In the textile and apparel industry, color fastness to rubbing is a critical indicator of quality. It not only determines the appearance of the product but also influences consumer satisfaction and the product’s durability. A fabric that performs poorly in a color fastness to rubbing test can lead to a frustrating experience for both manufacturers…

In the ever-evolving textile industry, the demand for high-performance fabrics, especially fast-drying materials, continues to grow, driven by the popularity of activewear and outdoor clothing. Understanding the science behind moisture absorption, wicking, and drying rate is critical for developing fabrics that meet consumer expectations for comfort and functionality. This is where Drying Rate Testing plays…

Introduction Standards guide and regulate production enterprises. They help them prepare the instructions for use of textile and apparel products. They also help consumers understand the product’s basic information when purchasing. However, many people have an inaccurate or inconsistent understanding of the standards. To address this, this paper explores the attributes of instructions for use….

This comprehensive blog explores the thermal comfort properties of various sports fabrics, including testing methods, performance analysis of different fiber fabrics, selection tips, and ways to improve thermal comfort. It also highlights the crucial role of machineries like Air Permeability Tester, CoolMax Cool Feeling Tester, and more in accurate fabric assessment. A must-read for textile…

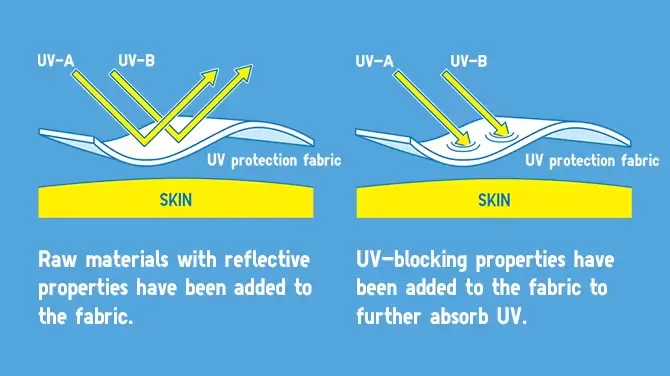

When purchasing garments, we often look at the sun protection index and the ultraviolet (UV) blocking rate of the materials. It’s also essential to understand the UV protection capabilities of our clothing and everyday items, as the effects of UV exposure are closely linked to our health. Let’s explore the following questions together: What is…

1. Purpose and Scope 1.1 This test method aims to evaluate the resistance of fabrics and other flexible materials to abrasion. 2. Principle 2.1 An impeler (rotor) drives an unfettered fabric specimen along a zigzag course in a generally circular orbit within a cylindrical chamber, causing it to repeatedly impinge on the walls and abradant…

Air permeability tester is an instrument. It measures a material’s permeability. It is widely used in the textile industry to test fabric porosity. You can also use it on other materials, like paper, plastic film, and leather. The tester works by applying a constant pressure across the test material. It measures the air flow rate…

ISO 13934-1 and ISO 13934-2 differ in their test method and scope. They are both textile tensile tests. Test method ISO 13934-1: The strip method tests the fabric’s width in a tensile fixture. It is for testing loose or wet fabrics. The fixture holds the sample in a low-stress area. This causes the sample to…

Why should I choose ASTM D7984 for Cool Feel Fabrics? They chose ASTM D7984 for Cool Feel fabric testing. It measures a textile’s thermal conductivity and fugacity. This quantifies a fabric’s insulation and conductivity. This method uses a modified transient planar heat source (MTPS) method. A single-sided heat sensor heats the sample surface for 1-3…

Tearing, or fabric tearing, happens when a load affects the fabric’s local yarns. In use, clothes can get caught on objects. This can pull off the local yarn in the fabric. It can form a strip or triangular tear, which is a type of fabric fracture. Definition of fabric tear strength Fabric tear strength is…