Washing change directly affects the garment’s shape and aesthetics, thus affecting its use and wearing. Therefore, the rate of washing dimension change is a crucial index for testing garment quality. In this article, we’ll explore the demands of international buyers for washing dimension change. Then, we’ll explain the comparison of testing methods for the rate of washing dimensions change in textiles. We’ll stress more emphasis on washing dimension change rate tests on textiles, including different testing methods analysis. Finally, some significant problems and suggestions are proposed, such as textiles testing standards and sample tests towards the rate of fabric dimensional change.

I. International Buyers’ Requirements for Dimensional Stability in the Wash

The dimensional stability of printing and dyeing products is basically determined by pretreatment, mercerising determines the dimensional stability of cotton and its blended fabrics, and heat setting determines the dimensional stability of chemical fibre and its blended fabrics, that is to say, mercerising and heat setting are the two key processes affecting the dimensional stability of fabrics. As for dimensional stability, international buyers usually assess washing dimensional stability, dry cleaning dimensional stability and steam dimensional stability, of which washing dimensional stability (shrinkage) is the most representative quality indicator. Although Chinese dyeing and printing enterprises attach great importance to the shrinkage rate of their products, the actual situation of unqualified shrinkage rate often occurs, especially for products exported to Europe and the United States. The failure rate of shrinkage rate in Chinese textile exports has always ranked in the top four among all the unqualified indicators. Sample test results found that in 2007, the product shrinkage failure rate of 2.40 per cent, in 2008 for 2.60 per cent, January to October 2009 for 3.20 per cent, which is mainly due to the fact that the product shrinkage failure rate of 2.40 per cent, 2008 for 2.60 per cent, January to October 2009 for 3.20 per cent. This is mainly due to the fact that the testing method of shrinkage rate adopted by Chinese enterprises is different from that adopted by European and American customers. For this reason, it is necessary to understand the specific assessment method of the shrinkage rate index in the international market.

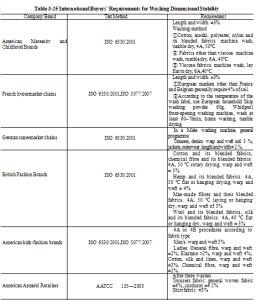

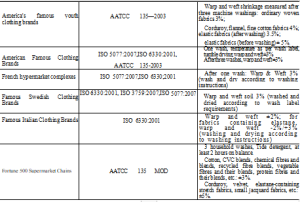

Therefore, it is important to understand the specific assessment methods of the international market for shrinkage indicators. The requirements of international buyers for washing dimensional stability are shown in Table 3-25.

Table 3-25 shows that the European market generally adopts ISO 6330:2000 “Textiles-Domestic washing and drying procedures for textile testing” method of washing, while the American market mostly adopts AATCC 135-2004 “Dimensional Changes of Fabrics after Home Laundering”.

The washing machines and dryers used in these two methods are very different, and the washing and drying equipment of the European standard usually treats the fabrics more intensively than those of the American standard. European and American customers also have different requirements for shrinkage washing procedures. European customers generally test shrinkage after one wash, while American customers usually measure shrinkage after three washes. In addition, different fibre components or different garments have different washing methods and specifications.

II. Comparison of testing methods for the rate of washing dimensions change of textiles

1. Overview

Among the many testing items of textile quality, the rate of dimensional change is an extremely important one, and the standards and testing methods for evaluating the rate of dimensional change of textiles in different countries and regions have some differences.

At present, the main international test methods for dimensional change are:

- ISO 5077:2007 “Textiles -Determination of dimensional change in washing and drying”

- ISO 6330:2000 “Textiles-Domestic washing and drying procedures for textile testing”,

- EN 25077- 1993 “Determination of dimensional changes in washing and drying of textiles”

- AATCC 135-2004 “Dimensional Changes of Fabrics after Home Laundering”

- JISL 1909-2005 “Textiles-Determination of dimensional change”

- JIS L0217-1995 “Methods of Test Handling of Fibre Samples and Related Marking Indications”

- GB/T 8630-2002 “Determination of dimensional change in washing and drying”

- GB/T 8629-2001 “Domestic washing and drying procedures for textile testing”

The following is a comparative experimental study of each test method.

2. Comparison of methods for testing the rate of washing dimensions change of textiles

The specimen is subjected to moisture equilibrium under specified temperature and humidity conditions. The front side of the specimen is marked with several groups of marks in the warp and weft directions without elution, and the distance between the marks is measured accurately and recorded (called initial size); the marked specimen is washed and dried. In the specified temperature and humidity conditions adjust the moisture balance, and again accurately measure the distance between the marks and record, calculate the rate of change in the size of the specimen.

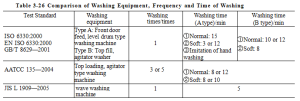

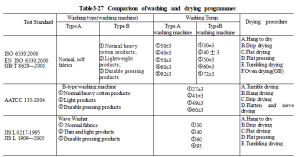

Table 3-26 and Table 3-27 compare the test methods and equipment of the standards and show the differences between the standards.

- Washing equipment

China’s national standard GB is the same as the international standard ISO and European standard EN, and there are two types of washing equipment to choose from, and more A-type washing machines are used; the American AATCC and Japanese JIS standards have only one type of washing machine, and Japan adopts the wave wheel washing machine.

The friction generated during washing is different for different washing machines. Due to the mechanical force of the wave wheel, the wave wheel washing machine in the washing of fabric winding phenomenon is more serious, the fabric and the water flow, drum wall friction and wringing friction are greater, but the washability is higher. A-type washing machine in the fabric and water flow, barrel wall and falling friction is small, with cold water washing low wash; and B-type washing machine in the work of the fabric and water flow, the bottom of the barrel and the barrel wall rubbing each other, the friction is more moderate.

- Washing time and frequency

The washing time stipulated in the AATCC standard is shorter than that of GB, ISO and EN, and obviously longer than that of the JIS standard; in terms of the number of washing times, the washing time is shorter than that of the JIS standard. The washing time specified in the AATCC standard is shorter than that of GB, ISO and EN, and significantly longer than that of the JIS standard, while the number of washing times is more than that of GB, ISO, EN and JIS.

- Washing procedure

GB, JIS and EN standard washing procedures are cited in ISO 6330 standard, the AATCC washing procedure is different from the ISO 6330 standard. The difference in washing type and temperature between ISO A-type and B-type washing machines is relatively large, while the difference in washing temperature between B-type washing machines and A-type washing machines is relatively large. The difference in wash type and wash temperature between the A and B models used by ISO is significant, whereas the B model and the AATCC wash temperatures are similar. Although differences in wash loads and detergent types and drying procedures do not affect fabric size and drying procedures are not the main factors influencing the rate of dimensional change of fabrics, the combination of these factors may change the results and the requirements for the wash loads should not be ignored.

3. Experimental comparison and analysis

Guo Chuanchuan et al. tested 21 common fabric samples (the samples were provided by some garment fabric factories in Shanghai and Changzhou) according to the standard method and analysed these data with mathematical and statistical software, and the results are described below.

1 Relationship between AATCC and GB dimensional change rate test standard

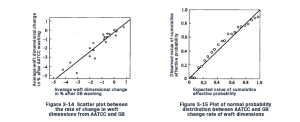

The test data were analysed by scatter plot and regression analysis, and the results are as follows.

① Weft direction relationship

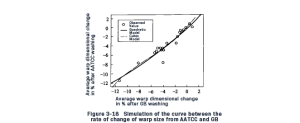

From Fig. 3-14, it can be seen that AATCC has a linear relationship with GB. The results of linear regression analyses show that AATCC and GB have a linear relationship.

Pearson’s correlation coefficient between AATCC and GB was 0.937, and the relationship between the two variables was very significant (P=0.0).

The relationship between AATCC and GB is very significant (P=0.000); according to the F-test value of 136.6 in the ANOVA table, and the Sig. 6, and Sig.=0.000<0.001, the relationship between the two variables is significant (P=0.000).

0.001, combined with the coefficient of determination R-squared value of 0.878, it can be seen that this regression equation is more significant.

As can be seen in Figure 3-15, these scatter points approximate a straight line. The resulting one-way linear regression equation is:

y=1.071x

where y denotes the rate of change in the weft dimension after the third washing of AATCC; x denotes the rate of change in the weft dimension after the washing of GB.

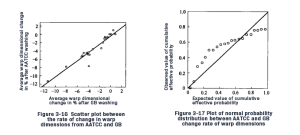

②Warp direction relationship

From Figure 3-16, it can be seen that there is an approximately linear relationship between the values of the warp dimension change rate, which was analysed by one-dimensional linear regression. However, according to the P-P normal regression plot (Figure 3-17), the actual values are not quite as linear as the expected values, which means that the linear relationship is not very satisfactory. In order to obtain a more satisfactory regression analysis, quadratic and cubic model regressions were performed (Figure 3-18).

Based on Figure 3-18 and the results of the regression analysis, it can be seen that both the quadratic and cubic models have a better regression relationship, but the regression equations of the quadratic and cubic models are not significant except for the primary term, which is significant. Therefore, the univariate linear model is used, i.e:

y=0.994x

where y denotes the rate of change in the meridional dimension after the third washing of AATCC; x denotes the rate of change in meridional dimension after the washing of GB.

2 Relationship between JIS and GB dimensional change rate test standards

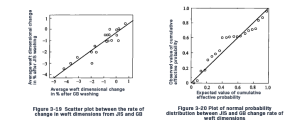

According to the method of (1), the scatter plot and regression analysis of the test data of JIS and GB standards are made, and the results are as follows:

① Warp direction relationship

From Fig. 3-19, it is known that there is a linear relationship between the dimensional change rate in the latitudinal direction according to the JIS and GB standards respectively. From the results of linear regression analysis, it can be seen that the Pearson correlation coefficient between JIS and GB is 0.925, and the relationship between the two variables is very significant (P=0.925).

The Pearson correlation coefficient between JIS and GB is 0.925, and the relationship between the two variables is very significant (P=0.000), according to the F-test value of 112.5 in the ANOVA table. 5, and Sig.=0.000<0.001.

According to the F-test value of 112.5 and Sig.=0.000<0.001 in the ANOVA table, and the coefficient of determination R-squared value is 0.856, the regression equation is significant.

As can be seen from the normal distribution plot in Figure 3- 20, with the exception of individual values, these scatters are approximately straight lines, and the linear regression equation is:

y=0.797x

The linear regression equation is y=0.797x, where y represents the rate of change of the weft dimension after JIS washing; x represents the rate of change of the weft dimension after GB washing.

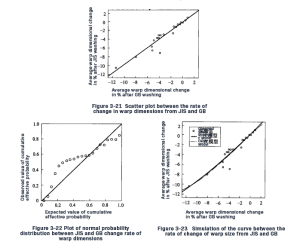

② Warp direction relationship

From Figure 3-21, it can be seen that there is a linear relationship between the values of the warp dimension change rate, which is analysed by one-dimensional linear regression. However, according to the P-P normal regression (Fig. 3-22), the actual values deviate from the expected values to a certain extent, which means that the linear relationship is not satisfactory.

However, according to the P-P normal regression (Figure 3-22), the actual values deviate from the expected values in the linear relationship, which means that the linear relationship is not satisfactory. This led to a quadratic and cubic model regression, which is shown in Figure 3-23.

From Figure 3-23, it can be seen that the regression relationship of both quadratic and cubic models is better, but the regression coefficients of both quadratic and cubic models are not significant. So the univariate linear model is chosen, i.e:

y=0.974x

Where y denotes the rate of change in transverse dimensions after washing of JIS; x denotes the rate of change in transverse dimensions after washing of GB.

4. Summary

The dimensional change rate of washed fabrics in China is more consistent with that of the United States and Japan in the weft direction and warp direction with the univariate linear model. By comparing the standards and analysing the test results, it can be concluded that the US standard is the most strict in terms of dimensional change rate, the Chinese and EU standards are closer, and the Japanese standard is relatively more lenient.

III. Textile Washing Dimension Change Rate Test

(I) Study on the correlation between washing time and the measured value of the rate of textile dimensional change

- Experimental results and analysis

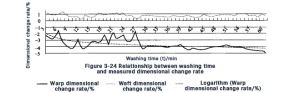

Wang et al. obtained the results from the middle part of the same cotton-dyed fabric (108/in×56/in, 20 inch×20 inch) (1in=0.0254m) which had a relatively consistent size change.

) (1in=0.0254m) from the middle part of the same piece of cotton dyed fabric (108/in×56/in,20in×20in) with relatively consistent dimensional changes (1in=0.0254m), 116 randomly selected 50cm×50cm specimens were tested by using YG701A fabric

Shrinkage rate machine, in different washing times, other conditions are consistent with the case (accompanied by the weight of the material 2kg, standard detergent 20g)

The specific procedures are as follows: water inlet (10cm) → warming up (60℃) → washing (t=3~60min) → water discharge → water inlet (13cm) → washing(12min) → draining → dehydration (6min).

The results of the tests carried out under the above experimental conditions are shown in Fig. 3-24, from which it is clear that the size of the measured rate of change in the measured dimensions of the fabrics is highly dependent on the washing time.

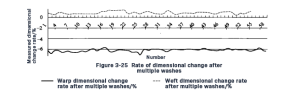

Although the tested fabric is randomly turned in the machine and subjected to rotational force, impact force, friction force, clamping force and gravity force, the total force on the tested fabric is different due to the difference in the clamping of the tested fabric by the accompanying fabrics and the state of the tested fabric in the machine. Generally speaking, for a short washing time, the randomly applied forces are more varied and the values obtained from each test are more different; for a long washing time, the values obtained from each test are less varied; when the washing time is long enough, the values of the rate of dimensional change tend to stabilise. When the washing time is longer than 30 minutes, the size change rate can be measured in a less discrete way. Since the standard GB 8629-88 stipulates that the evaluation time of washing rate is 12min, and the washing process in the warming programme is calculated as an average of 10min (since the washing in the warming programme is carried out in a gentle manner, in practice, the washing in the warming programme for 10min cannot reach the washing power of the washing programme for 10min, so let’s calculate it this way first), the washing power of the warming programme for 10min cannot reach the washing power of the washing programme for 10min, so let’s calculate it this way first). In practice, a 10-minute wash in the warming programme does not reach the 10-min washing power of the washing programme, so let’s calculate it this way), but only 24 minutes at most, which is the time when the dimensional change of the fabrics is unstable, so the measured rate of dimensional change varies greatly. After several washes, the measured rate of dimensional change is shown in Figure 3-25.

As can be seen from Fig. 3-25, after the test specimen has been washed several times, the measured rate of dimensional change reaches a relatively stable value, which can also be regarded as the true value of the fabric under test. At this point, even if the washing time is increased, due to the measured fabric in the weaving and dyeing and finishing process of the deformation of the various forces have been released, the measured fabric size change rate will not change again. The rate of dimensional change in many of the ASTM textile standards for apparel textiles is the rate of dimensional change after 5 washes as the rate of dimensional change of the fabric under test.

- Summary

The washing time affects the measured value of the rate of dimensional change of fabrics, and the long washing time will result in a small degree of dispersion of the measured value, while the short washing time will result in a large degree of dispersion of the measured value. In the use of the GB 8629-88 method, increase the number of washing provisions, as the size change rate requirements of higher products, the determination of the size change rate of the conditions, can be specified as 5 times the size change rate of washing; the size change rate requirements of general products can be specified 3 times the rate of change of the size of the washing; the rate of change of the size of the product is very small can be specified 1 times the rate of change of the size of the washing. For products with a small rate of change in size, the rate of change can be specified for one wash. Only in this way can the standards formulated be consistent with the actual situation of the products themselves, and also be consistent with the actual situation of the products themselves. Only in this way can the standards be formulated not only in line with the actual situation of the products themselves but also to make the data obtained from the measurement representative and comparable.

(II) The effect of washing conditions on the rate of dimensional change of woven fabrics in the wash

Chen Dongwang studied the effect of washing conditions on the rate of change of washing size of woven fabrics with reference to AATCC 135, and the results were as follows.

① Under home washing conditions, the effect of washing time on the rate of dimensional change of fabrics showed that the rate of dimensional change of fabrics tended to stabilise when the washing time was more than 30 min. The effect of washing time on the rate of change of fabric dimensions under home washing conditions was that the rate of change of fabric dimensions stabilised when the washing time was longer than 30 minutes.

② The effect of water temperature on the rate of dimensional change of fabrics during washing is that the rate of dimensional change of fabrics increases as the water temperature increases. The rate of change in fabric size is slightly higher when detergent is used, but the effect is not significant.

③ The effect of equilibrium time before and after washing on the rate of dimensional change of fabrics is that the rate of dimensional change of un-equilibrated fabrics is slightly greater than the rate of dimensional change of equilibrated fabrics.

(III) Influence of shrinkage machine and its test method on fabric shrinkage rate

- Influence of Shrinking Machine Structure on Fabric Shrinkage Rate

The washing principle of the YG701 shrinking machine is to use the three rounded convex bars (lifting wings) on the inner wall of the washing cylinder to drive the specimen and the accompanying cloth, so that the specimen and the accompanying cloth roll at a certain height without external pressure. Its rinsing action is positive rotation 12s→stop 3s→reverse rotation 12s→stop 3s, so that the specimen is not easy to be entangled, and not wrinkled, so that the fabric deformation is reduced accordingly, and the value of shrinkage rate is reduced.

The washing principle of the M988 type shrinkage machine is to use the stirring wheel on the inside of the box to rotate and drive the water and specimen to rotate, and the direction of rotation of the stirring wheel does not change, so that the specimen is very easy to entangle with each other, which makes the specimen to produce deformation and affects the shrinkage rate.

② YG701 type shrinkage machine is a horizontal drum type, the wings are evenly distributed, when it is running, the specimen force is uniform, and it is not easy to produce deformation so that the shrinkage rate is reduced. M988 type shrinkage machine its blades on the side wall, when it rotates, the fabric force is not uniform, deformation, and affecting the shrinkage rate.

③ YG701 type shrinkage machine washing rate is small, 53r/min, in the shrinkage test, the specimen subjected to external force is small, the fabric deformation is small, and the shrinkage rate is also small. The washing rate of M988 type fabric shrinkage machine is big, 500r/min, and the specimen is subjected to big external force and deformation in shrinkage test, which affects the shrinkage rate. 2.

- The influence of test method on shrinkage rate

( 1 ) with YG701 type fabric shrinkage machine to do shrinkage test method when the sample weight is not more than 210g (not calculated in pieces), the rest of the test cloth (polyester fabric, double size 30cm × 30cm), plus 5g sodium perborate, 18g low-foam laundry detergent. The sample is placed flat in the washing drum separated by the test cloth, heated to (40±3)℃, and then washed for 12min, and the water is discharged. Rinse 4 times, and finally shake for 6min, and take out for drying.

( 2 ) M988 type fabric shrinkage machine to do shrinkage test method ( bath ratio 1:50 ) will be clean water into the box to the prescribed mark and heated to ( 45 ± 2 ) ℃. The specimen (weight is not enough, can be added to accompany the test cloth to 800g, accompanied by the test cloth with a square, generally used about 60cm) immersed in the water tank. Turn on the motor so that the specimen and accompanying test cloth with the solution rotary turning. 30min later, the specimen with both hands out of immersion in cold water, in the dehydrator dehydration, dehydration specimen moisture content of (50 ± 10)%.

(3) Analysis of two specimen methods

① With YG701 type fabric shrinkage machine to do shrinkage test, the specimen is separated by the accompanying test cloth, so that the fabrics are not easy to contact each other entangled, and the accompanying test cloth size is small (30cm × 30cm), the fabric is polyester, the friction is correspondingly smaller than the cotton, so it is not easy to accompany the test cloth and the fabric is not easy to occur between the entanglement so that the fabric deformation is small. With the M988 type fabric shrinkage machine to do shrinkage test, in addition to the fabrics being entangled with each other, and with the test cloth being larger, the test cloth and the sample are also entangled with each other, so that the sample is easy to produce deformation, thus affecting the shrinkage rate.

② YG701 type fabric shrinkage machine shrinkage test, the final moisture content of the specimen is generally greater than 80% (daily empirical data), while the M988 type fabric shrinkage machine to do the test, the cotton fabric moisture content of the provisions of the (50 ± 10)%. The moisture content is large, the gravity when drying is large, and the direct shrinkage value will be low, therefore, the test method is different, which also has an impact on the shrinkage rate.

③ Verification experiment. Ten different fabrics are tested according to the above-mentioned methods, and it is found that the same fabrics in different shrinkage machines with different test methods will have lower shrinkage values. It is found that in the same fabric in different shrinkage machines with different test methods for shrinkage test, the shrinkage value has a certain difference, the results are in line with the law described above.

IV Drying method of cotton knitted underwear tops shrinkage test impact

In the daily inspection work, often encountered cotton knitted underwear’s straight shrinkage rate is large, while the lateral shrinkage rate is small or even upside down. When this situation occurs, the inspected unit will often question the test results.

GB/T 8878-1997 standard in the drying item is to use the hanging drying method. That is to say, the blouse is put through the sleeves with a pole, so that the bust and the hanging shoulders are kept straight, and the two pieces are separated and levelled by hand from the lower end. The trousers are folded in half and hung to dry, so that the transverse part is on the drying pole, and gently flattened. After drying, the specimen is spread out on the platform, and the creases are gently tapped and measured. However, undergarment tops come in many different styles and are becoming more and more like outerwear. There are many different styles, including tank tops, short-sleeved shirts, and long-sleeved shirts, due to changes in collars and sleeves. In these styles, the most commonly encountered is the phenomenon of cotton wool long-sleeved shirt shrinkage rate straight large, small horizontal or even upside down. Jiang Shaohua and others after many tests that the drying method has a great impact on this.

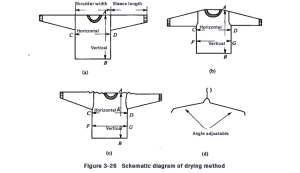

Theoretically, if a long-sleeved shirt is flattened out as shown in Figure 3-26(a): the sleeve length and shoulder width are at the same level, and the body length is perpendicular to the body length, that is to say when drying according to the test method of GB/T 8878-1997, the straight body length AB of the long-sleeved shirt will be subjected to the natural gravity of the underwear sagging only, and will not be subjected to any external force, and the transverse chest width CD will only be subjected to the natural gravity of the underwear sagging only. The lateral chest width CD is also subjected only to the natural gravity of the undergarment’s sagging without any other external force. In this way, the whole piece of underwear in the process of drying the front and back of the body, the force is uniform, shrinkage is uniform, and the test results will be true and objective. However, the majority of long-sleeved shirts are not as shown in Figure 3-26(a), but are cut and sewn to fit a person’s body, as shown in Figure 3-26(b). The sleeve length and shoulder width are not horizontal but are slanted downward on the left and right sides, and the slope of the sleeve length and shoulder width are different. When the rod is passed between the sleeves during drying, the sleeves and shoulders are horizontal and the ends of the sleeves and shoulders are lifted up [Figure 3-26(c)]. Determine the markings A and B in the straight direction, and C and D in the horizontal direction. Also mark E at the intersection of AB and CD, and F and G at the point where CD meets 1/2 of the bottom edge. Measure the lengths of AB, AE, EB, CD, and FG before and after the reduction, and calculate the lengths of each separately.

The lengths of AB, AE, EB, CD and FG were measured before and after shrinkage respectively, and the shrinkage rates were calculated. The experimental data are: the shrinkage rate is 4.2% straight to AB at the standard measurement position, and 5.7% straight to AE at the top half, which is higher than the shrinkage rate of AB. 7 per cent, which is 1.5 per cent greater than the shrinkage rate of AB; the lower half of the straight EB shrinks by 3.1 per cent, which is 1.5 per cent greater than the shrinkage rate of AB. EB in the lower half is 3.1 per cent, which is 1.1 per cent smaller than the shrinkage rate of AB. The transverse standard specifies a 1.0 per cent shrinkage at measurement position CD, whereas the new measurement position FG has a shrinkage of 2.7 per cent, which is 1.1 per cent smaller than that of CD. The shrinkage rate of the new measurement position FG is 2.7%, which is 1.6% larger than that of CD. The test shows that the drying method in GB/T 8878-1997 has an influence on the shrinkage test results of cotton knitted underwear, which cannot reflect the shrinkage rate of cotton knitted underwear objectively, resulting in large direct shrinkage and small transverse shrinkage of some products.

In order to reflect the shrinkage rate of cotton knitted underwear more realistically, the factors affecting the shrinkage rate should be avoided or reduced as much as possible, which means that the whole top, especially the measuring part of the top, should not be affected by any external force, and it should be more similar to the drying method of people in their daily life. Therefore, it is suggested that the drying method of cotton knitted underwear tops should adopt the hanging rack hanging drying method. That is to say, design a hanger, the shape is similar to the daily use of the hanger, the shoulder is not horizontal, but similar to the human body’s shoulders, down a certain degree of inclination, can also be made into a slant adjustable shape [as shown in Figure 3-26 (d)]. Of course, depending on the shoulder width of the underwear, you can make a set of 3 to 5 hangers of different sizes.

(V) Research on Shrinkage Test Methods for Thin Cotton and Viscose Cotton Denim Fabrics

- Overview

FZ/T 13001-93 “Colour Woven Denim” standard specifies its scope of application and makes specific provisions for the testing methods of relevant quality indicators. For example, to determine the rate of dimensional change after washing, the standard stipulates that it should be carried out according to GB 8632, in which the washing can be carried out by rotary drum washing machine, and GB 8629 horizontal rotary drum front-loading washing machine can also be used. Ironing can be done with a flat ironing machine or oven drying. Due to the difference between the two test instruments, the test results are also different.

- Experimental Results and Analysis

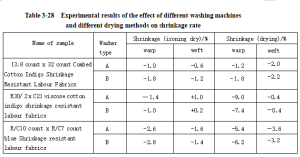

Li-Min He et al. tested and compared three kinds of thin cotton and viscose cotton denim samples with reference to FZ/T 13001-93, and the results are as follows.

The results are as follows.

① Test results

In order to explore the influence of different washing machines and different drying methods on the degree of shrinkage, each specimen was cut into four pieces, two of which were washed in a drum washing machine, then one piece was ironed in a flatbed ironing machine, and one piece was dried in an oven. The other two specimens were washed in a drum-type front-loading washing machine and dried in the same way as before. The results are shown in Table 3-28.

② Analysis of test results

From the test results, thin cotton denim, the drying method on the shrinkage rate of the influence of the warp direction is small, and the influence of the weft direction is larger. For viscose cotton shrinkage, the drying method is different, and the degree of influence is greater. This is due to the oven drying, the fabric spread in the oven on the wire mesh, without exerting any external force, stress relaxation is more complete, so the shrinkage rate is larger, and in the ironing machine ironing dry, the fabric drying process there is an external force on the fabric, the fabric has a stereotypical role, the existence of the fabric in the relaxation of internal stress is incomplete, so shrinkage rate to be smaller. From the structural properties of the fibre, because the structure of viscose fibre than cotton fibre is loose, its moisture absorption capacity is also larger than cotton fibre, and shrinkage in the heat conditions is also large. At this time, the ironing machine on the fabric exerts a certain pressure, and the fabric shrinkage is limited, so the shrinkage rate is relatively small. The situation is different in oven drying, where the fabric is dried under complete relaxation, and its shrinkage is more complete, so its shrinkage rate is also larger. Looking at the washing method of the washing machine, the drum washing machine is steam-heated and has a fast heating rate, reaching the specified temperature in two minutes. The drum-type front-loading washing machine adopts electric heating, the heating rate is slow, and it takes 30min or even longer to reach the specified temperature, so the fabric soaking and wetting time is longer than that of the former. Due to the strong moisture-absorbing ability of the viscose, it is saturated very quickly, so the impact of the washing machine is relatively small; and cotton fabrics, due to the drum washing machine than the front loading washing machine heating time is shorter than that of the relative washing process is also shorter, the fibre may not be saturated during the process, therefore, the relaxation of the internal stresses is also incomplete. So for the cotton fibre shrinkage rate, the impact of the type of washing machine is greater, in the use of a drum washing machine, and flat ironing machine way to determine the net shrinkage rate of fabrics, the same specimen is often to be repeatedly washed and ironed a number of times in order to measure.

③ Summary

The shrinkage rate of thin cotton and viscose cotton denim is not only related to fibre properties but also has a great relationship with the type of washing machine and drying method in the test method. Therefore, special attention should be paid to the actual test, try to use the same testing equipment, uniform operating practices, in order to reduce the error to a minimum, in order to ensure that the test results are accurate and uniform.

(VI) Washing procedure for testing the dimensional change of hemp and its blended products

Textile washing size change rate is one of the important quality indicators of the finished cloth, in 1988, the National Bureau of Standards issued GB/T 8629-1988 “textile test using the home washing and drying procedures” method standard. There are 10 kinds of washing procedures stipulated in this method, and many product standards on the determination of the rate of dimensional change are quoted from this standard. However, some hemp and its blended products do not have product standards, and some hemp and its blended products have product standards, but they do not stipulate the washing procedures for the rate of dimensional change.

Through a lot of experiments, Liuyan has come up with the following washing procedure suitable for the test of dimensional change rate of hemp and its blended products.

2A Washing Programmes: Linen/Cotton Colour Woven Fabric, Ramie Cotton Colour Woven Fabric, Linen/Cotton Dyed Fabric, Ramie Cotton Dyed Fabric.

② 5A Washing Program: Linen Colour Woven Fabric, Ramie Colour Woven Fabric, Linen Dyed Fabric, Ramie Dyed Fabric, Linen Viscose Dyed Fabric, Ramie Viscose Dyed Fabric.

(VII) Problems and Improvements in the Rate of Dimensional Change in Clothing Product Standards

1. Problems

Western-style trousers, children’s clothing, dresses, mackintoshes and other standards in the rate of change of size items usually have the following problems.

① The assessment part is not comprehensive

GB/T 2666-2001 “men’s and women’s trousers” Although the scope of application of the standard includes tweed skirts, the rate of change of dimensions of the finished product after dry-cleaning only provides for the rate of change of the dimensions of the trouser length and waist circumference of the two parts of the size of the skirt length part of the lack of the rate of change of the dimensions of the skirt length part of the dimensions of the change of the rate of change of the size of the trouser length. In FZ/T81003-2001 “children’s clothing, student clothing” standard only provides the collar, bust, and length of the size change rate, but the lack of waist, trouser length, skirt length and other parts of the size change rate of the provisions.

② Unreasonable assessment items

FZ/T 81003-2003 “Children’s Clothing, Student Clothing” standards for all the main parts of the finished product are dry cleaning and washing size change rate assessment. Because the garment manufacturers according to the characteristics of different clothing materials, in the washing instructions choose a different method of clothing maintenance, the above standard for non-washable products for finished products after washing size change rate assessment or for non-dry-cleaning products for finished products after dry-cleaning size change rate assessment, is obviously not appropriate. Similarly, although it is stipulated in FZ/T 81004-2003 “Dresses and Skirt Sets” and FZ/T 81007-2003 “Single and Clip Clothing” that the rate of dimensional change of the finished products after dry-cleaning shall only be assessed for the dry-cleanable products as labelled in the instructions for use, there is no stipulation that the rate of dimensional change of the washed products shall only be assessed for the products labelled as dry-cleanable products as labelled in the instructions for use. However, there is no provision for the rate of dimensional change after washing to be assessed only for products labelled as washable in the instructions for use. In this way, even for non-washable products, a washing test should be conducted to assess the rate of dimensional change after washing. On the other hand, in FZ/T 81010-2001 “Wind and Rain Coat”, only the rate of dimensional change after dry cleaning is required to be assessed, and the rate of dimensional change after dry cleaning is also required to be assessed for non-dry-cleanable products. Although the standard stipulates that the rate of dimensional change of fabrics after washing should be assessed, it is difficult to obtain the fabrics for testing during the inspection of finished garments, which makes the stipulation ineffective.

③ Differences in assessment regulations

When assessing the rate of dimensional change in the clothing standards formulated or revised in recent years, the rate of dimensional change of finished products after washing and the rate of dimensional change of finished products after dry-cleaning are selectively assessed according to the labelled content of the instructions for use of the finished products, but there are some differences in the regulations of each standard. For example, GB/T 2662-2008 “Cotton Garments” and FZ/T 81008-2004 “Jacket” standards stipulate that the rate of dimensional change of finished products after washing is only assessed on washable products marked in the instructions for use, and the rate of dimensional change of finished products after dry cleaning is only assessed on dry-cleanable products marked in the instructions for use. In GB/T 18132-2008 Silk Garments and FZ/T 81015-2008 Wedding Dresses and Gowns, it is stipulated in the standard that the rate of dimensional change of the finished products after washing shall not be assessed for the products labelled as non-washable in the instructions for use, and the rate of dimensional change of the finished products after dry-cleaning shall not be assessed for the products labelled as non-dry-cleanable in the instructions for use. The rate of change in the size of the finished products after dry cleaning is not assessed for products marked as non-washable in the washing instructions. In this way, inconsistent assessment requirements may arise in the case of incomplete labelling of washing instructions for garments. If the washing method of a finished garment is not labelled as dry-cleanable in the instructions for use, the rate of change in the size of the finished product after dry-cleaning need not be assessed according to the former provision; if according to the latter provision, the rate of change in the size of the finished product after dry-cleaning needs to be assessed.

④ Not clear enough in test methods

GB/T 2660-2008 Shirts, GB/T 2662-2008 Cotton Clothing, FZ/ T81004-2003 Dresses and Skirts, FZ/T 81007-2003 Single and Folder Clothing, FZ/T 81008-2004 The standards such as “Jacket” stipulate that the test method for the rate of dimensional change of the finished products after washing shall be in accordance with GB/T 8629, and the specific washing procedure shall be chosen in accordance with the washing method of the instructions for use or in accordance with the fibre properties of the samples, without any clear and uniform provisions, and the drying procedure is not stipulated accordingly. It is stipulated in these standards that the test method for the rate of dimensional change of the finished products after dry cleaning shall be in accordance with the provisions of FZ/T 80007.3. In FZ/T 80007.3-2006 “Test Methods for Dry Cleaning Resistance of Garments Using Fusible Interlining”, there are two kinds of operation procedures, namely, conventional dry cleaning and gentle dry cleaning, and the product standard does not specify which procedure should be chosen. The choice of different procedures may cause inconsistencies in the test results.FZ/T 81015-2008 “Wedding dresses and gowns” lacks a test method for the rate of dimensional change of the finished product after dry cleaning. FZ/T 81003-2001 “Children’s Clothing, Student’s Clothing” does not specify the number of samples to be tested in the test method for the rate of dimensional change in washing.

⑤ Calculation method and processing of results

GB/T 2662-2008 Cotton Garments, FZ/T 81004-2003 Dresses and Skirts, FZ/T 81007-2003 Single and Clip Garments, FZ/T 81016-2007 Denim Garments and other standards stipulate that the test method for the rate of dimensional change of finished products after washing is in accordance with GB/T 8629, and the results are taken as the average of the three pieces. FZ/T 81004-2003 “Dresses and skirts”, FZ/T 81007-2003 “Single and folder garments”, FZ/T 81016-2007 “Denim garments” and other standards stipulate that the test method of the rate of dimensional change of the finished products after washing is in accordance with the provisions of GB/T 8629, and the test is conducted by randomly sampling 3 samples, and the results are taken as the average of the 3 samples, and the contents of the calculation method and the modification of the average are missing. When both qualified and unqualified results appear in three samples, there is no corresponding provision on how to make a comprehensive judgement.

2. Improvement

Aiming at the above problems in the detection of the rate of change of clothing size, the following improvement methods are proposed.

① In GB/T 2666-2001 “men’s and women’s trousers”, FZ/T 81003-2001 “children’s clothing, student clothing” standard to increase the relevant parts of the rate of change of dimensions of the assessment requirements.

② suggested that according to the washing method specified in the instructions for the use of finished products determine whether to assess the rate of change in the size of finished products after washing and the rate of change in the size of finished products after dry cleaning. For products with no washing method or incomplete and unclear labelling of the washing method, the rate of dimensional change of the finished product after washing shall be assessed.

③ When conducting the test on the rate of dimensional change after washing, increase the number of test samples in the test method, specify the washing procedure and drying procedure, refer to the washing method specified in the instruction for use of the products, and choose the most suitable test conditions in GB/T 8629-2001 “Home Washing and Drying Procedures for Textile Tests”. For products with no washing method or incomplete washing method, the specific washing and drying procedures shall be specified in the test method of the product standard. When conducting the test on the rate of dimensional change in dry cleaning, select the operation procedures of regular dry cleaning or gentle dry cleaning in FZ/T 80007.3-2006 “Test Methods for Resistance to Dry Cleaning of Clothing with Bonded Interlining” according to the regular dry cleaning or gentle dry cleaning in the professional maintenance of the washing method specified.

④ It is suggested to add the processing method of calculating the result according to GB/T 8630-2002 “Determination of dimensional change of textiles after washing and drying”, and to add other contents for judgement of non-conformity.

(VIII) The effect of sampling garment fabric shrinkage on the specifications of washed garments

- Overview

The shrinkage rate of textiles is based on the samples taken by the shrinkage test, so the washing of clothing fabrics sampling method directly affects the results of the shrinkage rate, and the shrinkage rate affects the development of garment samples, thereby affecting the specifications of the garment after washing. After the analysis of some washed clothing specifications failed batch, the main problem affecting the development of washed clothing samples is that the garment factory used to do the shrinkage rate of the small samples taken by the test does not meet the standard requirements. Garment factories generally take small samples of fabrics to the washing machine of the washing factory to do the shrinkage test, and some garment factories take samples of fabrics to be made into garments and then put them into the washing machine to do the shrinkage test, so as to achieve the colour, hand feel and softness required by the customers. As the technicians in garment factories are all professionals in garment design and sampling, and very few people know how to test the intrinsic quality of textiles, they often rely on their experience or old habits when sampling washed garment fabrics, and the sampling method varies from person to person, and from person to person.

- Problems with sampling

① Some technicians in garment factories do not understand the textile standards and do not do batch tests on garment fabrics. They think that the shrinkage rate of garment fabrics purchased from the same textile factory or printing and dyeing factory is the same, and the fabrics purchased in batches of the same species only need to do a shrinkage test in the first batch. Customers want goods tight, there are individual factories that only received a few metres of sample fabrics at the start of the sampling board, large quantities of clothing fabrics to the factory on the cut, and no longer large quantities of fabrics sampling shrinkage test. The washing samples used for making boards Fabrics and clothing fabrics used for washing sample shrinkage rate of the big shipments are not consistent, which may lead to the specifications of the washing of the whole batch of clothing unqualified.

② Some garment factory technicians take samples for the shrinkage rate test when the sampling method is not correct. More common is to tear a section of cloth from the head of the cloth to do the test. Under the action of external forces, the tension of the washing sample will change, and the tested shrinkage rate will be inaccurate.

③ The number of samples of garment fabrics does not conform to the provisions of the textile shrinkage test, and the samples of the fabrics imported for the production of large quantities are not complete. When a batch of apparel fabrics with more colours is not taken in all colours, it is difficult to control the specification of the shrinkage rate of the fabrics in the sampling of the colours that are not taken.

④ When a batch of clothing fabrics with few colours, the number of sampling blocks is too small to calculate the average value of the shrinkage rate, and the result of the shrinkage rate will be very accidental. The unrepresentative shrinkage rate will certainly affect the accuracy of the sample.

When the shrinkage rate of the same batch of fabrics varies greatly according to different colours, the technical department of the garment factory does not make the boards according to the actual shrinkage rate of various colours of fabrics, resulting in the specification of the garments after washing varies according to the colours, and there is always a part of garments with unqualified specification.

- Suggestions for garment factories to strengthen the sampling and testing of fabric shrinkage and improve the qualified rate of washed garments.

Garment factories should strengthen the technical management, improve the quality of the work of making boards, and the sampling method must be in accordance with the provisions of the textile testing standards when taking the samples for shrinkage test, and the precautions should be as follows.

(1) Establish and improve the inspection system for garment fabrics after they are imported into the factory. The fabrics of washed garments must be sampled batch by batch for shrinkage rate test after entering the factory. When a variety of continuous production, from the same fabric factory to the same variety of fabrics can not be taken lightly.

② Clothing shrinkage sampling must be cut with scissors, and not allowed to tear by hand.

③ It shall not be taken within 2m from the head of the fabric shrinkage sample, to prevent the head of the fabric tension from the unstable and affecting the results of the fabric shrinkage.

④ When the same batch of garment fabrics has several colours, we must take all of each colour to do the shrinkage test, and if there is only one colour, we should take at least 3 pieces of specimens to do the test and take the average value of their shrinkage as the reference basis of the specification in the board.

⑤ When the shrinkage rate of the same batch of fabrics differs greatly due to different colours, the boards should be made separately according to the size of the shrinkage rate, instead of using only one board for production. Only in this way can ensure that after washing, the size of various colours of clothing specifications are basically the same, in line with the requirements of the standard process.