INTRODUCTION This article elaborates on the factors influencing the water absorption or waterproofness of fabrics and their testing methods, analyzing three influencing factors: the wettability of the fiber surface, the coating of the fabric, and the environment. People have demands for both waterproofness and water conductivity in fabrics. The wettability of the fiber…

Category Archives: Textile Knowledge

Linen fibre has a ‘natural fibre queen’ reputation. In the early 10th century, linen was a high-grade textile in Europe. It is now a benchmark for expensive foreign decorative fabrics. In China, the modern linen textile industry began in the early 1950s. Recently, the rapid growth of linen textiles created new demands for raw materials….

Introduction In the garments manufacturing process, the fabric material’s quality directly affects the finished garments’ quality. Understanding the standards for a qualified garment begins with fabric inspection, which is a crucial step. This is especially important for outerwear garments like down jackets, where the fabric’s unique properties highlight the significance of textile quality testing. Importance…

Introduction Every autumn and winter, a “warm” war erupts in the textile and clothing market. High-tech brands compete with their cold and warm clothing. They claim to be three times as warm. And they have a self-heating feature and a constant 37℃ temperature. They use super warm materials and “warm black technology.” They say they…

In the textile and apparel industry, color fastness to rubbing is a critical indicator of quality. It not only determines the appearance of the product but also influences consumer satisfaction and the product’s durability. A fabric that performs poorly in a color fastness to rubbing test can lead to a frustrating experience for both manufacturers…

Introduction Standards guide and regulate production enterprises. They help them prepare the instructions for use of textile and apparel products. They also help consumers understand the product’s basic information when purchasing. However, many people have an inaccurate or inconsistent understanding of the standards. To address this, this paper explores the attributes of instructions for use….

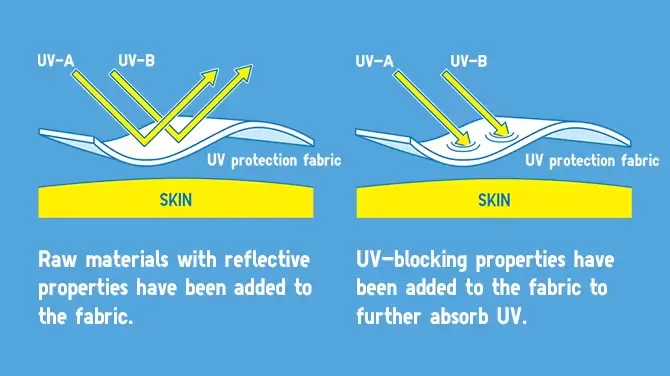

When purchasing garments, we often look at the sun protection index and the ultraviolet (UV) blocking rate of the materials. It’s also essential to understand the UV protection capabilities of our clothing and everyday items, as the effects of UV exposure are closely linked to our health. Let’s explore the following questions together: What is…

Tearing, or fabric tearing, happens when a load affects the fabric’s local yarns. In use, clothes can get caught on objects. This can pull off the local yarn in the fabric. It can form a strip or triangular tear, which is a type of fabric fracture. Definition of fabric tear strength Fabric tear strength is…

Printing and dyeing, or dyeing and finishing, is a kind of textile processing. It is also the general name for pre-treatment, dyeing, printing, finishing, and washing. Dyeing and finishing Dyeing and finishing is the chemical treatment of textiles (fibres, yarns, and fabrics). It is often called printing and dyeing. They combine it with spinning, weaving,…

GTexcare 2024: Bring together industry information, promote interaction and inspire boundless inspiration The 2024 Frankfurt International Textile Treatment Exhibition is on November 6-9. It has caught the attention of the global textile care industry. The exhibition will focus on key topics. These are automation, energy, resources, the circular economy, and textile hygiene. It will highlight…