Colour Fastness to Washing Test is one of the mandatory tests for textiles, today we share a test standard Colour Fastness to Washing Test Test: ISO 105-C08:2010

and explore how to improve the efficiency of the colour fastness test.

Scope of Color Fastness to Washing Test

This standard specifies a method for determining the colour fastness of textiles for domestic and commercial washing by using a standard detergent containing a low-temperature bleaching activator without phosphorus.

The discolouration and staining of the specimen due to adsorption and/or abrasion in one test cycle is very close to the discolouration and staining produced by one commercial and domestic washing procedure.

This test method does not reflect the effect of some commercial laundry products containing fluorescent whitening agents.

Normative References

The following documents are essential for the application of ISO 105-C08:2010. If a document is dated, only the dated version may be applied to ISO 105-C08:2010.

For undated references, the latest version (including all revisions) applies to ISO 105-C08:2010

ISO 105 A01 Colour fastness test for textiles, part A01: General provisions for the test

ISO 105 A02 Colour fastness test for textiles, part A02: Grey card for assessing colour change

ISO 105 A03 Colour fastness test for textiles, part A03: Grey card for assessing colour staining

ISO 105 A04 Textile colour fastness test, part A04: Instrumental method for assessing the degree of colour staining of lining fabric

ISO 105 A05 Textile colour fastness test Part A05: Instrumental method for assessing colour change in specimens

ISO 105 F01 Colour fastness test for textiles Part F01: Specification for wool interlining fabrics

ISO 105 F02 Textile colour fastness test, part F02: Specification for cotton and viscose fibre interlining fabrics

ISO 105 F03 Textile colour fastness test Part F03: Specification for polyamide interlining fabrics

ISO 105 F04 Textile colour fastness test Part F04: Specification for polyester interlining fabrics

ISO 105 F05 Textile colour fastness test Part F05: Specification for polyacrylonitrile fibre interlining fabrics

ISO 105 F06 Textile colour fastness test Part F06: Specification for silk interlining fabrics

ISO 105 F07 Textile colour fastness test Part F07: Specification for fabrics with diacetate fibre backing

ISO 105 F10 Colour fastness test for textiles, part F10: Specification for interlining fabrics: multifibre fabrics

ISO 3696 Water for analytical tests

The principle of Color Fastness to Washing Test

Textile specimens are washed, rinsed and dried together with a defined lining fabric or fabric combination. The specimens are washed under suitable conditions of temperature, alkalinity, bleaching and friction so that the test results can be obtained in a relatively short period of time. Friction is accomplished by the use of a suitable number of steel balls. The sample is placed in a closed stainless steel test cup with steel balls and soap in a constant rotating collision.

Then use the grey cards or instruments to assess the discolouration of the specimen and the staining of the lining fabric or fabric about the original fabric.

Reagents and Materials for Colour Fastness to Washing Test

4.1 Standard reagents.

4.1.1 ECE¹ “Phosphate-free standard detergent, powder (1998 formulation).

4.1.2 Bleach activator, tetraacetylethylenediamine (TAED).

4.1.3 Sodium perborate tetrahydrate.

4.2 Corrosion-resistant stainless steel beads, approximately 6 mm in diameter.

4.3 Interlining fabrics (see ISO 105 A01).

NOTE: The availability of acetate fibres may be limited due to reduced production.

Alternatively, a multi-fibre lining fabric according to ISO 105 F10 may be used, depending on the temperature of the test;

Type DW of Interlining fabrics, containing wool and vinyl fibres (used in the 40°C and 50°C tests. In some cases, it can also be used at 60°C and should be noted in the report).

Type TW of Interlining fabrics, without wool and vinyl fibre (used in the 95°C test. In some cases, it can be used at 60°C). When using multi-fibre interlining fabrics of wool, it should be noted that sodium perborate may cause damage to the wool at 60°C. The use of sodium perborate is not recommended.

Or use the two single-fibre interlining fabrics according to ISO 105 F01 to ISO 105 F07.

The first piece of lining fabric shall be of the same fibre composition as that of the sample to be tested or, if the sample is a blend, the first lining fabric should have the major fibre of the sample to be tested; the composition of the other piece of lining fabric shall be by Table 1 or, if the sample is a blend, the second piece of lining fabric should have the minor fibre of the sample to be tested, or as otherwise specified.

Table 1 Lining fabric combinations

| Lining fabric 1 | Lining fabric 2 | |

| 40℃ 50℃ | 60℃ 95℃ | |

| Cotton | Wool | Viscose fibre |

| Wool | Cotton | — |

| Silk | Cotton | — |

| Viscose fibre | Wool | Cotton |

| Acetic ester fibre | Viscose fibre | Viscose fibre |

| Polyamide fibres | Wool or Cotton | Cotton |

| Polyester fibres | Wool or Cotton | Cotton |

| Polyacrylonitrile fibres | Wool or Cotton | Cotton |

4.3.3 Use Non-coloured fabrics, e.g. polypropylene, if required.

4.4 Tertiary water, according to ISO 3696.

4.5 Grey card for assessment of colour change, according to ISO 105 A02.

4.6 Grey card for assessing colour staining to ISO 105 A03.

4.7 Spectrocrometer or colourimeter for assessing colour change and staining according to ISO 105A04 and ISO 105 A05.

4.8 Acetic acid solution, containing 0.2 g/L glacial acetic acid, if acidification is required.

Instruments for Color Fastness to Washing Test

5.1 Suitable mechanical devices. Includes a water bath with a radial, operational rotating shaft; a stainless steel vessel with a volume of (550 ± 50) mL, the diameter of (75 ± 5) mm, the height of (125 ± 10) mm, and the bottom of the vessel is (45 ± 10) mm from the shaft.

The rotating shaft/assembly vessel rotates at a frequency of (40±2) min-1. The temperature of the water bath is thermostatically controlled so that the test solution is kept within the specified temperature ± 2°C.

Other mechanical devices can be used in this experiment if they give the same results as those obtained with the apparatus described in 5. 1.

5.2 Balance, accurate to 0.01 g (see ISO 105 A01).

5.3 Mechanical mixer, minimum speed 16,667s¹ (minimum 1000r/min), to ensure thorough dispersion and prevent deposits.

5.4 Iron (if ironing is required), mass not exceeding 2,5 kg, capable of providing the appropriate temperature for the test fabric (see A.9b).

Specimens of Color Fastness to Washing Test

6.1 If the sample to be tested is a fabric, the specimen shall be prepared in one of the following ways:

a) Take a (100±2)mm x (40±2)mm specimen and fit the front of the specimen to a (100±2)mm x (40±2)mm piece of multifibre lined fabric (4.3.1), sewing along the short edge to form a combined specimen.

b) Take a piece of (100±2)mm x (40±2)mm specimen and place it between two pieces of (100±2) mm x (40±2)mm single-fibre lining fabric (4.3.2), sew along the short edge to form a combined specimen.

6.2 If the sample to be tested is a yarn, it should be woven into a fabric for testing. In the case of yarns or loose fibres, the specimen is prepared by taking a mass of yarn or loose fibres of approximately one-half of the total mass of the lining fabric in one of the following ways:

Place the specimen between a piece of (100±2)mm x (40±2)mm multifibre interlining fabric (4.3.1) and a piece of (100±2) undyed fabric (4.3.3), sewn together along all four edges (see ISO 105A01:2010, 10.3, Preparation of combined specimens).

The specimen shall be placed between two pieces of specified (100 ± 2) mm x (40 ± 2) mm single-fibre interlining fabric (4.3.2) and sewn together along all four edges to form a combined specimen.

6.3 Determine the mass of the combined specimen in grams using a balance (5.2) to accurately derive the specific volume of the bath.

Test procedure of Color Fastness to Washing Test

See Appendix A for washing procedures using a bleach activator and reference detergent.

Test Report

The colour fastness to washing test report shall include the following information:

a) information referring to this standard, i.e. ISO 105 C08:2010.

b) Details of the test sample;

c) The temperature used for the colour fastness to washing test (as shown in Table A.2).

d) The grade of discolouration of the specimen as assessed using a grey card or instrument;

e) If single-fibre interlining fabrics are used, report the number of staining levels for each type of interlining fabric as assessed by a grey card or instrument:

f) If multifibre interlining is used, report the type of multifibre interlining used and the colour staining level of each fibre bar in the interlining as assessed by a grey card or instrument.

g) Whether steel balls were used in the 40°C or 50°C tests;

h) Whether or not the sample has been treated with an acetic acid solution, as described in A.7;

i) The method of drying of the specimen, air drying or iron drying (as described in A.9), and if iron drying, the ironing temperature should be reported;

j) Detergents and bleaching activators used;

k) Any deviation from this standard.

Appendix A

(Normative Appendix)

ECE Phosphate-free Standard Detergent/TAED Programme

A.1 Standard detergents are supplied in a separate section and the composition is given in Table A.1.

a) ECE Phosphate Free Standard Detergent (1998 formulation).

b) Bleach activator, tetra-acetylethylenediamine (TAED).

c) Sodium perborate tetrahydrate (NaBO₃ -4H₂O).

Table A.1 ECE Phosphate-free Baseline Detergents (WOB), year of 1998

Basic Ingredient | % |

| Sodium straight-chain alkylbenzenesulphonate (average height of alkane chain C11.5)

| 9.7 |

| Ethoxylated ester alcohol C12-18(7EO)

| 5.2 |

| Sodium soap, chain length C12-1746 %: C18-2054 %

| 3.6 |

| Foam inhibitor (DC-42485)

| 4.5 |

| Sodium aluminium silicate(Zeolite 4A) | 32.5 |

| Sodium carbonate | 11.8 |

| Acrylic acid and maleic acid copolymer sodium salt

| 5.2 |

| Sodium silicate (SiOz:Na2O =3.3:1)

| 3.4 |

| Carboxymethyl Cellulose(CMC)

| 1.3 |

| Diethylenetriamine (methylene phosphonic acid)

| 0.8 |

| Sodium Sulfate | 9.8 |

| Water

| 12.2 |

| Tetra-acetylethylenediamine (TAED) (100 per cent active)a Tetra-acetyl (TAED) as a separate add-on | |

| Sodium perborate tetrahydrate as a separate additive

| |

| a The activity of TAED supplied will be specified and may be less than 100 per cent. The required amount of TAED solution per litre is expressed in grams. Calculated as follows: 0.15 x 100% Activity | |

If it is desired to evaluate the effectiveness of the enzymes, the standard detergent can be reduced accordingly by adding the following optional additions to the enzymes.

Protease: Savinase 12 tonnes, reduced by 0.5%;

Lipase: Lipase 100 tonnes, reduced by 0.1%;

Amylase: Termamyl 60 tonnes, reduced by 0.3%;

Cellulase: Celluzyme 0.7 tonnes, reduced by 0.3%

A.2 Preparation of Wash Solution:

Dissolve 4 g of ECE Phosphate Free Standard Detergent Powder (A.1 a)], 0.15 g of TAED (A.1 b) (100% active) (see Table A.1 for calculations when TAED is less than 100% active), and 1 g of Sodium Perborate Tetrahydrate (A.1 c)] in 1 L of tertiary water (4.4).

2) This information is provided for the information of users of this standard only and does not imply ISO endorsement of the products described. If other similar products can give the same results, they can be used in this standard.

A minimum of 1 litre of detergent solution should be prepared immediately before each wash run.

A.3 Use the stirrers (minimum speed 16,667s-1 (1000r/min) to agitate the quantities of ECE standard washing solution powder, sodium perborate tetrahydrate compound and TAED specified in A.2 homogeneously for (10±1)min. That should be done in tertiary water (4.4) at a temperature of (25±5)°C.

A.4 A quantity of washing solution is added to each washing vessel at a bath ratio of 20:1. see Table A.2.

Place the combined specimen and the specified number of steel balls in the vessel, note that the initial temperature is (25±5)°C, close the vessel, place it in the washing device and start spinning.

Table A.2 Test Conditions

Temperature ±2℃(℃) | Liquid: Fabric(m Lg | Temp. Duration(min) | Steel Ball |

40 | 20 | 30 | 25° |

| 50 | 20 | 30 | 25° |

| 60 | 20 | 30 | 25 |

| 95 | 20 | 30 | 25 |

a For products containing wool, silk or blends, steel balls are not applied in the test. If steel balls are used, they should be indicated in the test report. | |||

A.5 Increase the temperature to the temperature specified in Table A.2 at a rate of (1.5 ± 0.5) °C per minute and continue the colour fastness to washing test at the same temperature for (30 ± 1) min.

A.6 For all tests, remove the combined specimen at the end of the wash and place it in a 4 L beaker filled with 2L room temperature tertiary water. Shake gently, rinse for 1min, then rinse the beaker under a cold tap for 10 min.

A.7 In countries where acidification is performed at the end of the washing operation, the following optional operations may be performed. The combined specimen is treated in 100 mL of acetic acid solution (4.8) at 30 °C for 1 min and then rinsed in 100 mL of water (4.4) at 30 °C.

A.8 For all methods, withdraw excess water from the combined specimen.

A.9 For all colour fastness to washing test methods, dry the specimens by the following procedure.

- a) Suspend the specimen in air at a temperature not exceeding 60°C at the suture line area of the specimen;

- b) In some countries, drying with an iron is required. The lining fabric is fitted to the specimen, keeping the lining fabric uppermost, and each specimen is ironed dry with an iron (5.4) at a temperature matching that of the fabric under test, which in no case exceeds 150°C. The temperature used is indicated in the report.

A.10 Specimen discolouration and staining of the backing fabric are assessed using grey cards or instruments. See ISO 105 A02, ISO 105 A03, ISO 105 A04 and ISO 105 A05.

A.11 If the temperature used in the test is different from that specified above, this shall be agreed between the parties to the agreement and noted in the report.

How to improve the efficiency of Color Fastness to Washing Test?

Improving the efficiency of textile colour fastness to washing tests is essential for production and quality control. Here are some suggestions to help improve the efficiency of washing colour fastness testing:

Optimise the sample preparation process:

Prepare a sufficient number of samples in advance according to the test requirements and make sure they are representative.

Use automated equipment or moulds to cut samples quickly and accurately to save time and ensure consistent sample sizes.

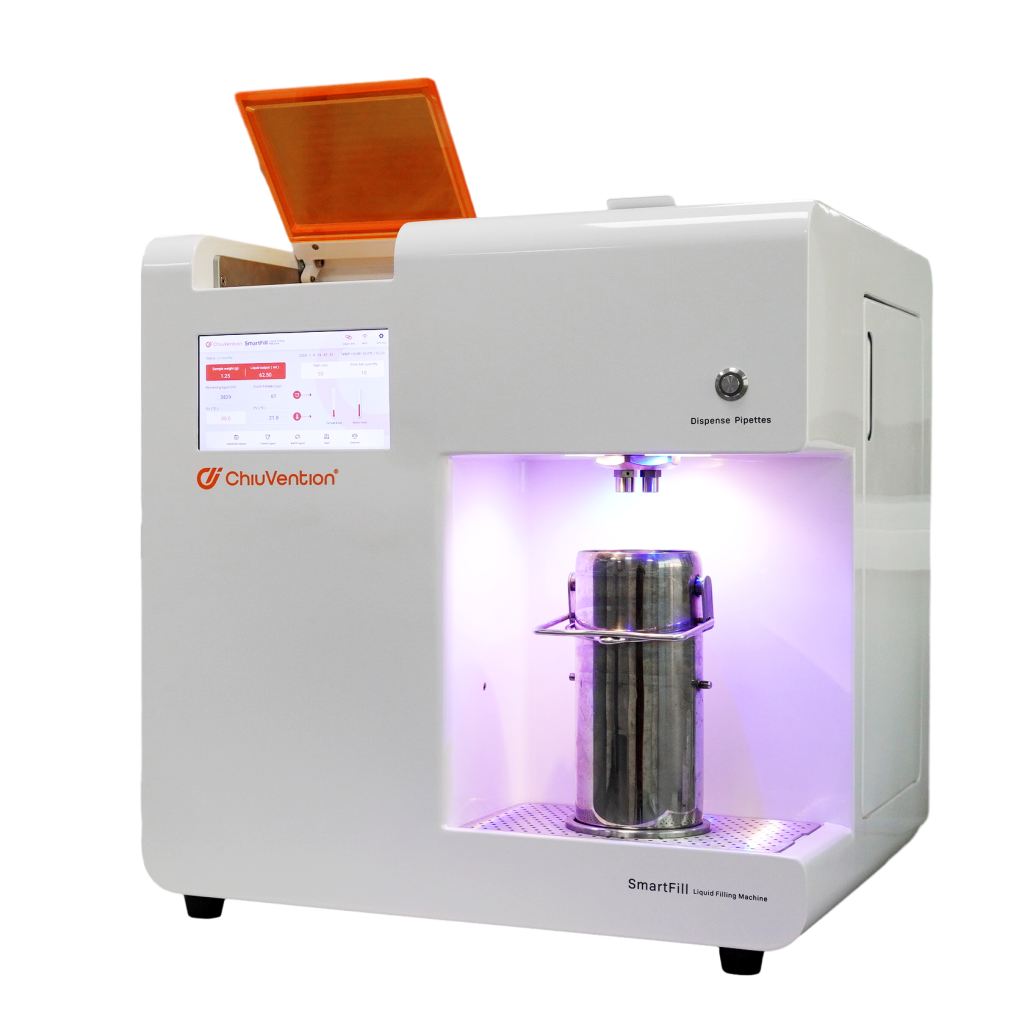

And here is an innovation for test sample preparation: SmartFill

The SmartFill is a matching device for washing colour fastness tester, which can greatly improve the accuracy and efficiency of the test.

It is equipped with a weighing balance. After weighing the sample, it automatically prepares and heats the soap solution according to the set bath ratio, and outputs the soap solution at a constant temperature, also outputs the set number of steel balls into the test cup. The SmartFill makes sample preparation more accurate and efficient, and it enhances economic efficiency by allowing wash colour fastness testing to be done immediately without waiting. The SmartFill can also be connected to the SmarTexLab App installed in the smartphone via WIFI, allowing the operator to perform a series of operations on the phone, such as setting the bath ratio, and temperature, and making appointments for replenishment of the soap and heating, etc.

More accurate testing

The high precision balance weighs the sample and the soap dosage is automatically dispensed strictly according to the bath ratio, accurate to 1ml, together with the precise temperature control and steel ball counting, it makes the whole sample preparation more accurate, thus making the test of washing colour fastness more reliable.

Testing is more efficient, saving nearly 30% of individual labour costs each year.

By choosing SmartFill, for 1 wash colour fastness tester with 12 test cups, each test preparation can save 10 minutes, according to 200 samples per day, or save 30% of individual labour costs for enterprises in a year.

Smart instrument

Can be connected through Wi-Fi with the SmarTexLab App installed in smartphones, then you can set parameters, monitor the test status, receive equipment warning

reminders, replenishment reminders, etc.

Well-known brands are using.

Anta supply chain chose SmartFill, which more quickly and efficiently got the garment colour fastness data so that corporate brand and quality management became more scientific.

Optimise the dye attachment process:

Using efficient dye transfer methods, such as heat transfer or printing techniques, can improve the efficiency and consistency of dye attachment.

Ensuring even distribution of dyes and full contact can be achieved through standardised pressure and temperature control.

Optimise the wash treatment process:

Use automated colour fastness to washing test machines to batch process samples to improve processing efficiency and ensure consistent test conditions.

Optimise detergent selection and use to minimise dye fading and ensure accurate test results.

Process multiple samples in parallel:

Multiple samples can be processed simultaneously during testing to increase efficiency.

Use multiple colour fastness to wash test machines or test equipment with a well-established sample management system to track and manage multiple testing tasks.

Automated data recording and analysis:

Test parameters and results can be recorded quickly and accurately using digital recording systems or real-time data acquisition techniques.

Use data analysis software or statistical tools to analyse test results, identify any anomalies or trends and take the necessary action promptly.

Continuous improvement and training:

Test processes and operating procedures are regularly evaluated to identify opportunities for improvement and optimisation.

Provide training and skill enhancement opportunities for testers to ensure they are proficient in testing methods and operational techniques.

Collaboration and Coordination:

Work closely with vendors and partners to share best practices and experiences to jointly improve testing efficiency and product quality.

Establish an effective communication and collaboration mechanism among internal teams to ensure the smooth execution of testing tasks and timely feedback on results. By taking these steps, you can effectively improve the efficiency of textile colour fastness to washing testing, providing the products for market faster, then reduced costs and increased customer satisfaction.

For more information on textile testing methods/standards

or textile testing machines, please contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com