Air permeability is a crucial factor in textile assessment, impacting performance across various industries. This guide offers a comprehensive overview for many of you, including manufacturers, researchers, and consumers. Starting with fundamental concepts and measurement methods, we explore factors influencing air permeability, emphasizing its role in sportswear, filtration, and medical textiles.

The guide clarifies the relationship between air permeability and breathability, dispelling misconceptions and comparing testing methods. It provides a step-by-step approach to conducting testing, interpreting results, and showcasing applications in the automotive and aerospace industries. We also examine the eco-friendly aspects, including certification programs, and conclude by addressing challenges and advancements in testing technologies.

Understanding Air Permeability in Textiles

What is Air Permeability?

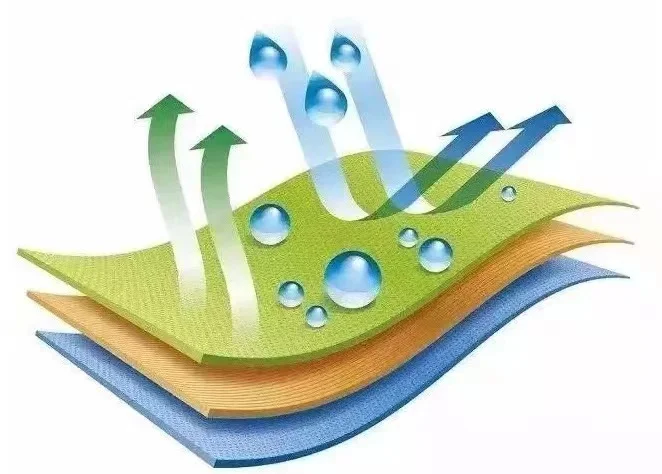

Air permeability in textiles indicates a fabric’s ability to allow air to pass through. It measures how easily air flows through the material, providing insights into breathability and airflow characteristics.

Measurement and Units

Air permeability is commonly measured using volumetric flow rate and pressure drop. Volumetric flow rate gauges the volume of air passing through a fabric in a specific time, while pressure drop assesses the fabric’s resistance to airflow. Air permeability is expressed in units such as cubic centimeters of air per second per square centimeter (cm³/s/cm²).

Air permeability Units used in testing include cubic centimeters per second (cm³/s) and the metric unit, liters per square meter per second (L/m²/s). Understanding these units is crucial for accurate interpretation and comparison. Conversions may be necessary for global standards, ensuring consistency in reporting.

Factors Influencing Air Permeability

- Fiber Type: The type of fibers used, whether natural like cotton or synthetic like polyester, significantly affects air permeability.

- Yarn Structure: The arrangement of yarns in a fabric is crucial. Tight weaves limit airflow, while looser weaves or knits enhance permeability.

- Fabric Construction: Overall fabric structure, including weave patterns and knit constructions, impacts air permeability. Open structures allow for greater airflow.

- Finishing Treatments: Chemical treatments, like water-repellent finishes, can alter surface characteristics, affecting air permeability.

- Environmental Factors: External conditions such as temperature, humidity, and air pressure influence air permeability. Standardized testing conditions are vital for accurate and comparable results.

Understanding these factors is crucial for textile manufacturers to optimize air permeability for specific applications.

Importance in Different Applications

Air permeability’s significance varies across textile applications. In sportswear, optimal permeability enhances comfort and athletic performance, influencing thermoregulation and moisture management.

Infiltration and air permeability ensure efficient airflow while maintaining desired particle capture. Medical textiles benefit, contributing to patient comfort in products like wound dressings and surgical gowns.

Acknowledging the significance of the air permeability test of fabrics enables the tailoring of fabrics to meet specific performance requirements and user expectations.

Importance of Textile Air Permeability in Sportswear

Enhanced Comfort and Performance

Air permeability is crucial for sportswear performance, impacting thermoregulation and moisture management. Efficient air permeability allows heat to escape during exercise, preventing overheating. It plays a key role in moisture transport, keeping the wearer dry and comfortable by facilitating quick sweat evaporation. Research shows a direct link between enhanced breathability and improved energy efficiency during exercise, highlighting textiles’ critical role in supporting peak athletic performance.

Role in Moisture Management

Air permeability’s impact on moisture management is vital in sportswear designed for intense activities. Facilitating efficient sweat evaporation prevents skin moisture accumulation and discomfort. Various fabric technologies, like wicking and moisture-absorbing features, work with air permeability to enhance breathability. Understanding these technologies used in air permeability testing machines is essential for manufacturers to optimize sportswear design, offering consumers informed choices based on climate, activity intensity, and personal preferences.

Air Permeability vs. Breathability: What’s the Difference?

Clarifying Terms and Misconceptions

In air permeability units like cfm/sq ft or L/s/m², Air permeability measures a material’s ability to allow air through. Breathability, a broader concept, involves both air and moisture vapor passage.

Common misconceptions need debunking for informed textile choices. A highly air-permeable fabric doesn’t guarantee superior breathability. Easy air passage doesn’t ensure effective moisture vapor transport, causing discomfort during prolonged use.

Relationship Between Air Permeability and Breathability

Air permeability significantly contributes to a fabric’s overall breathability, but it’s not the sole determinant. Breathability involves factors like moisture management and textile structure. Air permeability influences air circulation, aiding temperature regulation.

Breathability goes beyond air circulation, involving water vapor passage crucial for managing body-generated moisture. Optimal breathability expels accumulated moisture vapor, preventing condensation on the skin. Fiber density and arrangement impact textile openness.

Practical Implications in Textile Selection

In high-intensity activities, prioritize breathability. Choose fabrics with high air permeability and excellent moisture management.

For protection in outerwear, balance air permeability with wind and water resistance. Understanding practical implications helps consumers make informed decisions based on unique needs and preferences.

In textile selection, prioritize features based on intended use. Some prioritize air permeability, others a balanced combination. It ensures the chosen textiles align with specific needs, enhancing comfort and satisfaction.

Methods of Air Permeability Testing

Overview of Various Testing Methods

The following covers all commonly used air permeability test standards in the market.

ISO 9073:15

- Principles: ISO 9073:15 measures the air permeability of fabrics using a constant pressure differential method.

- Equipment: The test involves an air permeability test apparatus with a specified test area and clamping mechanism.

- Procedures: Fabric samples are mounted, and air permeability is determined by the rate of airflow.

JIS L1096 Item 8.26 Method C

- Principles: This Japanese standard assesses air permeability using a constant pressure differential.

- Equipment: Air tightness testing equipment with specific dimensions is employed.

- Procedures: The fabric is clamped, and air permeability is determined by the flow rate.

BS 3424-16

- Principles: British Standard 3424-16 involves the measurement of air permeability under specified conditions.

- Equipment: A permeability meter with defined parameters.

- Procedures: Fabric samples are subjected to a pressure differential, and airflow is measured.

BS 6F 100 3.1

- Principles: This British Standard determines the air permeability of fabrics using a constant pressure differential.

- Equipment: A testing apparatus with specified dimensions.

- Procedures: Fabric samples are prepared and clamped, and airflow through the fabric is measured.

NWSP 070.1.RO(15)

- Principles: NWSP 070.1.RO(15) outlines the evaluation of air permeability under defined conditions.

- Equipment: Specific apparatus with regulated parameters.

- Procedures: Airflow through fabric samples is measured at a constant pressure.

GB/T 24218.15

- Principles: This Chinese standard determines air permeability using a pressure differential.

- Equipment: An Air permeability tester for textiles with defined specifications.

- Procedures: Airflow through the fabric is measured under controlled conditions.

EN ISO 9237

- Principles: European Standard EN ISO 9237 measures air permeability using a constant pressure differential.

- Equipment: Testing apparatus with specific parameters.

- Procedures: Fabric samples are tested for air permeability, and airflow is quantified.

ASTM D737

- Principles: ASTM D737 is an American standard assessing air permeability using a constant pressure differential.

- Equipment: Specific testing apparatus, such as an air permeability tester for fabric.

- Procedures: Airflow through fabric samples is measured under defined conditions.

GB/T 5453

- Principles: This Chinese standard determines air permeability under specific pressure conditions.

- Equipment: Apparatus meeting defined criteria.

- Procedures: Airflow through fabric samples is quantified.

Key Differences and Applications:

Each standard has unique principles and equipment specifications.

- ISO 9073:15 and JIS L1096 focus on constant pressure differential methods, while BS 3424-16 and BS 6F 100 3.1 follow British standards.

- NWSP 070.1.RO(15), GB/T 24218.15, EN ISO 9237, ASTM D737, and GB/T 5453 each bring their own approaches and applications, catering to diverse testing needs.

Comparison of Dynamic vs. Static Methods

When considering air permeability testing, it’s essential to differentiate between dynamic and static methods based on airflow control:

Dynamic Methods

- Advantages: Dynamic methods allow for a more realistic representation of how fabrics behave in real-world conditions.

- Limitations: They may require more sophisticated equipment and are often time-consuming.

Static Methods

- Advantages: Static methods are generally quicker and more straightforward.

- Limitations: They may not fully capture the dynamic conditions fabrics experience in practical usage.

Understanding these differences is crucial for selecting the most suitable method based on material characteristics and intended applications.

Selection Criteria for Different Applications

Choosing the right air permeability testing method is pivotal, and it depends on various factors such as fabric type, intended purpose, adherence to industry standards, and cost considerations. Here is a decision-making table to guide you through the selection process:

| Criteria | Fabric Type | Test Purpose | Industry Standards | Cost Considerations |

| ISO 9073:15 | Versatile | General | Global Standards | Moderate |

| JIS L1096 Item 8.26 C | Japanese | Specific | Japanese Standards | Moderate |

| BS 3424-16 | British | General | British Standards | Low |

| BS 6F 100 3.1 | British | General | British Standards | Low |

| NWSP 070.1.RO(15) | Global | Specific | Global Standards | Moderate |

| GB/T 24218.15 | Chinese | General | Chinese Standards | Low |

| EN ISO 9237 | European | General | European Standards | Moderate |

| ASTM D737 | American | General | American Standards | Moderate |

| GB/T 5453 | Chinese | Specific | Chinese Standards | Low |

Air Permeability Testing Methods for Specific Textiles

Testing Equipment and Instrumentation

Precision in air permeability testing relies on specialized instruments for accuracy. Common equipment includes air permeability testers and data acquisition systems.

Air Permeability Testers

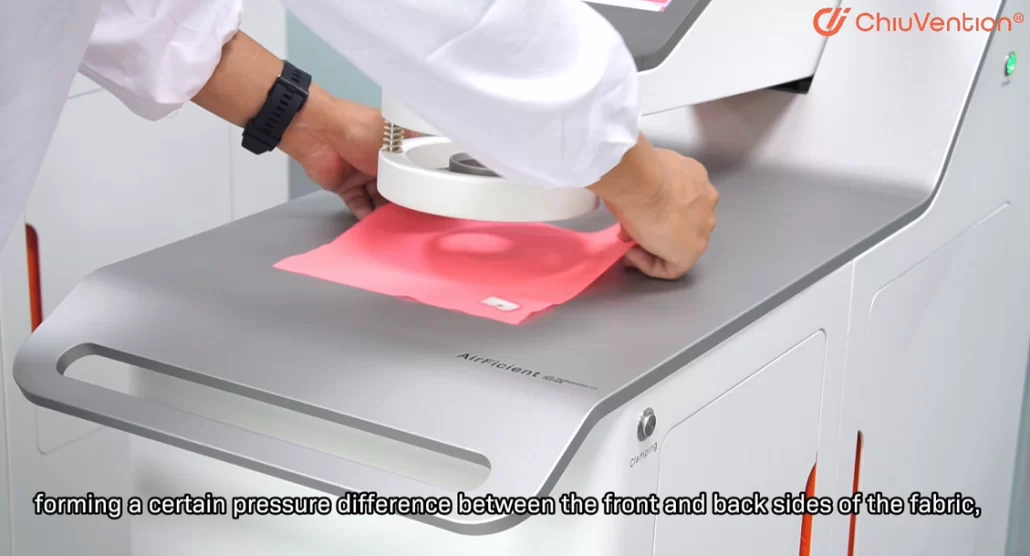

These instruments measure air passage through a fabric sample in a controlled environment, featuring a clamping mechanism, a test area, and a pressure differential system. Adhering to set standards, they offer adjustable parameters for pressure differentials, ensuring adaptability.

Data Acquisition Systems

Crucial for recording and processing test data, these systems interface with testers to collect real-time information on airflow rates and pressure differentials. Equipped with analysis software, they provide insights into fabric permeability, often customizable for specific testing needs.

Understanding these instruments’ functionalities and specifications is crucial for precise air permeability tests.

Get the details on air permeability tester prices and parameters by clicking on the picture below.

Variations for Different Textile Types

Air permeability testing must adapt to various textile types with unique properties:

- Woven Fabrics require specific clamping techniques to prevent distortion, standardized sample sizes, and conditioning procedures.

- Knitted Fabrics demand careful clamping for sample integrity, considering relaxed and stretched conditions during testing.

- Non-woven fabrics require attention to varied surface structures, ensuring uniform sample sizes and proper edge treatment.

- Coated Fabrics and Membranes may need specialized clamping methods and edge treatments due to layered structures.

Understanding sample preparation nuances for different textile types is imperative for reliable air permeability testing outcomes.

Standardized Testing Conditions

Ensuring standardized testing conditions is crucial for accurate, comparable, and reproducible air permeability results:

Temperature

Maintaining a constant temperature during testing eliminates variations that can influence fabric properties.

Humidity

Standardized humidity conditions prevent alterations in fabric permeability due to moisture content fluctuations.

Sample Conditioning

Fabric samples must be conditioned to a standardized moisture content before testing for uniform material properties.

Calibration Procedures and Quality Control Measures

Regular equipment calibration and quality control checks ensure the accuracy and reliability of test results.

Adhering to standardized testing conditions, including temperature, humidity, and sample conditioning, guarantees accurate and reproducible air permeability testing results.

Conducting Air Permeability Testing: A Step-by-Step Guide

Sample Preparation

For accurate air permeability test results, follow these steps:

Sample Selection

- Choose representative samples reflecting textile diversity.

- Ensure samples are defect-free.

Sample Size

- Cut samples based on specific testing standards.

- Sizes range from 100 cm² to 38.71 cm².

Conditioning

- Precondition samples in a controlled environment.

- Allow at least 24 hours for acclimation.

Edge Treatment

- Trim samples neatly to remove irregular edges.

- Avoid fraying during the process.

Identification

- Clearly label each sample with relevant information.

Documentation

- Maintain detailed records, noting any deviations.

Standard Testing Procedure

For consistent air permeability testing, follow these steps:

Apparatus Setup

Sample Mounting

- Affix samples securely, ensuring a flat position.

- Confirm centering and uniform clamping.

Pressure Differential

- Set the specified pressure differential.

- Ensure uniform pressure across the sample.

Test Initiation

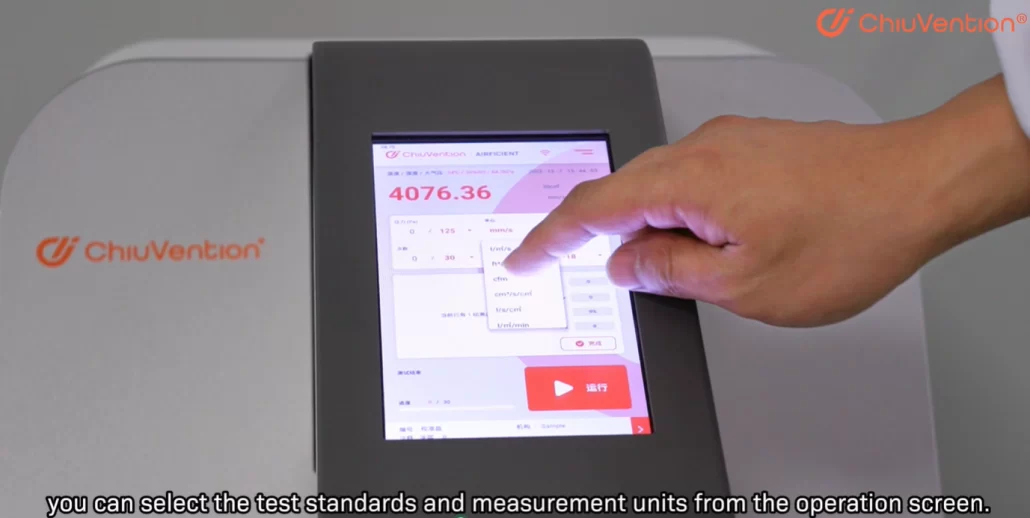

- Start the test with the designated airflow duration.

- Record parameters, including pressure differentials.

Data Recording

- Capture accurate airflow measurements.

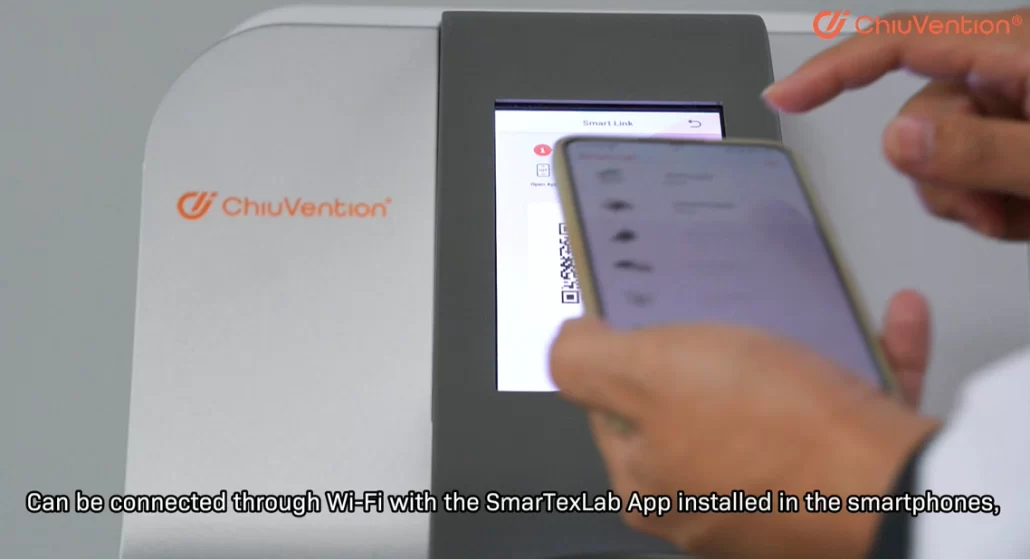

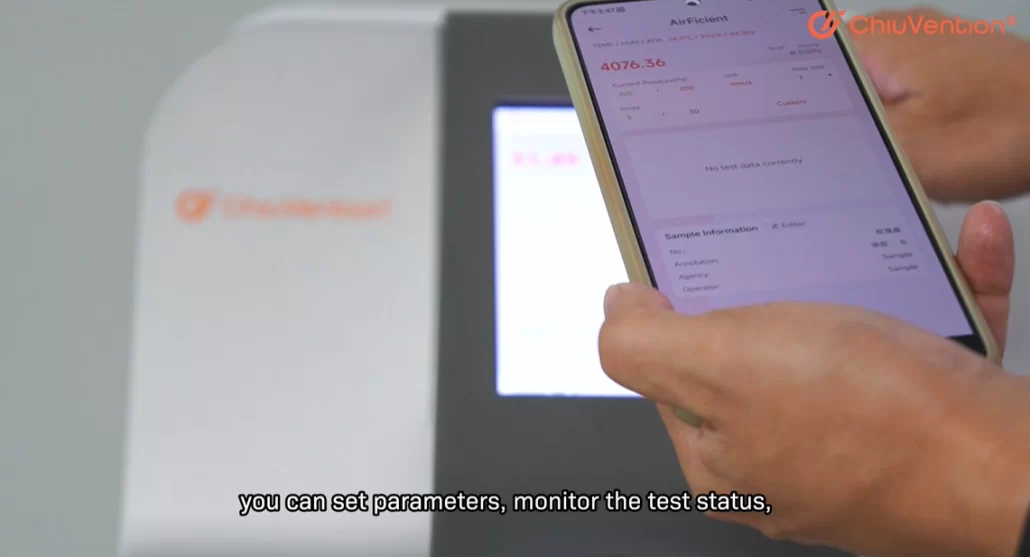

- Use appropriate tools for data recording. Choose AirFicient Air Permeability Tester, you can connect your phone to the machine via WIFI and share the test results from your phone.

Repeat Testing

- Repeat tests with multiple samples for consistency.

- Average results for a representative value.

Standard Testing Conditions and Precautions

For reliable results, adhere to these guidelines:

Temperature and Humidity

- Conduct tests in controlled temperature and humidity.

- Monitor and document deviations meticulously.

Sample Conditioning

- Adhere to recommended conditioning periods.

- Store samples consistently to prevent moisture variations.

Equipment Calibration

- Regularly calibrate equipment for accuracy.

- Document procedures and dates for traceability.

Precautions

- Minimize external disturbances during testing.

- Follow safety precautions for a secure environment.

Strict adherence to standardized conditions ensures precise and comparable air permeability measurements across textile samples.

Interpretation of Results

Understanding Numerical Values

To interpret air permeability test results, focus on key parameters:

Flow Rate (cm³/cm²/s/Pa): Quantifies ease of air passage through the fabric.

- Higher values indicate greater permeability.

- Reference values vary; industry standards provide benchmarks.

Pressure Differential (Pa): Represents applied pressure for airflow.

- Varying differentials assess fabric behavior in different conditions.

- Reference values contextualize material performance.

Factors Affecting Test Results

For accurate interpretation, consider the influencing factors:

Fabric Structure

- Tight weaves have lower permeability; open structures allow more airflow.

- Varied constructions impact results; consider when comparing materials.

Environmental Conditions

- Temperature and humidity changes affect fabric behavior.

- Maintain consistent testing conditions to minimize environmental impact.

Sample Preparation

- Flaws in preparation can distort results.

- Follow standardized procedures meticulously to minimize variations.

Statistical Analysis

- Use statistical tools for meaningful conclusions.

- Analyze variability for reliable insights.

Common Challenges in Result Interpretation

Address challenges in interpreting results:

Variability in Measurements

- Exercise caution when comparing due to inherent variations.

- Consider potential deviations in results.

Inconsistent Sample Conditions

- Document conditions rigorously to identify and mitigate issues.

- Fluctuations impact outcomes.

Limited Reference Values

- Seek industry-specific or application-oriented references for informed interpretation.

- Some materials lack benchmarks.

Data Analysis Techniques

Effective data analysis enhances result interpretation:

Basic Techniques

- Use mean, median, and standard deviation for a comprehensive data understanding.

Specialized Software or Tools

- Utilize software like MATLAB or Python for streamlined analyses.

- Facilitates fabric comparison.

Applications of Air Permeability Testing Beyond Textiles

Diverse Applications Across Industries

Air permeability testing is versatile, spanning various industries:

Automotive Sector

Evaluate interior materials for optimal air permeability to enhance in-cabin comfort and meet performance standards.

Medical Textiles

Assess breathability in medical fabrics for patient comfort, especially in applications like wound dressings or surgical gowns.

Geotextiles

Gauge air permeability in geotextiles for civil engineering applications, such as soil stabilization or drainage.

Packaging Industry

Evaluate air permeability of packaging materials to ensure product freshness, extending shelf life.

Aerospace Materials

Assess air permeability in aircraft interior materials for comfort and safety, meeting aviation standards.

Impact on Product Design and Manufacturing

Air permeability testing significantly influences product design and manufacturing:

Material Selection

Informed choices based on air permeability lead to tailored materials for specific applications, balancing permeability with other attributes.

Design Optimization

Understanding air permeability guides the optimization of product designs, refining patterns, structures, and compositions for improved functionality.

Quality Control

Implement air permeability testing in manufacturing as part of quality control measures to ensure consistency in material properties, meeting industry standards.

Innovation in Textile Products

Drive textile product innovation using air permeability data to meet market demands for comfort, performance, and sustainability.

Cost-effective Solutions

Optimize manufacturing costs by choosing materials with appropriate air permeability and identifying solutions without compromising functional requirements.

Understanding air permeability testing enables industries to create products that meet performance standards with enhanced comfort, functionality, and longevity across sectors.

Improving Air Permeability in Bedding Textiles

Air Permeability and Quality Sleep

Quality Sleep relies on the air permeability of bedding textiles. Optimizing air permeability contributes to enhanced sleep quality. Key points include:

Thermal Comfort

- Air permeability affects breathability for thermal comfort.

- Regulating temperature prevents overheating or excessive cooling.

Moisture Management

- Optimal air permeability facilitates effective moisture wicking.

- Reducing moisture accumulation ensures a hygienic sleep experience.

Air Circulation

- Improved air permeability promotes better air circulation during sleep.

- Adequate ventilation reduces discomfort from trapped heat or humidity.

Beyond Air Permeability

- Consider factors like thread count, fabric composition, and weave structure.

- Evaluate tactile properties for a soft feel against the skin.

Material and Design Impact

Analyzing fiber choices and design’s impact on air permeability is crucial for comfortable bedding:

Fiber Choices

- Natural fibers like cotton and linen exhibit favorable air permeability.

- Synthetic fibers can be engineered for balance with other properties.

Weave Structure

- Open weave structures like percale or sateen enhance air permeability.

- Experiment with weaves for optimal breathability and structural integrity.

Ventilation Features

- Integrate design elements for air circulation, like breathable patterns or mesh.

- Explore innovative designs promoting airflow without compromising aesthetics.

Layering Techniques

- Use multiple layers with varying air permeability for a balanced sleep environment.

- Allows customization based on preferences and seasonal variations.

Microclimate Management

- Develop bedding textiles for a microclimate conducive to comfortable sleep.

- Incorporate materials adapting to ambient conditions for a personalized experience.

Understanding Fabric Air Permeability and Comfort

Psychological and Physiological Aspects of Comfort

Comfort in Textiles involves both kinds of factors. Individual preferences, cultural influences, and personal experiences shape the perception of comfort. Soft textures, smooth surfaces, and pleasing aesthetics contribute to psychological comfort. Physiological comfort is directly impacted by skin temperature regulation and moisture management. Fabrics supporting natural cooling mechanisms and effective moisture control enhance physiological comfort. Harmonious comfort arises when fabrics align with both sensory preferences and physiological needs. Understanding wearer expectations and considering tactile, visual, and thermal comfort collectively is crucial.

Role of Air Permeability in Enhancing Comfort

Air permeability significantly influences fabric comfort by affecting thermal regulation, moisture management, and tactile sensations. Scientific evidence supports the positive impact of air permeability on reducing discomfort:

Thermoregulation

Adequate air permeability allows heat to dissipate, correlating with improved thermal comfort, especially in active or warm conditions.

Moisture Management

Optimal air permeability facilitates moisture evaporation, preventing discomfort caused by dampness. Studies show enhanced efficiency in moisture transport.

Tactile Comfort

Air permeability influences the tactile feel of fabrics. Balanced air permeability creates a comfortable microclimate, reducing stickiness or clinginess sensations.

Eco-friendly Textile Air Permeability Testing and Certification

Sustainable Testing Practices

Traditional textile testing methods often harm the environment through chemical use and high energy consumption. Embracing sustainable testing minimizes the ecological impact.

Environmental Impact

- Chemical Usage: Conventional methods may harm the environment.

- Energy Consumption: High energy use contributes to carbon emissions.

Sustainable Practices

- Reduced Chemical Footprint: Minimize harmful chemical use.

- Energy Efficiency: Implement energy-efficient equipment and procedures.

- Waste Reduction: Adopt practices to minimize waste during testing.

Transitioning to sustainable testing mitigates environmental impact while ensuring accurate air permeability testing.

Eco-friendly Textile Certification Programs

Certification programs are crucial for promoting eco-friendly textiles and establishing sustainability standards. Key programs include GOTS, Bluesign, and OEKO-TEX.

Certification Programs

- GOTS: Ensures adherence to strict organic and environmental criteria.

- Bluesign: Focuses on sustainable and responsible production.

- OEKO-TEX: Ensures textiles are free from harmful substances.

Significance of Certification

- Consumer Assurance: Builds consumer confidence in environmentally friendly textiles.

- Industry Accountability: Manufacturers contribute to industry-wide sustainability goals.

- Certification programs guide the industry towards environmentally responsible practices and transparency.

Trends Towards Sustainable Textile Industry

Sustainability is a driving force in the textile industry, evident in trends like the circular economy and the use of alternative materials.

Current Trends

- Circular Economy: Embracing recycling and upcycling minimizes waste.

- Alternative Materials: Exploring eco-friendly and biodegradable options aligns with sustainability goals.

Role of Transparency and Consumer Demand

- Transparency: Increased disclosure of manufacturing practices due to consumer demand.

- Consumer Demand for Sustainability: Growing awareness drives the adoption of eco-friendly practices.

Committing to sustainability and certification standards meets consumer expectations and supports the long-term environmental health of the textile sector.

Challenges and Solutions in Textile Air Permeability Testing

Challenges in Textile Air Permeability Testing

Variability in Test Conditions

- Inconsistent environmental conditions during testing can lead to result variations.

Instrument Calibration and Maintenance

- Calibration drift over time affects measurement accuracy.

- Lack of regular maintenance causes instrument malfunctions.

Sample Preparation Discrepancies

- Variations in sample size and shape introduce discrepancies.

- Inadequate edge sealing affects airflow and leads to inaccurate readings.

Solutions and Best Practices

Environmental Controls

- Adhere strictly to standardized environmental conditions for consistency.

- Pre-test sample conditioning minimizes the impact of environmental variations.

Instrument Maintenance and Calibration

- Implement routine calibration checks to promptly rectify drift.

- Establish a regular maintenance schedule for optimal instrument operation.

Sample Preparation Protocols

- Follow established guidelines for consistent sample cutting.

- Clearly define and adhere to edge treatment protocols to eliminate airflow disruptions.

Ethical Considerations in Testing

- Ensure transparency in reporting test conditions and sample preparation.

- Uphold ethical standards for data integrity and results.

- Obtain informed consent when human subjects are involved, respecting ethical guidelines.

Emphasizing ethical considerations is essential for credibility, participant well-being, and industry trust in textile air permeability testing. Continuous improvement and adherence to best practices contribute to overcoming challenges.

Comparison of Different Air Permeability Testing Standards for Textiles

Overview of Testing Standards

In the field of air permeability testing for textiles, various standards guide manufacturers, researchers, and regulators. Understanding key features, applications, and limitations is essential for informed decision-making.

ISO 9073:15

- Features: Specifies a method for determining air permeability using a constant airflow.

- Applications: Commonly used for woven and non-woven textiles.

- Limitations: May not capture the full spectrum of characteristics for specialized fabrics.

JIS L1096 Item 8.26 Method C

- Features: Measures air permeability by determining airflow through a defined area.

- Applications: Widely adopted in the Japanese textile industry.

- Limitations: Specific applicability concerns for fabrics beyond standard clothing.

BS 3424-16

- Features: Outlines procedures for measuring air permeability.

- Applications: Used in the UK and Europe, providing insights into textile breathability.

- Limitations: Variations in interpretation and application in different regions.

BS 6F 100 3.1

- Features: Emphasizes testing coated fabrics for air permeability.

- Applications: Relevant for materials with added coatings.

- Limitations: Specialized focus may limit applicability to standard textiles.

- NWSP 070.1.RO(15)

- Features: Assesses air permeability of geotextiles.

- Applications: Designed for civil engineering and construction projects.

- Limitations: Not suitable for textiles intended for clothing or consumer applications.

GB/T 24218.15

- Features: Chinese national standard for air permeability testing.

- Applications: Widely used in China for quality control and research.

- Limitations: Regional adoption may limit global recognition.

Comparison of International Standards

ISO 9073:15 vs. JIS L1096 Item 8.26 Method C

- Both focus on constant airflow methods, with variations in sample preparation and testing conditions.

- Differences in units and calibration procedures may impact direct comparability.

BS 3424-16 vs. BS 6F 100 3.1

- Both British Standards, with BS 3424-16 being more general and BS 6F 100 3.1 specializing in coated fabrics.

- Variations in sample conditioning and testing apparatus may affect the cross-application of results.

NWSP 070.1.RO(15) vs. GB/T 24218.15

- Cater to different industries (geotextiles vs. general textiles) with distinct testing protocols.

- Adapting results may require careful consideration of the intended application.

Challenges and Harmonization Efforts

Challenges in harmonizing testing standards arise from differences in methodologies, regional preferences, and diverse applications. Efforts include:

- International Collaboration: Led by organizations like ISO.

- Regular Revisions: Periodic updates address emerging challenges.

- Industry Cooperation: Stakeholders align testing standards with practical applications.

Benefits include enhanced comparability, improved product quality, and simplified international trade, contributing to a cohesive global textile industry and promoting transparency and confidence.

Advancements in Air Permeability Testing

Emerging Technologies and Equipment

Air permeability testing in textiles is evolving with innovative technologies. Pressure differential scanning provides dynamic permeability assessment by applying varying pressure differentials across fabrics. This method yields detailed insights into material responses under different conditions.

Computerized Tomography (CT) imaging comprehensively analyses the fabric structures, visualizing internal elements and density variations in three dimensions. This aids researchers in understanding fabric contributions to overall breathability.

Integration of advanced sensors enhances precision in testing equipment. Real-time data collection on airflow, temperature, and humidity during tests contributes to a more holistic understanding of fabric behavior.

Potential Benefits and Limitations

Adopting emerging technologies brings benefits like increased accuracy and expanded capabilities. However, challenges, such as high initial costs and standardization issues, need addressing for widespread adoption.

Automation and Digitization in Testing Processes

The textile industry is shifting towards automated testing for efficiency and reduced human error. Automated air permeability testers streamline the process, offering precise control over testing conditions and immediate insights through real-time data analysis.

Digital data acquisition systems facilitate seamless storage, retrieval, and analysis of test results, improving workflow efficiency and enabling trend tracking.

Addressing Potential Challenges

Challenges in automation and digitization include initial investment, maintenance costs, and ensuring compatibility with testing standards. Standardization efforts are crucial for widespread adoption and cross-industry comparisons.

Potential Future Developments

The future of air permeability testing involves integration with other evaluation techniques, like tensile testing and surface energy analysis, for a comprehensive understanding of fabric performance.

Advancements in miniaturization may lead to portable air permeability testing devices, enabling on-site assessments for quicker decision-making in product development and quality control.

Continuous Drive for Innovation

The textile industry’s commitment to innovation in air permeability testing reflects a dedication to enhancing product quality, sustainability, and consumer satisfaction. Stakeholders in academia, industry, and research institutions play a crucial role in driving this innovation.

Conclusion

In essence, this comprehensive guide navigates essential concepts, methodologies, and applications of air permeability testing in textiles. From understanding influencing factors to the role of Air Permeability in various applications, we shed light on the critical interplay between textiles and airflow. Explaining testing methods and standards equips you to make informed choices in textile selection.

The guide emphasizes the global relevance of air permeability testing, impacting product design and consumer satisfaction. In the era of sustainability, we focus on eco-friendly practices, signaling a shift towards an environmentally conscious textile industry. Harmonizing international testing standards is crucial, and the guide concludes by glimpsing into the future of innovative and sustainable textile landscapes.

With air permeability intricacies demystified, apply this knowledge for a future where textiles seamlessly blend science, comfort, and conscientious practices.