Have you heard of Smart Textile Testing? It’s the hottest topic of the textile industry in 2024 and has attracted a great deal of attention from the brand side of the textile industry and the supply chain. Today we share with you a few core messages about textile smart testing.

Pain Points in Conventional Textile Testing

What are we facing in the textile testing lab every day?

The tests may not be transparent.

Buyers may not trust the suppliers.

So the products from suppliers need to be tested again and again,

causing waiting time, even though the quality may qualify for the first test.

Repeating tests cause longer cycling time.

The production of textiles may take 2 days only,

but factories need to wait for the test results for 3 days:

preparing the samples, cutting samples and writing test records, typing data……a lot of manual work and paperwork.

That causes longer production cycling time.

In the whole value chain, it may take about 15 days.

On the other hand, the tests are not reliable enough.

In a conventional test process, with a lot of manual work, 3 persons may get 3 different test results. Accompanied by unavoidable manual errors or mistakes, the tests may not be reliable.

And more…

What if…

The Smart Textile Testing Application Scenarios

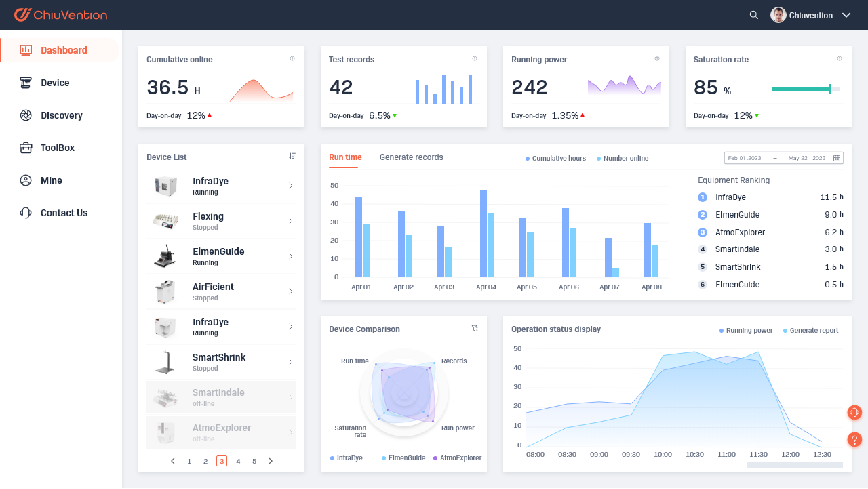

When you walk into your textile testing lab, all the test tasks are listed on the large screen on the wall, and each test can be clicked to check the current status.

The situation of each instrument is displayed, whether they are running well need to be calibrated, or to be fixed. Besides, licensed brand buyers, supply chain, and quality management can view the textile testing status and results in real-time on their mobile devices.

Just like…

How about the Workflow of Smart Textile Testing?

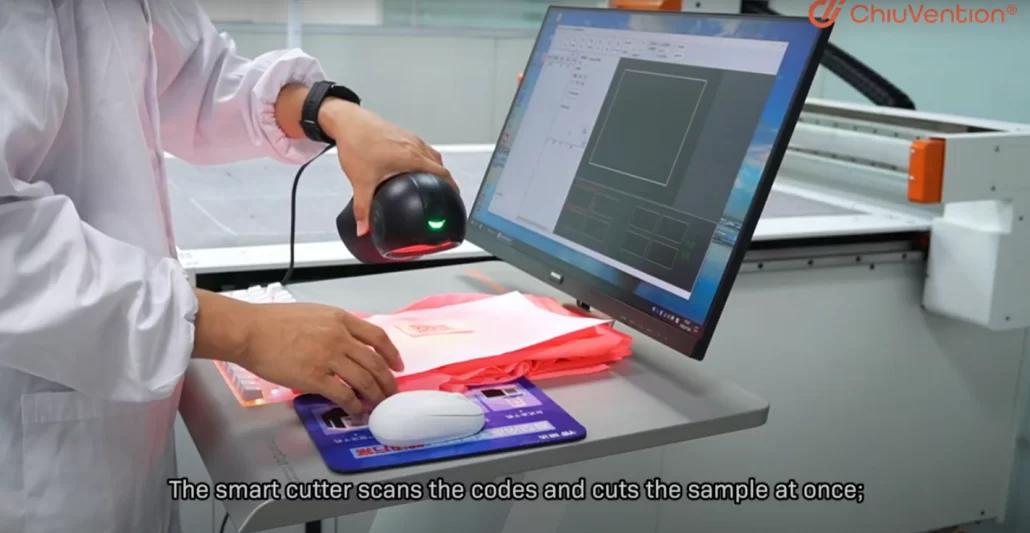

Next to the reception desk of the lab, there is a cutting machine. A fabric sample with a barcode label is scanned and to be identified, and then to be placed on the table.

The sample fabric will be cut according to the requested shape and the needed quantities automatically.

Samples get stuck on the sample clamp with an RFID chip, or sewed with a bar-code label. Then the sample can be scanned and identified by all test instruments and processes.

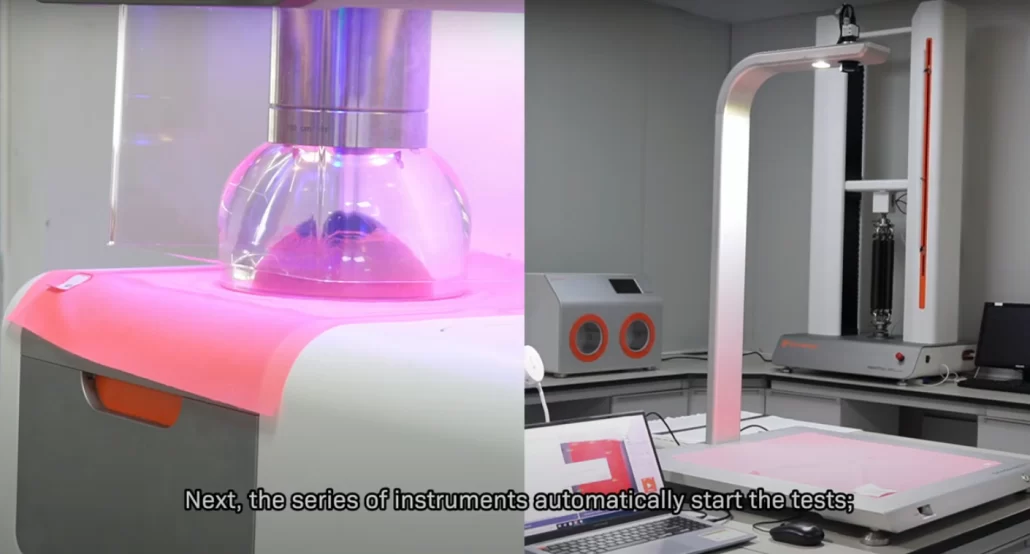

When the test operators receive a notice that samples are ready, they will take the samples and place them on the instruments.

Then instruments identify the sample ID and then set the requested test methods accordingly (of course some settings are done by test operators), after the sample is installed, the test starts and the operator leaves it alone, he can do other jobs, except for those with immediate results.

1 or 3 minutes before the test is finished,

the operator will receive a ring call, and then he will move to the textile testing machines and confirm the test result.

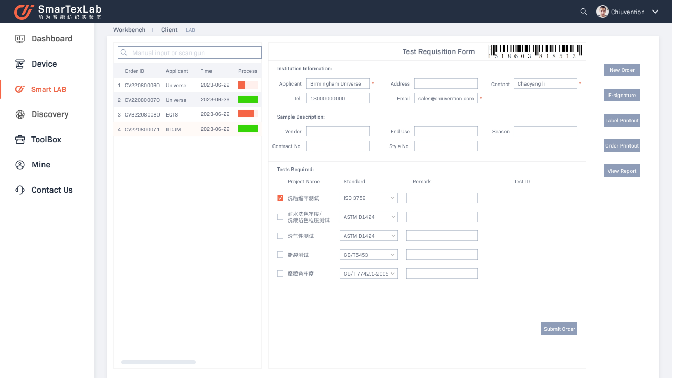

The textile test results, sample information, test conditions, instrument No. and operator’s ID ……every detail in the Original Record will be sent to the SmarTexLab system (developed by the ChiuVention Team) to be summarized as a report, and will be sent to the test applicants automatically.

Therefore, smart textile testing greatly shortens the entire testing process through digitized and intelligent technology, and the testing process is open to all stakeholders, testing is truly transparent, avoiding repeated testing and time wastage due to mistrust.

The efficient generation of electronic summarized test reports is even more significant for textile companies’ laboratories and third-party testing organizations, which reduced labor costs and achieved paperless work.

What is SmarTexLab?

ChiuVention combines cutting-edge RFID, visual inspection, and other technologies as well as a variety of sensors with AI algorithms, to upgrade conventional textile labs to digital and smart ones, connecting smart instruments, smartphones/tablets/computers to the SmarTexLab system through IoT technology, link to the factory ERP or lab LIMS and the Buyer’s system.

SmarTexLab makes lab testing more transparent, allowing apparel brands and buyers at all levels to master the quality control of supply chain companies in real time, and reduces lab labor costs by about 40% in each lab; Besides, digital transmission is paperless, helping fashion brands to achieve sustainability even in the testing process.

In a word, by combining textile test instruments with the Internet and the newest textile testing technology, SmarTexLab makes textile testing intelligent and efficient, which is a complete revolution of the traditional testing mode.

How the Internet of Things (IoT) functionality of textile testing instruments is realized?

Sensor Technology: Various sensors like temperature sensors, humidity sensors, tension sensors, etc., are integrated into textile testing instruments to measure physical, chemical, electronic, and other properties. Data acquisition from sensors is the basis for realizing the Internet of Things.

Data Acquisition and Processing: The data collected by the sensors is acquired in real-time or at regular intervals and initially processed using an embedded system or microcontroller. This includes steps such as data filtering, calibration, etc.

Communication modules: Integration of modules capable of communicating with the Internet, such as Wi-Fi, Bluetooth, LoRa (long-range low-power radio frequency communication), etc. These modules enable textile test instruments to exchange data with cloud platforms or other devices.

Cloud Platform Connect: Connecting textile test instruments to a cloud platform provided by a cloud service company (e.g. AWS, Azure, Google Cloud, etc.) or a platform specifically designed for the IoT. Those Cloud platforms allow for centralized data management, remote monitoring, and control.

Remote monitoring and control: Through the Internet connection, users can remotely monitor the operating status, real-time data, and remote control of the test instruments. This improves equipment work efficiency and management efficiency.

Data Analysis and Intelligent Decision Making: Utilize data analysis tools on the cloud platform to perform in-depth analysis of textile test data and extract useful information. This can include predictive maintenance, quality control optimization, and more. In some cases, artificial intelligence (AI) techniques can also be utilized for intelligent decision-making.

Security: As it relates to the transmission and storage of data, ensuring the security of communications and data storage is critical. The use of encrypted communications, authentication, and other security measures is necessary.

Through these steps, textile testing instruments can be seamlessly integrated with the Internet to form an IoT ecosystem that enables real-time operating and monitoring, remote control, and data analysis & transmission to improve testing efficiency, reduce costs, and optimize production processes.

How Does Smart Textile Testing Benefit Customers?

Faster obtain the test results: Textile testing instruments connected to the Internet can transmit test data in real time to a cloud platform or server for real-time data analysis and processing. Through cloud analysis, users can get more accurate and timely test results and analysis reports, as well as data visualization to help users better understand the test results.

Traceability and better quality control: Through the Internet connection, the textile testing instrument can support product traceability and quality control. The test data can be combined with the production data to realize the whole process of monitoring and tracing the product production process, to ensure that the product quality is in line with the standard requirements, and to quickly locate and solve quality problems.

Intelligent production and optimization: Integrating Internet-connected textile testing instruments with other production equipment and systems enables intelligent production and optimization. By monitoring and analyzing production data in real-time, the whole system enables automated control and optimization of the production process, improving production efficiency and product quality.

Faster support from the manufacturer: Through an Internet connection, the customers can achieve closer contact with test instrument manufacturers and get more personalized and professional service. Users can also access product information, technical support, and training resources through the Internet platform.

ChiuVention—The Digital Future of Textile Testing

ChiuVention is the first company to focus on smart textile testing solutions. It is registered in Europe and the United States and is designed in Germany. ChiuVention is developed from TESTEX founded in 2010, headquartered in Dongguan, China. We specialize in textile footwear and apparel testing instruments.

In 2020, our brand was upgraded comprehensively to ChiuVention and realized the global launch of the new brand at the ITMA 2023, Milan, Italy, the world’s most influential textile and garment technology exhibition.

At ITMA 2023, a series of ChiuVention revolutionary and innovative textile testing instruments such as the SmartShrink Shrinkage Rate Tester, the SmartFill Liquid Filling Machine, and our SmarTexLab system gained a great deal of attention from the industry’s benchmark brands, such as Adidas and Decathlon, as well as the major academic and standards organizations. ChiuVention has been recognized widely since its launch.

ChiuVention provides smart textile testing instruments and solutions for 42 countries and regions worldwide. We have been serving third-party testing organizations such as BV, SGS, Intertek, and sports and fashion brands such as SHEIN, NIKE, Adidas, ANTA, Decathlon, etc. With customer-centered belief and the mission of leading the digital future of textile testing, ChiuVention is committed to becoming a global leader in smart textile instruments.

A Brief Introduction to Smart Textile Testing Machines

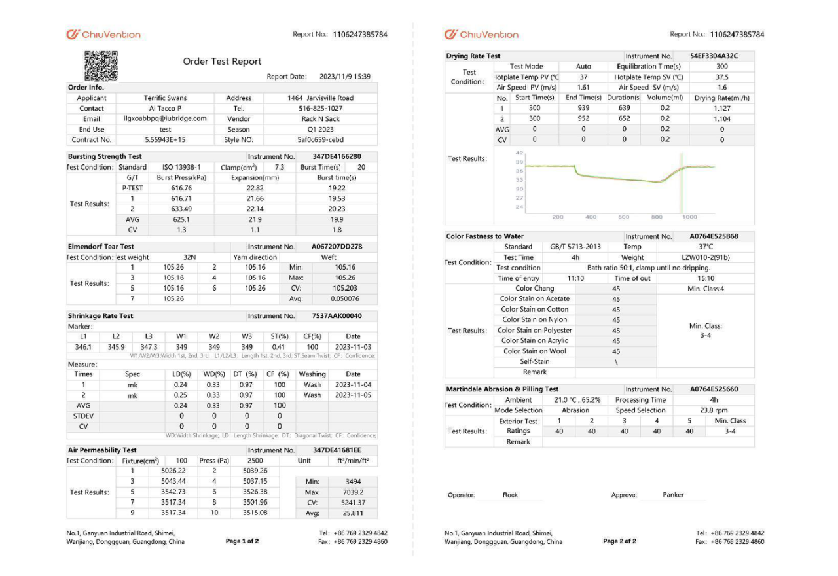

SmartShrink Shrinkage Rate Tester

SmartShrink Shrinkage Rate Tester determines multiple shrinkage rate test results in 5 seconds for fabrics after washing, steaming, and dry-cleaning.

SmartShrink takes a picture of a fabric sample by using a camera-equipped on the top, automatically measuring the distances between the marked dots, and calculates the test results by the patented vision inspection algorithm of ChiuVention. The test results will be shared with the IoT-connected SmarTexLab app installed on the computer and smartphone.

SmartCut Sample Cutting System

The SmartCut Fabric Sample Cutting Machine can complete the sampling of fabrics within 3 minutes.

It can be connected with the customer’s ERP or LIMS system docking through the network port, then automatically gets the test item information from the scanning of the bar code. Then the SmartCut fabric sample-cutting machine will lay out the sample graphics of the items to be tested following the standard requirements through a unique algorithm.

Next step, the sample graphics will be projected on the fabric and the SmartCut fabric sample cutting machine will start cutting fabric samples, automatically marking the samples as the the customer’s settings.

It is suitable for sampling requirements of dozens of tests such as pilling, tearing strength, water repellency, anti-static, tensile strength, color fastness, flammability, etc. It supports various standards such as GB/T, FZ/T, ISO, EN, JIS L, AATCC, ASTM, CAN, AS, and so on.

Smartindale Martindale Abrasion and Pilling Tester

Smartindale Martindale Abrasion and Pilling Tester are used for fabric abrasion and pilling tests. It generates a Lissajous curve with a digital algorithm, and then drives the friction, achieving accurate running without calibration. You can switch test modes such as the abrasion test to the pilling test with one click without changing the pins. You can also control and monitor the Smartindale from your smartphone by SmarTexLab app connection and the test data can be uploaded to ERP or LIMS system, to realize smart testing.

It can test the abrasion and pilling resistance of cotton, linen, silk woven fabrics and other textiles, film materials, knitted fabrics, woolen fabrics, artificial leather, synthetic leather, gloves, labor protection materials, and so on. It is widely applicable to more than 20 international standards such as ISO 12945-2-2020, ISO12947-2-2016, BS EN 530-2010; ASTM D4970/4970M-22, etc.

AirFicient Air Permeability Tester

The AirFicient Air Permeability Tester allows you to quickly get reliable air permeability testing results, and it is a smart instrument so you can set parameters, monitor the test status, etc., from your smartphone, which greatly improves work efficiency.

This Air Permeability Tester is suitable for a variety of textiles including technical fabrics, non-woven fabrics, and other breathable products such as sponges paper, and other materials for air permeability testing. Applicable to GB/T5453, ISO 9237, ISO 9073:15, JIS L1096 Item 8.26 Method C, BS 3424-16, BS 6F 100 3.1, NWSP 070.1.RO(15), GB/T 24218.15, etc.

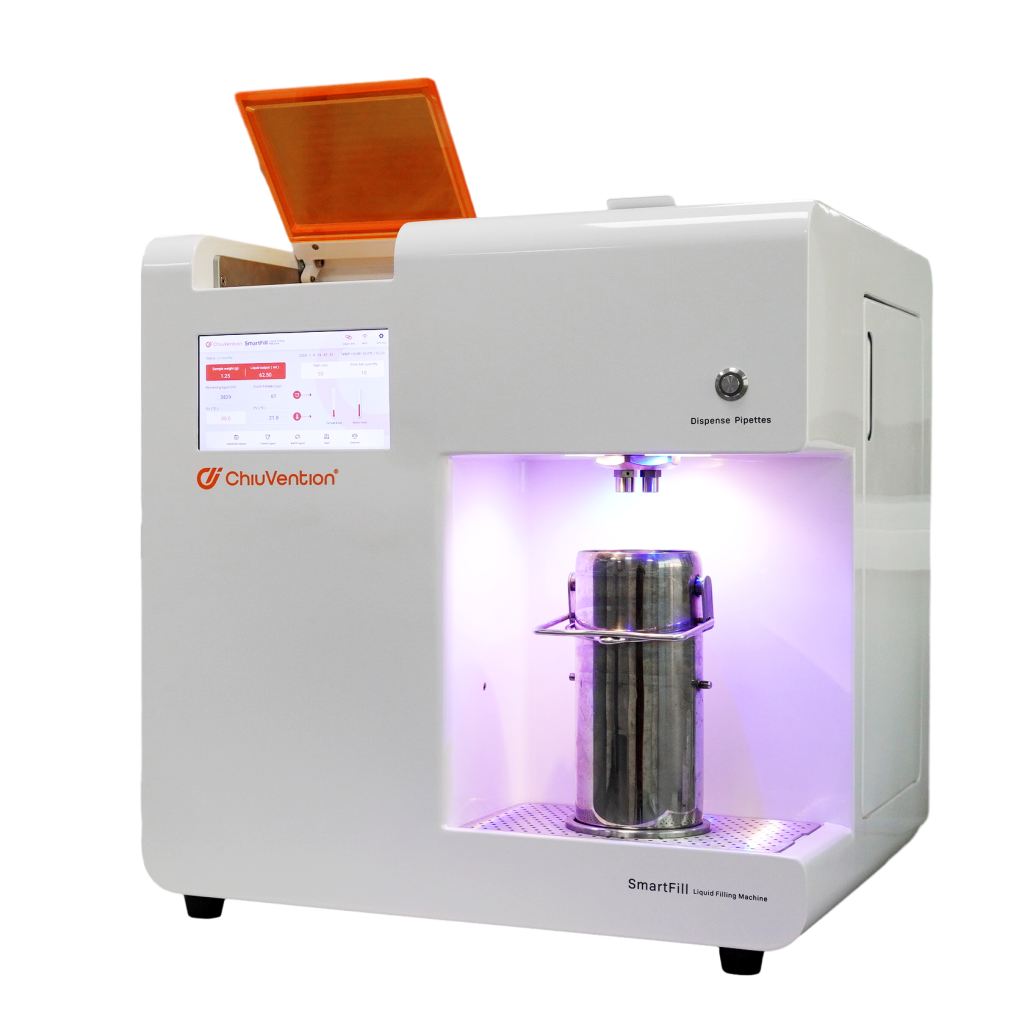

HydroBurst Bursting Strength Tester

The HydroBurst Automatic Bursting Strength Tester utilizes hydraulic bursting (diaphragm method) to determine the bursting strength and expansion of knitted fabric, woven fabric, non-woven fabric, laminated fabric, elastic woven fabric, paper, and other materials when subjected to stress in both warp and weft directions, as well as in all other directions, to get the material’s resistance to bursting.

This Bursting Strength Tester can be connected through Wi-Fi with the SmarTexLab APP installed in smartphones, set parameters, monitor the test status, receive equipment warning reminders and replenishment reminders, etc., and share burst test results with one click.

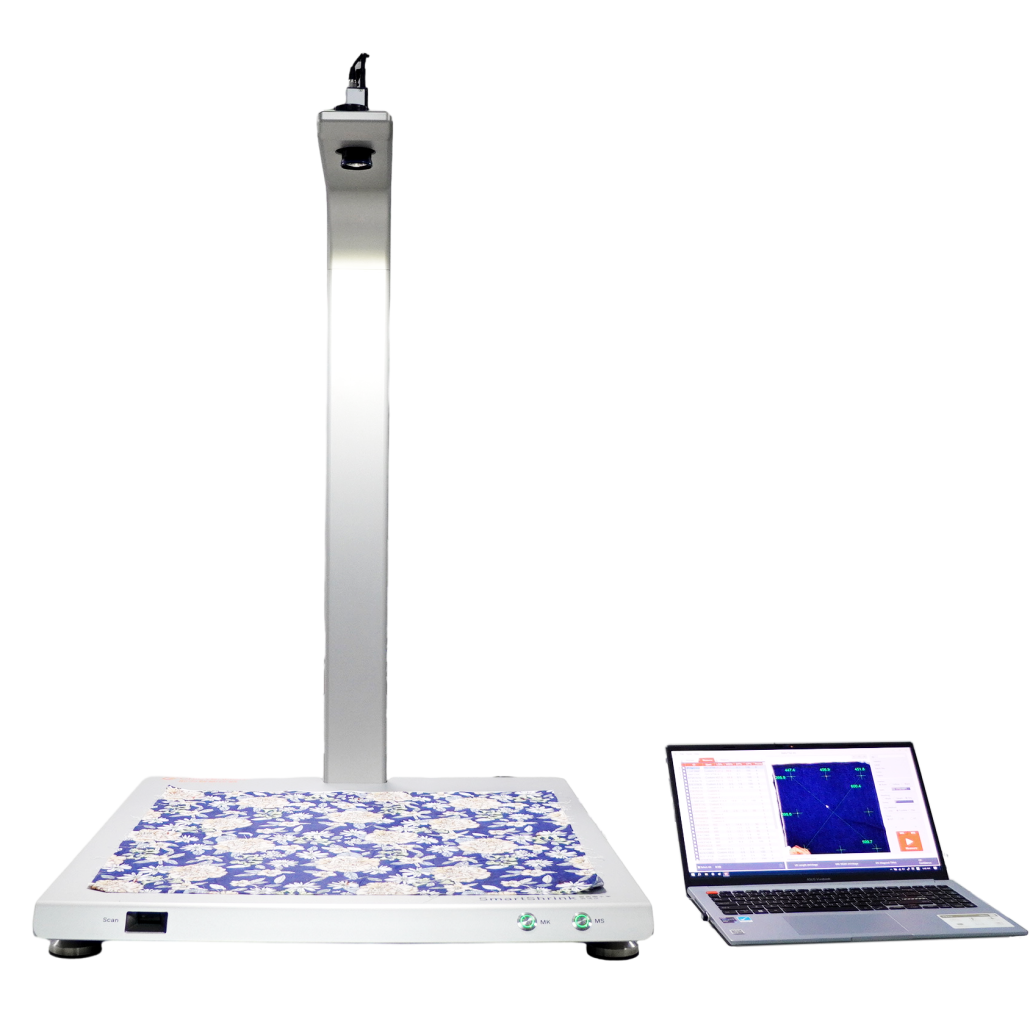

SmartFill Liquid Filling Machine

SmartFill Liquid Filling Machine

The SmartFill is a matching device of washing color fastness tester, which can greatly improve the accuracy and efficiency of the test.

It is equipped with a weighing balance. After weighing the sample, it automatically prepares and heats the soap solution according to the set bath ratio, and outputs the soap solution at a constant temperature, also outputs the set number of steel balls into the test cup.

By choosing SmartFill, for 1 wash color fastness tester with 12 test cups, each test preparation can save 10 minutes, according to 200 samples per day, or save 30% of individual labor costs for enterprises in a year.

For more Smart Textile Testing Machines, Please visit: https://chiuvention.com/products

For more smart textile testing knowledge, instrument knowledge, and textile testing laboratory knowledge, please contact us:

sales@chiuvention.com.

WhatsApp +86 180 2511 4082