INTRODUCTION

This article elaborates on the factors influencing the water absorption or waterproofness of fabrics and their testing methods, analyzing three influencing factors: the wettability of the fiber surface, the coating of the fabric, and the environment.

People have demands for both waterproofness and water conductivity in fabrics. The wettability of the fiber surface indicates the water conductivity and comfort of the fabric; waterproof treatment or coating on the fabric can enhance its waterproof performance. Different methods are used to test the water permeability of fabrics, and the different parameters obtained are all to characterize the water permeability of the fabric.

This article delves into the factors that influence a fabric’s ability to repel or allow water passage and explores four essential testing methods that help us gauge these properties accurately.

The Science Behind Fabric Waterproofness and Water Permeability

Water permeability refers to a fabric’s ability to allow liquid water to pass through. The following factors primarily affect a fabric’s waterproof fabric performance:

The Role of Fiber Surface Wettability

When the contact angle θ of the fiber is < 90°, the fibrous assembly material is a water – conductive material, and a denser structure will only lead to more capillary wicking and water conduction. When the fiber θ > 90°, the fiber has waterproof characteristics, and the denser the fabric structure (i.e., the smaller the pores), the better the waterproof effect. Therefore, only when the contact angle of the fiber is known can the waterproofness or water permeability of the fabric be better discussed. Denser fabric structures enhance the waterproof effect, which is critical for achieving a high hydrostatic head rating.

The Impact of Fabric Coatings

Applying a continuous, impermeable, and water – insoluble film layer on the fabric surface reduces the water permeability of the fabric, making it non – breathable. Applying waterproof coatings creates a continuous, impermeable film that significantly enhances the fabric’s hydrostatic pressure resistance. It is not very suitable for clothing but can be used for tarpaulins or raincoats. Microporous coatings offer a balance between water repellency and breathability, making them ideal for waterproof fabrics like raincoats.

Environmental Influences on Fabric Performance

Most water – repellent fabrics or coated fabrics are made of non – hygroscopic fibers or coating materials, so changes in relative humidity will not affect their waterproof performance. However, most water – conductive fabrics are made of hygroscopic fiber materials. As the relative humidity increases, the fiber absorbs more moisture, expands, and the capillary action is enhanced, so the water conductivity of the fabric is enhanced. The influence of temperature is the same as that of humidity. Therefore, the environment has a great impact on water – conductive fabrics.

Measuring the water permeability or waterproofness of a fabric is to measure its water repellency or water conductivity. Different methods are adopted according to the actual use of the fabric, and various corresponding indicators are used to represent the water permeability or waterproofness of the fabric. These changes, however, have minimal effects on hydrostatic pressure tester results for non-hygroscopic materials.

Testing Methods

Hydrostatic Pressure Method

The hydrostatic pressure method refers to the water seepage ability of the fabric under a certain water pressure. It is applicable to all types of fabrics, including those that have undergone waterproof finishing.

The waterproofness of a fabric is related to the water resistance of the fiber, yarn, and fabric structure. The test results are different from those obtained when water is sprayed or rained on the fabric surface. For testing the waterproofness of fabrics using the hydrostatic pressure method, there are static pressure and dynamic pressure methods. The static pressure method involves applying a static water pressure on one side of the fabric and measuring the water output, the time when water droplets appear, and the static water pressure value at a certain water output. The static water pressure value can be the height of the water column or the pressure. In actual measurement, the water permeability per unit area and unit time (mL/cm²·h) is measured. For waterproof fabrics, the time required for water droplets to appear on the other side of the sample is measured, or the number of water droplets that appear on the other side after a certain period of time is observed.

The dynamic pressure method involves applying an increasing water pressure P at a constant speed on one side of the sample until a certain number of water droplets appear on the other side. The principle of the imposed water pressure P is the same as that of the static pressure method, except that P is a variable. This method is more suitable for coated fabrics or fabrics with a dense structure. The waterproof performance of the fabric is reflected by the hydrostatic pressure. Fabrics with a large hydrostatic pressure have strong waterproof performance, and those with a small hydrostatic pressure have weak waterproof performance. Water – conductive fabrics have strong moisture absorption ability, get wet when in contact with water, have no water resistance, and will not generate hydrostatic pressure.

In the AATCC 127 – 2003 test method experiment, at least three samples with a size of 200 mm × 200 mm are taken diagonally from the test sample. If the two sides of the sample have different waterproofness, mark them. Test with distilled water at (21 ± 2) °C. The test area is 100 cm². The test surface is in contact with water, and the water pressure increases at a speed of 60 mbar/min (or 10 mm/s). If water droplets seep out at three different places on the sample, the test reaches the end point. However, water droplets that seep out within 3 mm from the sample clamp are invalid. The test result is the average of the three test samples under the same conditions. The larger the test value, the greater the pressure required for water to seep out of the sample, and the better the waterproofness.

The hydrostatic pressure test evaluates a fabric’s resistance to water penetration under pressure. This method is suitable for all fabric types, including those with waterproof finishes.

The hydrostatic pressure value is determined by applying water pressure to one side of the fabric and observing when water droplets appear on the opposite side. A high hydrostatic head rating indicates superior waterproof performance.

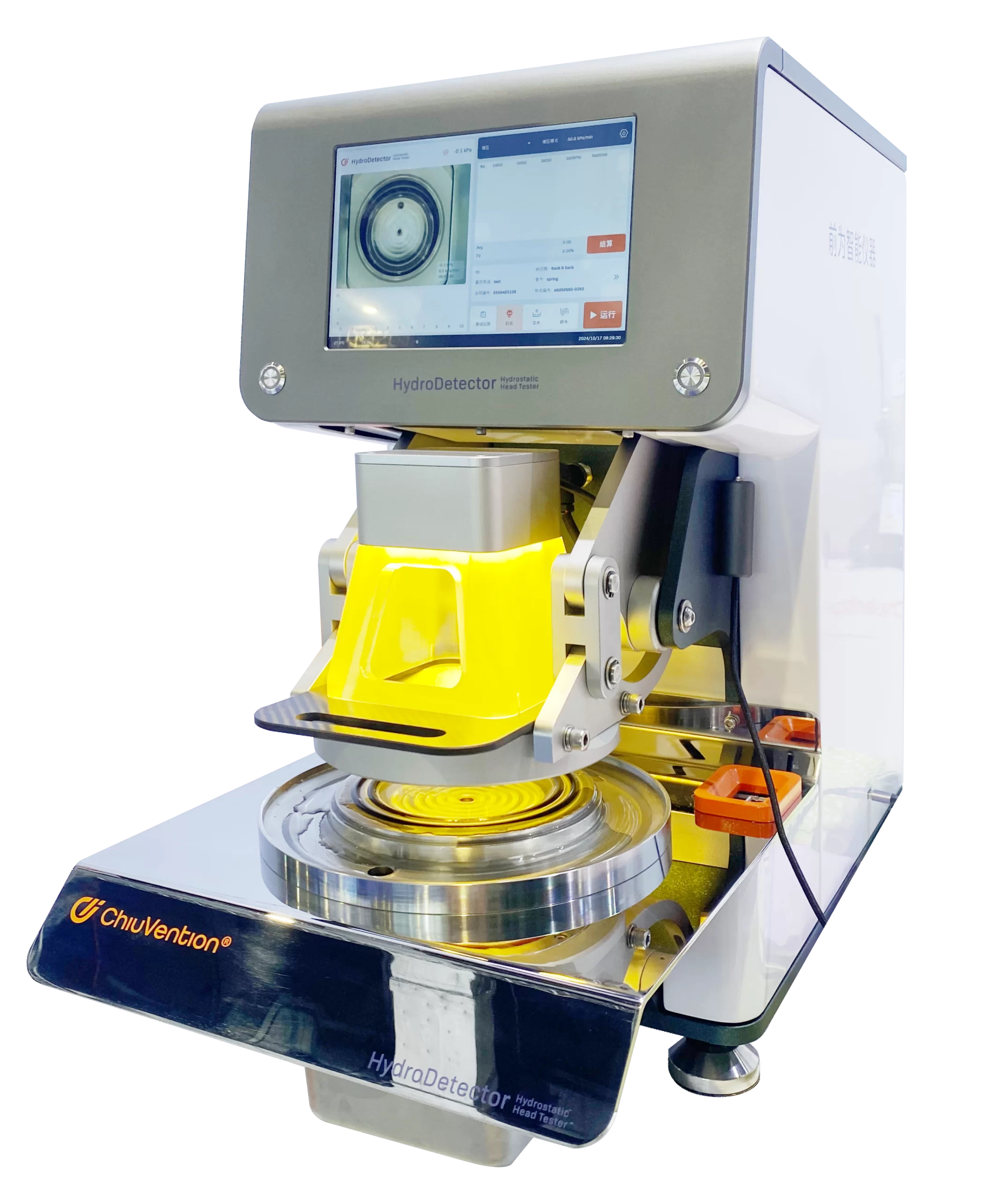

For example, theHydroDetector HydroDetector Hydrostatic Head Tester measures the water resistance of materials in terms of water column height, providing precise fabric waterproof ratings for industrial and apparel applications.

Spray Method

The spray method involves continuously spraying or dripping water onto the sample, observing the water stain characteristics on the surface of the sample after a certain period of time, and comparing it with sample photos of various wetting degrees to evaluate the waterproofness of the fabric. The spray method simulates the degree to which clothing gets wet when exposed to light rain. This method is applicable to all fabrics that have undergone waterproof treatment and untreated fabrics. The waterproof results obtained are closely related to the treatment of fibers, yarns, and fabrics as well as the fabric structure. A spray performance tester determines how water droplets interact with the fabric’s surface, providing insights into its waterproof fabric capabilities.

Usually, a spray – type water – repellent performance tester is used for measurement. In the AATCC 22 – 2005 test method, the test sample is fixed with an iron ring with a diameter of 152.4 mm. The sample is in a taut state with a flat surface and no wrinkles. 250 mL of distilled water is sprayed at a 45° angle from a standard nozzle onto the sample 150 mm below the nozzle for 25 – 30 s. The bottom of the iron ring with the sample is tapped once against a solid object, with the test surface facing the solid object. Then, the iron ring is rotated 180° and tapped again. After that, the sprayed sample surface is compared with the standard chart for grading to evaluate the water repellency of the fabric. There are five evaluation levels, with 5 being the best and 1 being the worst. Level 5 – no water droplets adhere to the test sample surface; Level 4 – slight wet spots on the test sample surface; Level 3 – obvious raindrop marks on the test sample surface; Level 2 – part of the test sample surface is wet; Level 1 – the entire test sample surface is wet.

Rainfall Method

The rainfall method simulates the water repellency of the fabric exposed to the air during heavy rain. This method is applicable to any fabric that has or has not undergone water – repellent finishing.

This test is essential for verifying hydrostatic head ratings for outdoor gear.

The impact water permeability of a single – layer fabric or a composite fabric is measured under different water impact intensities. The test results are related to the water – repellent performance of the fibers, yarns, and fabric structure in the fabric. The principle is to wrap the test sample around a pre – weighed absorbent paper. After the test, the absorbent paper is weighed again, and the difference in weight between the two times is the water permeability of the sample. It is required that the mass difference of the absorbent paper before and after the test does not exceed 1 g; if the mass difference is greater than 5 g, it indicates that the fabric has very poor water resistance.

In the experiment, a rainfall tester is used. In the AATCC 35 – 2006 test method, a 15.2 cm × 15.2 cm standard absorbent paper is placed behind the sample. The standard absorbent paper is weighed accurately to 0.1 g. On a vertical rigid surface, the sample is clamped in a sample holder and placed in the middle of the spray. It is 30.5 cm away from the nozzle, and water at (27 ± 1) °C is sprayed horizontally directly onto the sample for 5 min. After the spraying is completed, the absorbent paper is carefully removed and weighed quickly and accurately to 0.1 g. Calculate the weight increase of the absorbent paper during the 5 – min spraying time, and take the average of the test data. If it is greater than 5.0 g, report it as + 5.0 g or > 5.0 g.

Wicking Method

The wicking method measures water absorption through capillary action. While not directly related to hydrostatic pressure, this method evaluates water conductivity, a critical factor in comfort for non-waterproof textiles.

The wicking method (i.e., the capillary effect commonly referred to) is currently the most commonly used and simplest method for directly testing the water absorption of fabrics. Usually, the test sample is cut into a long strip. One end of the test sample is hung on an iron stand, and the other end is in contact with the water surface (or immersed in water to a certain height). After immersion for a certain time (t), the height (h) that the water climbs through the capillaries and fiber pores of the fabric is measured. Fabrics with good water conductivity have strong water absorption and a fast water absorption speed (i.e., wicking speed). The climbing height per unit time is large, that is, the water conduction height is high. If, during the test, due to the fabric structure, fiber, yarn, and color, the water climbing process is not very obvious and cannot be clearly observed with the naked eye, a little coloring agent can be added to the water.

The wicking speed (v) depends microscopically on the physical and chemical properties of the fiber and the thermal equilibrium process of the liquid molecules; macroscopically, it depends on the shape and direction of the pores. The wicking speed is the height value that the water rises per unit time, that is, v (cm/s) = h/t. The strength of water conductivity is related to the wicking speed. Therefore, wicking can be used to test the water conduction ability of fabrics.

Choosing the Right Testing Method for Different Fabrics

The above various testing methods for water permeability are applicable to all fabrics. In actual work, different testing methods can be used for different fabrics to better measure the water permeability or waterproofness of the fabric:

- For coated fabrics, due to their organizational structure, the water permeability can be tested by the spray method, rainfall method, and hydrostatic pressure method, but the wicking method is not applicable.

- Generally, when testing by the wicking method, it will be found that the water absorption performance of knitted fabrics is better than that of woven fabrics.

- Fabrics that get wet immediately when in contact with water cannot be tested by the hydrostatic pressure method, but can be tested by the spray method.

In conclusion, accurate testing of waterproof fabrics ensures their performance aligns with industry standards and specific applications. Methods like the hydrostatic pressure test and rainfall simulations provide reliable insights into a fabric’s water resistance, while wicking tests complement by assessing water conductivity.

Understanding and applying these tests effectively can enhance product design, quality control, and customer satisfaction in the textile industry.