The realm of textile chemistry has undergone a profound evolution over the years, shaping the landscape of the textile industry. This introductory section delves into the historical development of textile chemistry, emphasizing its pivotal role in the modern textile sector.

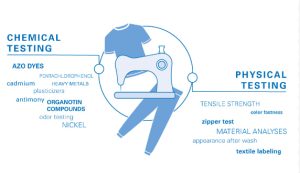

Additionally, we explore the significance of chemical testing as an integral component of ensuring product quality and compliance with evolving regulations and standards.

Evolution of Textile Chemistry

Origins and Early Innovations

Textile chemistry traces its roots to ancient civilizations, where rudimentary dyeing and finishing processes were employed. The utilization of natural extracts from plants and minerals laid the foundation for the intricate chemical processes that would later define the textile industry.

Industrial Revolution and Technological Leap

The Industrial Revolution marked a turning point, introducing mechanization and chemical advancements to the textile manufacturing process. Synthetic dyes, such as mauveine, revolutionized the coloration of fabrics. This period witnessed a shift towards a more systematic and scientific approach to textile chemistry.

Innovations in Fiber Chemistry

The mid-20th century witnessed breakthroughs in fiber chemistry with the development of synthetic fibers like nylon and polyester. These innovations not only expanded the range of available materials but also posed new challenges in terms of chemical testing and quality assurance.

The Role of Chemical Testing in the Modern Textile Industry

Ensuring Product Integrity

Chemical testing plays a critical role in guaranteeing the integrity of textile products. By analyzing the chemical composition of fibers, dyes, and finishes, manufacturers can ascertain the quality and safety of their products, addressing potential issues before they reach consumers.

Compliance with Regulatory Frameworks

The modern textile industry operates within a complex web of regulations and standards. Let’s explore how chemical testing acts as a tool for compliance, ensuring that textiles meet international and national standards for safety, environmental impact, and quality.

Scope and Objectives of the Comprehensive Guide

As we embark on this comprehensive guide, it is essential to outline its scope and objectives. This guide aims to provide an in-depth exploration of various aspects related to fabric chemical testing, including methodologies, specific tests, regulatory landscapes, and emerging trends. The objective is to empower industry professionals, researchers, and consumers with a nuanced understanding of the critical role chemical testing plays in the textile industry.

The Imperative of Chemical Textile Testing

The significance of chemical textile testing is underscored by its pivotal role in safeguarding both human health and the environment. This section delves into the intricate web of health and safety implications, emphasizing the pressing need for comprehensive testing methodologies. Additionally, we explore the challenges and nuances associated with navigating the complex regulatory landscape governing the textile industry.

In-Depth Analysis of Health and Safety Implications

Human Health Concerns

Allergies and Skin Reactions

Chemical compounds present in textiles can trigger allergic reactions and skin sensitivities. This sub-section delves into the potential allergens found in fabrics, the mechanisms behind skin reactions, and the importance of chemical testing in identifying and mitigating these concerns.

Respiratory Issues

Certain chemicals used in textiles may contribute to respiratory problems when inhaled. This sub-section explores the respiratory implications of textile chemicals, the identification of volatile compounds, and the role of chemical testing in ensuring breathable and safe fabrics.

Environmental Impact

Pollution and Ecological Consequences

The manufacturing and disposal of textiles can have adverse effects on the environment, including water and soil pollution. This sub-section examines the chemical footprint of textiles, exploring pollutants released during production and the ecological consequences of improper disposal.

Sustainability Initiatives

Recognizing the environmental impact, sustainability initiatives have gained prominence. This sub-section delves into the role of chemical testing in evaluating the eco-friendliness of textiles, supporting sustainable practices, and meeting the demands of environmentally conscious consumers.

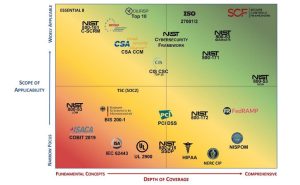

International Regulatory Frameworks (ISO, REACH)

Comparative Analysis

A comparative analysis of international regulatory frameworks, such as ISO (International Organization for Standardization) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), provides insights into their scope, applicability, and harmonization efforts.

Harmonization Challenges

Harmonizing standards across borders presents challenges due to diverse regulatory approaches. This sub-section explores the hurdles associated with aligning international standards and the ongoing efforts to achieve a more cohesive global regulatory framework.

National Regulations and Variations

Regional Nuances

National regulations often reflect regional nuances and priorities. This sub-section examines how different regions address chemical testing in textiles, considering cultural, economic, and environmental factors influencing regulatory decisions.

Emerging Market Trends

The textile industry is dynamic, with emerging market trends influencing regulatory landscapes. This sub-section analyzes evolving market dynamics, such as the rise of sustainable fashion and the impact on chemical testing requirements.

Comprehensive Examination of Testing Methods

In ensuring the efficacy of fabric chemical testing, a thorough examination of testing methods is paramount. This section meticulously explores the intricacies of sampling strategies and techniques, advanced laboratory methodologies, and the emerging landscape of in-field testing.

Sampling Strategies and Techniques

Statistical Sampling

Statistical sampling is a fundamental aspect of chemical testing, ensuring that the samples chosen are representative of the entire textile batch. This sub-section delves into the principles of statistical sampling, exploring techniques such as random sampling and stratified sampling and their application in textile quality assurance.

Sampling Protocols for Varied Textile Types

Different textile types necessitate tailored sampling protocols. This sub-section outlines the nuances of sampling procedures for various textiles, considering factors such as fiber composition, weave structures, and finishing processes. Understanding these intricacies is crucial for obtaining accurate and meaningful test results.

Advanced Laboratory Techniques

Fourier Transform Infrared Spectroscopy (FTIR)

FTIR stands as a powerful tool for chemical analysis in textiles. This sub-section provides an in-depth exploration of how FTIR works, its applications in identifying functional groups within textiles, and its role in ensuring the quality and integrity of textile materials.

Gas Chromatography-Mass Spectrometry (GC-MS)

The combination of gas chromatography and mass spectrometry offers unparalleled precision in chemical analysis. This sub-section elucidates the principles behind GC-MS, its application in detecting volatile compounds, and its significance in identifying specific chemicals within textile samples.

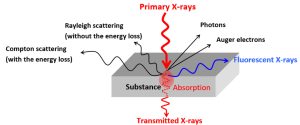

X-ray Fluorescence (XRF)

XRF is a non-destructive technique employed for elemental analysis in textiles. This sub-section examines the principles of XRF, its advantages in determining the elemental composition of textiles, and its role in identifying potential contaminants or non-compliant substances.

In-Field Testing: Pros and Cons

Handheld Devices and their Applications

The advent of handheld devices has revolutionized in-field testing. This sub-section explores the capabilities of handheld devices for on-the-spot chemical analysis, examining their applications in identifying specific chemicals, checking for compliance, and ensuring product quality throughout the supply chain.

Real-Time Monitoring Challenges and Solutions

While in-field testing offers real-time monitoring benefits, challenges exist. This sub-section delves into the complexities associated with real-time monitoring, including factors such as instrument accuracy, environmental conditions, and the need for calibration. Solutions and best practices for overcoming these challenges are also discussed.

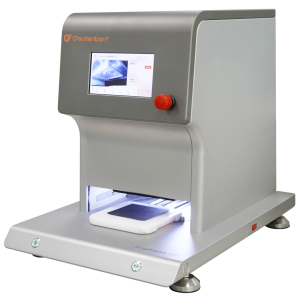

ProPress Sample Press-pH Test Sample Cutter: Enhancing Precision and Efficiency in Fabric Chemical Testing

In the ever-evolving landscape of fabric chemical testing, the efficiency and precision of sample preparation play a pivotal role in ensuring reliable test results. It is a cutting-edge solution designed to revolutionize the way samples are prepared for formaldehyde, pH, azo, and heavy metals tests.

ProPress: Elevating Sample Cutting Efficiency

The ProPress Sample Press-pH Test Sample Cutter stands as a beacon of innovation in the realm of fabric chemical testing. Engineered with precision and efficiency in mind, this cutting-edge machine is tailored to cut samples into small, precise pieces (e.g., 5×5 mm) within a matter of seconds. What sets ProPress apart is its ability to control pressure with unparalleled accuracy, applying it to a precision die for a meticulous sample cut.

Unleashing the Power of Precision

ProPress doesn’t just cut samples; it cuts with precision. This level of precision is paramount for fabric chemical tests where accurate sample sizes contribute directly to the reliability of test outcomes. By utilizing it, laboratories and manufacturers can significantly enhance the precision of their sample preparation, leading to more trustworthy and consistent results across various chemical tests.

Boosting Work Efficiency

One of the standout features of the ProPress Sample Press-PH Test Sample Cutter is its remarkable ability to boost work efficiency.

The machine outperforms manual shearing by increasing the efficiency of cutting samples by more than 80%, equivalent to six times the speed of traditional manual methods. This leap in efficiency not only accelerates the testing process but also enables laboratories and manufacturers to streamline their workflows.

Versatility in Material Cutting

ProPress isn’t limited to fabric alone; it’s a versatile solution capable of cutting various materials, including fabrics, leather, plastics, and other flexible sheet materials. This versatility ensures that it is a comprehensive tool for preparing test samples across a spectrum of fabric chemical tests. Whether it’s formaldehyde, pH, azo, or heavy metals tests, ProPress delivers consistent and precise sample cuts across diverse materials.

Elevating Fabric Chemical Testing Practices

In the dynamic landscape of fabric chemical testing, the ProPress Sample Press-PH Test Sample Cutter emerges as a game-changer. Its precision, efficiency, and versatility make it an invaluable asset for laboratories, manufacturers, and industries aiming for excellence in their testing practices. Also, stakeholders can elevate their sample-cutting processes, contributing to more reliable and efficient fabric chemical testing outcomes.

IV. Elaborating on Types of Chemical Tests

Embarking on an exhaustive exploration of chemical tests in textiles involves navigating the intricacies of physical tests and delving deep into the chemical composition analyses that underpin fabric quality and safety.

Unraveling the Complexity of Physical Tests

Tensile Strength and Beyond

Principles of Tensile Strength Testing

Tensile strength, a cornerstone of material analysis, scrutinizes a fabric’s ability to endure stretching and pulling forces without tearing. Understanding the principles of tensile strength involves appreciating the role of a universal testing machine, which systematically applies force to a textile specimen until rupture, providing insights into the material’s mechanical properties.

Beyond Tensile Strength: Elongation and Modulus

While tensile strength offers a primary measure, evaluating a textile’s flexibility and stiffness requires an exploration beyond tensile strength. Delving into parameters like elongation (the material’s ability to stretch) and modulus (its stiffness) provides a holistic view, ensuring a comprehensive understanding of a textile’s mechanical behavior under stress.

The Intricacies of Abrasion Resistance Testing

Abrasion Resistance and Wear Testing

Abrasion resistance is a pivotal factor determining a textile’s durability in real-world conditions. This sub-section scrutinizes the nuances of abrasion resistance testing methods, such as the Martindale and Wyzenbeek tests. By simulating wear and tear, these tests gauge a textile’s resistance to friction, providing critical data for assessing its longevity and suitability for specific applications.

Surface wear is a distinctive aspect of fabric performance. The Taber Abrasion test focuses on this dimension, employing a specialized instrument to subject textiles to controlled abrasion. This sub-section explores the principles behind the Taber Abrasion test, shedding light on its significance in predicting a textile’s resilience to surface wear and maintaining aesthetic and functional integrity.

Chemical Composition Tests Demystified

Fiber Type Identification Techniques

Microscopic Analysis

Microscopic analysis emerges as a foundational technique for identifying fiber types. This sub-section delves into the microscopic methods employed in textile laboratories, emphasizing the utility of polarized light microscopy and scanning electron microscopy. These techniques unveil intricate details, enabling the precise determination of fiber composition and aiding in quality control processes.

Solubility Tests

Solubility tests provide a chemical avenue for discerning fiber types. This sub-section dissects the principles governing solubility tests, where fibers are selectively dissolved in specific solutions. By observing the dissolution behavior, textile analysts can deduce crucial information about the chemical nature of fibers, contributing to a comprehensive understanding of material composition.

Additive Detection in Textiles

UV-Visible Spectroscopy

UV-visible spectroscopy emerges as a sophisticated tool for detecting additives in textiles. This sub-section offers a nuanced exploration of the principles underpinning UV-visible spectroscopy. By analyzing the absorption and transmission of light, this technique facilitates the identification of colorants, additives, and other chemical constituents, contributing significantly to the quality control and safety of textile products.

Liquid Chromatography

Liquid chromatography plays a pivotal role in unraveling the complex chemical composition of textiles. This sub-section delves into the principles of liquid chromatography, with a focus on high-performance liquid chromatography (HPLC). By separating and quantifying compounds within textiles, liquid chromatography aids in the precise detection of additives, dyes, and other chemical constituents, ensuring compliance with quality standards.

In-Depth Analysis of Specific Chemical Tests in Fabric

The fabric’s chemical composition is a paramount consideration in the textile industry, with a profound impact on product safety, quality, and adherence to regulatory standards. This section conducts an extensive exploration of specific chemical tests applied to fabrics, providing a nuanced understanding of the molecular basis, testing protocols, and global standards for formaldehyde, pH, heavy metals, and azoic compounds.

Formaldehyde Testing

Molecular Basis of Formaldehyde Detection

Formaldehyde, a ubiquitous chemical in textile processing, necessitates rigorous testing due to its potential health implications. Understanding the molecular basis of formaldehyde detection is crucial for implementing effective testing methodologies. At the heart of formaldehyde testing lies the chemical reaction between formaldehyde and chromotropic acid, leading to the formation of a colored compound. This reaction forms the basis for various testing methods, including the widely employed chromotropic acid method and the acetylacetone method.

Elaborate Testing Protocols

Accurate formaldehyde testing demands elaborate protocols to ensure reliable results. The chromotropic acid method involves the reaction of formaldehyde with chromotropic acid in the presence of sulfuric acid, producing a pink-to-violet color. Similarly, the acetylacetone method relies on the formation of a colored complex between formaldehyde and acetylacetone under acidic conditions. These protocols, when meticulously followed, provide a robust framework for detecting and quantifying formaldehyde in textiles.

Global Standards and Harmonization Efforts

The textile industry operates within a global marketplace, necessitating standardized approaches to formaldehyde testing. International organizations and regulatory bodies, including the International Organization for Standardization (ISO) and the European Union’s Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH), play a pivotal role in establishing global standards. Harmonization efforts seek to align testing protocols and acceptable formaldehyde levels, ensuring consistency and facilitating international trade.

pH Testing: A Fundamental Aspect

pH as a Quality Indicator

pH, a fundamental aspect of textile chemistry, serves as a crucial quality indicator. The acidity or alkalinity of textiles profoundly influences various properties, including colorfastness and fiber integrity. Maintaining an optimal pH level is imperative for ensuring product quality and performance.

Multi-Stage Testing Processes

Achieving accurate pH measurements involves a multi-stage testing process. Initial stages include sample preparation, where textile samples are carefully treated to extract soluble components. Subsequent stages involve the use of pH meters, which measure the concentration of hydrogen ions in the solution. This multi-stage approach ensures precision in determining and adjusting the pH of textile materials.

Striking a Balance with Industry Standards

Balancing optimal pH levels with industry standards is a delicate equilibrium. Textile manufacturers must ensure that the pH of their products meets both internal quality specifications and external regulatory requirements. Striking this balance is crucial for delivering textiles that not only meet consumer expectations but also comply with global industry standards.

Heavy Metal Testing: Unveiling Hidden Dangers

Elemental Analysis Techniques

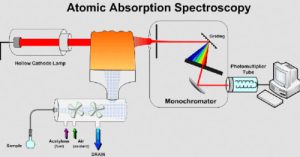

Atomic Absorption Spectroscopy (AAS)

Heavy metal testing in textiles involves advanced elemental analysis techniques, with Atomic Absorption Spectroscopy (AAS) standing out as a reliable method. AAS measures the concentration of specific heavy metals by determining the absorption of light at characteristic wavelengths. This technique offers high sensitivity and precision, making it a preferred choice in identifying and quantifying heavy metals such as lead, cadmium, and mercury in textiles.

Inductively Coupled Plasma Mass Spectrometry (ICP-MS)

Inductively Coupled Plasma Mass Spectrometry (ICP-MS) represents the pinnacle of elemental analysis. This technique goes beyond AAS by simultaneously measuring multiple elements at ultra-low concentrations. ICP-MS provides unparalleled sensitivity and accuracy, making it indispensable for detecting trace amounts of heavy metals in textiles.

Setting the Gold Standard with Regulations

Recognizing the potential dangers of heavy metal contamination, regulatory bodies worldwide have established stringent standards. The Restriction of Hazardous Substances (RoHS) directive in the European Union, for instance, sets strict limits on the concentration of heavy metals in textiles and other consumer goods. Compliance with these regulations is not only a legal requirement but also a fundamental commitment to consumer safety.

Azo Dyes and their Ramifications

Azo dyes, widely used in textile coloration for their vibrant hues, introduce a potential dilemma due to the potential formation of aromatic amines, some of which are known carcinogens. Understanding the chemical structure of azo dyes is crucial for assessing the associated risks and implementing effective testing protocols.

Comprehensive Testing Procedures

Mitigating the risks associated with azo dyes requires comprehensive testing procedures. Screening for azo compounds involves utilizing methods such as the Diazotization-UV Spectrophotometry test, which detects the presence of specific azo groups. Subsequent analysis of aromatic amines involves techniques like High-Performance Liquid Chromatography (HPLC), ensuring a thorough evaluation of the dye composition and the potential release of harmful substances.

Global Standards and Legal Frameworks

The dye dilemma necessitates adherence to global standards and legal frameworks governing the use of azo dyes. Regulatory initiatives such as the EU Regulation 1907/2006 (REACH) and the American Apparel & Footwear Association (AAFA) Restricted Substance List (RSL) outline permissible limits and restrictions on certain azo dyes. Navigating this complex legal landscape ensures that textiles containing azo dyes meet stringent safety requirements.

Technological Leaps in Chemical Testing

Artificial Intelligence Algorithms

Artificial Intelligence (AI) algorithms are revolutionizing fabric chemical testing by enhancing accuracy, speed, and efficiency. This sub-section delves into how AI is applied in analyzing complex chemical compositions, automating testing processes, and identifying subtle variations that may escape traditional methods. Case studies and practical examples showcase the transformative potential of AI in ensuring the precision and reliability of chemical testing outcomes.

Internet of Things (IoT) in Textile Quality Assurance

The Internet of Things (IoT) introduces a new dimension to textile quality assurance, offering real-time monitoring and control. This sub-section explores how IoT devices embedded in manufacturing equipment and textiles themselves enable continuous data collection. This data-driven approach enhances the visibility of chemical processes, reduces the risk of defects, and facilitates proactive decision-making in quality assurance.

The Green Wave: Sustainability and Circular Economy

Recycling Textiles

As the textile industry confronts environmental challenges, recycling textiles emerges as a pivotal trend. This sub-section explores innovative methods for recycling textiles, including mechanical, chemical, and biological processes. Case studies highlight successful initiatives that repurpose discarded textiles, reducing waste and minimizing the environmental impact of textile production.

Eco-Friendly Manufacturing Processes

The adoption of eco-friendly manufacturing processes is reshaping the textile industry’s approach to chemical testing. This sub-section examines sustainable practices, such as the use of non-toxic dyes, waterless dyeing technologies, and energy-efficient production methods. Case studies illuminate how embracing eco-friendly processes not only aligns with environmental goals but also elevates product quality and consumer appeal.

From the integration of advanced technologies like AI and IoT to the transformative impact of sustainability practices, these trends underscore the industry’s commitment to pushing boundaries, fostering efficiency, and addressing the pressing environmental challenges of our time.

Confronting Challenges Head-On

Addressing the complexities of fabric chemical testing involves navigating challenges inherent to the textile industry. This section delves into the intricacies of supply chain transparency, standardization hurdles, and the delicate balance between cost, time, and precision in chemical testing.

Predictive Models for Fabric Chemical Testing

Machine Learning Applications

The integration of machine learning into fabric chemical testing represents a paradigm shift in how we approach and interpret complex data sets. Machine learning algorithms, capable of learning patterns and making predictions based on historical data, offer unparalleled potential in enhancing the efficiency and accuracy of chemical testing processes.

Machine learning applications in chemical testing extend across various stages of textile production. One notable application is predicting potential chemical interactions during the manufacturing process. By analyzing historical data on chemical compositions and reactions, machine learning models can identify patterns and anticipate the likelihood of adverse reactions. This proactive approach allows manufacturers to modify formulations, reducing the risk of undesirable chemical outcomes and ensuring product safety.

Another crucial area of machine learning applications lies in optimizing testing protocols. Traditional testing methods may be time-consuming and resource-intensive. Machine learning algorithms can analyze vast datasets of testing results, identifying correlations and optimizing testing parameters for efficiency. This not only expedites the testing process but also contributes to cost savings for manufacturers.

Predictive Analytics for Risk Mitigation

Predictive analytics is poised to play a pivotal role in mitigating risks associated with fabric chemical testing. By leveraging advanced statistical algorithms and machine learning techniques, predictive analytics models can forecast potential issues before they manifest, enabling manufacturers to take proactive measures to prevent recalls and ensure product safety.

One notable application is in predicting the likelihood of non-compliance with regulatory standards. By analyzing historical data on testing outcomes and regulatory changes, predictive analytics models can assess the risk of non-compliance for specific chemical compositions or manufacturing processes. This foresight empowers manufacturers to adjust formulations or processes in advance, avoiding costly regulatory penalties and preserving their reputation.

Additionally, predictive analytics can contribute to supply chain resilience by forecasting potential disruptions. This is particularly relevant in the context of raw material shortages, geopolitical events, or unforeseen challenges. By anticipating these disruptions, manufacturers can implement contingency plans, ensuring a steady supply chain and minimizing the impact on production schedules.

Blockchain Integration for Unparalleled Transparency

Securing the Supply Chain

Blockchain technology holds immense promise in revolutionizing supply chain transparency within the textile industry. Blockchain operates as a decentralized and distributed ledger, providing an immutable record of every transaction and interaction within the supply chain. This level of transparency enhances traceability, reduces the risk of fraud, and strengthens the overall integrity of the supply chain.

Blockchain ensures the secure and transparent recording of every step in the textile supply chain, from the sourcing of raw materials to manufacturing, distribution, and retail. Each transaction or movement is recorded in a block, linked to the preceding one through cryptographic hashes. This creates an unalterable chain of information, making it virtually impossible to manipulate or falsify data.

One of the key advantages of blockchain in supply chain security is its ability to trace the origin of raw materials. For instance, in the cotton industry, blockchain can provide a detailed record of the cotton’s journey from the farm to the final textile product. This not only ensures authenticity but also allows consumers to make informed choices based on the ethical and sustainable practices of manufacturers.

Enhanced Consumer Information

Blockchain’s impact extends beyond supply chain security to empower consumers with unprecedented access to information. By integrating blockchain into product labeling and documentation, consumers can trace the entire lifecycle of a textile product with a simple scan of a QR code or the use of a mobile app.

This enhanced transparency provides consumers with insights into the fabric’s composition, testing results, and sustainability credentials. They can access information about the chemical testing protocols employed, ensuring that the product meets safety standards. Moreover, consumers gain visibility into the manufacturing process, allowing them to make informed decisions based on their values and preferences.

Blockchain’s role in consumer empowerment aligns with the growing demand for transparency in the textile industry. Consumers, now more than ever, are conscious of the environmental and ethical aspects of the products they purchase. Blockchain ensures that manufacturers adhere to their claims of sustainability and safety, fostering trust and loyalty among consumers.

Conclusion

The exploration of fabric chemical testing has taken us through the intricate realms of science, industry practices, challenges, and innovations. As we conclude this comprehensive guide, we reflect on the depths we’ve explored, issue a call to industry stakeholders for collective responsibility, and acknowledge the perpetual quest for excellence in chemical textile testing.

As we conclude, it is essential to acknowledge the continuous quest for excellence in chemical textile testing. This field is dynamic, with new technologies, regulations, and consumer expectations constantly evolving. The pursuit of excellence involves an ongoing commitment to staying informed, adopting innovative technologies, and adapting to emerging challenges.

Industry stakeholders are encouraged to embrace a culture of continuous improvement, investing in research and development, and fostering a mindset of innovation. By doing so, the textile industry can not only meet current standards but also proactively shape the future of fabric chemical testing, ensuring that textiles are safe, sustainable, and of the highest quality.

Lastly, fabric chemical testing is a multifaceted discipline that goes beyond laboratory analyses; it is a cornerstone of consumer safety, product quality, and industry integrity. As we navigate the complexities of the textile industry, let us remember that our collective efforts shape the fabric of a safer, more transparent, and sustainable future.