Introduction

Standards guide and regulate production enterprises. They help them prepare the instructions for use of textile and apparel products. They also help consumers understand the product’s basic information when purchasing. However, many people have an inaccurate or inconsistent understanding of the standards. To address this, this paper explores the attributes of instructions for use. It discusses test attributes, result judgement, and the application of testing scales. And it offers suggestions to improve the situation.

It says that instructions for use only carry product information. They do not measure quality. You should not use them to judge a product’s quality level. The test attributes of instructions for use are a form of testing. We can apply the results to trade acceptance and market supervision.

If someone needs a comprehensive assessment, they should use defect documents. You should test and evaluate instructions for use and product quality separately. We should only deem them conforming or non-conforming, not qualified or unqualified.

This paper proposes principles for a test of the instructions for use. It should be comprehensive. It includes a check of the relevant scales in the inspection when there are no specific rules.

Background

The national standard for textile and clothing instructions was first introduced in 1987. They revised it three times. In March 2017, it changed from a mandatory to a recommended standard. The standard aims to guide and regulate production enterprises. It helps them prepare the instructions for using textile and apparel products. It also helps consumers understand the products’ basic information when buying. This has been vital for the product standards in the use instructions. It has also aided in supervising the product market.

The standard desk has been in use for over 30 years. But, there are still many problems with it. Some misunderstand it. Others do not apply it properly. The code is also unlimited. Judgments are subjective. Some arbitrarily decide a product’s quality.

In general, the left side is tight, especially in supervision. These problems and biases hurt production and marketing units. They harm the economy and the reputation. Such cases are common.

The inspection agencies have different understandings and skills with the scale. This has confused the production and marketing units, the agencies, and the regulators. We must discuss and share ideas to reach a clear, shared understanding.

Currently, the product description of the judgment is more reflected in enterprise production. The issue is a strict, subjective, and arbitrary focus on scale. Compared to enterprises, agencies, inspection bodies, malls, and e-commerce platforms have more power. There are also biases in understanding concepts and standards. This has led to a rise in various problems in recent years. The local mastery of institutions is inconsistent. This confuses not only enterprises but also the agencies.

For example:

The instructions for use do not meet the situation. The product is of substandard quality. There are exposures and fines. Enterprises feel wronged but do not know how to argue.

There is no difference between heavy and general defects. The principle of division is unclear and arbitrary.

People dislike heavy defects, unclear general defects, or unfair treatment.

The use instructions are specific and demanding. Judges will consider any deviation unqualified. This includes the manufacturer’s and millimetre-registered names (even if abbreviated). The product name must match the standard name. You must list the standard’s specification number. The product name must match the standard’s implementation. The standard’s application scope must be fully covered. There must also be no printing discrepancies.

Some organizations have a ‘double standard’. They are more lenient with their customers but strict with other businesses. Their purpose is clear.

1.On the nature of the product instructions for use attributes

What are the instructions for use of the product? Does it belong to the category of product quality? To clarify this issue is crucial to the accurate use of instructions.

1.1 The concept of produc instructions

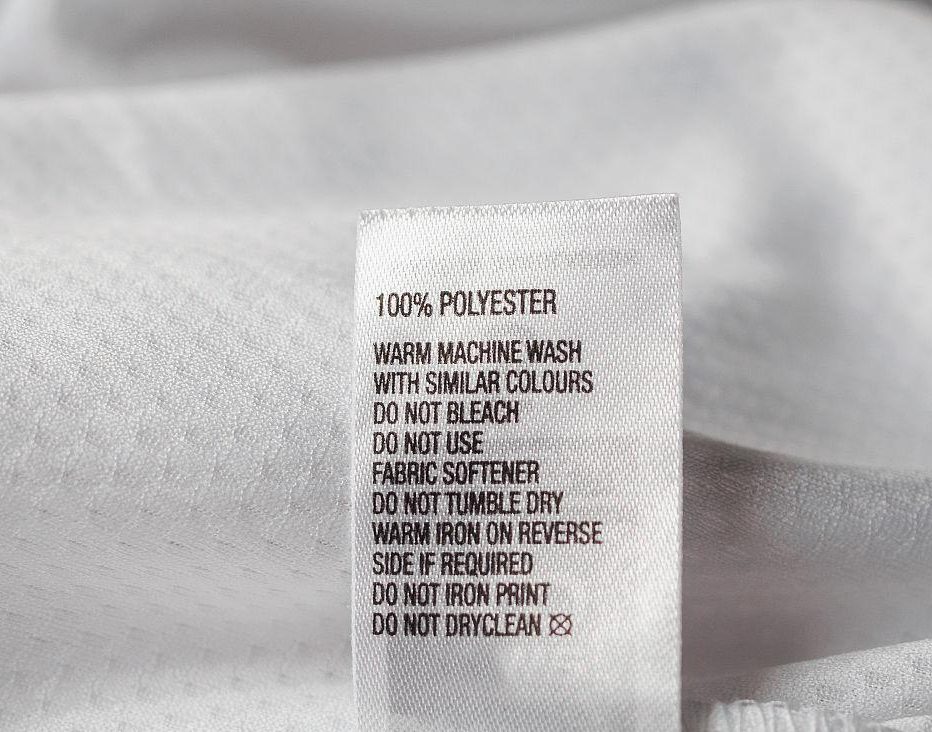

The introduction to the standard’s general provisions has this paragraph: ‘Instructions for use’ is to truthfully inform consumers of the correct and safe use of products. It must protect their safety, health, and property. It should avoid pollution and prevent deception. The goal is to protect consumers’ interests.

The standard for using instructions is to inform consumers. They must convey how to use the product safely and correctly. They must also explain the product’s function and performance. This information is usually in user instructions, labels, and nameplates. You can express it in words, phrases, logos, symbols, charts, diagrams, and audio or visual info. And you can do this alone or in combination. You can use them on the product, the packaging, or in documents.

The standard’s terms show that the “instructions for use” only transfer product info. They are separate from the product. The instructions are a necessary part of the product to the consumer, not the product itself. They describe a method to transfer the product’s performance, not its traits.

So, the use of instructions is to show the product’s features. It is a key source of info about textile and apparel products. It is also the main way for consumers to learn the product’s basic attributes.

1.2 Product instructions and product quality

Product quality is the sum of its characteristics and features. It must meet specified and potential needs. This applies to both simple and complex products. We can describe product quality using its characteristics or features. Product quality characteristics vary with the product. The parameters and indicators also perform in diverse ways. Users want quality that meets their needs. They summarize it in performance, life (durability), reliability, maintenance, safety, adaptability, and economy.

The Product Quality Law holds producers responsible for product quality. But, it only covers the product itself.

It defines three quality aspects:

① The product must not endanger people or property. It must meet national and industry standards for health and safety.

② The product must perform as intended.

③ The product or its packaging must match the stated use. The product or its packaging states it meets quality standards. This is in line with the product description, samples, and tests. Article 27 sets the requirements for product instructions. Other articles state that producers must be legally responsible for product quality. They must not produce obsolete, counterfeit, or substandard products. A limit defines the penalty for substandard, counterfeit products. The product must meet health and safety standards. Also, its labels must meet the requirements. If they don’t, the product is of a different nature. The quality law defines separate penalties for those cases. The special article on product labelling sets rules. It orders a fix for noncompliance, with light penalties for violations.

So, quality law defines product instructions (labelling) as a sign of quality. The product technical/quality standard information contains the instructions. They are the basis for assessing product quality. They show the manufacturer’s commitment to quality, not the product’s quality. In other words, if a product’s label doesn’t comply with the regulations, it only indicates that. It does not involve the product’s quality.

1.3 Quality in Textile Product Standards

For specific products, like shirts and bedding, there are standards. These set requirements, test methods, grading, inspection rules, and marking. They also cover packaging, storage, and transport. So, the standards define the product quality. They are the main basis for judging quality.

The standard clearly defines the link between product quality and instructions. Each standard method is different. We can summarize them in the following cases.

(1)The standard requirements, grading provisions, and inspection rules do not cover the instructions for use. Only the final chapter on the standard logo mentions it. It says that the product quality assessments do not involve the instructions for use. Also, it does not involve the use of the product, its packaging, or its storage and transport. It’s only about the delivery of essential accessories or general guidance. But, it does not involve any assessments or judgments. Such as knitted products, home textile products, leather and fur clothing, bags and other standards are basically this situation.

2. Grading provisions

2.1 We divide quality grade into superior, first-class products, and qualified products.

2.2 Intrinsic quality, per the criticism; appearance, per the tests. The lowest grade sets the combination of the two.

2.3 Use the lowest test result of each quality index to evaluate the batch of products.

2.4 Assess the lowest grade if a product has cosmetic quality problems of different grades. If two extreme surface defects of the same grade exist, downgrade the one that exceeds the limit.

3 Judgement rules

3.1 Batch judgement

3.1.1 Intrinsic quality

If any product does not meet the requirements of 1.2, we will deem the batch unqualified. Of them, the colour fastness project does not meet. The batch of products failed the colour test. If at least 2 pieces pass inspection after washing, the batch qualifies. Otherwise, it has failed.

3.1.2 Appearance quality

The variety and color of the non-conformity rate determine the appearance quality. A non-conformity rate of 5% or less qualifies a batch of products. A rate above 5% deems the batch unqualified.

4 Product instructions, packaging, transport, storage

Use the product as per the standard. It applies to children’s products.

4.1 Packaging in accordance with the standards or agreements.

4.2 The transport of products should be moisture-proof, fire prevention, pollution prevention.

4.3 Store products in a cool, dry, clean, ventilated warehouse, moth-proof and mould-proof.

(2) The standard requires using the instructions in its provisions. But, the inspection rules and quality assessments do not mention them. The standard’s product quality assessment and the instructions do not relate to each other. The same applies to the logo at the end of the standard and the sections on the instructions, packaging, and storage. Most woven garments are in this situation.

5 Requirements

5.1 Instructions for use

The product’s instructions for use must meet the standard. The product for children aged 3 to 14 must also meet the standard.

5.2 Size specification

5.2.1 Model set according to the standard (all parts) selection.

5.2.2 The main part of the finished product specs standard (all parts) and the standard design’s relevant parts.

6.Batch grade judgement

Superior batch: 90% of the samples must be superior. Less than 10% must be first-class or qualified. We do not allow substandard products. All tests of physical and chemical performance meet the standards for top products.

First-grade batch: The appearance test must have at least 90% first-grade products. The qualified products must be less than 10%. We do not allow substandard products. All physical and chemical tests must meet the first-grade standards.

Qualified products batch: Appearance inspection samples of qualified products and more. At least 90% must qualify. Non-qualified products must be less than 10%. There must be no serious defects. The products must meet public standards and tests. The physical and chemical tests must meet the required indexes.

7. Marking, packaging, transport and storage

Finished product marking, packaging, transport and storage in accordance with the standard implementation.

Among them, the standard part of the content

8. Marking

8.1 Product instructions

Instructions for use is an integral part of the delivery of the product. A product description must meet the standards. It must detail the content, form, location, and other requirements.

8.2 Packaging mark

8.2.1 Transport packaging must show the goods’ number, name, type, and quantity. It must also show the enterprise’s name and address.

8.2.2 Transport, storage signs must match the relevant criteria.

8.2.3 Packaging signs should be clear and conspicuous.

9.Packaging

9.1 Packaging requirements

9.1.1 Packaging materials should be clean and dry. They should be eco-friendly, non-polluting, or recyclable.

(3)There are very few standards in the requirements for using instructions. Some did not mention them. The table did mention defects, but only light ones. The grading provisions, inspection rules, and tests did not use the instructions to judge. The standard is to assess only the instructions. A minor defect, like “product instructions,” is not relevant. So, the case’s quality excludes the use of the product instructions. The standard’s section on labelling, packaging, and transport includes product use instructions. This is the same as in 2) above.

10. Requirements

10.1 Instructions for use

The instructions for use are set out in the standard. Mark the down filler with its type and content. The down content must meet the sub-stage’s rules.

10.2 Model specifications

The size of the police in accordance with the provisions of the standard (all parts).

In either case, the standard grades the product’s quality. The evaluation considers its internal and external performance. The assessment does not consider the product’s instructions for use.

11. Summary

The product instructions are only a carrier of product info. They are not a quality standard. The product standard does not rate quality, but covers packaging, storage, and transport. They are like a product’s delivery of accessories or general guidance. They do not involve assessment or evaluation. You can only use the instructions to meet the evaluation requirements. They must make them separately.

A common example is this:

Buyers will read the instructions, labels, and packaging of goods. They want to verify their contents. Some people still trust some channels for direct factory buys. These include cashmere sweaters and liquor. They also trust them for batch orders. They believe in the quality, even if there is no label or just a minimalist “white label.” This is because they know the brand and the product. They need the product, not the instructions. A lack of labels won’t affect their trust in the product’s quality. This shows that the instructions and the product are different. They are even less related to product quality. The instructions are to help people buy and use the product. In some cases, a full understanding of the instructions is not needed. Their omission or simplification does not affect people’s choices or trust.

Since the product quality law on labeling, consumers must use the goods’ instructions. It’s the main way to know the product’s attributes. So, it’s very necessary. So, the product standard on using instructions (signs) cites 5.2. It requires testing if the product instructions meet the standard. The tests for the product and the instructions must be separate. The product quality law has different requirements for product quality and labeling. It also requires separate disposal of the results. If the instructions for use deviate from the standard, it means they are defective. The product quality is not related to the instructions. Mixing these judgments is unacceptable. Thus, we should not determine that the product is unqualified. Back up a thousand steps, even if the third case above. The instructions for use and the light defects appeared at the same time. Supervision and sampling usually do not detect the defects. The appearance of the batch of samples is generally difficult to meet. So, we cannot conclude that someone has deemed the quality unqualified.

In short:

Product instructions are part of the product delivery (with the packing list, packaging, etc.).

And product use instructions are not the basis for judgement of product quality

Product use instructions do not match ≠ product quality is unqualified

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: medium@chiuvention.com