When purchasing garments, we often look at the sun protection index and the ultraviolet (UV) blocking rate of the materials. It’s also essential to understand the UV protection capabilities of our clothing and everyday items, as the effects of UV exposure are closely linked to our health.

Let’s explore the following questions together:

What is ultraviolet light?

What are the potential health risks associated with prolonged exposure?

How can we care for sunscreen clothing in our daily routines?

What methods can we use to assess the UV protection performance of sunscreen clothing?

Read this article below to learn more about the UV protection performance of textiles.

Introduction to Ultraviolet Light

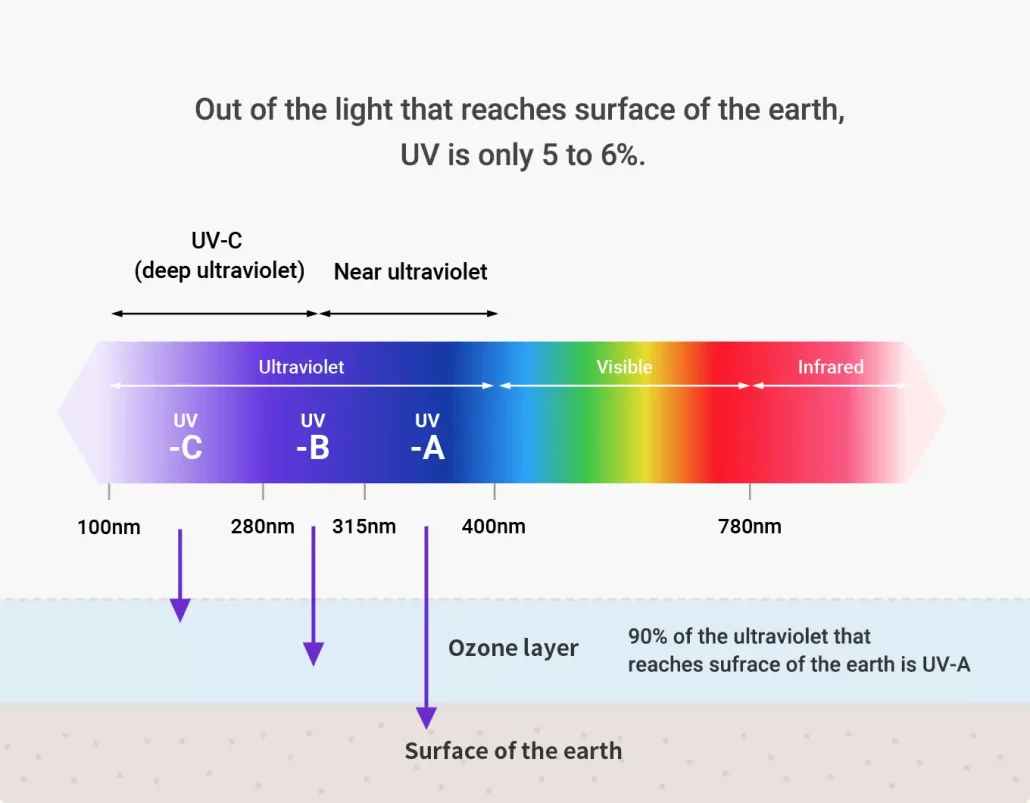

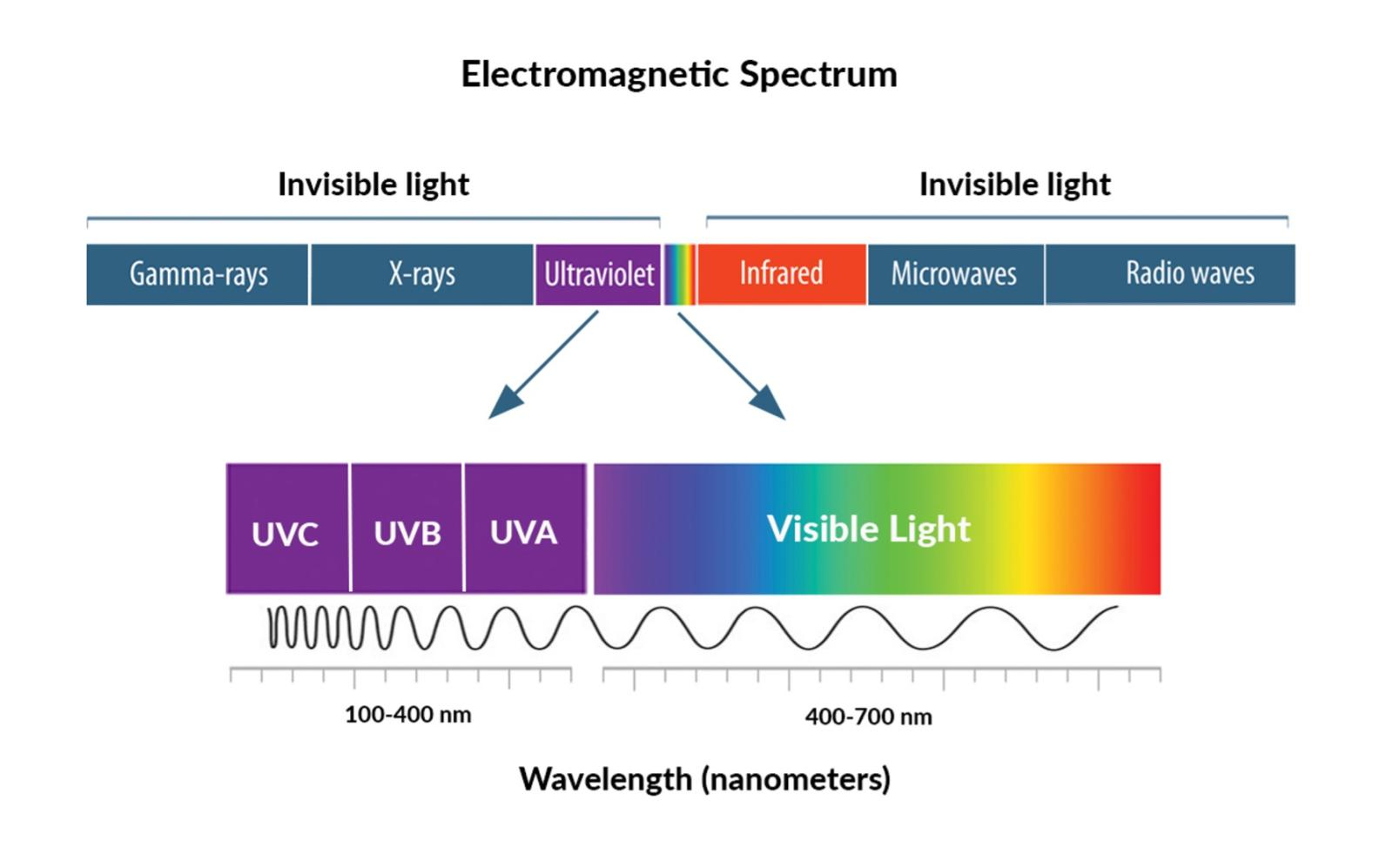

The sun emits various types of radiation, including infrared (IR), ultraviolet (UV), visible light, and others. Ultraviolet light, specifically, is part of the electromagnetic spectrum with wavelengths ranging from 0.01nm to 0.40nm. It is further divided into UVC (100nm – 280nm), UVB (280nm – 315nm), and UVA (315nm – 400nm). Understanding the nature of ultraviolet radiation is crucial as it plays a significant role in textile ultraviolet protection.

UV reactive fabrics, also known as photochromic fabrics, are innovative textiles that transform their appearance when exposed to ultraviolet (UV) light. These fabrics utilize special dyes or pigments that react to UV rays, causing a visible change in color or revealing hidden patterns and designs. Typically reversible, these effects fade once the fabric is removed from UV exposure, making them both dynamic and versatile. Commonly used in fashion, outdoor gear, safety equipment, and children’s products, UV reactive fabrics add an interactive and functional dimension to textiles. For instance, clothing made from UV reactive fabrics can shift colors outdoors, creating unique and eye-catching designs, while outdoor equipment and safety gear can incorporate UV-sensitive features to enhance visibility.

The technology relies on photochromic dyes embedded in the fabric, which undergo structural changes in UV light, altering how they absorb and reflect light. This combination of aesthetic appeal and functional adaptability makes UV reactive fabrics a popular choice in various industries.

Impacts of Ultraviolet Radiation on Textiles an Humans

Positive Impacts

Ultraviolet radiation aids in the production of vitamin D in our bodies, which is essential for maintaining healthy bones and overall well-being.

It can be used therapeutically to treat certain skin conditions, providing relief and promoting healing.

Exposure to UV light in moderation can have a positive effect on mood, potentially reducing symptoms of depression and improving mental health.

In some cases, ultraviolet radiation serves as an effective disinfection factor, helping to kill bacteria and viruses on surfaces.

Negative Impacts

Prolonged exposure to UV radiation is a major risk factor for skin cancer, with both melanoma and non-melanoma cancers being linked to UV exposure.

It causes sunburn, which not only damages the skin but can also lead to pain, peeling, and long-term skin damage.

The immune system can be weakened by excessive UV exposure, making the body more susceptible to infections and diseases.

Ultraviolet radiation is harmful to the eyes, potentially causing cataracts, macular degeneration, and other eye disorders.

It accelerates skin aging, leading to wrinkles, fine lines, and loss of skin elasticity.

For textiles, UV exposure can degrade the strength of polymers and fibers, and cause textile dyes to fade or change color, reducing the aesthetic and functional lifespan of the fabric.

Textile Ultraviolet Protection Performance Testing Standards

Ultraviolet Protection Factor (UPF)

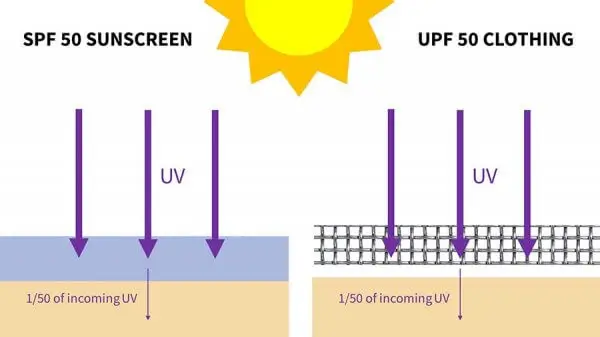

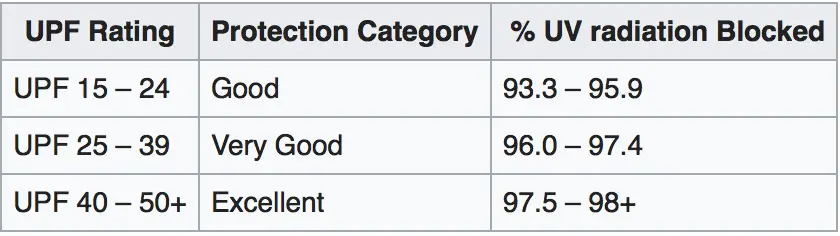

UPF measures the ability of a fabric to block ultraviolet rays from reaching the skin. It is calculated as the ratio of the average effect of ultraviolet radiation on unprotected skin to that on skin protected by the fabric. A higher UPF indicates better protection.

Common Testing Standards

Chinese Standard: GB/T 17032 – 1997 and GB/T 18830 – 2009 are applicable to various textiles. The latter stipulates that a sample with UPF > 40 and ultraviolet transmittance < 5% is considered an ultraviolet protection product.

Australian and New Zealand Standard: AS/NZS 4399 – 1996 (revised in 2017) provides a framework for evaluating and classifying sun protective clothing.

International Standard: UV Standard 801 uses the AS/NZS 4399 testing method and considers multiple factors affecting sunscreen effectiveness. Certified products receive a time-limited certificate and can display the UV Standard 801 label.

American Standards: ASTM D6544 – 2012, AATCC 183 – 2014, and ASTM D6603 – 2010 cover different aspects of textile UV testing and labeling.

British Standard: BS 7914 – 1998 focuses on testing the UV transmittance of fabrics in close contact with the skin.

European Union Standards: EN 13758 – 1:2006 and EN 13758 – 2:2003 + A1:2006 deal with the testing methods and classification/marking of textile UV protection, respectively.

Let us specify the following testing methods:

GB/T 18830 – 2009

Scope of Application: Evaluation of the performance of fabrics in protecting against solar ultraviolet radiation under specified conditions.

Sampling Requirements: For homogeneous materials, at least 4 representative samples shall be taken, and the fabric within 5cm from the fabric edge shall be discarded. For non-homogeneous materials with different colors or structures, at least two samples shall be tested for each color and structure.

Testing Result Evaluation Index: When the UPF of the sample is > 40 and T (UVA) AV < 5% according to this standard, it can be called an “ultraviolet protection product.”

Parameters to be issued for test results: UPF, (UPF) AV, T (UVA) AV, T (UVB) AV

BS EN 13758 – 1:2002

Scope of Application: The solar ultraviolet protection performance of apparel fabrics under standard conditions, not applicable to textiles that provide protection at a certain distance, such as umbrellas, sunshade structures, or artificial light sources. This standard may not be applicable to fabrics with small changes in color and structure.

Sampling Requirements: The same as the above standard, and the samples shall not be collected within 1 meter from the fabric head or tail.

Testing Result Evaluation Index: Only textiles with a UPF of 30* can be marked as sunscreen clothing.

Parameters to be issued for test results: UPF, (UPF) AV, T (UVA) AV, T (UVB) AV

AATCC 183 – 2020

Scope of Application: Testing the ultraviolet radiation protection performance of samples in dry and wet states, and can also be used to determine the UPF of samples in a stretched state.

Sampling Requirements: At least two samples in dry and wet states shall be prepared for each sample, and the size of each sample shall be at least 50mm x 50mm. Test each color and fabric structure.

Testing Result Evaluation Index: Good ultraviolet protection (applicable to UPF 15 – 24), very good ultraviolet protection (applicable to UPF 25 – 39), excellent ultraviolet protection (applicable to UPF ≥ 40).

Parameters to be issued for test results: UPF, T (UVA) AV, T (UVB) AV, UVA and UVB blocking rates.

Testing Methods for Fabric Ultraviolet Resistance

Direct Testing Method: This method is quick and can handle a large number of samples. However, it suffers from poor objectivity and reproducibility due to factors like sample irregularities, which can cause UV absorption, refraction, and reflection, leading to inaccurate results.

Human Body Testing Method: While it provides a direct measure of how a fabric protects human skin from UV, it is highly variable due to differences in skin types among testers. Moreover, it poses risks of harm to the testers, making it less practical for routine testing.

Related Testing Machines on Ultraviolet-resistant Fibre Testing

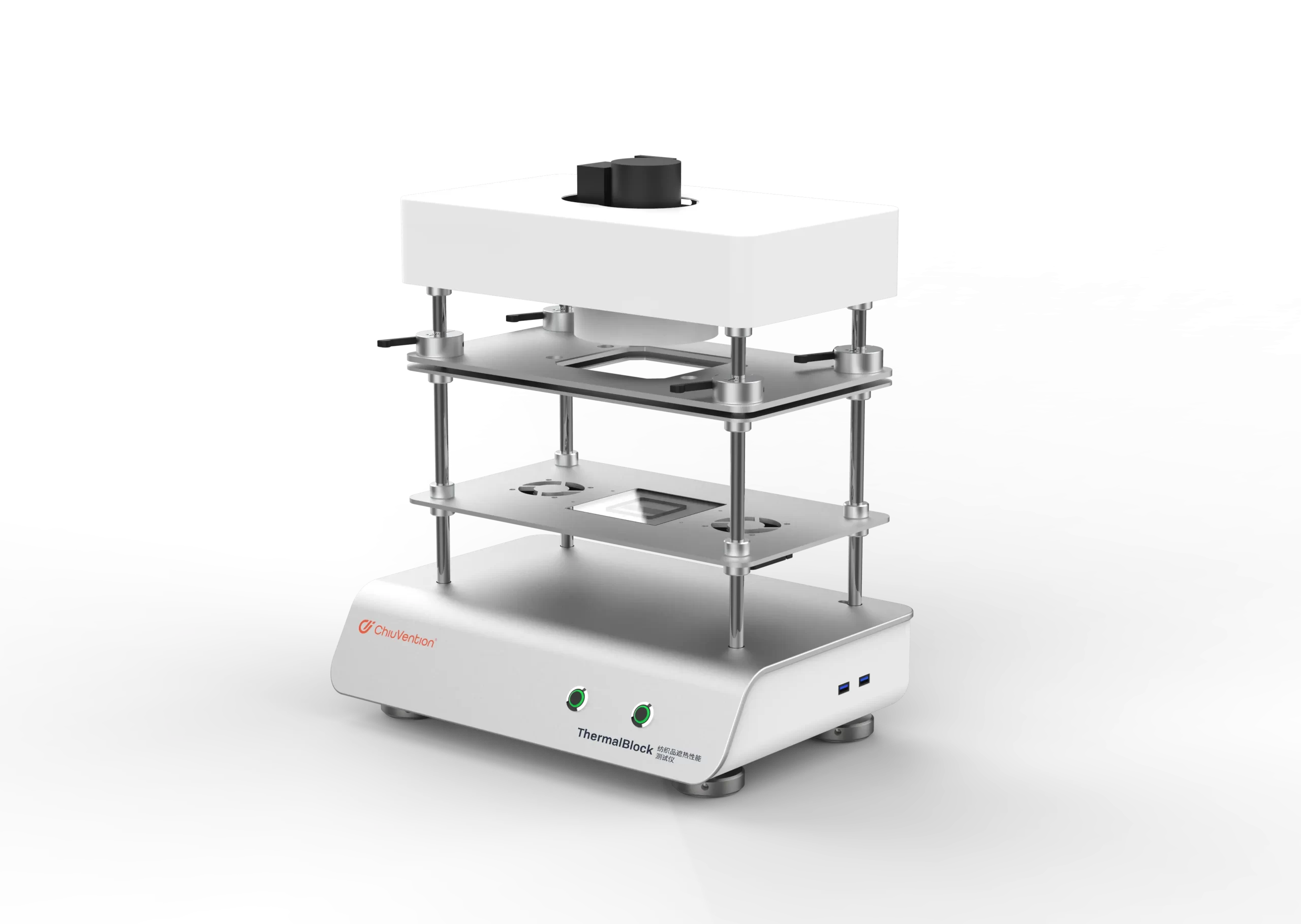

Heat Shielding Performance Tester

The heat shielding performance tester is designed to evaluate the protective performance of textile materials against heat radiation when exposed to natural light sources (sunlight). It is particularly suitable for the research and development and testing of functional textiles, such as the evaluation of materials for protective clothing, curtains, sunshade products, sportswear, etc. This tester plays a crucial role in ensuring that these textiles can effectively block heat, thereby providing comfort and protection to the user. For example, in the case of protective clothing, it helps to prevent heat-related injuries in high-temperature work environments. In the context of curtains and sunshade products, it determines their ability to reduce heat transfer into indoor spaces, contributing to energy conservation and a more comfortable indoor climate.

CoolMax Cool Feeling Tester

The CoolMax Cool Feeling Tester is used to test the cold or warm feeling when the material comes into contact with the skin. It is applicable to various types of fabrics, including those for sportswear, outdoor clothing, household items, underwear, car seat covers, and other functional fabrics. The tester offers several advantages. It conducts tests quickly and accurately, precisely controls the temperature difference, ensuring more reliable test results. Moreover, it realizes intelligent cold and warm feeling testing, making the process more efficient. It provides authoritative reference values for the research and development, production, and quality control of cold and warm feeling fabrics. It is compliant with standards such as JIS L1927, FTTS – FA – 019, GB/T 35263 – 2017, and CNS 15678 – 2013.

This tester is essential for manufacturers and researchers in the textile industry as it helps them understand how different fabrics interact with the human skin in terms of temperature perception. This knowledge is then used to develop fabrics that can enhance user comfort in different environmental conditions. For instance, in sportswear, it can assist in creating fabrics that keep athletes cool during intense physical activities or warm in cold weather, thereby improving their performance and overall experience.

In addition to these two testers, there are other equipment and instruments used in the testing of ultraviolet-resistant fibres.

Spectrometers

For example, spectrometers are often employed to analyze the absorption and reflection spectra of fibres in the ultraviolet range. This helps in understanding the fundamental mechanisms of how fibres interact with ultraviolet radiation and provides valuable data for the development of more effective ultraviolet-resistant materials. Tensile testing machines are also used to evaluate the mechanical properties of fibres and fabrics after exposure to ultraviolet radiation. This is important because ultraviolet exposure can potentially degrade the mechanical strength of materials, and understanding these changes is crucial for ensuring the durability and performance of ultraviolet-resistant textiles in practical applications.

Environmental chambers

Environmental chambers are utilized to replicate real-world conditions, including different levels of ultraviolet radiation, temperature, and humidity. By subjecting textile samples to these simulated conditions, researchers can more accurately predict the long-term performance and stability of ultraviolet-resistant fibres and fabrics. These chambers allow for accelerated aging tests, enabling manufacturers to evaluate the lifespan and effectiveness of their products more efficiently. Overall, a comprehensive set of testing equipment and methods is essential for the development and quality assurance of ultraviolet-resistant textile materials.

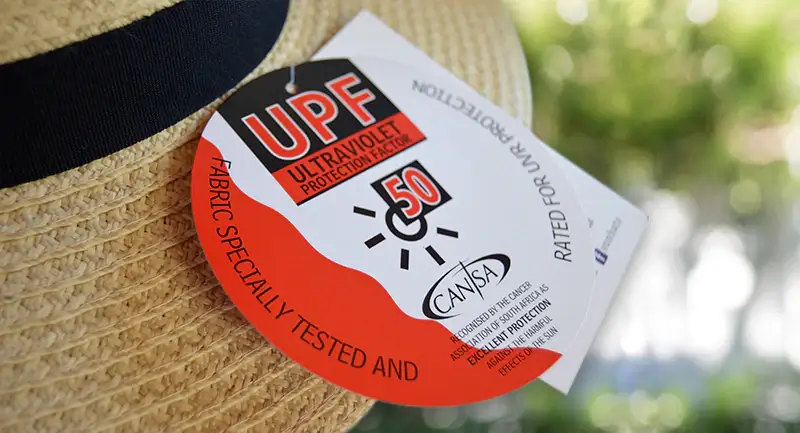

Judging the Quality of Sunscreen Clothing

In China, according to GB/T 18830 – 2009, a sample is considered an “ultraviolet protection product” if its UPF > 40 and T (UVA) AV < 5%. A convenient way to assess sunscreen clothing is by checking the label. Look for the standard number (GB/T 18830 – 2009), and the UPF rating. If 40 < UPF ≤ 50, it should be marked as UPF 40+; if UPF > 50, it should be marked as UPF 50+. Additionally, note that the protection may decrease with long-term use, stretching, or wetting.

Factors Affecting Textile Ultraviolet Resistance

Fiber Type

Natural fibers like wool, jute, and bamboo pulp have relatively lower UV transmittance compared to silk and flax, but still may not offer sufficient protection. Synthetic fibers such as polyester show good UV resistance, but may have drawbacks in terms of comfort. The chemical and physical properties of fibers determine their UV absorption and reflection capabilities, and the overall UV protection cannot be judged solely based on fiber type.

Yarn Structure

Yarn thickness, twist, hairiness, and spinning method impact the fabric’s density, thickness, and porosity. High-twist yarns can create more compact yet irregular surfaces, affecting the fabric’s UV resistance. Yarns with lower hairiness may result in higher UV transmittance in some cases. Additionally, fiber line density and yarn surface protrusions influence UV protection, although they may also increase the likelihood of pilling.

Fabric Structure

The porous nature and geometric arrangement of fabric affect UV propagation. In porous fabrics, UV can pass through gaps between yarns, reducing the effectiveness of anti-UV treatments. Single pore size and fabric thickness are crucial in determining UV protection. Most research focuses on woven fabrics, with limited studies on knitting fabric UV protection, despite the latter being widely used in clothing.

Fabric Color

Fabric color is determined by dye absorption in the visible light region, which also affects UV resistance. Different dye chemical structures and color depths influence UV absorption. Dark-colored fabrics generally absorb more UV than light-colored ones, but may also absorb more infrared radiation, leading to increased heat.

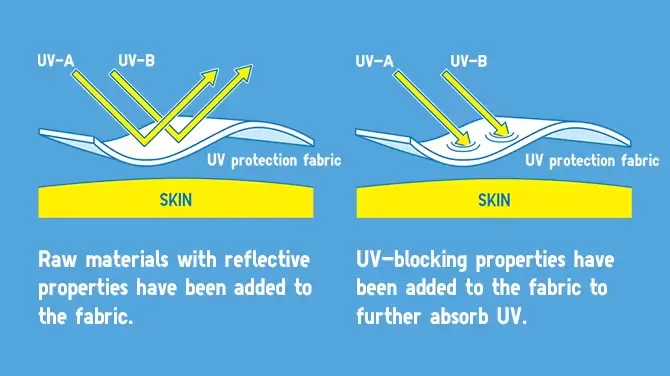

Chemical Additives

Inorganic UV absorbers like TiO2 and ZnO nanoparticles are popular due to their stability and non-toxicity. They can be added to fibers or fabrics to enhance UV protection. Fluorescent whitening agents and other additives can also improve UV resistance, either alone or in combination with other agents. However, their effectiveness may be reduced in porous structures like knitted fabrics.

Final Use Conditions

Stretching: Knitted fabrics, commonly used in T-shirts and sportswear, are stretchable. When stretched, the fabric thins, increasing pore size and UV transmittance. Although stretching significantly affects UV protection, it is not widely included in testing standards.

Wetting: Wet fabrics have higher UV refractive indices, allowing more UV to pass through. Different fabrics respond differently to wetting, with cotton fabrics showing a more significant reduction in UV protection in some cases. However, certain treatments can improve wet-state UV protection.

Washing: The washing process, including soaking, stirring, and drying, can change fabric structure. Knitted fabrics are more prone to shrinkage and deformation, which can affect UV protection. Washing impact on UV protection is significant as detergents with fluorescent whitening agents can increase UPF values, but multiple washings may also cause fabric damage and affect UV resistance.

Strategies to Improve Textile Ultraviolet Protection

Using Specific Dyes: Azo dyes can absorb ultraviolet radiation and prevent polymer degradation, enhancing the fabric’s UV resistance.

Adding Inorganic Absorbers: Incorporating TiO2 or ZnO nanoparticles into the fabric can effectively shield UV radiation and increase UPF.

Coating with UV Finishing Agents: Applying a coating with UV finishing agents forms a protective film on the fabric surface, improving its UV-blocking ability.

Selecting Appropriate Fibers: Polyester and nylon fibers can provide better UV protection due to their inherent properties. Increasing fabric density and thickness also helps reduce UV transmission.

Tips for Ultraviolet-sensitive People Wearing Protective Clothing

Choose High-UPF Clothing: Opt for clothes labeled with UPF > 40 and with low visible light transparency.

Prefer Dark Colors and Polyester Blends: Dark-colored fabrics and polyester or polyester-blended materials generally offer better UV protection.

Be Cautious with Cotton Fabrics: Cotton fabrics may lose significant UV protection when stretched or wet.

Use Supplementary Protective Gear: Wear long sleeves, long pants, hats, and use umbrellas for added protection.

Time Outdoor Activities Wisely: Avoid being outdoors during peak UV hours (10 am – 4 pm).

Avoid High-Reflection Areas: Minimize time spent in places with strong UV reflection, such as beaches and snowy areas.

Frequently Asked Questions

How to Test Fabric for UV Protection?

Testing fabrics for UV protection involves specialized methods to measure their ability to block ultraviolet (UV) radiation. The most widely used standard is the Ultraviolet Protection Factor (UPF), which indicates how much UV radiation the fabric allows to pass through. A few common testing methods include:

AS/NZS 4399: This evaluates how effectively clothing blocks UV rays and assigns a UPF rating.

AATCC 183: This measures UV transmission through the fabric under controlled conditions.

ISO 13758: An international standard specifically for UV protective textiles and apparel.

These tests use UV light sources to simulate sunlight and determine the percentage of UV rays absorbed or blocked by the fabric. A higher UPF rating, such as UPF 50+, signifies superior protection, allowing less than 2% of UV rays to penetrate.

What UV Light Protection Clothing Offers Better UV Protection Performance?

The UV protection performance of clothing depends on multiple factors:

Fabric Composition: Synthetic fibers like polyester and lycra are more effective at blocking UV rays than natural fibers like cotton.

Tight Weave: Dense fabrics with minimal gaps provide higher UV resistance compared to loosely woven textiles.

Color: Darker and more saturated colors absorb UV radiation more effectively than lighter or pastel shades.

Additives and Treatments: Fabrics treated with UV-inhibiting chemicals or finishes enhance their protective properties.

Clothing designed specifically for sun protection often combines these features, with labels displaying their tested UPF ratings for consumer confidence.

How Durable Are UV Sun Protection Textiles?

The durability of UV protection in textiles depends on how the protective properties are achieved and maintained:

Built-in Protection: Fabrics with inherent UV-blocking properties (e.g., through dense fibers) retain their effectiveness longer.

Chemical Treatments: Coated fabrics may lose their protection after repeated washing or prolonged sun exposure.

Usage and Care: Factors like stretching, abrasion, or improper washing can reduce UV resistance.

To prolong the life of UV protection textiles, follow care instructions, avoid bleach or fabric softeners, and minimize excessive wear.

Are All UV Protection Textiles Safe?

UV protection textiles are generally safe, but a few considerations should be kept in mind:

Chemical Safety: Ensure that any UV-blocking agents or treatments used on fabrics comply with safety regulations and do not release harmful substances.

Certified Products: Look for certifications such as OEKO-TEX or bluesign® that guarantee the absence of toxic chemicals in treated fabrics.

Skin Sensitivity: For those with sensitive skin, choosing untreated UV-protective fabrics or hypoallergenic options is recommended.

By selecting high-quality textiles from trusted brands, you can enjoy both safety and performance in your UV protective clothing.

By understanding these aspects of textile ultraviolet protection, consumers can make informed choices when purchasing clothing and textiles, and manufacturers can develop products with enhanced UV protection capabilities. Summer clothing UV performance is especially important as people are more exposed to the sun during this season.

For more valuable insights on textile testing, we encourage you to subscribe to our website or reach out to us using the following contact information:

Email: sales@chivention.com

WhatsApp: +86 180 2511 4082