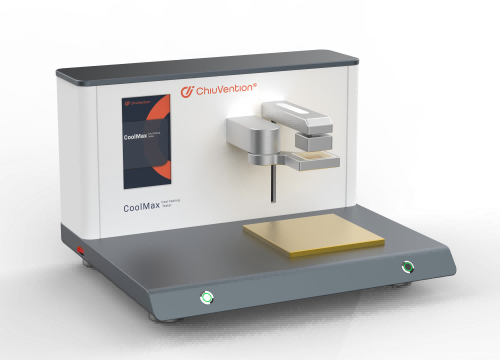

Cuts the samples strictly by the standards. This makes the test more reliable.

Our SmartCut Textile Sample Cutting Machine supports many types of sampling. It can do decentralized, trapezoidal, full-width, and 45° sampling. It can cut samples by rules, like aligning to the grid and to the edge. So, the reliability of the test is guaranteed from the sampling.

More precise cutting and higher sample pass rate.

The blade of the SmartCut Textile Sample Cutting Machine is made of tungsten steel. It’s sharp and can rotate 360°. It’s accurate to within 0.1mm and has a round-trip cutting error rate of under 0.01mm. In other words, it can cut specimens accurately.

Saves 5 laborers per year (about $420, 000) for large-scale labs.

If you need to cut 100 whole samples per day, the conventional manual cutting requires 3,000 minutes, i.e, 6 laborers. But the SmartCut Textile Sample Cutting Machine can cut 100 whole samples in 0 . 6 laborers, saving 5 laborers per year for the laboratory.

SmartCut Fabric Swatch Cutter can also cut many fabrics at once. It can also cut many layers, up to 7mm thick. It can cut 1 to 20 layers at once. It can also do shaped cutting of irregular graphics.

It can mark samples.

Designed in Germany, quality is our life.

All our textile lab instruments are developed in-house and in cooperation with a team of renowned German industrial designers, which makes our textile lab instruments of outstanding quality. 100% source factory and factory price.

The Specification of SmartCut Fabric Sample Cutting Machine

Cutting accuracy ±0 .1 mm

Repeatability ±0. 01 mm

Maximum cutting thickness 7mm

Fabric fixing method vacuum adsorption to ensure flatness

Table top wear resistance, it is recommended to replace the table top once a year.

Standard order: smart sample cutting software, smart cutting machine, computer, projector, brush function

Optional Inkjet marking function of the software, vibrating cutter head can be added.

Power Supply 220V 50Hz- 60Hz 20A-40A Other voltages require an extemal transformer

| Model | Working Area(cm) | Weight(kg) | Power(kw) | Warranty Period |

| CV517- 6060 | 60* 60 | 400 | 4 .5 | 1 year |

| CV517- 1410 CV517- 1610 | 140* 100/ 160* 100 | 600 | 4 .5 | 1 year |

| CV517- 1516 | 150* 160 | 650 | 4 .5 | 1 year |

| CV517- 1810 CV517- 1812 | 180* 100/ 180* 120 | 700 | 4 .5 | 1 year |

| CV517- 2516 | 250* 160 | 1000 | 9 .5 | 1 year |

| CV517- 3020 | 300* 200 | 1200 | 9 .5 | 1 year |

Applicable test items and standards of Fabric Sample Cutting Machine

| Test Items | Corresponding Standards |

| Abrasion & Pilling | GB/T4802、 ISO12945、 JIS L1076、ASTM D4970 |

| Tearing Strength | GB/T3917 、 ISO 13937 、 JIS L1096 、ASTM D751 |

| Water Proof | GB/T4745、ISO 4920、AATCC 22、ISO 9865、JIS L1092 |

| Antistatic Test | GB/T12703 、 GB/T 22042、EN 1149、ISO 6330 |

| Core Suction Height | GB/T21655、JISL1907、ISO6330 |

| Dimensional Stability | GB/T 8629、ISO 6330、JIS L0217、AATCC 135、AS2001.5.4 |

| Elastic Elongation | FZ/T01062、ASTMD3107、JIS L1096、EN 14704 |

| Tensile Strength | GB/T3923、 ISO 13934 、 ASTM D5034、EN 29073-3 |

| Fabric Weight | GB/T4669、ASTM D3776、ISO 3801、JIS K6772、EN 12127 |

| Abrasion Resistance | GB/T21196.2、ISO 12947、ASTM D3884、AS 2001.2.28 |

| Peel Strength | FZ/T80007.1、ISO 8096、JIS L1089、ASTM D2724 |

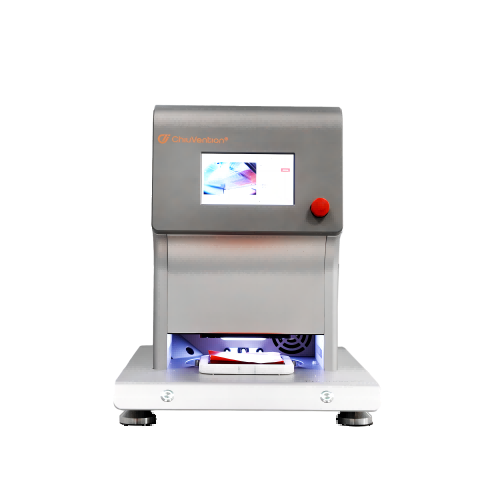

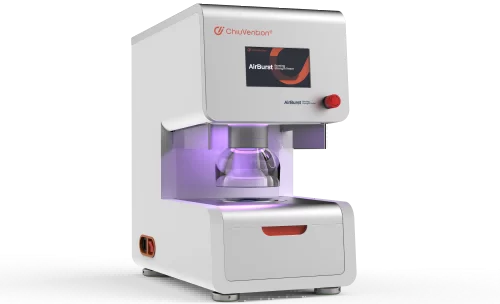

| Burst Strength | GB/T7742.1、ISO13938-1、ASTM D3786 |

| Seam slippage | GB/T13772.1 、 FZ/T20019、ISO13936 、 JIS L1096 |

| anti-hooking | GB/T11047、BS8479、ASTMD3939 |

| down-proof | GB/T12705 、 GB/T 14272、EN 12132、ISO 6330 |

| Colorfastness to rubbing | GB/T3920、AATCC 8、ISO 105 X12、ASTM D2054、JIS L0849 |

| Colorfastness to sunlight | GB/T8427、AATCC-16(3)、ISO 105-B02、ASTM D6544 |

| other color fastness items | GB/T、FZ/T、ISO、EN、JISL、AATCC、ASTM、CAN、AS |

| Flammability | GB/T5455、FZ/T01028、ISO 3795、GB 8410、ASTM D5132 |

| other items | …… |

Frequently Asked Questions of SmartCut Fabric Sample Cutting Machine

The Smart Cut Fabric Sample Cutting System is a unique machine. It is designed for the precise cutting of fabrics. This machine simplifies the process. It speeds things up for many industries. These include textiles, fashion, and manufacturing.

The SmartCut Fabric Swatch Cutting Machine uses technology. It automates the cutting process. Smart software is designed to quickly understand digital patterns. It guides the cutting tool to get better results. This provides a quick and exact cutting of fabric.

-

Cutting Accuracy and Repeatability

The machines excel at cutting fabric samples with great precision. The machines have an accuracy of ±0.1 mm and a repeatability of ±0.01 mm. They ensure that they make problematic designs perfectly. This precision is crucial. Creating great fabric samples is necessary. They must meet the exact needs of designers and manufacturers.

-

Maximum cutting Thickness

These Fabric Swatch Cutting Machines have a standout function. They can cut many materials. The machines cut 7mm thick samples. They cut diverse materials, from light to thick fabrics.

-

Fabric fixing technique

Fabric sample-cutting machines use a vacuum adsorption method. This method ensures exact cutting by fixing the material. This technique ensures flatness during cutting. It stops distortions from fabric movement.

-

Table Top Wear Resistance

A wear-resistant table top improves the durability of the Fabric Swatch Cutter. It’s supported to update the tabletop annually.

-

Trendy Order and elective functions

Fabric pattern-slicing machines come with smart sample-cutting software. They also have a laptop, a projector, and a brush feature. Those who need more features can add options like inkjet marking and a vibrating cutter. They give customers better customization and flexibility.

-

Power Supply

The machines cut textile samples. They run on 220V/380V power at 50Hz-60Hz. They draw 20A to 40A. This ensures compatibility with modern electric systems. It also delivers the needed strength for efficient and uninterrupted operation.

The sample cut machine connects through the network port. It connects with the customer’s ERP or LIMS device. It gets test item information by scanning barcodes.

The SmartCut fabric swatch-cutting machine is suitable for many testing standards. These include GB/T, FZ/T, ISO, EN, JIS L, AATCC, ASTM, CAN, AS, and others. It works with global testing protocols.

1. Rapid Sampling

One thing that stands out about the SmartCut Fabric Swatch Cutting Machine: it’s very fast. The textile sample-cutting machine can sample fabrics. It takes 3 minutes. Producers and designers treasure this great performance. It allows for quick turnaround times in making fabric samples.

2. Seamless integration

SmartCut does more than just cut fabric. It joins with customers’ ERP or LIMS systems via the community port. The system retrieves test item data by scanning barcodes. This ensures the smooth flow of data from the testing device to the cutter. It cuts guide input mistakes and streamlines operations.

3. Computerized sketch technology.

The SmartCut Sample Cutting Machine is powered by a unique algorithm. It excels at making specific fabric sample layouts. The system follows standards. It lays out sample photos carefully. This option guarantees accuracy. It also cuts the chance of mistakes in sampling.

4. Customizable marking system.

The SmartCut fabric sample-cutting machine has a complex marking device. It can be custom-designed to fit customer settings. This allows for flexible identification and categorization of fabric samples. It caters to the needs and preferences of individual customers.

5. Versatility in Testing

The SmartCut fabric swatch-cutting machine addresses many checkout needs. It is suitable for dozens of tests. These include pilling, tearing, water resistance, anti-static, tensile strength, color fastness, and flammability. This versatility makes the system a complete solution. It works for many fabric testing needs.

The Smart Cut Fabric sample Cutting Machine is a versatile and superior tool. It handles many tests. It ensures a thorough and detailed analysis of fabric properties. Right here are some of the critical forms of tests that the Smart Cut machine can handle:

-

Pilling Resistance Test

The device can assess the fabric’s pilling resistance. It can also give insights into its durability and wear over time.

-

Tearing Strength Test

The Fabric sample cutting machine reduces precision. It helps with tearing strength tests. These tests compare the fabric’s ability to resist pulling.

-

Water Repellency Test

You can hire the Fabric sample-cutting machine to check fabrics. This checks their water repellency. It is critical to assess their performance in wet conditions.

-

Anti-Static test

For fabric, anti-static properties are key. The SmartCut system lets you test a fabric’s ability to resist static.

-

Tensile strength Test

The machine is great at doing tensile tests. They measure how much pressure a fabric can withstand. The pressure comes from being stretched or pulled by electricity.

-

Color Fastness check

Making sure that fabric preserves its coloration over the years is critical. The Smart Cut fabric sample cutting machine supports color fastness tests. It also checks the cloth’s resistance to fading.

-

Flammability Test

The Textile Sample Cutting Machine is for fabrics. They are used in applications where fire resistance is key. It tests flammability to see how the fabric reacts to ignition and flame spread.

-

Numerous standardized tests

The Textile Sample Cutting Machine guides many testing standards. These include GB/T, FZ/T, ISO, EN, JIS L, AATCC, ASTM, CAN, AS, and more. This ensures that the Textile Sample Cutting Machine follows international testing rules. This makes it a good fit for global manufacturing standards.

-

Customizable testing options

In the past, the SmartCut Textile Sample Cutting Machine passed standardized tests. It gives flexibility with customizable testing choices. Customers can tailor the try-out parameters to meet unique needs. They can do this to get a more personal and specific evaluation of fabric samples.