As the global ‘greenhouse effect’ intensifies, demand for summer garments is rising. People want cool, quick-drying, moisture-absorbent fabrics. There is a need for new, cool fabrics. The exact name of coolness is ‘instantaneous coolness on contact’. Here, “instant coolness” means the fabric is cooler than the skin. It causes rapid heat loss from the skin’s surface, lowering its temperature. The skin’s temperature-sensitive nerves send a signal to the brain. This creates a feeling of coolness.

At first, ‘cool feeling clothes’ was only a conceptual garment. In the international arena, it was first developed by Japan. Japan aims to reduce dependence on air conditioning in summer. This is to save energy and slow global warming. It also seeks to create a national movement to combat global warming. Next, researchers made a man-made fibre called Cupro Breathable Fibre. It has deodorising properties. Then the United States improved the Japanese technology. The idea of coolness led the American Fibre Research and Development Corporation to create many cool fibres from their structure and the raw materials.

Cool, feeling fabrics can absorb moisture and sweat. They dry and cool, with instant cooling and other traits. On contact, they quickly export moisture and heat from the skin. This keeps the skin dry and cool, making the clothes like a personal air conditioner. In hot summers, they cool silk. This lets people enjoy a refreshing world. This is a new innovation in sportswear and outdoor leisure clothing fabrics. Cool Feeling Fibre uses extraction and nanotech to modify natural powders. These include jade, shell, and mica. They then processed these into nanoscale particles. Finally, they spun the particles with hydrophilic slices. The fibre’s cross-section design creates a ‘capillary effect.’ It speeds up heat dissipation.

1. Cool feeling fabrics cool feeling principle

Cool sensation, the exact name is ‘contact instant cool sensation’. Here, it refers to the skin and fabric touching. It causes rapid heat loss from the skin’s surface. The temperature drops instantly. Then, the skin’s temperature-sensitive nerves send signals to the brain. This creates a cool feeling. The cool feeling formed after the brain. Cool feeling fabrics are comfortable, absorb moisture, and wick sweat. They quickly remove heat and moisture from the skin, keeping it dry and cool. Cool feeling fabric’s cool performance depends on the fibre’s thermal conductivity. Dryness refers to the fabric’s ability to absorb and dissipate moisture.

2.What is coolness in the end?

Coolness mainly refers to ‘instant coolness on contact’. Textile sensory performance means that fabric cools the skin. It causes a rapid heat loss, which drops the skin’s temperature. The skin’s temperature-sensitive nerves signal the brain. This creates a cool feeling.

Cooling fabric is unique. It uses modified fibers or special finishes. It quickly diffuses body heat and speeds up sweating. This cools you and keeps the fabric comfortable. And cool, functional fabrics are widely used in clothing, home textiles, and outdoor gear.

Cool fibre products’ cool feeling comes from their thermal conductivity. “Cool products of dryness” means the fabric can absorb sweat and moisture.

3.Cool fibre products of cool feeling and dryness is mainly reflected in what aspects?

Cool fibre products cool feeling and dryness is mainly reflected in two aspects:

(1) The fabric has good thermal conductivity. Its cold contact is obvious. So, the wearer feels a coolness.

(2) Various processing techniques change the original fabric structure of cool fibre products. This allows sweat to quickly disperse. It keeps the body’s surface dry and comfortable.

4. Realisation of cool sensation function

Skin contact with textiles can cause rapid heat loss from the skin. So, textiles must have good thermal conductivity. They should absorb and retain heat slowly. Or fabrics that absorb moisture and sweat. They should cool and dry quickly. This helps to expel moisture and heat from the skin, keeping it dry and cool.

Now, there are three main ways to make textiles cool-sensitive. They are cool-sensitive fibres, cool-sensitive finishing, and new tech materials.

01 Cool Feeling Fibre

Cooling fibre is mainly prepared through physical modification and chemical modification.

Physical modification is divided into two methods:

(1) We micronised, using a special process, mica, jade, and other heat-dissipating substances. Then, we added a spinning solution in a specific ratio. Next, we passed it through a specially shaped spinneret. Finally, we formed cool-sensitive fibres with a high, consistent thermal conductivity.

(2) Change the spinneret shape to get a special fibre cross-section. This will increase the fibre’s moisture absorption and permeability. Chemical modification is to change the types of atoms or groups on the macromolecular chain, or their combinations. It usually uses three methods: copolymerisation, grafting, and cross-linking. It improves the thermal conductivity, moisture, and air permeability of textiles. Such as Sophista fibre.

02 Cool Feeling Finish

Cool sense finishing adds cool sense additives to fabrics. It mainly uses the volatility of cool sense finishing agents. They react with water to absorb heat. This cools the skin. The finishing agents take away heat due to their volatility. They also lower the skin’s temperature by absorbing heat from sweat. Common cool sense finishing agents are peppermint oil and xylitol. They have good volatility and a heat-absorbing reaction with water. Xylitol, etc. The cool sense finishing aid has a drawback. It is not persistent and will fade with more washes.

03 Other new materials

Phase change material is a latent heat storage material. It can absorb, store, and distribute heat at a specific temperature by changing its phase. This allows for good temperature regulation, making it ideal for cool textiles. They have applied the technical material to space suits. They can control temperature and manage heat and humidity on the human surface.

As technology develops, innovative nanomaterials have emerged for temperature-regulating textiles. Monash University researchers have made a nanofilm of caesium-doped tungsten oxide (CsxWO3). It can coat fabrics, blocking near-infrared rays and cooling them.

5. The test of cool-sensitive effect:

There are two main tests for cool-sense textiles. One is the direct temperature sensor method. The other is the Qmax method.

A. Temperature sensor direct measurement method

The direct temperature sensor method tests cool fabrics that absorb and conduct moisture. It is suitable for both. First, dry the sample in an oven at 70°C. Then, put it in a chamber with a controllable temperature and humidity. Set the temperature to 35±0.5°C and the humidity to 27%±3%. Next, drop 0.5mL of water (35±0.5°C) in the center of the specimen. Quickly fold the specimen to place the temperature sensor in its center. Finally, clamp the sensor in place. Researchers recorded the temperature every 5 minutes until the end of 60 minutes. You can obtain a temperature-time curve from the recorded temperature data. A lower temperature at the curve’s lowest point makes the cooling more noticeable. A lower temperature at the end of the test makes the fabric stay cool longer.

B. Qmax Method

The standard ‘Testing and Evaluation of Textiles for Instantaneous Cool Feeling Performance in Contact’ took effect on 1 July 2018. It specifies test methods for the cool feeling of textiles in contact with skin. It applies to all types of fabrics and their products. The test principle is as follows. Under specified test conditions, a thermal test plate, hotter than the specimen, is put in contact with it. We then measure the thermal test plate’s temperature change over time. From this, we calculate the contact coolness coefficient (Qmax). This coefficient characterizes the specimen’s instantaneous coolness in contact with the skin. The contact coolness coefficient Qmax is the temperature above the sample’s specified temperature. It is the maximum heat flow in the transfer process between a heat detection plate and a sample at a certain pressure. A larger Qmax value means the skin feels cooler. A smaller value means a weaker coolness sensation.

6. Cool sense of fabric purchase tips

To buy the real cool feeling fabric, first, use the proper channels. It’s best to choose a famous brand. Also, pay close attention to the commodity tag. Don’t trust the business propaganda. Check if the label meets the relevant standards. If you make the purchase offline, we recommend feeling the surface of the fabric to ensure it is flat and smooth. The fabric’s surface is flat and smooth. So, it feels cool to the touch.

Finally, some cool fabrics use finishing agents. Others add a trace of jade or mica powder to create a ‘cool feeling.’ Therefore, consumers can smell the smell when shopping, if there is an irritating odour, it is best not to buy. Also, the added finishing agent, cool fabrics, will weaken after many washes.

7.Cool Feeling Fabric Performance Test

7.1 Moisture absorption and quick drying test

The standard ‘Evaluation of moisture absorption and quick drying of textiles part 1: single combination test method’ tests the sample fabric’s moisture absorption. It uses the water absorption rate and drip diffusion time. It tests the quick drying performance by the evaporation rate.

7.2 Cold sensation performance test

Provided after testing the instant coolness of fabrics per the standard ‘Measurement and Evaluation of Instantaneous Cooling Performance of Textiles in Contact’.

8. Cool Feel Fabric Testing Procedure

The cool-feeling fabric testing procedure includes the following key steps:

Test sample preparation:

SmartCut Fabric Sample Cutting System has smart sample-cutting software. Users can select cutting patterns and sizes based on project or test standards. You can save these as a template for easy future access. The SmartCut will use a unique algorithm. The team will lay out the sample graphics of the test items per the standards. Next, we will project the sample graphics on the fabric. Then, the SmartCut will cut the fabric samples, marking them as per the customer’s settings. It can complete the sampling of fabrics within 3 minutes. And it is suitable for dozens of tests, including pilling, tearing strength, and flammability. It also tests water repellency, anti-static, tensile strength, and color fastness. They cut the test into 20 x 20 cm² samples to ensure they were flat and defect-free.

We kept the samples at 20±2°C and 65±2% RH for 24 hours to acclimatise.

Test Environment Setup:

Using the AtmoExplorer chamber, set the temp to 25±2°C and humidity to 65±5% RH. Wait at least 1 hour for stability.

Test Equipment Operation:

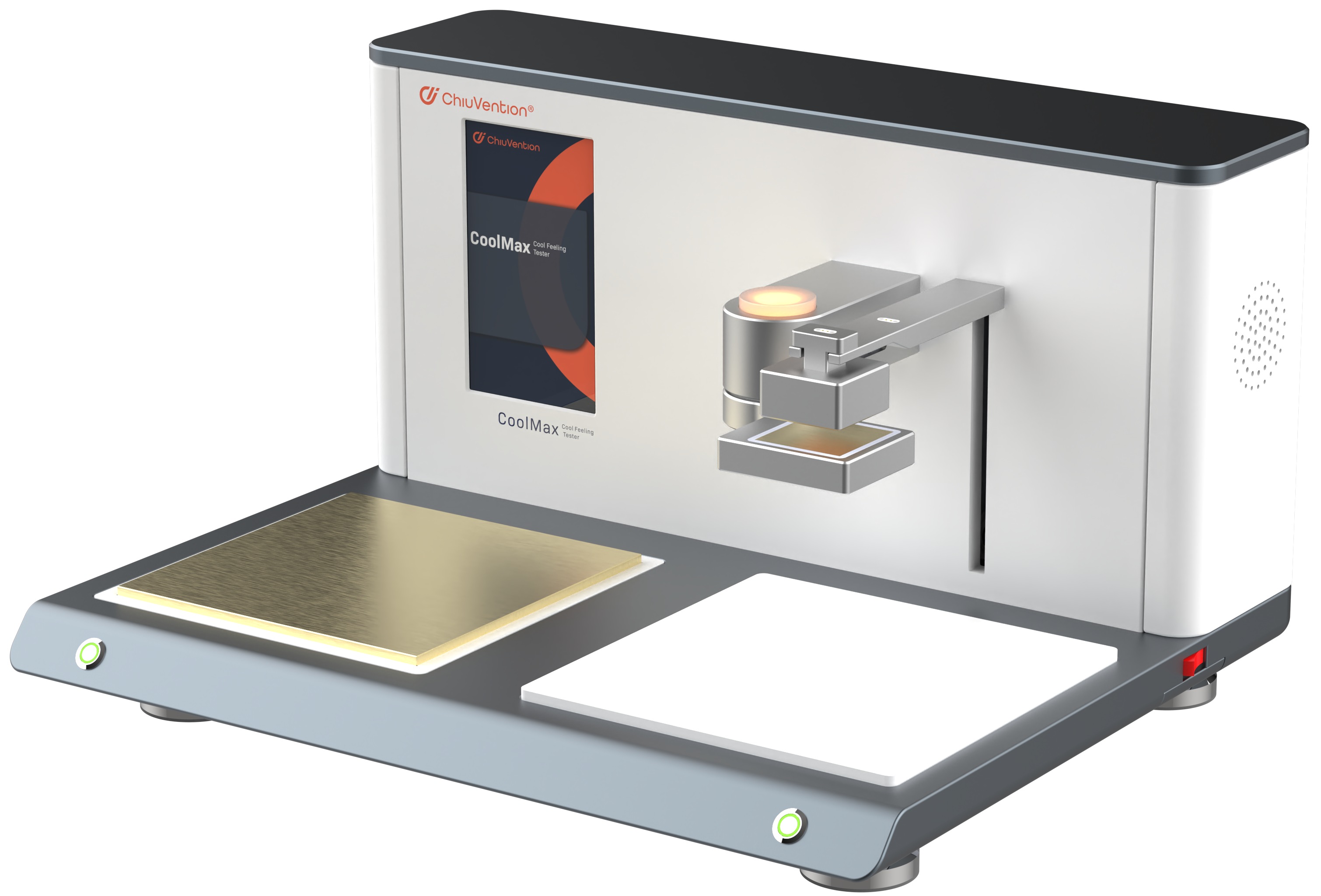

Use the CoolMax Cool Feeling Tester for operation.

The CoolMax Cool Feeling Tester takes just 10 seconds to test. This makes it ideal for batch testing in textile R&D, production, and quality control. Adjustable parameters: test settings (like heating plate temp and pressure) a device at the same time to meet various standards. It must adapt flexibly to many tests. The device must simulate human-body and textile contact scenarios. High-precision temperature sensors will record temperature changes every 10 seconds. This will quickly and accurately measure how well the textile cools. You can adjust test parameters to different standards. This allows for flexibility in testing.

Test execution:

Set the cold plate at 25°C, then place the sample fabric on the cold plate with the fitted side up.

When the hot plate reaches 35±0.5℃, quickly place it on the sample fabric. Record the Qm value on the display screen. It is the maximum instantaneous heat loss of the fabric in contact with the cool feeling. The unit is W/cm².

Result processing:

The instrument uses IoT to connect to the SmarTexLabAPP on a phone or computer. It also connects to ERP/LIMS via API. The instrument can connect directly to ERP/LIMS software. It will analyze and generate Q-max.

Report writing:

After the test, make digital raw records of the process, results, temperature, and humidity. Upload them to the system, along with a test summary, to create reports. All relevant parties can view the report in real time.

The above steps can effectively test cool fabric. They will ensure its cool effect in real-world use.

9. Factors affecting the results of cool-feeling fabric tests

The main factors that affect the results of cool-feeling fabric tests include the following:

Fibre type:

Different fibres have different coefficients of thermal conductivity and specific heat capacities, resulting in differences in the performance of cool-feeling fabrics. For example, the contact coolness of Ramie, Linen, Modal, Polyester, Viscose, Cotton and other fibres are in the following order from strong to weak: Ramie > Linen > Modal > Polyester > Viscose > Cotton.

Surface structure and organisation of fabrics:

The surface roughness and organisational structure of fabrics affect their contact coolness. Fabrics with greater surface roughness, such as knitted fabrics, usually have better coolness. In addition, the organisation of the fabric (e.g. plain, twill, wrought) also affects its contact area with the skin and the cooling effect.

Fabric thickness:

The thickness of a fabric directly affects its heat capacity and coolness duration. Thicker fabrics have a greater heat capacity and are able to absorb more heat, thus providing a longer lasting cool sensation.

Fabric moisture content:

The moisture content of a fabric in different environments affects its coolness performance. For example, fabrics in motion have a higher moisture content, which may affect their cooling effect.

Temperature and humidity of external environment:

The temperature and humidity of the external environment can also affect the coolness performance of fabrics. The cool sensation of fabrics may be diminished in high temperature or high humidity environments.

Other factors:

Factors including the thermal conductivity of the fabric, moisture retention, and pressure on the human body may also affect the performance of cool-feeling fabrics.

In summary, the test results of cool-feeling fabrics are affected by a variety of factors, including the type of fibre, the surface structure and organisation of the fabric, the thickness of the fabric, the moisture content of the fabric as well as the temperature and humidity of the external environment. These factors work together to determine the actual performance and user experience of cool feeling fabrics.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com