Fabric tear resistance is crucial for safety, product durability, and customer satisfaction. The Elmendorf test is a standardized method widely used across industries. It helps quantitatively measure a material’s ability to withstand tearing forces. This test ensures materials meet rigorous standards, from traditional textiles to advanced composites. The meticulous test procedure involves careful specimen preparation, strategic clamping, and tear initiation.

Interpreting Elmendorf test results provides quantitative insights into a material’s tear strength, guiding material selection and product design. Adherence to stringent test standards ensures reliability and comparability across different materials and industries.

This Complete Guide of the Elmendorf Tear Testing explores tear resistance testing dimensions, application areas, standards, methodologies, troubleshooting, and the future landscape of tear analysis. Key takeaways and practical insights empower informed decisions in material science.

Application of Elmendorf Tear Testing in Industry

In various industrial sectors, Elmendorf testing is an invaluable tool for assessing tear resistance, ensuring that materials meet the stringent requirements of different applications.

1. Apparel

Tear resistance is crucial in assessing the durability and safety of clothing. Elmendorf testing evaluates fabrics, providing insights into tear resistance characteristics influenced by weaves and weights. Manufacturers use this data to optimize fabric choices.

2. Upholstery

Tear resistance is vital for furniture fabrics to endure daily use. Elmendorf testing tailors tear resistance specifications for materials like leather, polyester, and natural fibers, ensuring compliance with safety standards in applications like seat belts and airbags.

3. Geotextiles

Elmendorf testing assesses tear resistance in geotextiles for construction and infrastructure projects. It verifies robust tear resistance in materials crucial for erosion control, filtration, and drainage, contributing to their effectiveness in challenging conditions like landfills.

4. Technical Textiles

Technical textiles in aerospace, medical, and industrial sectors require exceptional tear resistance. Elmendorf testing assesses high-tech fabrics, ensuring they meet safety standards in extreme conditions, medical devices, and critical applications like parachute fabric for aerospace safety.

5. Niche Applications

Elmendorf testing extends to niche industries such as filters, membranes, wearable technology, and smart textiles. It ensures tear resistance in materials crucial for structural integrity in air purification systems, industrial filtration processes, and innovative products like wearable technology and smart textiles.

Elmendorf Tear Testing Standards

1. Major International Tear Resistance Standards

a. Introduction to Standards Organizations

- ASTM International (US): A leading organization providing standards for various industries globally.

- ISO (International Organization for Standardization): A global body producing international standards for a wide range of sectors.

b. Prominent Tear Resistance Standards

- ASTM D1424: Standard test method for tearing strength of fabrics by the trapezoid procedure.

- ISO 13934: Determination of the tear resistance of fabrics (Elmendorf method).

c. Key Differences and Applications

- ASTM D1424: Commonly used in the United States, measures trapezoidal tear resistance.

- ISO 13934: Internationally recognized, evaluates Elmendorf tear resistance.

- Applications: ASTM D1424 is often used for domestic textiles while ISO 13934 for broader international textile applications.

2. Comparing these Standards

| Aspect | ASTM D1424 | ISO 13934 |

| Test Method | Trapezoid Procedure | Elmendorf Method |

| Specimen Preparation | Cut into a trapezoidal shape | Rectangular specimens, no specific shape |

| Data Interpretation | The force required to tear the fabric | The energy needed to propagate a tear |

Advantages and Limitations

- ASTM D1424: Simplicity, but may not fully represent tearing conditions.

- ISO 13934: Represents more practical scenarios but a complex setup.

- Materials and Industries: ASTM for basic textiles; ISO for broader applications.

Other Relevant Standards

- Paper: ISO 1974, determining tear resistance.

- Plastic Films: ASTM D1922, measuring tear propagation.

- Leather: ISO 3377-1, assessing tear strength.

3. Regional Regulations and Requirements

Importance of Regional Regulations

- EU Directives: Define tear resistance requirements for personal protective equipment.

- US Flammability Standards: Influence tear resistance standards in upholstery.

Adaptation of Standards

- Standards like ASTM D1424 and ISO 13934 can be tailored to meet regional requirements without compromising core principles.

4. The Impact on Product Development

Guiding Material Selection and Design

- Tear resistance standards are crucial in selecting materials and determining design specifications.

Ensuring Compliance and Safety

- Manufacturers use test results to ensure products meet tear resistance requirements and safety standards.

Role of Quality Control

- Continuous quality control throughout production to guarantee consistency and adherence to standards.

5. Emerging Standards and Trends

Development of New Standards

- Ongoing efforts to establish standards for advanced materials and specific applications.

Potential Trends

- Growing focus on sustainability in tear resistance testing.

- Harmonization of global standards for better consistency and efficiency.

Evolving Landscape

Tear testing is a dynamic field with constant improvements and adaptations to address industry needs.

In conclusion, the comprehension and application of tear resistance standards ensure materials’ quality, safety, and regulatory compliance across diverse industries globally. As standards evolve, a more comprehensive and harmonized approach is anticipated to shape the future of tear resistance testing.

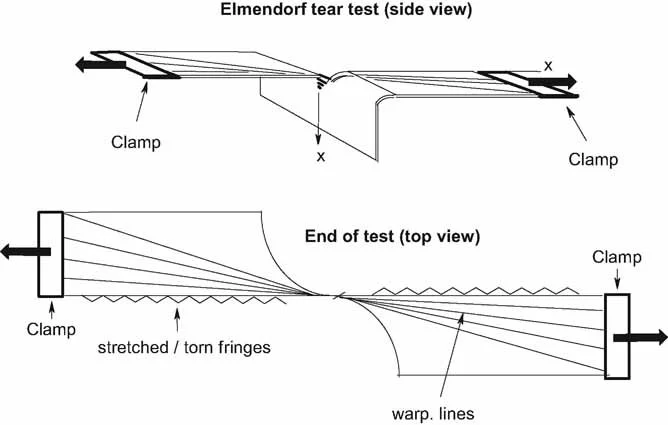

Test Methodology: A Step-by-Step Guide to Elmendorf Tear Testing

1. Essential Tools

The Elmendorf tear tester, crucial for tear resistance testing, consists of specialized components for precise measurements:

- Pendulum: Imparts controlled force, determining tear resistance through calibrated swing.

- Clamps: Secure specimens to prevent slippage or distortion.

- Scale: Records force for tear initiation and propagation analysis.

- Cutting Blade: Ensures precision in specimen preparation.

2. Specimen Preparation

Before Elmendorf testing, meticulous specimen preparation is crucial for accuracy:

- Dimensional Requirements: Follow specified dimensions for consistency and comparability.

- Preconditioning: Control environmental factors through procedures to enhance result reproducibility.

3. Step-by-Step Breakdown

Understanding Elmendorf testing involves clear steps for practitioners:

- Specimen Clamping: Affix the specimen securely in clamps.

- Pendulum Positioning: Align the pendulum precisely for tear initiation.

- Blade Activation and Tear Initiation: Calibrately activate the cutting blade to initiate the tear.

- Force Measurement and Recording: The scale records quantitative tear strength data.

- Specimen Removal and Data Analysis: Post-testing, analyze the data for accurate interpretation.

4. Interpreting Results

Unlocking insights from Elmendorf testing involves understanding nuanced results:

- Calculating Tear Strength: Obtain metrics like tear energy and tear factor for the material’s tearing resistance.

- Significance of Values: Different tear strength values indicate material properties and applications.

- Repeatability and Statistical Analysis: Emphasize repeatability and statistical analysis for result reliability.

5. Quality Control Procedure

Maintaining Elmendorf testing integrity demands a robust quality control framework:

- Importance of Quality Control: Ensure equipment precision and test reliability through quality control procedures.

- Calibration and Verification: Regularly calibrate and verify testing equipment for accurate results.

- Record-keeping and Data Management: Thoroughly document testing parameters and outcomes for traceability and analysis.

- Minimizing Errors: Be aware of potential error sources and implement best practices to minimize discrepancies, reinforcing credibility.

Troubleshooting Tips for Elmendorf Tear Testing

1. Common Elmendorf Test Errors and Solutions

- Specimen Misalignment: Ensure meticulous specimen placement within clamps to prevent distortion of tear initiation points.

- Improper Clamping: Secure clamps precisely, avoiding over-tightening or misplacement to prevent specimen slippage or distortion.

- Instrumentation Errors: Regularly calibrate and verify testing instruments to maintain consistent and reliable results.

2. Troubleshooting Sample Preparation and Testing Issues

- Dimensional Deviation: Adhere to specified dimensions outlined in standards and use accurate measuring tools for precise sample dimensions.

- Blade Malfunction: Regularly inspect and maintain the cutting mechanism to prevent disruptions in tear initiation.

- Data Recording Errors: Implement rigorous data management practices, double-checking entries to eliminate inaccuracies in tear strength recording.

- Unexpected Tear Propagation: Investigate root causes of unpredictable tear paths, including material defects or inconsistencies in specimen preparation.

3. Interpreting Elmendorf Test Results

- Outlier Values: Identify and scrutinize outlier values, investigating potential causes such as material defects or testing irregularities. Implement statistical analysis for a comprehensive assessment.

- Inconsistencies Across Samples: Evaluate sample homogeneity and ensure uniform testing conditions to address variations in tear strength among samples.

- Relating Results to Standards: Align tear strength values with applicable standards, considering material characteristics and intended applications for contextualized results.

4. Causes of Tear Strength Variations

- Material Heterogeneity: Employ additional testing or analysis methods to unveil hidden material variations impacting tear resistance.

- Processing Variations: Establish a correlation between processing parameters and tear resistance through systematic investigation.

- Environmental Factors: Conduct tests under controlled conditions to isolate and understand the impact of environmental variables on tear strength.

5. Minimizing the Impact of Manual Errors

- Training and Standardization: Foster a culture of precision through thorough training and standardization of procedures to mitigate human errors.

- Clear Communication and Documentation: Enhance consistency through transparent communication and meticulous documentation of procedures, observations, and results, minimizing ambiguity.

By addressing these troubleshooting aspects, practitioners elevate the rigor and reliability of Elmendorf testing, ensuring that challenges become stepping stones to accurate and meaningful results.

Predicting Tear Behavior with Cutting-Edge Tools

1. Finite Element Analysis (FEA) for Elmendorf Tear Prediction

In the realm of technological advancements, FEA proves crucial for predicting tear behavior. It virtually explores tear initiation, propagation, and energy expenditure in Elmendorf testing, offering advantages over traditional methods.

Finite Element Analysis (FEA)

A robust tool for simulating material behavior, FEA predicts outcomes and allows for optimization without physical experimentation. This virtual testing enhances tear resistance by refining designs and material choices.

Advantages over Traditional Methods

FEA brings efficiency through cost-effective virtual simulations, providing insights into tear dynamics and facilitating design modifications before physical testing.

2. Predicting Tear Behavior with Cutting-Edge Algorithms

Machine Learning (ML) enters Elmendorf testing, harnessing data-driven approaches. ML algorithms discern patterns in tear behavior from extensive datasets, offering predictive insights for material selection and design.

Fed with diverse Elmendorf test results, ML algorithms unravel hidden correlations and trends, contributing to informed decision-making.

3. Advanced Techniques for Extracting Meaning from Elmendorf Test Results

Beyond conventional analysis, advanced statistical techniques are pivotal in unraveling tear behavior dynamics:

- Statistical Analysis Techniques: Regression analysis and principal component analysis delve into Elmendorf test data, identifying correlations for enhanced material selection and design precision.

- Data Visualization Tools: Emerging data visualization tools simplify complex Elmendorf test results, aiding effective communication of critical insights.

4. The Future of Tear Analysis

Looking ahead, tear analysis transforms cutting-edge tools:

- Modeling and Simulation Tools: Artificial intelligence and cloud computing usher in a new era in tear analysis. Evolving with advanced algorithms, these tools promise real-time prediction during manufacturing and online monitoring of product performance.

Future Applications:

Envision a future where tear behavior prediction becomes integral to the manufacturing process and revolutionizes decision-making for tear-resistant and optimized products.

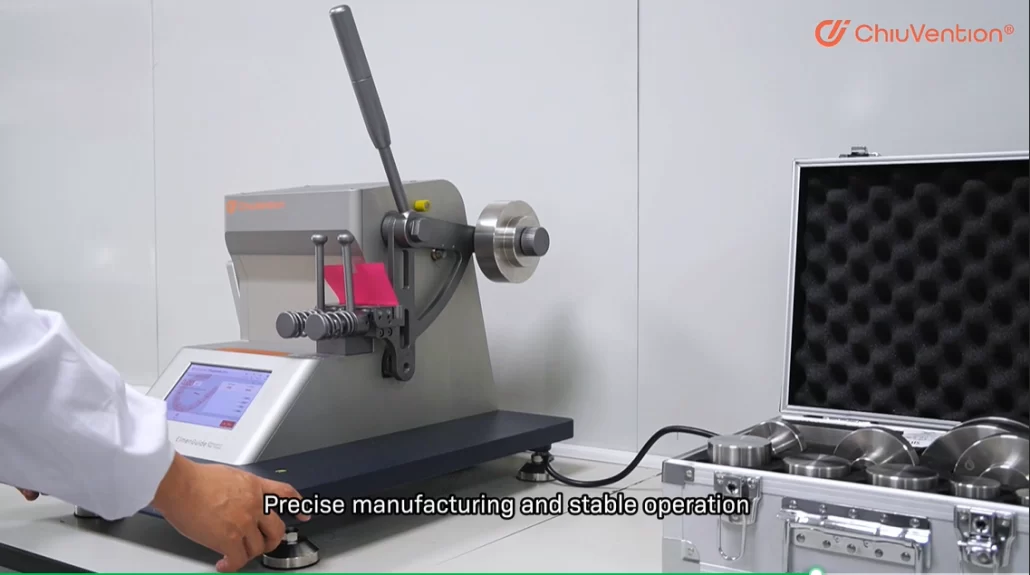

Choosing the Right Elmendorf Tear Testing Equipment

1. The Classic Pendulum

The classic pendulum tester is a foundational Elmendorf testing tool known for its simplicity, robust design, and affordability. Its core components – pendulum, clamps, and scale – work together to provide valuable insights into tear behavior.

Advantages

The classic pendulum design excels in simplicity and robustness, offering a cost-effective solution for tear testing across various industries.

Limitations

Traditional Elmendorf testers have limitations, including manual data recording, limited automation, and the absence of advanced features, which may hinder efficiency, especially in settings that require high-throughput or detailed data analysis.

2. The Advanced Elmendorf Testers

Digital evolution in Elmendorf testers brings significant advancements to tear resistance analysis. Equipped with data acquisition, analysis software, and automation-like features, these testers provide unprecedented accuracy, efficiency, and data management capabilities.

Benefits of Digital Features

Digital Elmendorf testers redefine tear analysis with enhanced accuracy and efficiency. Automated data recording and analysis software streamline processes for reliable results and in-depth tear behavior examination.

3. Emerging Technologies in Tear Testing

Explore alternative tear testing methods beyond the classic pendulum approach:

Alternative Testers

Falling Weight Tear Testers and Grab Tear Testers offer distinct advantages in specific applications. Understanding their capabilities and limitations is crucial for informed equipment selection.

Innovative Technologies

Optical tear testing introduces non-contact measurement, revolutionizing tear analysis by minimizing interference with delicate materials.

Automation and Connectivity

Modern tear testing equipment features increased automation and connectivity, enhancing efficiency and seamless incorporation into industrial processes.

4. Choosing the Right Tool

Selecting the appropriate Elmendorf tester requires a thoughtful approach. Consider the following factors:

- Budget: Evaluate financial constraints and choose a tester aligning with budgetary considerations.

- Testing Frequency: Tailor the selection to the required testing frequency, ensuring the chosen equipment meets production demands.

- Material Types: Different materials exhibit varied tear behaviors; choose a tester compatible with the materials under scrutiny.

- Testing Features: Identify desired testing features, such as automation levels, data analysis capabilities, and compatibility with relevant standards.

5. Considerations for Upgrading Tear Testing Equipment

Explore the benefits of transitioning from traditional to advanced Elmendorf testers:

- Efficiency Gains: Upgrading unlocks efficiency gains through automated processes, reducing manual intervention and enhancing testing throughput.

- Accuracy Improvements: Advanced testers offer superior accuracy, providing precise insights into tear behavior for data-driven decision-making.

- Return on Investment: The potential return on investment is significant, encompassing improved quality control, streamlined product development, and adherence to evolving standards.

Navigating the tear-testing equipment landscape requires a strategic mindset. By aligning specific requirements with available testers’ capabilities, industries can make informed decisions for optimal tear resistance analysis, contributing to enhanced product quality and performance.

Tear Behavior Analysis: Understanding Material Tear Properties

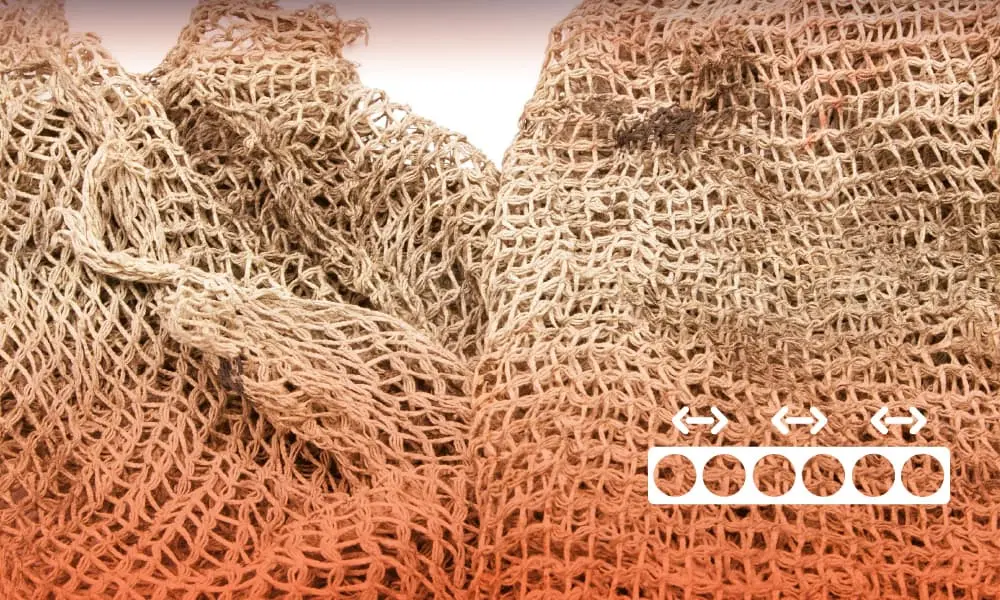

1. Modes of Tear: The Different Ways Fabrics Rip

- Mode I (Opening): Occurs when a tear moves perpendicularly to the applied force, typical in scenarios of sudden force application.

- Mode II (Shearing): Involves tear movement parallel to the applied force, common when applied tangentially, causing a sliding or shearing motion.

- Mode III (Tearing): Combination of opening and shearing, creating a complex tear pattern influenced by external factors and material properties.

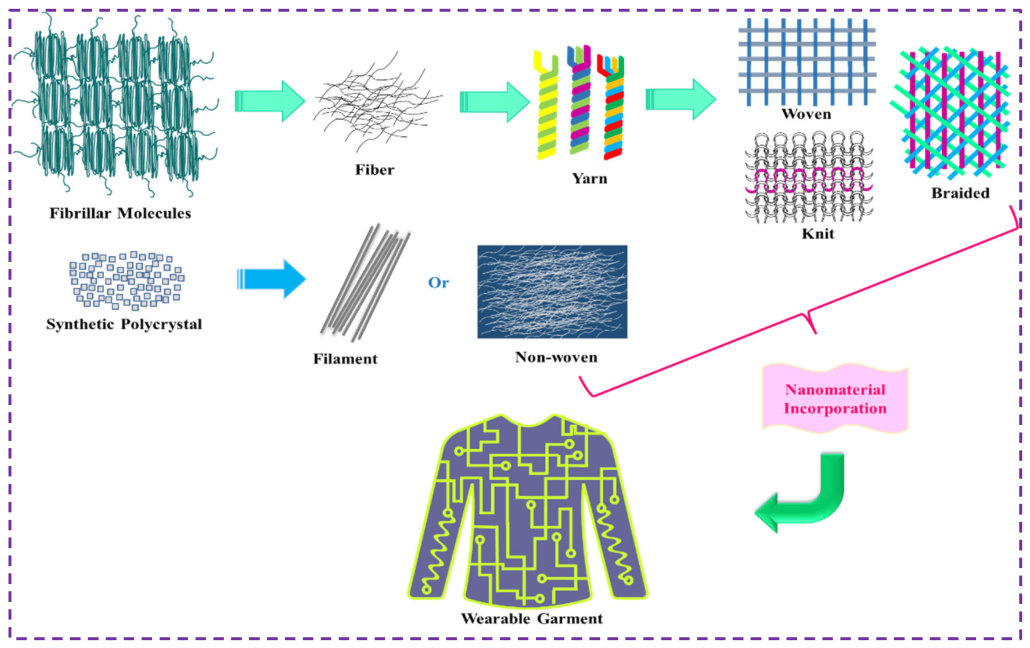

2. Material Influences: The Science Behind the Rips

Tear resistance is tied to various material properties:

- Fiber Type: Different fibers exhibit varying tear behaviors; for instance, synthetic fibers may provide higher tear resistance due to uniformity and strength.

- Weave Pattern: The arrangement of fibers significantly impacts tear strength, with tight weaves enhancing resistance.

- Fabric Density: Higher fabric density correlates with increased tear resistance, preventing easy tear propagation.

- Surface Treatments and Finishing Processes: Coatings or treatments can modify surface characteristics, affecting tear behavior by altering fabric-external force interactions.

3. The Physics of Rupture

Understanding tear behavior involves delving into the mechanics of rupture:

- Stress, Strain, and Energy Dissipation: The interaction of stress, strain, and energy dissipation at the tear crack tip dictates tear behavior.

- Crack Initiation and Propagation: Tear behavior involves crack initiation influenced by stress concentrations or defects, followed by crack propagation.

4. The Future of Tear Analysis

The landscape of tear analysis is evolving with cutting-edge technologies:

- Non-Contact Optical Tear Testing: Technologies like non-contact optical tear testing revolutionize tear analysis by enabling interference-free measurements, particularly in delicate materials.

- AI-Powered Data Analysis: Artificial Intelligence (AI) transforms tear behavior analysis by deciphering complex tear patterns and correlations, providing a deeper understanding of material behavior and tear resistance.

- In-Situ Monitoring Systems: The future holds promise for in-situ monitoring systems that track tear propagation in real-time during manufacturing or product use, allowing immediate intervention and optimization of tear resistance.

The evolving landscape of tear behavior analysis encompasses a better understanding of tear modes, material influences, and rupture mechanics. Embracing technologies like non-contact methods and AI-driven insights promises more efficient, accurate, and real-time tear behavior analysis, contributing to advancements in material science and product development.

Factors Affecting Tear Strength

1. Environmental Influences and External Forces

- Temperature, Humidity, and UV Exposure: Changes in temperature and humidity can alter a material’s molecular structure, affecting tear resistance. UV exposure over time may degrade fibers, reducing strength and increasing susceptibility to tearing.

- Mechanical Forces: Stress, strain rate, and cyclic loading are crucial in tear initiation and propagation. Understanding their interaction with the material is pivotal for accurate tear strength assessment.

2. The Impact of Manufacturing Techniques

- Spinning, Weaving, and Knitting: These processes influence fiber alignment, density, and inter-fiber cohesion, impacting tear strength. Tight weaves generally provide greater resistance to tears.

- Chemical Treatments and Additives: Used in finishing processes, they can alter material properties. Some chemicals enhance tear resistance, while others may compromise it. Consideration of their impact on tear strength is necessary.

3. Age and Damage

- Aging, Degradation, and Fatigue: These factors weaken materials over time and reduce tear resistance. Understanding the impact of prolonged use, environmental exposure, and repeated stress is crucial for predicting tear behavior.

- Mitigation Strategies: To extend material lifespan, strategies involve careful consideration of tear resistance requirements. Protective coatings, proper storage, and periodic assessments can help prolong the life of materials with high tear resistance needs.

4. Flaws and Imperfections

- Initiation Points for Tears: Inherent flaws like fiber breaks, misweaves, and uneven density compromise tear strength. Quality control practices, including thorough inspection and testing, are essential for identifying and rectifying such imperfections.

5. Understanding the Interplay of Factors

- Synergistic Interaction: Factors affecting tear strength often exhibit synergistic interactions. For instance, environmental exposure, mechanical stress, and inherent flaws can synergistically impact tear behavior. Understanding these interplays is essential for accurate tear resistance assessments and effective material design.

In essence, tear strength is influenced by multiple factors, each playing a distinct role in determining a material’s ability to resist tearing. From external environmental conditions to manufacturing processes and intrinsic material characteristics, a holistic understanding of these factors is crucial for predicting and optimizing tear strength in various applications.

Addressing Challenges and Advancing Elmendorf Tear Testing

1. Harmonizing Global Requirements and Methods

International and regional standards diversity in Elmendorf testing poses challenges, emphasizing the need for harmonization and collaboration among testing bodies and industry stakeholders. Online databases and standardized data formats contribute to a cohesive global testing environment.

2. Addressing Real-World Applications and Limitations

Laboratory Elmendorf testing may not fully replicate tear behavior in real-world conditions. New testing methods and equipment aim to simulate realistic scenarios, providing representative data. In-situ monitoring and non-destructive testing techniques offer continuous tear resistance assessment in practical applications.

3. Minimizing Human Error and Data Integrity Issues

Mitigating human error in Elmendorf testing is crucial. Best practices involve comprehensive training, procedure standardization, and automation to reduce errors and ensure data integrity. Data validation and statistical analysis identify and rectify inconsistencies in test results.

4. Bridging the Gap between Measurements and Insights

The challenge lies in translating raw Elmendorf test data into actionable insights. Advanced data analysis techniques like machine learning and finite element analysis are essential for extracting meaningful conclusions. Expert systems and predictive models further aid in interpreting data and recommending solutions based on tear behavior analysis.

5. The Future of Elmendorf

Emerging technologies such as AI-powered data analysis, non-contact optical measurement, and in-line monitoring systems have the potential to revolutionize Elmendorf testing, promising increased accuracy, efficiency, and real-time insights into material performance.

Continuous Improvement: Emphasizing continuous improvement and embracing innovation is essential for Elmendorf testing to remain a valuable tool. These advancements ensure Elmendorf testing is crucial in advancing material science and product development.

By harmonizing standards, considering real-world applications, minimizing human error, bridging the gap between measurements and insights, and embracing emerging technologies, we pave the way for a more robust and effective tear resistance testing methodology.

Alternative Methods for Assessing Tear Resistance

The Falling Weight Tear Test (FWTT)

Principle and Operation

Assesses tear resistance by dropping a weight onto a pre-cut notch in the material, measuring the energy required for tearing. Different from Elmendorf testing, it offers advantages in high loading rates, suitable for simulating dynamic stresses.

Advantages and Limitations

Advantageous for simulating rapid tearing events, but comes with limitations like higher impact costs and complexity compared to Elmendorf testing. The choice depends on material requirements and intended tear conditions.

The Grab Tear Test

Principle and Operation

Involves gripping a specimen at both ends and pulling it apart to measure the force needed for tearing. Particularly useful for assessing tear strength in larger specimens and simulating seam tears with a simple test design.

Advantages and Limitations

Significant advantages include simplicity and suitability for large materials. Potential issues like gripping slippage and less standardized procedures compared to Elmendorf testing should be considered. Valuable for scenarios involving pulling forces.

Tearing Pendulum Test

Principle and Operation

Employs a swinging pendulum impacting a pre-cut notch, measuring the energy absorbed during tear propagation. Useful for studying tear progression and analyzing tear behavior under controlled conditions.

Advantages and Limitations

Advantages include applicability for studying tear modes and progression. Less common than Elmendorf testing, might require specialized equipment. The choice depends on specific insights needed and tear behavior under investigation.

Non-Destructive Methods

Optical Methods like Digital Image Correlation (DIC)

Involves recording and analyzing deformation patterns near a pre-cut notch without causing a tear. Advantages include minimal sample damage, real-time monitoring, and studying tear initiation and propagation. Comes with higher equipment costs and complexity compared to traditional methods.

Material-Specific Approaches

Taber Tear Tester (for Paper)

Designed specifically for paper tear testing, involving applying a controlled force to a free-endpaper segment for tear resistance evaluation. Crucial in industries where paper tear properties are critical.

Dart Drop Impact Test (for Plastic Films)

Employed plastic films to assess tear resistance by dropping a weighted dart onto the material, measuring the force required to puncture and tear. Essential for evaluating tear strength in plastic films used in various applications, including packaging.

Tongue Tear Test (for Textiles)

Tailored for textiles, focusing on assessing the tear resistance of woven or non-woven fabrics. It involves tearing fabric along a straight path and measuring the force required for tear propagation. Vital for industries where textiles are crucial, such as clothing, upholstery, and technical textiles.

Environmental Impact of The Elmendorf Tear Testing

1. Environmental Costs of Testing

The pursuit of tear-resistant materials is crucial for product quality and safety but poses environmental challenges. Traditional tear resistance tests like Elmendorf generate material waste, consume energy, and involve chemicals. Quantifying these impacts is essential for informed decisions on the ecological footprint. Sample size, testing frequency, and disposal methods are key factors in assessing the overall environmental cost.

In the broader context, sustainability in materials testing is gaining prominence. Industries worldwide strive for greener practices, making understanding and mitigating the environmental costs of tear resistance testing a responsible step forward.

2. Applying Sustainability Principles to Tear Testing

- Reduce: Optimize specimen preparation and adopt smaller-scale testing methods to minimize material consumption and waste. Efficiency-focused strategies contribute to sustainability and align with cost-effective practices.

- Reuse: Explore opportunities to reuse test specimens for non-destructive analysis or educational purposes, promoting resource efficiency and a circular economy mindset.

- Recycle: Implement initiatives for recycling discarded materials, considering material types and local recycling infrastructure to contribute to sustainable tear resistance testing practices. This fosters a closed-loop system where materials are repurposed rather than disposed of as waste.

3. Green Testing Equipment and Practices

Energy Efficiency

- Modernize tear resistance testing equipment to align with energy-efficient practices, reducing the overall carbon footprint.

- Adopt renewable energy sources to power laboratories, demonstrating a commitment to sustainability.

- Optimize test parameters and automation routines to improve testing efficiency and reduce energy consumption.

In addition to energy considerations, explore eco-friendly alternatives to traditional testing consumables, such as lubricants and cleaning agents, adhering to environmentally friendly standards.

4. Data-Driven Sustainability: Optimizing Tests and Minimizing Resources

Advanced Analysis Techniques

- Leverage advanced data analysis techniques like machine learning (ML) to optimize tear resistance tests and minimize resource usage.

- ML algorithms identify optimal testing parameters, reducing the need for unnecessary runs, streamlining the testing process, and conserving resources.

- Virtual testing simulations minimize the need for physical testing through simulated environments, decreasing resource consumption and aligning with the trend of incorporating digital technologies into materials testing.

Ongoing research and development in sustainable materials and testing methods signify a commitment to continuously improving the environmental impact of tear resistance testing and exploring innovative, eco-friendly solutions for a more sustainable future.

5. Building a Culture of Sustainability in Testing Labs

Creating Awareness

- Promote awareness among testing personnel about the environmental impact of testing processes and the importance of adopting sustainable practices.

- Educate professionals to foster a culture of responsibility in tear resistance testing.

- Implement eco-friendly laboratory protocols and waste management procedures, integrating sustainability into every aspect of the testing process.

- Encourage collaboration between manufacturers, testing labs, and research institutions to share knowledge, best practices, and innovations, contributing to the development and widespread adoption of greener tear resistance testing methodologies.

Global Market Trends in Tear-Resistant Products

1. Growing Demand for Tear-Resistant Products:

The global market for tear-resistant products is growing rapidly due to an increased focus on sustainability, enhanced safety requirements, and emerging applications.

- Increased Focus on Sustainability and Product Lifespan: Consumers’ rising environmental consciousness is boosting demand for tear-resistant products with extended lifespans, reducing waste, and minimizing the environmental impact of disposable items.

- Enhanced Safety and Performance Requirements: Industries such as construction, sports, and the military require tear-resistant materials to ensure safety and functionality in demanding applications.

- Emerging Applications and Niche Markets: New applications in medical, aerospace, and wearable technology are creating a demand for specialized tear-resistant materials.

2. Diverse Tear-Resistant Materials

Tear-resistant materials now include high-performance polymers, bio-based materials, and nanomaterials.

- High-Performance Polymers: Advancements in polymers like polyethylene terephthalate (PET) and polyamides offer exceptional tear strength in automotive parts, protective gear, and composite materials.

- Bio-Based Materials: Sustainable alternatives like wood-based composites and cellulose nanocomposites provide robust tear resistance with lower environmental impact.

- Nanomaterials: Incorporating nanomaterials like graphene into fabrics and composites enhances tear resistance without compromising weight and flexibility.

3. Innovation at the Edge: Emerging Approaches to Tear Resistance

Cutting-edge technologies are revolutionizing tear resistance, including self-healing materials, smart textiles, and 3D printing.

- Self-Healing Materials: Polymer materials embedded with healing agents automatically repair minor tears, extending product life and reducing replacements.

- Smart Textiles: Integrating sensors and actuators into fabrics detects and responds to potential tears, ensuring material integrity in challenging conditions.

- 3D Printing: 3D printing enables customized designs with optimized tear resistance for specialized applications.

4. Market Players and Regional Shifts

The global market for tear-resistant products is influenced by key players and regional dynamics.

- Dominance of Asian Companies: Asian companies lead textile production, developing innovative tear-resistant fabrics for diverse industries.

- European and North American Markets: European and North American markets focus on high-performance materials, emphasizing technological innovation and stringent quality standards.

- Emerging Economies: Emerging economies like India and Brazil experience a surge in demand for durable and affordable tear-resistant products amid economic growth.

5. The Future of Tear Resistance

The future of tear-resistant products includes a continued focus on sustainability, integration of advanced technologies, and collaboration for innovation.

- Continued Focus on Sustainability and Bio-Based Materials: The industry will maintain a strong focus on sustainability, with an increasing shift towards bio-based materials to meet rising consumer demands for eco-friendly products.

- Integration of Advanced Technologies: Advanced technologies like self-healing materials and smart textiles will become more common, enhancing tear resistance and offering innovative solutions for various applications.

- Collaboration for Innovation: Increased collaboration between researchers, manufacturers, and consumers will drive innovation and adoption of tear-resistant materials to address evolving market needs and stay at the forefront of technological advancements.

Conclusion of The Elmendorf Tear Testing

Material science relies on understanding tear resistance for product quality and innovation. The Elmendorf test is a crucial tool in this pursuit. It serves as a dynamic conversation between materials and machines, revealing properties of fibers, seams, and weaves. From silk to steel, it interprets a material’s ability to resist everyday wear, stress, and time.

The standardized Elmendorf test ensures trustworthy product quality, preventing catastrophic failures and ensuring durability in garments, structural integrity in buildings, and reliability in safety gear. It quietly safeguards everyday lives by being woven into the fabric of various products.

Beyond being a sentinel, the Elmendorf test drives innovation by providing data for material science. It guides researchers toward stronger, lighter, and more sustainable materials, from bio-based composites to self-healing fabrics. The test unlocks the potential for materials that challenge preconceptions.

Next time you interact with a product, remember the Elmendorf test. Its measurements signify dedication to quality, safety, and a future where materials are resilient, tears are subdued, and the power of a tear contributes to building a better world.