Different Types of Fabrics

Ordinary types of fabrics

(1) Woven Fabric

It is also known as woven fabrics, which are the warp and weft yarns vertically interwoven with each other to form the fabric. Its basic organisation has plain, twill and satin weave. Different woven fabrics are also composed of these three basic organisations and their varied organisations. Mainly chiffon, Oxford, Denim, Drill, Flannel, Damask and so on.

(2) Knitted Fabric

With knitting needles, the yarn or filament is composed of loops, and then the loops are strung over each other and become, due to the characteristics of the loop structure of knitted fabrics, the amount of yarn storage per unit length is more, so most of them have very good elasticity. Knitted fabrics are single-sided and double-sided. Mainly Single Jersey, Velvet, Birdseye, Mersh fishnet and so on.

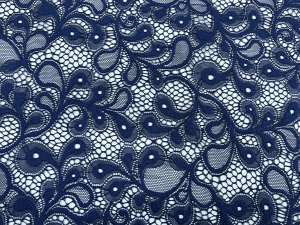

Lace fabric

Lace fabrics are divided into elastic lace fabrics and non-elastic lace fabrics, collectively known as lace fabrics.

Common lace fabrics can be divided into elastic lace fabrics and non-elastic lace fabrics such as 100% nylon. This fabric can be dyed in a single colour. 100% polyester. This fabric can be dyed in a single colour. 85% cotton + 15% nylon. This fabric can be dyed single colour. 65% nylon + 35 polyester. This fabric can be dyed in two colours, i.e. two colours.

The lace fabric is widely used in women’s intimate apparel because of its thin and light texture and translucent, elegant and mysterious artistic effect.

Burnt-out fabrics

Burnt-out fabrics are lightweight blended fabrics with translucent floral patterns on the surface. Burnt-out fabrics are usually polyester filament outer coloured cotton fibre core yarn, woven into fabrics with acid paste printing, drying, and steaming, so that the printed part of the cotton fibre hydrolysis rotten, after washing, that is, only polyester translucent floral pattern.

Burnt-out fabrics are usually polyester filament outer coloured cotton fibre core yarn, woven into fabrics, with acid paste printing, drying, and steaming, so that the printed part of the cotton fibre hydrolysis rotten, after washing, that is, showing only polyester translucent flower shape. It can also be processed by embroidery and yarn drawing to make the products more noble and beautiful.

Coated fabrics

Coated fabric is a kind of fabric treated by special technology. It can make a layer of uniform covering rubber material on the surface of the fabric, to achieve waterproof, windproof, breathable and other functions. Coated fabrics use solvents or water to dissolve the required coated glue particles (PU glue, A/C glue, PVC, PE glue) into a salivary form, and then coated evenly on the fabric (cotton, polyester, nylon, etc. substrate) in a certain way (round net, scraper or roller), and then after the oven temperature fixation, so that a layer of uniform coverage of the adhesive layer on the surface of the fabric.

Coated fabrics are widely used in sportswear, down jackets rainproof parkas, jackets, tents, shoes and socks, curtains, bags advanced waterproof and moisture-permeable functions of skiing shirts, mountaineering clothing, windbreakers and so on. It can also be used in the fields of national defence, navigation, fishing, offshore oil wells, transport and so on.

Compound fabric

Compound fabric is a new type of material made of one or more layers of textile materials, non-woven materials and other functional materials by bonding and laminating. Suitable for sofa, clothing and other textiles, is one of the indispensable fabrics for people’s home life. compound fabric is a kind of ultra-fine fibre in a specific textile processing and unique dyeing and finishing, and then by the “compound” equipment processing and become. compound fabric in English is: “Lamination Fabric”, or “Soft Shell Fabric.” Because of the compound fabric using microfibre, the fabric has a very high cleaning ability, that is, the ability to remove dirt.

The compound fabric applies high technology and a new material of “new synthetic fibre”, which has many excellent properties, compared with the common synthetic fibre, such as the fabric performance is fine and clean, delicate, elegant and warm, and the fabric appearance is plump, windproof, breathable, and has certain waterproof function, and its main feature is warmth and good breathability. The fabric also has a feature: good abrasion resistance, microfibre fabrics feel soft, breathable, and have moisture permeability, so in terms of tactile and physiological comfort, with obvious advantages, microfibre fabrics have poor wrinkle resistance. This is because the fibre is soft, with wrinkled elasticity due to poor recovery, to overcome this shortcoming, it has taken the “compound” process, which greatly improves the microfibre fabrics wrinkle-resistant poor shortcomings. compound fabrics are popular in Europe and the United States coat fabrics.

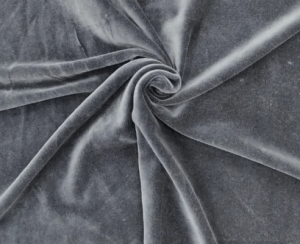

Flocking fabrics

The so-called flocking fabrics, it is all kinds of fabrics as a base cloth, front planted with nylon fluff or viscose fluff, and then after steaming and washing processed into a rich velvet surface, soft feel, bright colour, chic style, won the favour of consumers.

This fabric has a wide range of uses, it is not only the ideal fabric for making winter ladies’ suits, skirts and children’s wear. It is also widely used in the field of home textile. At present, it is mainly used for sofa, cushion, cushion and other cloth. Made of clothing, not only can keep warm but also adds a few charming. Knitted flocking fabrics can also be used to make scarves, it is important to keep warm, and middle-aged and elderly women are happy to enjoy. Although the amount of fabric used per article is lower than that of clothing, the demand is wide, suitable for both men and women, young and old.

Fleece fabric

Fleece fabric refers to the raw materials such as cotton, chemical fibre and other raw materials woven into the backing fabric, after the pilling machine and other equipment, pulling, cutting and other processing and finishing. The warp yarn is pulled out from the surface of the fabric or the yarn is cut off and formed into a fluffy fabric.

This kind of fabric can also use weft knitting or warp knitting knitting terry shearling fabrics, and then by flocking treatment and the formation of plush fabrics. Common pile fabrics are single-sided pile material double-sided pile material, whole pile material and partial pile material.

Fleece fabrics in the surface of the fleece are usually in one direction parallel and neatly tilted, forming the characteristics of the hair direction in the downward or reverse tilt so that the surface of the fabric due to the difference between the downward and reverse direction of the hair and the formation of different colour performance. This characteristic of fleece fabrics directly leads to the production process being prone to inverted hair, yin and yang colour and easy to slide difficult to align and other phenomena, to the production management and processing difficulties. Therefore, in the wool fabric garment processing process, must be for the characteristics of wool fabric, using scientific and technical means of processing production, to ensure that the wool fabric clothing quality and appearance of the quality of taking.

Fabric sampling machine

Cutting fabric is not difficult, but some mistakes are often easy to make. Manual cutting is easy to cause deviation, cutting the wrong front and back, cutting the same single side of the trouser legs and sleeves, resulting in inaccurate test data.

SmartCut Fabric Sample Cutting System can complete the sampling of fabrics within 3 minutes. It is suitable for sampling requirements of dozens of tests such as pilling, tearing strength, water repellency, anti-static, tensile strength, colour fastness, flammability, etc. It supports various standards such as GB/T, FZ/T, ISO, EN, JIS L, AATCC, ASTM, CAN, AS, and so on.

The tungsten steel blade of the SmartCut cloth sample cutting machine is sharp and can be rotated 360°, with a cutting accuracy of 0.1mm, and a round-trip cutting error rate of less than 0.01mm, i.e. cut grams of specimens accurately.

The sample graphics will be projected on the fabric and the SmartCut fabric sample cutting machine will start cutting fabric samples, automatically marking the samples as the customer’s settings.

If you need to cut 100 whole samples per day, the conventional manual cutting requires 3000 minutes, i.e . 6 labourers; while using the SmartCut sample cutting system, 100 whole samples need only 0 . 6 labourers, saving 5 labourers per year for the laboratory.

More details about the SmartCut Fabric Sample Cutting System can be shown here.

Fabric sampling rules

The forms of fibre products in real life are very different, including fibre, yarn and fabric. To make the samples taken representative, different sampling methods are used for different categories of products. Now used for qualitative analysis of fibre standards GB/T 10629-2009 “Textiles-Preparation of laboratory test samples and test specimens for chemical testing”, and some specific standards in some of the provisions of the standard, such as GB/T16988-1997 “Quantitative determination for mixtures of special animal fibre and wool”. What standards should be used in the detection process under standards? According to the form of fibre products are mainly the following sampling methods:

Fibre

These samples are usually in a loose fibre state. Different test methods have different sampling methods.

(1) GB / T 16988-1997 “Quantitative determination for mixtures of special animal fibre and wool” in the provisions of: “the sample is laid flat on the test bench, with tweezers in different parts of the equal amount of tweezers about 200mg of fibre (not less than 20 points) mixed and divided flat into three test samples.” This method does not specify the thickness of the samples to be laid flat and how the 20 points are to be arranged. To ensure that the sample is uniform and representative, it is recommended that the sample be taken to less than 1cm thickness of the sample laid flat on the test bench, with tweezers in the specimen on the front and back of different parts of the sample (front and back of the sampling points to cross) each take 20 points, tweezers about 200mg fibre mixed and divided into three test samples.

(2) GB 18383-2007 “General technical requirements for products with filling materials”, FZ/T 62005-2003 “quilt, quilt cover” and FZ/T 62009-2003 “pillows, cushion products” in the following:

A Sampling method of filling fibre content, randomly take about 10g samples at each sampling place and mix each sample thoroughly and evenly to form the first group of mixed samples.

B Combine the 1st sample with the 2nd sample in the first group of mixed samples, then divide into two halves, discard half and keep half; the 3rd sample is combined with the 4th sample, also divided into two halves, discard half and keep half …… The 7th sample is combined with the 8th sample. Split in half again, discard half and keep half. Four mixed samples from the second group were formed.

C Combine the 1st sample from the second group of mixed samples with the 2nd sample, split in half again, discard half, keep half; combine the 3rd sample with the 4th sample and split in half again, discard half, keep half; form a third group of 2 mixed samples.

D Split the mixed samples of the third group according to the method of the second group, and finally obtain a laboratory test sample of about 10g for fibre content testing.

In the above method, the description of the sampling method and the representation of additional diagrams seem to give full consideration to the representativeness and uniformity of the sampling, and the number of samples is also given, but it is not specified in the standard how the samples are to be taken at the sampling place when taking the samples. If this method is used its premise must be the entire sample in the filler itself must be very uniform. In the daily inspections often encountered some manufacturers to achieve the purpose of cutting corners, was, pillow cushions, cotton and other products the use of “sandwich” filler, some silk quilts close to the fabric part of the silk in the middle of the interlayer with viscose fibre, if the standard method of sampling random sampling, will inevitably result in qualitative error, even if qualitatively correct, the fibre content does not necessarily correspond to the truth. Even if the qualification is correct, the fibre content is not necessarily in accordance with the facts.

Therefore, in order to prevent the unevenness of the filler, it is recommended that the sampling In order to prevent the unevenness of the filler, it is recommended to increase the number of sampling points appropriately;

When taking samples at the sampling point, the samples should be taken from one side of the filler to the other side at one time, so as to prevent the interlayer from being missed.

Samples in a loose fibre state are prone to increased uncertainty in fibre characterisation and content due to the overall inhomogeneity. The provisions of each standard can not fully cover the actual situation of the product, so do not be completely limited to the provisions of the standard in the inspection process is to ensure that the sample taken representative and uniform.

Yarn

Yarn type of products are usually mostly in the form of tube yarn, tube yarn, twisted yarn, clusters of fluff and so on. As the uniformity of the sample itself is relatively good, after determining the batch of samples from a single sample can be taken randomly according to its form. Such as the total number of samples for 10 tube yarn (tube yarn, twisted yarn, fluff) from 10 tube yarn (tube yarn, twisted yarn, fluff) to take the length of the sample is basically the same and will be mixed evenly.

Fabrics

Fabric fibre qualitative and quantitative analysis is relatively complex and slightly more difficult. Fabrics are mainly the following categories, respectively, are described below:

(1) Colour fabrics or jacquard fabrics

Such fabrics are often woven from several colours of yarn, each with a different composition of fibers, sampling should be at least a complete cycle of tissue or pattern.

(2) Interwoven fabrics

Woven fabrics: such fabrics due to different fibre composition of the warp and weft yarns, warp and weft yarns qualitatively, it is best to take separate samples;

Interwoven knitted fabrics: a yarn is wool, a cotton, a polyester, or a yarn by 2 strands of yarn or more than 2 strands of yarn twisted, without destroying the original structure of the premise, you can first separate the yarns and then separately characterised to improve its accuracy. The advantage of separate qualitative also lies in that if each kind of yarn (including warp and weft yarns, knitted fabrics with yarns) is composed of a kind of fibre, in the quantitative can be used to determine the textile fibre content by physical method, reduce the laboratory link, shorten the inspection cycle and save costs. But in the quantitative analysis must be taken in the complete organisation.

(3) Blended textiles

Take the warp and weft yarns were qualitative, if mixed together is fine, but must ensure that the amount of warp and weft yarns are the same. Quantitative analysis according to GB/T2910.1-2009 provisions of each sample at least 1g.

(4) Special fabrics

Products containing 2 or more clearly distinguishable yarn types, patterns or structures can be marked separately for each type of yarn, pattern or structure of the fibre content; can also be used as a whole, marked for each type of fibre content. For products with more variations in yarn types, patterns or structures, only the fibre content of the larger part of the area may be marked.