In the ever-evolving textile industry, the demand for high-performance fabrics, especially fast-drying materials, continues to grow, driven by the popularity of activewear and outdoor clothing. Understanding the science behind moisture absorption, wicking, and drying rate is critical for developing fabrics that meet consumer expectations for comfort and functionality. This is where Drying Rate Testing plays a crucial role.

Through standardized Drying Tests and advanced Dry Rate Testers, textile manufacturers can measure the efficiency of moisture evaporation, ensuring their products perform well in various environmental conditions. This article provides an in-depth exploration of Drying Rate Testing, highlighting its significance, key procedures, innovative advancements, and standards that guide its application. For those wondering how to calculate drying rate or understand the dry test meaning, this guide is your comprehensive resource. Whether you’re developing the next generation of quick-dry materials or enhancing your product labeling, mastering these concepts will empower your business in a competitive market.

Understanding the Importance activewear is more Famous in the Textile Industry

Today’s textile industry is more competitive than ever. Whole suppliers & manufacturers focus is to meet consumer satisfaction with high demand. In current global context in textile, active wear gained immense demand & popularity due to change of lifestyles in globe & lot of evolving trends as below. Those factors dominate the active wear segment in current industry.

- Rise in Health and Fitness Awareness – With growing awareness about health and wellness, people are greatly engaging in physical activities such as gym workouts, yoga, running, and sports.

- Athleisure Trend – The fusion of athletic wear and leisurewear has revolutionized fashion. Activewear is no longer limited to workouts; it is now worn casually in daily life, blending style with functionality.

- Technological Advancements in Fabrics – Modern activewear incorporates advanced textile technologies, such as: Moisture-wicking properties to keep the wearer dry. Breathable fabrics to ensure comfort.

- Comfort and Performance – Activewear provides a balance of comfort and performance, making it suitable for high-intensity workouts and casual wear.

Understanding the Importance of dry rate Testing in active wear Textile Industry

The textile business is exceptionally competitive, expecting manufactures to fulfill best quality guidelines to fulfill consumer needs. One basic quality control measure in this industry is dry rate testing. This test assesses the drying execution of materials after expose to moisture, giving important bits of knowledge into fabric’s behavior and functionality in real-world conditions.

Key Purposes behind Leading Dry Rate Testing

Consumer Satisfaction

Fast drying materials are profoundly attractive for sports clothing, outside stuff, and home materials. Dry rate testing guarantees material dry quickly, taking special care of consumer preferences comfort. Materials that dry quicker are seen as additional agreeable, especially in hot or humid circumstances.

Product Performance

Active apparel and outside pieces of clothing frequently guarantee / claim moisture wicking and quick drying properties. Dry rate testing validate these cases, assisting brands with keeping up with validity and consumer trust.

The test helps suppliers & manufactures with optimize yarn material blends texture mixes (e.g., synthetic filaments like polyester or nylon) to improve drying execution.

Energy Efficiency and Sustainability

Textures with better drying rates consume less energy during machine drying processes. This decreases functional expenses for customers and lines up with manageability objectives.

Durability and Life span

Testing recognizes materials that hold their speedy drying properties after repeated washes. This is imperative for guaranteeing item life span.

Compliance with Industry Standards

Numerous worldwide brands have laid out benchmarks for moisture management. Dry rate testing guarantees adherence to these principles, empowering market competitiveness.

Consistence testing is additionally essential for meeting legal requirements in international markets.

Key Steps in Conducting dry rate Testing in Textiles

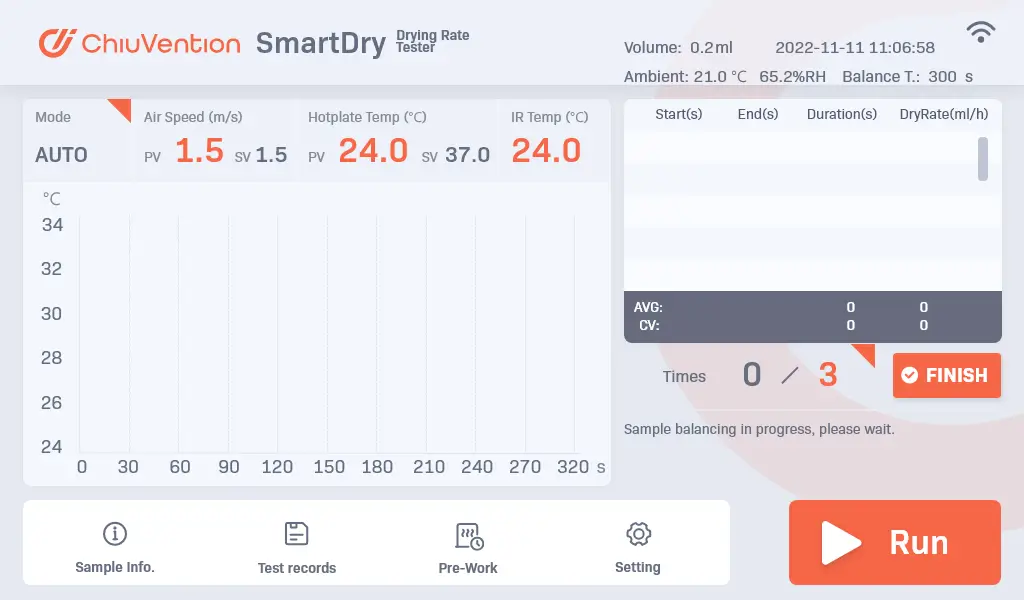

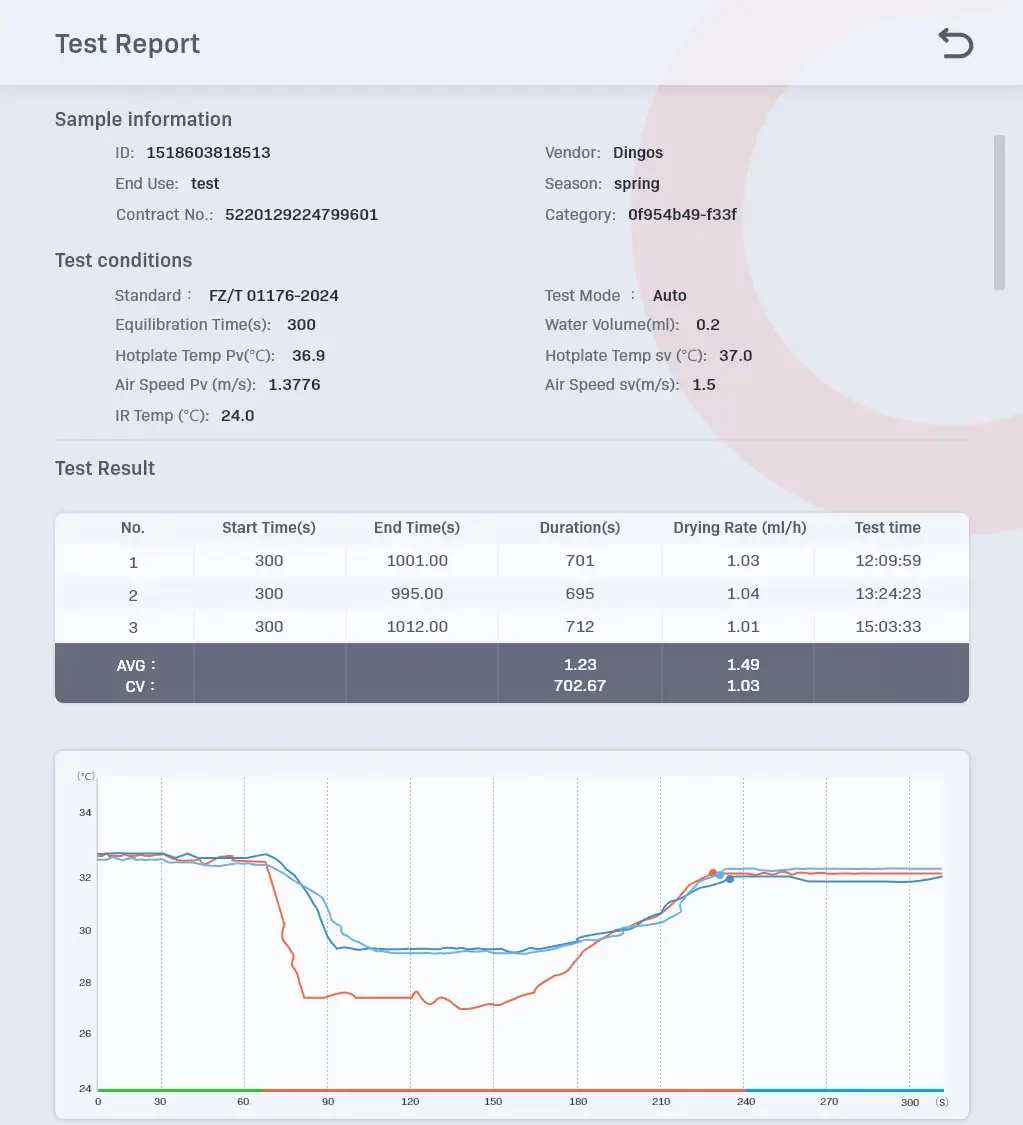

1. Turn on the temperature controller for the flexible heater and fan to let the metal plate temperature stabilize to 37 Celsius.

2. Use a hot wire anemometer to verify the air flow across the plate is 1.5 m/s.

3. Test specimen place on the metal plate for 5 min to allow specimen equilibrate to the metal plate temperature.

4. Position the IR thermocouple probe in the middle of the specimen 1.0 cm above the specimen.

5. Apply 0.2 ml of water on the plate below the specimen directly under the IR thermocouple probe.

6. The start time is when the specimen comes in contact with water.

7. View the specimen to determine the wicking profile generated by the water.

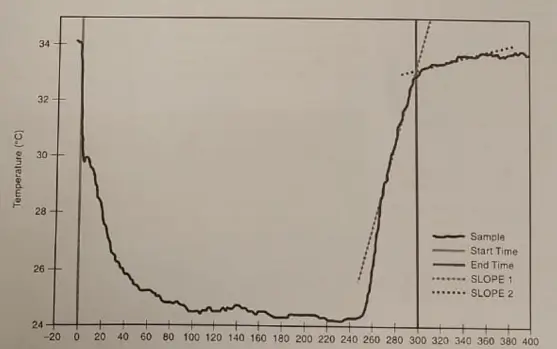

8. Collect and record the temperature every second until temperature returns to initial temperature.

9. Calculation part shows as below.

R = V / Drying time

R = Drying rate, in ml/h

V = Volume of water used in the test. In hours

Drying time = End time – Start time, in hours

** Start time is when the water is added to the specimen (Time 0 in figure). The end time is the time at the intersection of the section with steepest slope and flat section of the temperature plot. (Slope 1 & 2)

Innovations in dry rate Testing for the Textile Industry

Currently most of textile equipment suppliers competitively developing the advanced technology to measure dry rate test without doing manual calculations. Now most newly innovated machines are giving accurate values with automate calculations. Recent innovations in this field are transforming how textiles are tested and optimized for performance, efficiency, and sustainability.

- Advanced Testing Equipment

- Moisture Management Testers: These devices simulate real-world conditions such as sweating and environmental exposure. They measure the fabric’s ability to absorb, spread, and evaporate moisture efficiently.

- Infrared Imaging: Thermal cameras are used to visualize moisture evaporation patterns, offering a detailed assessment of drying performance.

- Dynamic Climate Chambers: These simulate varying temperature and humidity conditions to study how fabric performance changes across environments.

2. Automation and Digital Integration

- Automated Testing Systems: Modern systems can simultaneously test multiple fabric samples, significantly increasing efficiency and reducing manual intervention.

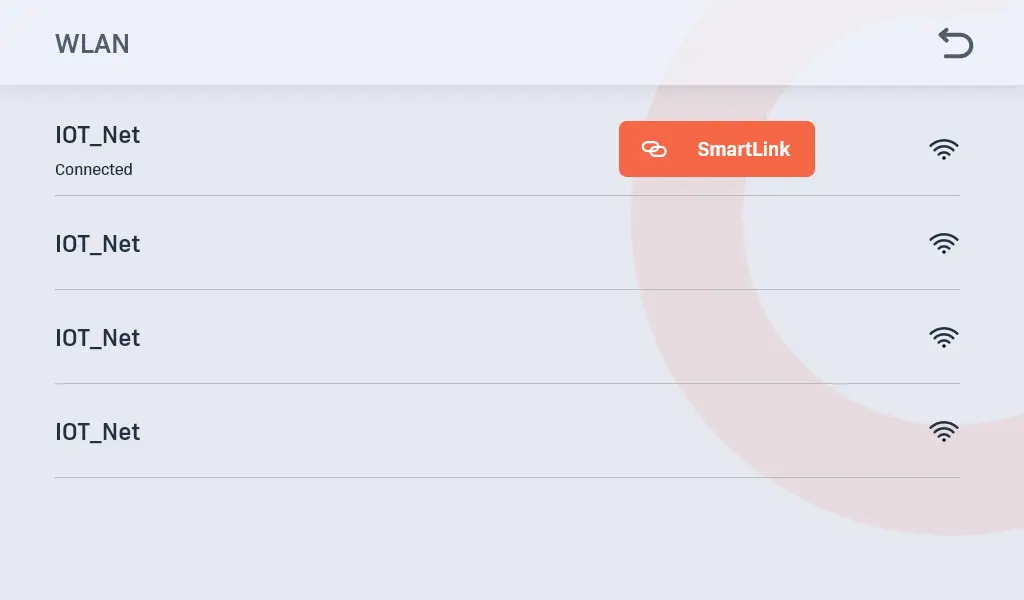

- IoT-Enabled Monitoring: Internet of Things (IoT) sensors integrated into test setups allow real-time data collection, analysis, and remote monitoring.

3. High-Precision Measurements

- Gravimetric Testing: Advanced scales measure moisture loss with high precision, providing accurate drying rate data.

- Nano-Level Analysis: Innovations in microscopy allow analysis of fabric structure at the nanoscale, revealing how fiber composition impacts drying.

Standards for Moisture Absorption and Quick-Drying Performance Assessment

Two national standards are used to evaluate moisture absorption and quick-drying performance:

GB/T 21655.1-2023

Evaluation of Moisture Absorption and Quick-Drying Performance of Textiles, Part 1: Combined Single Test Method

This standard assesses the grade of moisture absorption and quick-drying performance. Products must meet the technical requirements of the corresponding grade both before and after washing.

Evaluation Criteria:

| Item | Grade III | Grade II | Grade I |

|---|---|---|---|

| Absorption Rate (%) | ≥150 | ≥100 | ≥80 |

| Drop Diffusion Time (s) | ≤2 | ≤4 | ≤6 |

| Capillary Rise Height (mm) | ≥110 | ≥90 | ≥80 |

| Drying Rate (g/h) | ≥0.40 | ≥0.30 | ≥0.20 |

- Grade I: Indicates moisture absorption and quick-drying properties.

- Grade II: Indicates good moisture absorption and quick-drying properties.

- Grade III: Indicates excellent moisture absorption and quick-drying properties.

GB/T 21655.2-2019

Evaluation of Moisture Absorption and Quick-Drying Performance of Textiles, Part 2: Dynamic Moisture Transmission Method

Products are graded based on the requirements in Table 1 of GB/T 21655.2-2019. The corresponding performance is assessed according to Table 2 in the standard. Products must meet the requirements before and after washing. Table 2 categorizes performance into moisture absorption and quick-drying properties and moisture-wicking properties.

Table 1: Performance Index Grades

| Performance Index | Grade 1 | Grade 2 | Grade 3 | Grade 4 | Grade 5 |

|---|---|---|---|---|---|

| Wetting Time (T/s) | >120.0 | 20.1–120.0 | 6.1–20.0 | 3.1–6.0 | ≤3.0 |

| Water Absorption Rate (A/%/s) | 0–10.0 | 10.1–30.0 | 30.1–50.0 | 50.1–100.0 | >100.0 |

| Maximum Wetting Radius (R/mm) | 0–7.0 | 7.1–12.0 | 12.1–17.0 | 17.1–22.0 | >22.0 |

| Liquid Spread Rate (S/mm/s) | 0–1.0 | 1.1–2.0 | 2.1–3.0 | 3.1–4.0 | >4.0 |

| Unidirectional Index (O) | <-50.0 | -50.0–100.0 | 100.1–200.0 | 200.1–300.0 | >300.0 |

Note: The grading is applicable to both the wetting side and wicking side. Grade 5 is the best, and Grade 1 is the worst.

Table 2: Technical Requirements for Performance Evaluation

| Property | Test Item | Requirement |

|---|---|---|

| Moisture Absorption & Drying | Wetting Time | ≥ Grade 3 |

| Water Absorption Rate | ≥ Grade 3 | |

| Maximum Wetting Radius on Penetrating Side | ≥ Grade 3 | |

| Liquid Spread Rate on Penetrating Side | ≥ Grade 3 | |

| Moisture Absorption & Wicking | Wetting Time on Wicking Side | ≥ Grade 3 |

| Water Absorption Rate on Wicking Side | ≥ Grade 3 | |

| Unidirectional Index | ≥ Grade 3 |

Note: Both the wetting side and wicking side must meet the same requirements.

Instructions for Labeling Moisture Absorption and Quick-Drying Performance on Apparel

Clothing with moisture absorption and quick-drying properties should include functional labeling, as per the following requirements:

For GB/T 21655.1-2023 (Clause 9.2):

Products must include the following information in their user instructions:

(1) Standard number: GB/T 21655.1-2023

(2) Performance grade, such as Grade I (Excellent), Grade II (Good), or Grade III (Basic).

For GB/T 21655.2-2019 (Clause 10.2):

Products must include the following information in their user instructions:

(1) Standard number: GB/T 21655.2-2019

(2) Corresponding performance, such as moisture absorption and quick-drying properties or moisture-wicking properties.

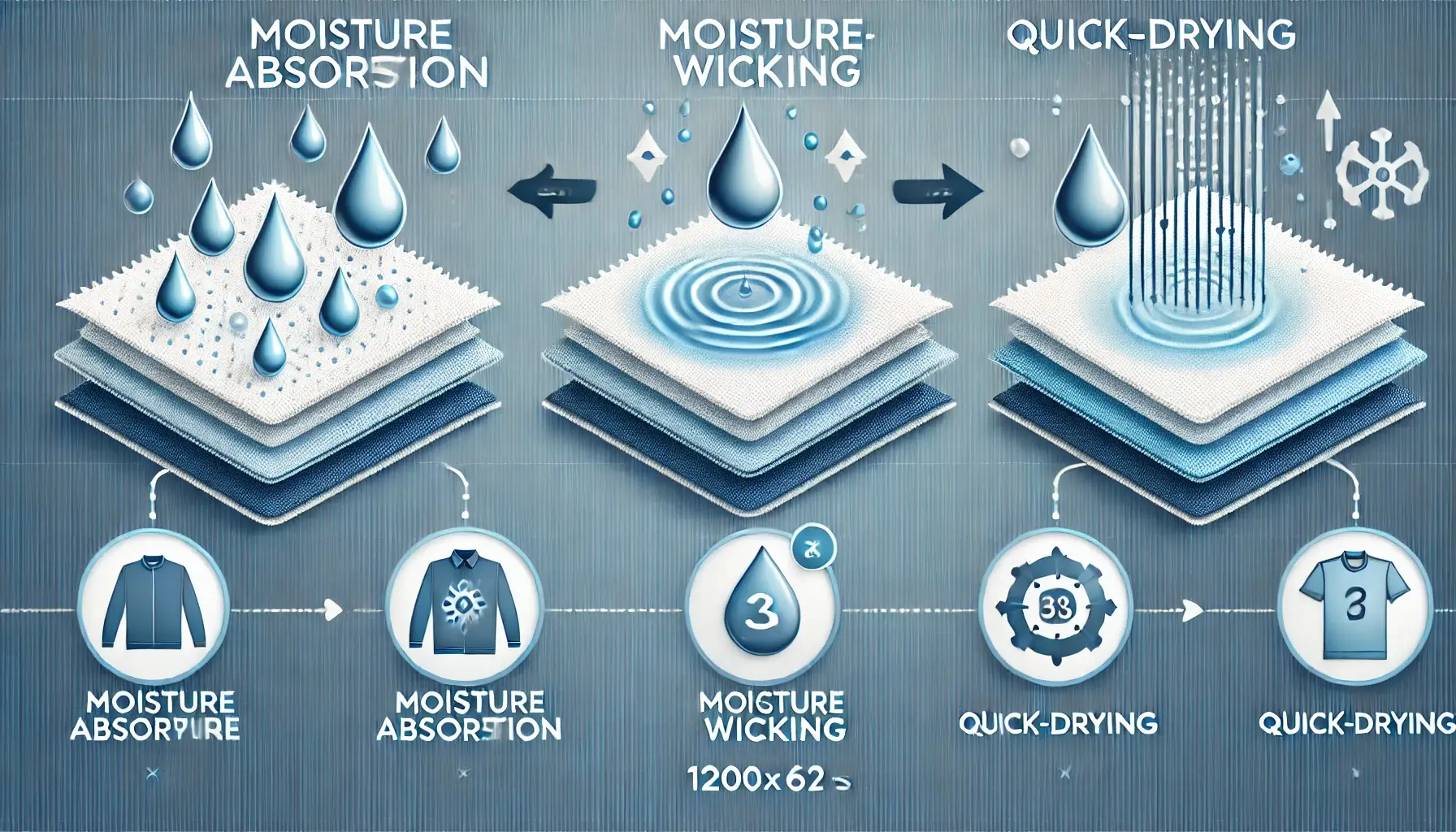

What is Moisture Absorption, Moisture-Wicking, and Quick-Drying Performance?

Moisture absorption and quick-drying performance refer to a garment’s ability to quickly absorb sweat produced by the human body and transfer it to the fabric’s outer surface for rapid evaporation. This keeps the skin dry and comfortable. The process involves moisture absorption, sweat-wicking, and quick-drying.

Moisture Absorption Performance

Definition: The ability of the fabric’s inner surface to quickly absorb sweat or water vapor.

Measurement Indicators:

Water Absorption Rate: The percentage of water absorbed relative to the original weight of the fabric after complete immersion and removal from water. A higher rate indicates stronger sweat absorption.

Drip Diffusion Time: The time taken for a droplet of water to completely diffuse into the fabric after contact. Shorter times indicate faster absorption.

Capillary Rise Height: The height that water rises along a vertically suspended textile within a specified time. Higher values indicate better sweat conduction, quickly transferring sweat from the skin-contacting side to the outer surface for evaporation.

Moisture-Wicking Performance

Definition: The ability of the fabric to transfer absorbed sweat from the inner surface to the outer surface.

Key Characteristics:

Good sweat-wicking properties ensure that sweat is quickly transferred to the outer fabric layer, preventing sweat buildup between the skin and clothing. This minimizes discomfort and heat. The property is influenced by fiber structure, yarn structure, and fabric weave. For example, fabrics with specialized weaving can form capillary-like structures, enhancing sweat transmission.

Quick-Drying Performance

Definition: The ability of the outer fabric surface to rapidly diffuse and evaporate sweat.

Measurement Indicators:

Evaporation Rate: The weight of evaporated water per unit time under standard atmospheric conditions. Faster rates indicate better drying performance.

Moisture Vapor Transmission Rate (MVTR): The mass of water vapor passing through a unit area of fabric over a specified time under controlled temperature and humidity. Higher values indicate better vapor permeability and faster drying.

Factors affecting moisture absorption and quick-drying performance

Factors affecting moisture absorption and quick-drying performance include fiber type, fabric structure, and finishing processes. For instance:

Natural Fibers: Cotton and linen have good moisture absorption but relatively poor quick-drying properties.

Synthetic Fibers: Polyester and nylon offer better quick-drying properties but weaker moisture absorption.

Blended or Interwoven Fabrics: Combining fibers can utilize the strengths of each, improving overall moisture absorption and quick-drying performance.

Conclusion

As the textile industry embraces the growing demand for high-performance fabrics, mastering the science of moisture management becomes paramount. Through Drying Rate Testing, manufacturers can ensure their products, such as fast-drying fabrics and quick-dry materials, meet the highest standards of comfort and durability. Understanding how to calculate drying rate and leveraging innovations in Dry Rate Testers enables businesses to stay ahead in designing fabrics that align with modern consumer needs. By adhering to established standards for moisture absorption and quick-drying performance and providing accurate labeling, companies can instill confidence in their products while promoting sustainability and innovation. The future of textiles lies in mastering these performance characteristics, and your journey toward excellence starts with embracing the tools and knowledge shared in this guide.

Some of the content of this article is authored by a professional engineer below. Thanks for his hardwork!

Nipuna De Silva (PhD, MBA, BSc)

Material Performance Specialist

chanukanipuna@gmail.com

LinkedIn Profile: Nipuna De Silva

We welcome any professional and informative topics or articles related to textile testing. Please feel free to reach out to us if you have any insights to share!

If you have any questions regarding this article, please feel free to leave your comments below.