What is a Fabric Sample Cutting Machine

A Fabric Sample Cutting Machine is a device used to cut textile samples. It utilizes different cutting technologies such as laser cutting, die cutting, and automated cutting systems to achieve a precise and efficient sample cutting process.

These cutting machines are widely used in various segments of the textile industry including fashion, home textiles, automotive interiors, furniture, footwear, and technical textiles. Today, we share the Complete Guide to Fabric Sample Cutting Machine with you.

The Application of Fabric Sample Cutting Machine

The Fabric Sample Cutter is suitable for a wide range of textiles, including but not limited to the following types:

Fabrics: Whether it is natural fibers (e.g., cotton, linen, silk) or synthetic fibers (e.g., polyester, nylon, acrylic), the Fabric Sample Cutter is capable of handling a wide range of fabric types.

Leather and Artificial Leather: Fabric Sample Cutting Machines are capable of cutting leather and artificial leather in a variety of thicknesses and textures,

providing precise sample cutting.

Non-wovens: Non-wovens are made from fibers or cellulose fibers that are chemically, thermally, or mechanically bonded,

fabric sample cutters can also easily cut non-woven samples.

Films and coverings: Fabric sample cutters can be used to cut a wide range of films and coverings such as plastic films, coated papers, and laminates.

Soft materials: In addition to traditional textiles, fabric sample cutters are also suitable for a variety of soft materials such as foam, rubber, foam, and fleece.

In short, fabric sample-cutting machines are suitable for a wide range of textile types, whether it is fabric, leather, nonwoven, or other soft materials, and can be used to cut samples accurately and efficiently.

Typically, fabric sample cutters are bulky, but there are also desktop-type sample cutters (e.g., the ProPress Sample Cutter from ChiuVention Company) for cutting miniature samples (e.g., samples for fabric chemical tests: textile pH, formaldehyde, and heavy metal content testing).

Types of Fabric Sample Cutters

When it comes to categorizing the types of textile sample-cutting machines, there are several common classifications:

Laser cutting, die cutting, and automated cutting systems. Let’s start with laser cutting.

Laser cutting is a modern and highly accurate method of cutting samples. It uses a high-energy laser beam to accurately cut a variety of textile materials. A laser cutter cuts textiles by focusing the laser beam on the textile, generating intense heat energy that melts or vaporizes the textile at the focal point. Laser cutting is ideally suited for intricate patterns and details as it enables highly accurate cuts.

The advantages of the textile sample laser cutting machine

High-precision cutting: laser cutting machines are capable of cutting that is precise to the millimeter and can handle complex shapes and details, providing high-quality sample cutting results.

Non-contact cutting: Laser cutting is a non-contact cutting technique that eliminates the need to physically touch the sample, avoiding damage or deformation caused by tool wear or pressure.

Low thermal impact: laser cutting produces a small area of thermal impact, reducing the risk of thermal distortion of textile materials.

Efficient and fast: laser cutting is fast, enabling large numbers of samples to be cut in a short period, increasing productivity.

Flexibility and versatility: laser cutting machines are suitable for a wide range of textile materials.

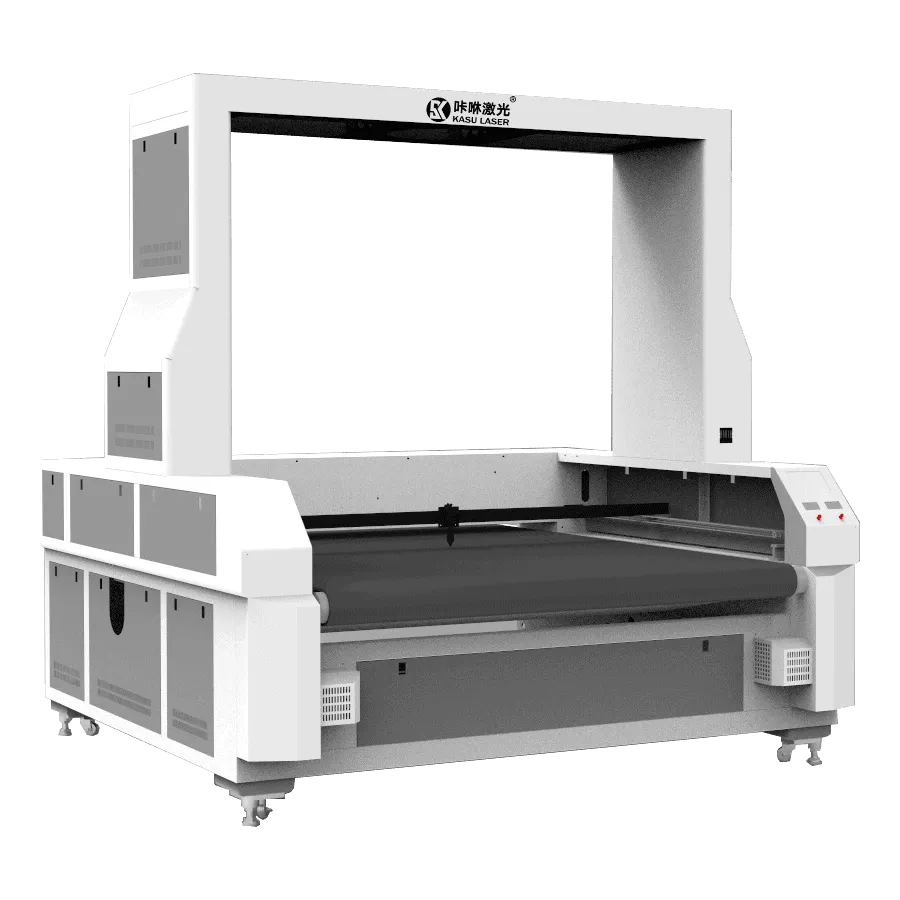

The Laser Fabric Sample Cutting Machine

Nowadays, laser cutting machines have been widely used in various industries, and when it comes to laser cutting, it is widely believed that laser cutting machine is mainly used for cutting metal and steel plates. But in fact, the laser cutting machine has been widely used in non-metal, such as wood, acrylic, plastic, leather, paper, etc., and flexible fabric related to a variety of sewing products have long been in the use of laser cutting machines to replace the traditional manual cutting and other mold cutting way.

Unlike the fiber laser for cutting metals, the laser machine for cutting fabrics mainly uses a CO2 light source. CO2 laser cutting machines have proved to be advantageous in cutting soft textured materials such as fabrics and textiles.

The following lists are laser cutting machines in the textile field of several application scenarios: such as plush velvet, although the traditional punching machine, ironing machine, and even scissors can be used to deal with this material, the CO2 laser cutting machine is a good choice, because the laser cutting machine’s thermal cutting method can secure the edges of plush velvet, enhancing the tensile strength of the finished product. In addition, the laser cutting machine has a small thermal response range and high precision of cutting, which can realize the cutting piece of zero spacing, so it can reduce the loss of raw material.

After years of technological innovation, the birth of a multi-head laser cutting machine with an automatic feeding function also doubles the cutting efficiency of the laser cutting machine, which is the main reason why the laser cutting machine can be batch applied in the factory of plush customers.

For silk samples, it is difficult to fix the material when being cut. Traditional cutting methods in dealing with silk fabrics are generally faced with challenges that the cut piece size is not uniform, the kerf is rough, the silk, the cut piece spacing is large, etc. The application of a CO2 laser cutting machine can be a solution to the requirements of cutting silk fabrics. The laser’s non-contact cutting method can ensure that each piece of silk cut piece size is the same. In addition, the thermal cutting can form an especially smooth cut effect, not yellowing, and can eliminate the post-processing procedures, saving labor.

Cutting non-woven felt material with a CO2 laser cutter will benefit very clean edges and beautiful cuts. The non-woven felt is especially easy to cut through by the laser without sticking to the edge, so it can also realize the small multi-layer cutting.

However, it is worth noting of choosing the laser cutting machine manufacturers. You should take samples to try the machine several times and pay attention to the cutting edge to observe whether there is a smoked yellow or smoked black problem, after all, the quality of the laser cutting machines from different factories are different.

The Die Fabric Sample Cutter

Die cutting is another common technique for cutting textile samples. It uses a die or knife to cut the textile material into a desired shape by applying pressure. Die-cutting machines usually have interchangeable dies or knives to accommodate different cutting needs. This type of cutting is suitable for a wide range of textiles, including fabrics, leather, and non-woven. Die cutting can finish a large number of cutting tasks in a short period, making it ideal for mass production and large-scale prototyping.

Efficient and fast: the textile sample die-cutting machine adopts automatic operation and can work efficiently and fast to cut textile samples of various shapes quickly.

High accuracy: The machine adopts advanced cutting technology, which can accurately cut out samples with various detail requirements, ensuring the accuracy and consistency of the samples.

Versatility: The textile sample mold cutting machine can be adapted to different types of textile materials, such as fabric, leather, etc., with strong adaptability and flexibility.

Automatic Control: The machine is equipped with an advanced automation control system, which can realize automatic cutting operation, reducing manual intervention and improving production efficiency.

And of course, you should pay attention to the other features of die-cutting machines:

Higher manufacturing cost: as the textile sample mold cutting machine needs to adopt advanced cutting technology and automation control system, its manufacturing cost is higher and not suitable for small-scale production.

Need professional operation: Operating the textile sample mold cutting machine requires certain professional knowledge and skills.

Difficulty in maintenance: As the equipment adopts complex cutting technology and automation control systems, the maintenance requirement of the equipment is high, and professional personnel are needed for repair and maintenance.

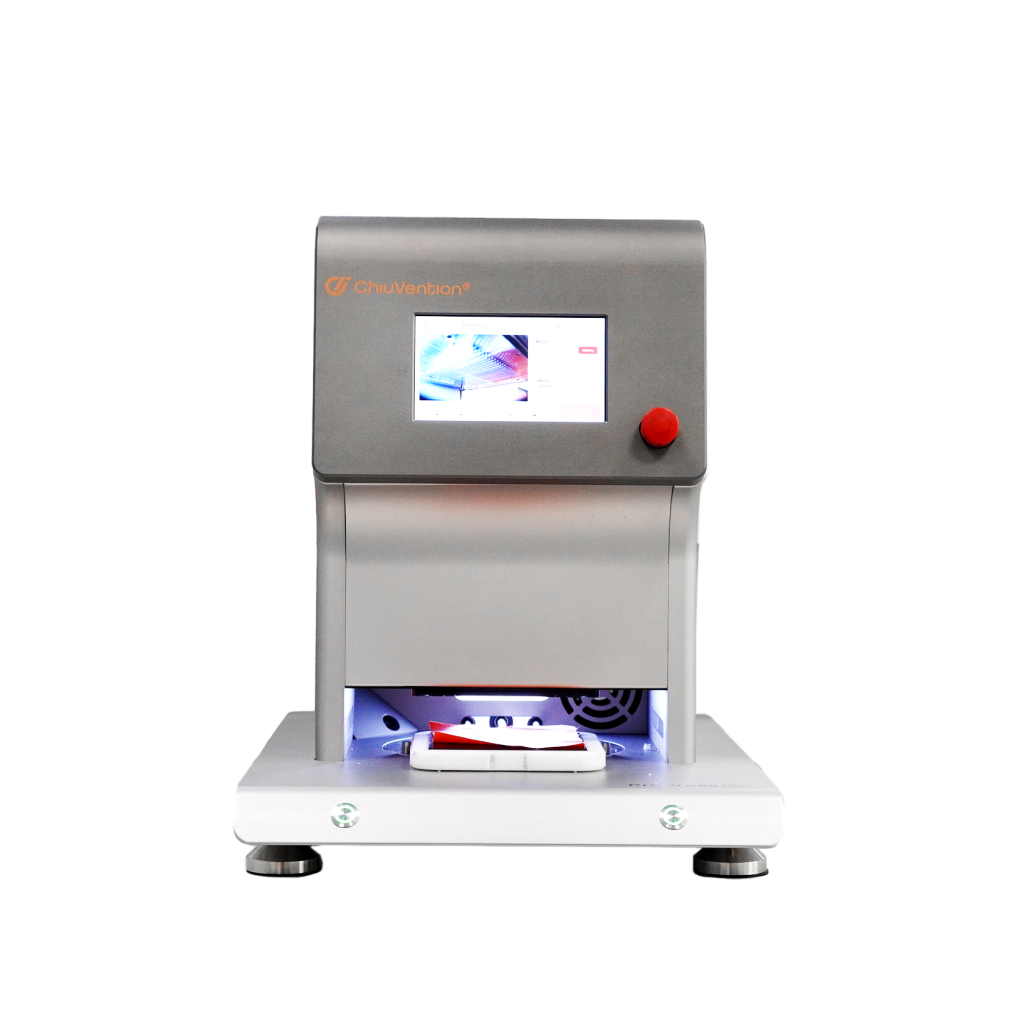

Die Cutting Machine Case: ProPress

The ProPress cuts the samples into small pieces (e.g. 5×5 mm) within several seconds and it can control the pressure precisely and apply it to a precision die to cut the sample. By cutting precise samples, ProPress is conducive to more reliable test results for formaldehyde, pH, and other tests. In a word, it is suitable for fabric tiny sample cutting. The cutting principle of this ProPress is hydraulic punching and cutting.

By using ProPress, the work efficiency of cutting samples increases by more than 80%, which is 6 times manual shearing. ProPress can cut fabrics, leather, plastics, and other flexible sheet materials to prepare test samples for formaldehyde, pH, azo, and heavy metals tests.

Lay the sample flat on the plate, and press the button with both hands, then the plate will enter and the machine automatically press and cut the samples. When the cutting is finished, the machine automatically activates a strong air-cleaning system to blow away any fibers and debris left behind, ensuring that the samples are not mixed.

The operator can observe whether there is any sample residue through the high-definition camera equipped with ProPress from the operation screen, and can manually start the cleaning program again.

In addition, ProPress ensures your safety: start-up with two hands, and the work area is equipped with a light barrier to prevent accidental injury. Applicable for various cutting sizes such as 5x5mm,10x10mm, or the dimensions can be customized.

More accurate sample preparation, for more reliable test results.

Traditional manual cutting of samples can easily lead to large differences in sample shape and size, which can cause insufficient dissolution, thus affecting the reliability of the test; ProPress cuts samples by pressing, which is precise and fast, and the highly consistent samples make the test results of formaldehyde, pH value, etc. more reliable.

Faster sample preparation, saving more than 80% of the time.

The ProPress presses samples in several seconds per operation, compared to at least 60 seconds for manual cutting, making it valuable for large-scale testing labs that prepare large numbers of test samples every day.

Ensures the quality of samples throughout the whole process.

The ProPress is equipped with a self-cleaning system that blows air to clean all kinds of fiber debris generated during the cutting process, and a built-in high-definition camera is used for observing the cleaning and ensuring that there is no mixing between samples.

Automated Cutting System

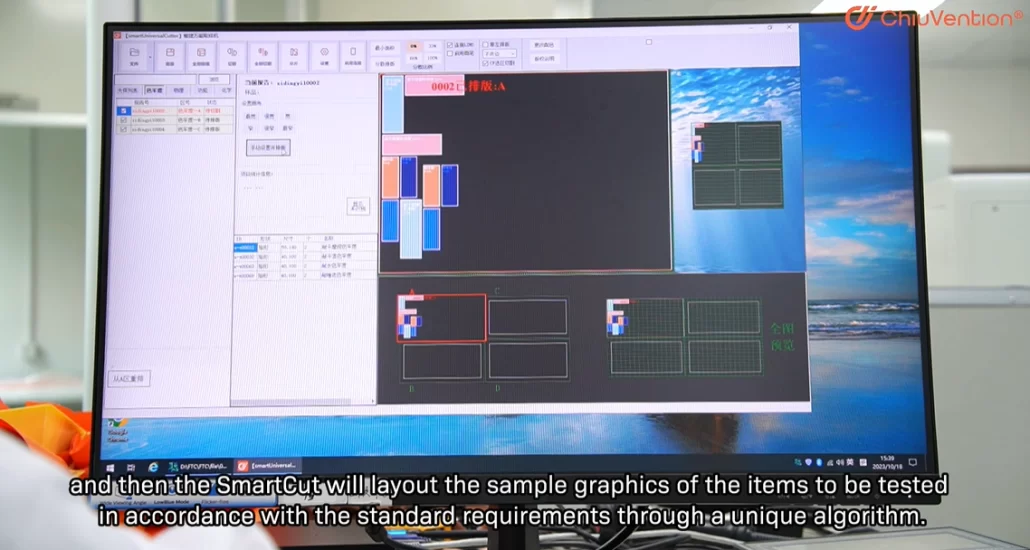

The Automated Fabric Sample Cutting System is a highly automated solution for cutting textile samples. It combines advanced mechanical and control technologies to automate the sample-cutting process. These systems are typically equipped with computer control and image recognition technology to automatically recognize and cut textile samples according to pre-set design patterns and dimensions. Automated cutting systems are highly productive and accurate, and are suitable for large-scale production processes and demanding cutting tasks.

For example, SmartCut of ChiuVention Company is this kind of machine. The SmartCut can complete the sampling of fabrics within 3 minutes.

It can be connected with the customer’s ERP or LIMS system docking through the network port, then automatically gets the test item information from the scanning of the bar code. Then SmartCut will lay out the sample graphics of the items to be tested by the standard requirements through a unique algorithm.

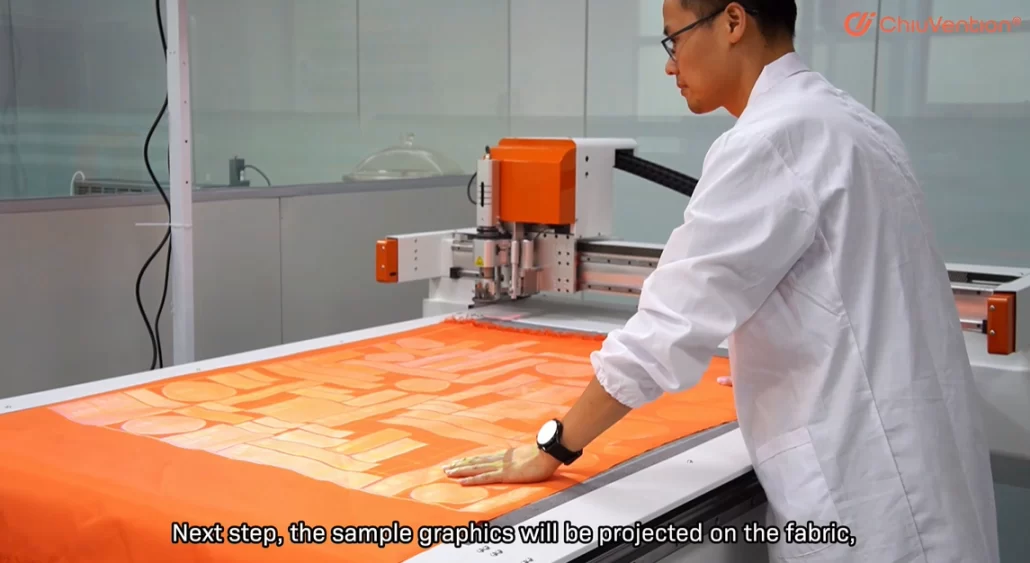

Next step, the sample graphics will be projected on the fabric and the SmartCut will start cutting fabric samples, automatically marking the samples as the the customer’s settings.

It is suitable for sampling requirements of dozens of tests such as pilling, tearing strength, water repellency, anti-static, tensile strength, color fastness, flammability, etc. It supports various standards such as GB/T, FZ/T, ISO, EN, JIS L, AATCC, ASTM, CAN, AS, and so on.

Strictly cuts the samples according to the standards, making sure the test is more reliable.

It supports decentralized sampling, trapezoidal sampling, full-width sampling, and 45° sampling, and can cut samples according to the rules such as alignment to the grid and the edge. So, the reliability of the test is guaranteed from the sampling.

More precise cutting and higher sample pass rate.

The tungsten steel blade of SmartCut is sharp and can be rotated 360°, with a cutting accuracy of 0.1mm, and a round-trip cutting error rate of less than 0.01mm, i.e. cut grams of specimens accurately.

Saves 5 laborers per year (about $420,000) for large-scale labs.

If you need to cut 100 whole samples per day, the conventional manual cutting requires 3000 minutes, i.e. 6 laborers; while using the SmartCut sample cutting system, 100 whole samples need only 0.6 laborers, saving 5 laborers per year for the laboratory.

And SmartCut can also achieve multi-station cutting (cutting different fabrics at the same time); multi-layer cutting (maximum cutting thickness of 7mm, can cut 1-20 layers); shaped cutting (irregular graphics). It can mark samples.

Besides, it has other advantages:

Versatility: The automated textile sample-cutting system can be adapted to different types of textile materials, such as fabric, leather, etc., with strong adaptability and flexibility.

Material saving: The system is capable of intelligent cutting according to the design requirements, maximizing material saving and cost reduction.

Traceability: the system can record the cutting process and parameters of each sample, realizing the traceability of the sample production process, which is convenient for quality management and tracking.

While you should also care about this:

Higher initial investment: The purchase and installation of the automated textile sample cutting system requires a certain initial investment, which is suitable for large-scale production enterprises.

Benefits of Using Fabric Sample Cutter

Increased productivity: textile sample cutting machines are automated to complete cutting tasks quickly and efficiently, greatly increasing productivity and saving time and labor costs.

Accuracy and Consistency: Textile sample cutting machines are equipped with advanced cutting technology and precision control features to accurately cut textile samples of all shapes and sizes, ensuring sample accuracy and consistency.

Material and cost saving: The textile sample-cutting machine can cut intelligently according to the design requirements, maximizing material savings and cost reduction. At the same time, it reduces errors and waste from manual operation, further saving costs.

Versatility and Flexibility: The textile sample cutting machine can be adapted to different types of textile materials, such as fabric, leather, etc., with strong adaptability and flexibility. It can cut samples of various shapes and sizes to meet different design requirements.

Enhance product quality: Due to the high precision and consistency of the textile sample cutting machine, it ensures that the shape and size of each sample meet the design requirements, enhancing the quality and consistency of the product and increasing customer satisfaction.

Customer Cases of Fabric Sample Cutting Machine

Global Fashion Brand Zesty Couture: Zesty Couture is a well-known fashion brand that uses textile sample cutting machines to cut fabric and leather samples. By using this cutting machine, they can cut a variety of complex sample shapes quickly and accurately, increasing their design and production efficiency. This not only saves time and material costs but also strengthens the quality of their products and their ability to innovate, allowing them to stay ahead of the curve in the highly competitive fashion market.

Fabrica Home: Fabrica Home is a company that specializes in high-quality home textile manufacturing. They use a textile sample cutting machine to cut a variety of fabrics such as curtains, sofa covers, and bedding. By using this cutting machine, they can quickly produce samples that meet design requirements, reducing manual errors and waste, and improving efficiency and product quality. This has helped them meet customers’ individual needs and win more orders and market share.

A supplier of textile materials: They use textile sample cutting machines to produce fabric samples. They can quickly cut and process different types of fabrics to show their customers the texture and characteristics of the fabrics, helping them to develop the market, and sell their products.

Fashion Education Institution: A fashion education institution uses the textile sample cutter for teaching and training purposes. Students can use the machine to practically manipulate and create garment samples, improving their skills and creativity and preparing them for future employment.

Entrepreneurial Designer: An entrepreneurial designer who is new to the fashion design industry uses a textile sample cutting machine to create the first samples for their brand. As they did not have much capital and resources, the machine helped them to produce high-quality samples in a short period, which provided strong support for their brand positioning and marketing.

These success stories demonstrate the wide range of applications of textile sample-cutting machines in different industries and scenarios, helping users to improve production efficiency, reduce costs, and achieve better creation and sales results.