control and Improvement

Based on the results, manufacturers adjust dyeing processes. Next, select different dyes, or change fabric treatments to enhance color fastness.

What is the ISO Standard for Color Fastness to Wash?

The ISO provides various standards for evaluating the color fastness of textiles. The most used standard is ISO 105-C06. It outlines the test methods for determining the resistance of textiles to washing. It also provides detailed procedures for sample preparation, washing, drying, and evaluation.

What is ISO 105 C06 Wash Color Fastness?

ISO 105 C06 specifies the test methods for assessing the color fastness of textiles. It also includes domestic and commercial washing. The procedures for different washing conditions include varying temperatures and detergent compositions. These simulate real-life washing scenarios.

The test involves washing the fabric samples with a specified detergent. The next step is to set the temperature and agitation level. After washing, you test the samples for color change. Also, check the staining using gray scales. ISO 105-C06 provides a comprehensive framework for ensuring consistency. It also evaluates reliable testing across different laboratories and industries.

What is Good Wash Color Fastness?

Good wash color fastness indicates that a fabric withstands washing without color change. It also can withstand staining. In practical terms, this means it retains its original color, after repeated washes. The color from the fabric does not transfer to other items in the wash. The fabric is consistent across different washing conditions. The good wash color fastness rating is 4 or 5 on the grayscale, indicating little to no noticeable change.

What is Color Fastness Level 4?

Colorfastness level 4 refers to a high rating on the grayscale. It indicates minimal color change or staining. On a scale from 1 to 5, level 4 suggests that the fabric has excellent resistance to washing. There’s only a slight if any, visible change in color. This level is acceptable for high-quality textiles. It ensures that the fabric maintains its appearance and integrity through regular washing.

What is the Difference Between Color Fastness to Washing and Color Fastness to Water?

Both methods test a fabric’s ability to keep color. But, they focus on different conditions:

Color Fastness to Washing

It assesses the fabric’s resistance to fading and staining during washing with detergents. It also tests mechanical action and simulates real-life laundering conditions.

Color Fastness to Water

This evaluates the fabric’s resistance to color change when exposed to water alone. It doesn’t consider detergents or mechanical action. It’s relevant for items that may get wet without washing such as swimwear or rainwear.

How to Improve Color Fastness to Washing?

Improving color fastness to washing involves several strategies. These include the selection of dyes and chemicals and the finishing processes.

- The choice of dyes plays a crucial role in color fastness. Reactive dyes, for example, form strong chemical bonds with cellulose fibres. This leads to better wash fastness. Disperse dyes are suitable for synthetic fibres like polyester. They provide good resistance to washing.

- Proper dyeing techniques can enhance color fastness. It includes maintaining optimal temperature, pH, and time during the dyeing process. This ensures that dyes attach to the fibers. Chemical fixatives enhance the bond between the dye and fibre, improving wash fastness. Common fixatives include cationic agents and formaldehyde-free compounds.

- Pre-treating fabrics before dyeing can improve dye uptake and fixation. Scouring and bleaching remove impurities. This prepares the fabric for dyeing, resulting in more uniform and durable coloration.

- Post-dyeing treatments can further enhance color fastness. Washing the dyed fabric with a soaping agent removes unfixed dyes. This reduces the risk of color bleeding during later washes. Applying cationic softeners improves the feel of the fabric and enhances dye fixation.

- Innovations in textile technology offer new ways to improve color fastness. Nano-coatings enhance the durability of dyes. This provides better resistance to washing and other environmental factors. Enzymes can change the surface of fibres, improving dye uptake and fixation.

- Regular testing and quality control are essential to ensure consistent color fastness. Conducting a routine helps identify and address any issues early on. Adhering to standardized testing methods, such as ISO 105-C06, ensures reliability.

- Educating consumers on proper care can also help maintain color fastness. Providing clear washing instructions can prevent damage to the fabric. Advising consumers not to mix dark and light colors reduces the risk of color transfer.

Conclusion

Improving color fastness to washing involves careful selection of dyes and optimized dyeing. It also includes the finishing processes, advanced technologies, and effective quality control. Users can ensure that their products maintain vibrant colors and meet consumer expectations.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com