Introduction Evaluating fabric quality is essential for manufacturers, suppliers, and quality control professionals to ensure consistent textile performance. Whether working with cotton, wool, silk, or synthetic blends, precise laboratory testing plays a crucial role in determining strength, durability, and appearance standards. This guide explores six essential testing methods, including color fastness, strength testing, and…

Introduction Accelerated Colorfastness Testing to Laundering, the AATCC TM61 – 2013E(2020) standard offers a detailed framework for conducting the Color Fastness to Washing Test under home and commercial laundering conditions. This test, an essential component of textile durability tests, evaluates fabric performance using an accelerated Washing Fastness Tester. By replicating multiple wash cycles, it provides…

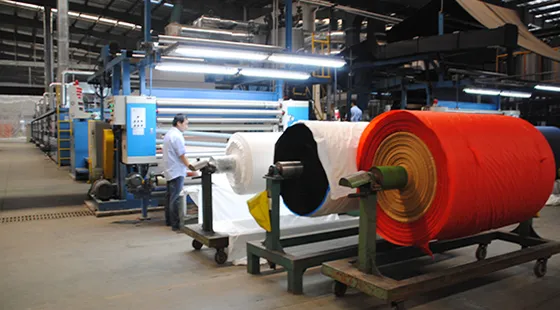

In the vibrant world of textiles, the dyeing and finishing process stands as the crucial bridge between raw fibers and the beautiful, functional fabrics we use in our daily lives. This comprehensive guide dives deep into the four essential steps of textile dyeing and finishing – pretreatment, dyeing, printing, and finishing – uncovering the specific…

Introduction Laboratory dyeing plays a pivotal role in ensuring the color accuracy of dyed polyester fabrics in textile factories. Proper sampling methods, accurate equipment usage, and precise dye preparation are essential for achieving consistent results in bulk production. This guide explores the importance of laboratory dyeing in textile dyeing processes, focusing on polyester fabric dyeing with disperse…

Winter are undeniably the “season of static electricity.” Dry air with low humidity, skin that has lost moisture, and an increase in clothing made from synthetic fibers all contribute to the accumulation of electric charges. There has been widespread complaining online, with many lamenting that they’ve been shocked by static electricity. “Opening a door gives…

Introduction In the world of textile and material testing, bursting tests play a crucial role in determining the durability and performance characteristics of various fabrics and materials. This article delves deep into the bursting test standards, specifically focusing on GB/T7742.1, ISO13938-1, and ASTM D3786/D3786M:2013. We will explore the fundamental aspects such as test principles,…

The Significance of Fabric Dimensional Change In the textile industry, understanding fabric shrinkage and dimensional change is critical to ensuring the quality and performance of fabrics. Whether it’s the shrinkage of fabric during washing, the effect of dry cleaning on size, or the alterations caused by steaming, these factors significantly influence consumer satisfaction and fabric usability. This…

As the global ‘greenhouse effect’ intensifies, demand for summer garments is rising. People want cool, quick-drying, moisture-absorbent fabrics. There is a need for new, cool fabrics. The exact name of coolness is ‘instantaneous coolness on contact’. Here, “instant coolness” means the fabric is cooler than the skin. It causes rapid heat loss from the skin’s…

INTRODUCTION This article elaborates on the factors influencing the water absorption or waterproofness of fabrics and their testing methods, analyzing three influencing factors: the wettability of the fiber surface, the coating of the fabric, and the environment. People have demands for both waterproofness and water conductivity in fabrics. The wettability of the fiber…

Pilling on fabrics is not just an aesthetic concern; it directly affects product quality and customer satisfaction. Understanding and implementing reliable fabric pilling test methods is essential for quality control in the textile industry. This article explores four major methods—Circular Locus Method, Martindale Method, Pilling Box Method, and Random Tumble Pilling Method—to evaluate and grade…