In the textile industry, ensuring the quality and longevity of fabrics is paramount. Consumers expect their clothing, furniture, upholstery, and other textile products to withstand everyday wear and tear. To guarantee these expectations are met, manufacturers and quality control professionals rely on various testing methods. Among these essential tools, the Martindale Abrasion and Pilling Tester stand out as a cornerstone for evaluating fabric durability.

This guide is here to explain the ten most frequently asked questions regarding the Martindale Abrasion and Pilling Tester. By providing clear and concise answers, we aim to equip you with a thorough understanding of this crucial instrument and its role in our top 10 most practical FAQs.

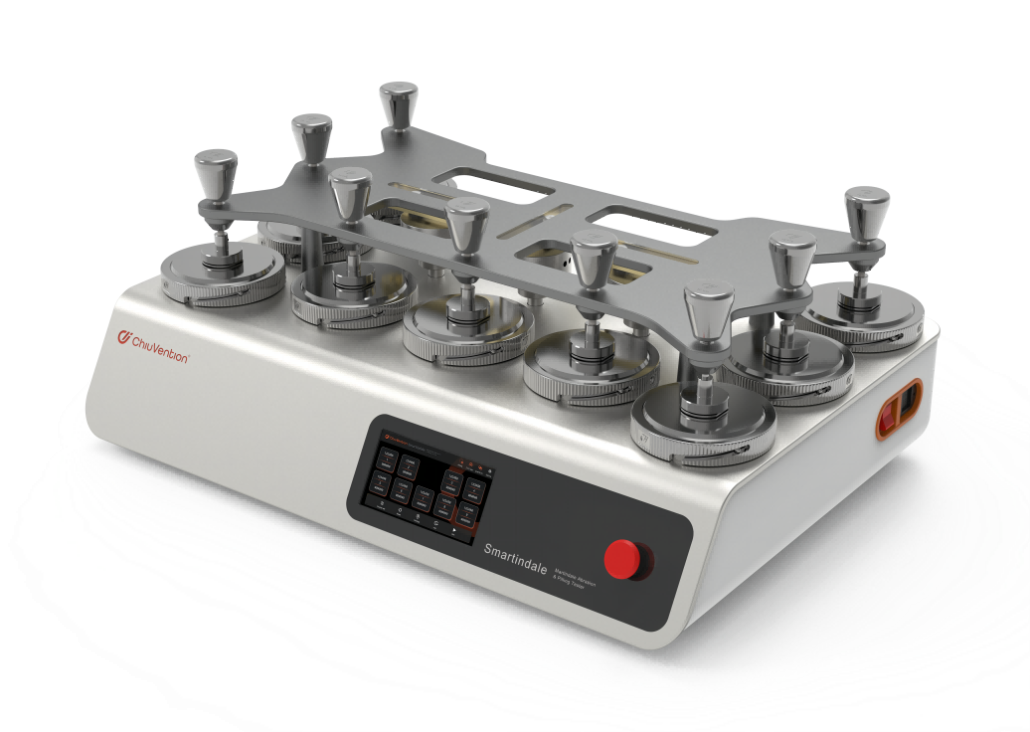

1. What is a Martindale Abrasion Pilling Tester?

The Martindale Abrasion and Pilling Tester, often referred to simply as the Martindale Tester, is a workhorse in the textile industry. This apparatus serves a critical purpose: evaluating a fabric’s resistance to two main types of wear and tear – abrasion and pilling.

Understanding Abrasion and Pilling

Abrasion:

Imagine your favorite pair of jeans rubbing against a chair repeatedly. Over time, you might notice the fabric thinning or even developing holes in those high-friction areas. This gradual wearing away of a fabric’s surface due to rubbing against other materials is precisely what abrasion is. It can significantly impact the lifespan and aesthetics of a textile product.

Pilling:

Have you ever noticed those pesky little balls of fiber forming on the surface of your sweater? That’s pilling, and it occurs when loose fibers on the fabric surface tangle and clump together. While not necessarily a functional issue, pilling detracts from the overall appearance and quality of the textile.

How The Martindale Tester Saves the Day?

The Martindale Tester simulates these wear and tear mechanisms in a controlled laboratory setting. Here’s a closer look at how it functions:

Sample Preparation:

The testing process begins with preparing a sample of the fabric under evaluation. Following specific standards, a circular piece is typically cut from the material.

Test Configuration:

This prepared sample is then mounted on a rotating arm within the tester. The opposing rubbing surface can vary depending on the test type. For abrasion testing, a standard abrasive material might be used. For pilling evaluation, another fabric sample, often a standard woolen fabric or even the same fabric itself, may be used as the rubbing surface.

The All-Important Rubbing Motion:

The Martindale Abrasion and Pilling Tester is programmed to run for a set number of cycles, replicating the expected duration of wear the fabric might encounter in its intended application. During each cycle, the rotating arm rubs the fabric sample against the opposing surface in a complex path known as a Lissajous pattern. This intricate path ensures all areas of the sample experience rubbing at various angles, mimicking real-world wear scenarios where the fabric doesn’t rub in just one direction.

Evaluation – The Final Verdict: Once the test is complete, the fabric sample undergoes a thorough visual inspection. For abrasion testing, this inspection focuses on identifying signs of wear. In the case of pilling evaluation, the degree of pilling formation is assessed.

2. What is a Martindale Abrasion Tester Diagram?

While a detailed technical diagram of the Martindale Abrasion and Pilling Tester can be intricate, understanding the basic concept behind its internal workings is quite interesting. Imagine the diagram as a blueprint for a machine with multiple testing stations, each designed to mimic real-world wear and tear on a fabric sample. Here’s a breakdown of the key components you might see in a simplified version of the diagram:

Testing Station:

Each station typically features a circular base that holds the fabric sample in place.

Sample Holder:

Think of this as a small clamp or clip that securely attaches the circular fabric sample to the base. It ensures the fabric stays taut and experiences consistent rubbing throughout the test.

Rotating Arm:

Picture a short arm extending upwards from the base. This arm holds the sample holder and rotates, mimicking the rubbing motion the fabric might experience in real-life use.

Weight:

A designated weight is placed on top of the rotating arm, pressing down on the fabric sample. This weight simulates the pressure the fabric encounters during use. Heavier weights might be used for upholstery fabrics, while lighter weights might be used for delicate materials.

Opposing Rubbing Surface:

Depending on the test type, this surface can vary. For abrasion testing, imagine a rough, textured plate representing surfaces the fabric might rub against, like furniture or backpacks. In pilling evaluation, this surface could be another fabric sample, often a standard woolen fabric, mimicking the rubbing of fabric fibers against each other.

Drive Mechanism:

This unseen component is responsible for rotating the arm that holds the fabric sample and the weight. It ensures consistent speed throughout the test.

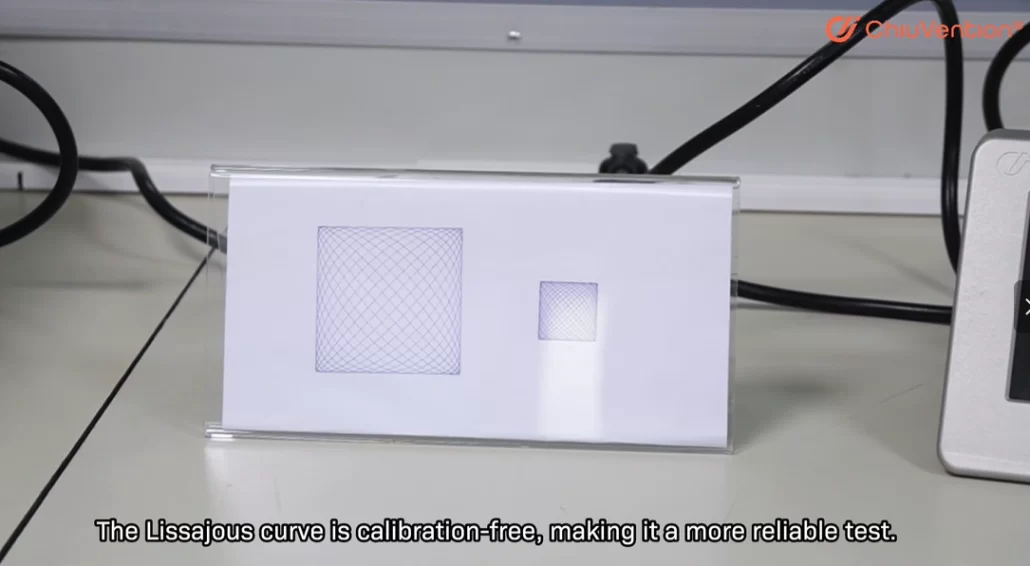

Lissajous Path:

This might sound complex, but imagine the path of the rotating arm as an oval shape, not a simple back-and-forth motion. This oval path ensures all areas of the fabric experience rubbing at various angles. Think of it like a fabric rubbing against different surfaces at different angles during everyday use.

Remember, this is a simplified explanation. Actual Martindale Testers might have additional components or variations in design depending on the manufacturer. However, the core principle remains the same.

3. What is the Martindale Abrasion Tester Working Principle?

The Martindale Abrasion and Pilling Tester may seem like a simple machine, but its working principle involves a well-defined process to accurately assess fabric durability. Here’s a breakdown of the key steps involved:

- Sample Preparation: Setting the Stage:

The testing journey begins with preparing the fabric sample. Following specific standards, a circular piece, typically around 38 or 140 millimeters in diameter, is cut from the material under evaluation. This ensures consistency and allows for comparison between different fabrics tested using the same method.

- Test Configuration: Putting the Pieces Together:

Once the sample is prepared, it’s time to configure the Martindale Tester for the specific test type – abrasion or pilling. Here’s what happens:

Sample Mounting:

The prepared fabric sample is securely fastened onto the sample holder on the rotating arm of the testing station.

Opposing Rubbing Surface Selection:

Depending on the test type, the appropriate opposing rubbing surface is chosen and positioned. For abrasion testing, a standard abrasive material with a defined texture is used. For pilling evaluation, the opposing surface could be another fabric sample, often a standard woolen fabric or even the same fabric itself.

Weight Application:

A predetermined weight is applied to the top of the rotating arm, pressing down on the fabric sample. This weight simulates the pressure the fabric might experience during its actual use. The specific weight used depends on the test standard and the type of fabric being evaluated.

- The Crucial Rubbing Motion: Replicating Real-World Wear:

With everything set up, it’s time for the core functionality of the Martindale Tester – the rubbing motion. Here’s how it works:

Programmed Cycles:

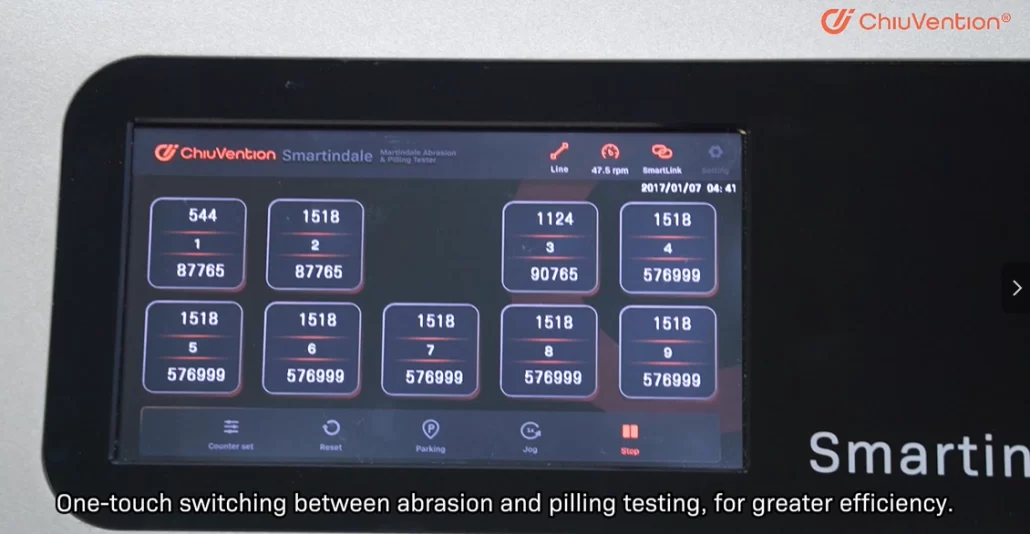

The tester is programmed to run for a specific number of cycles, replicating the expected wear duration for the fabric in its intended application. For instance, upholstery fabrics might need to endure more rubbing cycles compared to delicate scarves.

The Lissajous Path:

Unlike a simple back-and-forth motion, the rotating arm holding the fabric sample follows a complex path known as a Lissajous pattern. This intricate oval-shaped path ensures all areas of the fabric experience rubbing at various angles. Imagine a fabric rubbing against different surfaces throughout the day, not just in one direction. The Lissajous pattern replicates this real-world scenario for a more accurate evaluation.

Consistent Speed:

The drive mechanism of the tester ensures the rotating arm maintains a consistent speed throughout the programmed cycles. This controlled speed allows for standardized testing and reliable comparisons between different fabrics.

- Unveiling the Results: The Fabric’s Story:

After the pre-determined number of cycles is complete, the fabric sample is removed from the tester and undergoes a thorough visual inspection. Here’s what the inspection reveals:

Abrasion Testing:

For abrasion testing, the fabric sample is examined for signs of wear and tear. This might include thinning, fraying, or even the formation of holes. The number of cycles endured before reaching a pre-defined level of wear determines the fabric’s abrasion resistance.

Pilling Evaluation:

In pilling evaluation, the focus is on assessing the degree of pilling formation on the fabric surface. Standardized grading systems, often using a five-point scale, are used to quantify the severity of pilling observed. Higher grades indicate less pilling and superior resistance.

By analyzing the results of the visual inspection and the number of cycles endured before reaching a set level of wear or pilling, the Martindale Tester provides valuable data on the fabric’s durability.

4. What is the Price Range of a Martindale Abrasion Tester?

The price of a Martindale Abrasion and Pilling Tester can vary depending on several key factors. Martindale abrasion tester price typically ranges from $3,000 to $15,000. The exact cost mainly depends on a few factors such as the number of testing stations, brands, and feature sets.

Number of Testing Stations:

Martindale Testers come equipped with multiple testing stations, allowing for simultaneous evaluation of several fabric samples. The more stations a tester has, the higher its price tends to be. For labs with high testing volumes, a multi-station tester offers efficiency, while lower-volume labs might opt for a more basic model with fewer stations.

Feature Set:

Basic models offer the core functionality of abrasion and pilling evaluation. However, some advanced models come equipped with additional features that can increase the cost. These features might include:

- Automated weight application for improved consistency.

- Data logging capabilities for easy record keeping and analysis of test results.

- Touch screen interfaces for user-friendly operation.

Here’s a general estimate to provide a starting point:

Basic Models: For a basic Martindale Tester with a few testing stations and limited features, the price range can start around $2,000.

Advanced Models: High-end models with multiple testing stations, advanced features, and automation capabilities can reach $10,000 or even more.

The decision of which Martindale Tester to purchase depends on individual needs and budget constraints. Laboratories with high testing volumes or those requiring advanced features might opt for a higher-priced model. For lower-volume labs or those focused on basic abrasion and pilling evaluation, a more economical model might be sufficient. Curious about ChiuVention’s Martindale abrasion tester price? Click on the picture below to get a quick quote!

5. What is the Martindale Pilling Test Method?

Pilling, those pesky little balls of fiber that form on fabric surfaces, can be a major aesthetic concern for textiles. Consumers expect their clothes and furnishings to remain smooth and attractive throughout their lifespan. The Martindale Pilling Test Method steps up to the challenge, offering a standardized approach to assess a fabric’s resistance to this unwanted fuzz.

Here’s a closer look at the key steps involved in this specific test:

- Sample Preparation:

The Martindale Pilling Test Method mainly remains the same as for Martindale abrasion test, but it has its differences. For instance, a circular piece of cloth, typically around 38 millimeters in diameter is prepared for testing.

- Test Configuration: Choosing the Right Rubbing Partner:

Unlike abrasion testing where a standard abrasive material is used, the opposing rubbing surface in a pilling test can vary depending on the specific standard and the fabric itself. Here are the two main possibilities:

Standard Woolen Fabric:

A common choice for the opposing surface is a standardized woolen fabric. The rubbing action between the fabric sample and the woolen fabric replicates the friction that can occur between different garments or between furniture upholstery and clothing.

Self-Pilling Test:

In some cases, the test might use the same fabric itself as the opposing rubbing surface. This scenario simulates situations where fibers within the fabric itself are more prone to entanglement and pilling formation.

In both scenarios, a predetermined weight is applied to the rotating arm of the Martindale Tester, pressing the fabric sample against the chosen opposing surface. This weight mimics the pressure the fabric might experience during real-world use.

- The Crucial Rubbing Motion: Replicating Wear and Tear:

With the sample and opposing surface in place, the tester is programmed to run for a specific number of cycles. This number is chosen to reflect the expected wear duration for the fabric in its intended application. For instance, upholstery fabrics might undergo more rubbing cycles compared to delicate scarves. During these cycles, the rotating arm follows the same intricate Lissajous path as in abrasion testing, ensuring all areas of the fabric experience rubbing at various angles.

- Unveiling the Results: The Pilling Verdict:

Once the programmed cycles are complete, the fabric sample is meticulously examined for signs of pilling formation. Standardized grading systems, often using a five-point scale, are used to quantify the severity of pilling observed. Higher grades indicate less pilling and superior resistance to unsightly fuzz.

6. What are the commonly used Abrasion Test Standards?

The Martindale Abrasion Tester doesn’t operate in a vacuum. To ensure consistent and reliable results, standardized test methods are followed. These established procedures outline specific details like sample preparation, test configuration, and evaluation criteria. Here, we’ll explore some of the most commonly used Martindale Abrasion Test Standards:

ISO 105-X12: Textiles – Tests for color fastness – Part X12:

Resistance to rubbing (Martindale method): This international standard, published by the International Organization for Standardization (ISO), serves as a general guideline for assessing abrasion resistance using the Martindale Tester. It outlines the basic procedures for sample preparation, test configuration (including weight application and rubbing cycles), and evaluation methods for identifying signs of wear and tear on the fabric sample.

ASTM D4966: Standard Test Method for Resistance of Fabrics to Abrasion by Flexing and Abrasion (Martindale Method):

Developed by the American Society for Testing and Materials (ASTM), this standard is widely used in the United States for evaluating fabric abrasion resistance. Similar to ISO 105-X12, it provides specific instructions for sample preparation, test configuration, and evaluation of wear and tear on the fabric sample. However, there might be slight variations in specific details like the type of abrasive material used or the weight applied.

ISO 12945-2: Textiles – Determination of fabric propensity to surface fuzzing and to pilling:

This ISO standard specifically focuses on evaluating a fabric’s resistance to pilling and fuzzing. It utilizes a modified version of the Martindale method, outlining procedures for sample preparation, test configuration (including selection of the opposing rubbing surface and weight application), and assessment of pilling formation on the fabric sample. While not strictly an abrasion test, it leverages the core functionality of the Martindale Tester for pilling evaluation.

National Standards:

Many countries may have their own established national standards for Martindale Abrasion Testing. These standards might be based on existing international standards like ISO 105-X12 or ASTM D4966, with some adaptations specific to the country’s textile industry needs.

7. What is the Martindale Pilling Test – ISO 12945-2 Test Method?

The battle against fabric fuzz doesn’t stop with generic pilling test methods. For a more specific and internationally recognized approach, ISO 12945-2 test method emerges as the champion. Published by the International Organization for Standardization (ISO), this standard provides a dedicated protocol for evaluating a fabric’s resistance to pilling, fuzzing, and matting using the Martindale Tester.

- Sample Preparation: Setting the Stage for Pilling Evaluation

Similar to other Martindale testing methods, ISO 12945-2 test method begins with preparing a fabric sample. The standard specifies a circular piece, typically around 38 millimeters in diameter, to be cut from the material under evaluation. This ensures consistency and allows for comparisons between different fabrics tested using the same method.

- Test Configuration: Choosing the Right Rubbing Partner:

Unlike abrasion testing where a standard abrasive material is used, ISO 12945-2 test method focuses on assessing pilling Martindale propensity. Therefore, the opposing rubbing surface plays a crucial role. Here are the two possibilities outlined in the standard:

Same Fabric:

The standard allows for using the same fabric itself as the opposing rubbing surface. This scenario simulates situations where fibers within the fabric are more prone to entanglement and pilling formation.

Wool Abrasive Fabric:

Alternatively, the standard permits the use of a specific wool abrasive fabric as the opposing surface. This replicates the friction that can occur between different garments or between furniture upholstery and clothing.

In both scenarios, a predetermined weight is applied to the rotating arm of the Martindale machine, pressing the fabric sample against the chosen opposing surface. This weight mimics the pressure the fabric might experience during real-world use.

- The Crucial Rubbing Motion: Replicating Wear and Tear

With the sample and opposing surface in place, the tester is programmed to run for a specific number of cycles as defined by the standard. This number is chosen to reflect the expected wear duration for the fabric in its intended application. For instance, upholstery fabrics might undergo more rubbing cycles compared to delicate scarves. During these cycles, the rotating arm follows the intricate Lissajous path, ensuring all areas of the fabric experience rubbing at various angles.

- The Pilling Verdict:

Once the programmed cycles are complete, the fabric sample undergoes a meticulous examination for signs of pilling, fuzzing, and matting. ISO 12945-2 test method provides a standardized visual assessment method, often using a five-point scale. Higher grades indicate less pilling and superior resistance to these unwanted surface changes.

By analyzing the pilling grade and the number of cycles endured before reaching a set level of surface alteration, the ISO 12945-2 test method provides valuable insights into the fabric’s performance.

The ISO 12945-2 test method is widely employed in the textile testing industry. In addition to the above Martindale abrasion test method, a range of other methods exist, including DIN 53887, ISO 12947, ISO 20344, ASTM D4970, and ASTM D4966. Our Smartindale Martindale pilling and abrasion tester is capable of meeting the aforementioned test abrasion methods. For further information, please do not hesitate to contact us.

8. The Evaluation of Martindale Test Results?

After the fabric sample endures its pre-programmed rubbing cycles in the Martindale Pilling Tester, the real work begins – interpreting the results. These results provide valuable insights into the fabric’s durability and resistance to wear and tear. However, understanding how to evaluate these results and what constitutes a “good” score can be a bit puzzling. Here’s a breakdown to help you decipher the code:

The Power of Numbers: Cycles Endured Before Wear or Pilling

The core outcome of a Martindale rub test is the number of cycles the fabric sample withstands before reaching a pre-defined level of wear or pilling. Higher cycle counts indicate superior durability. For instance, a fabric that endures 50,000 cycles in an abrasion test might be considered highly durable for upholstery fabric, while a delicate silk scarf might only need to reach a few thousand cycles to meet expectations.

There isn’t a universal “good” score applicable to all fabrics. The acceptable cycle count depends on the intended use of the fabric. Here’s a general guideline:

Heavy Duty Fabrics (Upholstery, Car Seats): These fabrics should endure higher cycle counts (potentially exceeding 50,000 cycles) to withstand frequent rubbing and wear.

Medium Duty Fabrics (Clothing, Bags): Fabrics in this category might have acceptable cycle counts ranging from 10,000 to 50,000 cycles, depending on the specific use.

Lighter Duty Fabrics (Lingerie, Delicate Garments): Lower cycle counts (in the range of a few thousand cycles) might be considered acceptable for these fabrics, as they are not subjected to the same level of abrasion in everyday use.

It’s important to note that these are just general examples, and specific expectations for cycle counts will vary depending on industry standards and manufacturer requirements.

9. The Comparison of the Different Abrasion Test Methods.

The Martindale abrasion test method, while a workhorse in the textile industry, isn’t the only method for evaluating fabric wear and tear. Different fabric abrasion testing methods can provide valuable insights tailored to specific types of wear a fabric might encounter. Here, we’ll explore some other commonly used wear testing methods and fabric abrasion testers and how they compare to the Martindale fabric Test:

- ICI Pilling Test:

This test focuses specifically on a fabric’s propensity to form pills. Unlike the Martindale Test Equipment, which uses a rotating arm, the ICI Pilling Test utilizes a tumbling chamber. Fabric samples are placed inside the chamber with cork or rubber cubes, and the chamber tumbles for a set duration. The tumbling motion replicates the rubbing of fabrics against each other during wear, which can lead to pilling formation. After the tumbling cycle, the fabric samples are assessed for the degree of pilling observed. While less versatile than the Martindale Tester, the ICI Pilling Test offers a more focused evaluation of pilling resistance.

- Wyzenbeek Abrasion Tester:

Wyzenbeek Abrasion Tester shares some similarities with the Martindale Pilling Tester Machine but with a key difference in the rubbing motion. The Wyzenbeek Tester uses a reciprocating motion, where the fabric sample rubs back and forth against a standard abrasive material. This motion simulates the type of abrasion that might occur on areas like armrests or chair backs. The Wyzenbeek Test is often used in conjunction with the Martindale Test to provide a more comprehensive picture of a fabric’s abrasion resistance under different types of rubbing motion.

- Taber Abrasion Tester:

With abrasive surfaces to rub against the fabric sample, this testing method employs a rotating wheel. The Taber Tester offers the ability to adjust the abrading wheels and the test parameters to simulate various wear scenarios. For instance, a coarse abrasive wheel might be used to replicate heavy-duty abrasion, while a finer wheel could represent milder wear. The Taber Tester provides valuable insights for evaluating fabrics intended for use in specific applications with unique abrasion challenges.

Choosing the Right Test Method:

The selection of the most appropriate wear testing method depends on several factors, including:

The Intended Use of the Fabric: Upholstery fabrics might require testing methods that simulate wear from sitting and rubbing, while fabrics for clothing might benefit from tests that replicate abrasion against other garments.

The Specific Type of Wear of Concern: If pilling is a major concern, the ICI Pilling Tester Machine might be a good choice. For general abrasion resistance, the Martindale or Wyzenbeek Testers might be more suitable.

Industry Standards and Regulations: Certain industries might have specific regulations that mandate the use of a particular wear testing method.

10. Example of the use of Martindale Abrasion Pilling Test in product design and quality control.

The Martindale Abrasion and Pilling Tester isn’t just a piece of lab equipment; it’s a powerful tool that plays a crucial role in product design and quality control across the textile industry. Here’s how this test helps bring durable and attractive textiles to market:

The Martindale Abrasion and Pilling Tester transcends the realm of scientific equipment; it plays a crucial role in the real world of product design and quality control. Here’s how this testing method translates into practical applications:

Enhancing Product Design:

- Material Selection: Imagine a designer developing a new line of high-end sofas. Durability is a key factor. By testing various upholstery fabric options using the Martindale Tester, the designer can identify fabrics that can withstand the expected wear and tear of daily use. This ensures the sofas maintain their attractive appearance and functionality for an extended period.

- Prototyping and Refinement: During the development of a new backpack design, the manufacturer might use the Martindale Tester to evaluate the abrasion resistance of different strap materials. Testing different fabrics allows designers to refine their prototypes and select materials that can handle the rigors of everyday carrying.

Maintaining Quality Control:

- Incoming Material Inspection: Fabric manufacturers rely on the Martindale Tester to ensure consistent quality in their raw materials. By testing incoming fabric shipments, they can identify any deviations from expected durability standards and prevent low-quality materials from entering the production line.

- Production Monitoring: Throughout the production process, manufacturers might utilize the Martindale Tester to perform random checks on finished products. This helps ensure that the final product meets the expected abrasion and pilling resistance standards, ultimately leading to a consistent and high-quality end product for consumers.

By incorporating the Martindale Tester into their design and quality control processes, companies can make informed decisions about material selection. They optimize production processes and ultimately deliver products that are not only aesthetically pleasing but also built to last.