Textile testing is the most important process in the textile industry to produce clothes and other things without any issues. Textile manufacturers highly prioritize textile testing to strengthen brand image and organizational reputation. It involves evaluating the chemical, mechanical, and physical properties of the garment. Today our topic is Textile Testing Industry Status and Trends.

The process often guarantees the clothes quality and safety and then manufactures, distributes, and sells in the market. Textile testing aims to determine the colorfastness, stability, strength, flammability, and shrinkage of clothes.

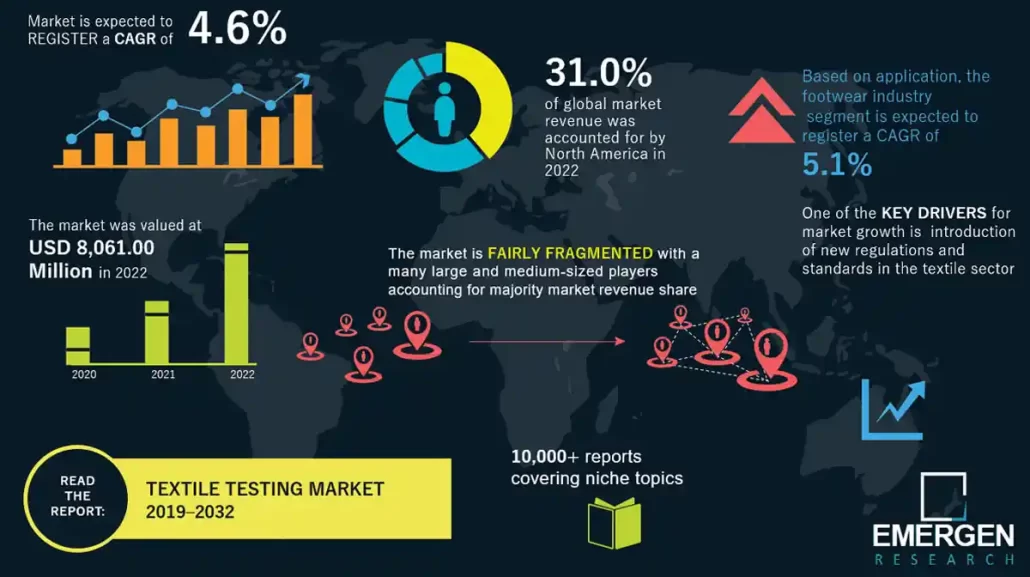

Textile Testing Industry Market Size

Textile testing market size can increase and grow between 2019 and 2025 for several reasons. Textile testing is an essential requirement for clothing production and lets the end product fulfill the necessary quality standard. Executing the strict regulatory requirement for clothes is the main element for increasing the textile testing market size.

Market size will also grow in the upcoming year because of the demand for textiles in different industries. The market is estimated to reach USD 11.02 billion in 2025. Various initiatives wish to promote sustainable and environmentally friendly clothes in the market. It denotes the growing demand for textile testing services in the future.

A key element for the textile testing market size growth is the demand for protecting wear and clothing, strict regulatory standards, and consumer awareness about textile safety and quality. In the present scenario, people often rely on high-performance, water-repellent, and flame-resistant clothes.

It is also a main part of fueling the market size. Apart from that, e-commerce and modern technologies like machine learning, artificial intelligence, and big data analytics give great chances for the textile testing market size growth.

The Hottest News or Topics about Textile Testing Industry in 2024

Textile business owners are often willing textile testing to ensure quality and safety. They focus latest news and topics about the testing.

AATCC introduces a manual of internal test methods and procedures:

It comes with four standards and provides updated textile testing methods and procedures. New standards make the textile industry stay with the advanced technology and reach stunning quality and testing control excellence. It contains two laboratory procedures and two test methods.

Test method for measuring condensation on textiles

AATCC committee developed a new standard determining the water condensation buildup in clothes back surfaces in humid microclimates with and without virtual precipitation on the outermost fabric. The outermost fabric surface can be subject to dry and wet conditions when testing. Condensation buildup can be decided by computing the mass change of filter paper present in the inner chamber for a given time. Such a testing method is ideal for the fabric or multi-layer fabric systems.

Test Method for Soil Release

The test method has a procedure to evaluate the clothes’ ability to release soil after washing. It denotes the staining grade of every common household soil about clothes, including ketchup, coffee, salad dressing, and others. It is effective for quantifying the fabric or complete performance that is exposed to regular stains.

Laboratory Procedure for Synthetic Soil

It serves as a good solution for the soil and stain assessment. Although synthetic soil is initiated from the carpet-relevant method, it may be used in other methods that need synthetic soil application.

Laboratory Procedure for Home Laundering

Such lab procedure grants process for the home laundering chlorine and non-chlorine bleach. It enables clothes to test for suitability with any type of bleach. Based on it, the manufacturer bears out bleach care instructions combined with different color change evaluations and stability testing.

British Textile Machinery Association Reveals Advanced Fibre Testing System:

British Textile Machinery Association launches powerful system for fiber and advanced material. The latest testing instrument makes the testing process smooth and intuitive. Airpro air permeability tester is effective for testing the resistance of airflow in kitted, woven, and non-woven clothes.

HydroView hydrostatic head tester is ideal for determining the penetration of water in the material. It has end use that needs water resistance in the medical, nonwovens, and geotextiles sectors. It is essential for testing high-end applications for technical clothes such as diving suits, winter sports garments, protective gloves, and a lot more.

England-based VeriVide Ltd. commences three new products:

England-based company introduces hot products like Visionview, Ultra View, and Omnistretch. These are clothes opacity assessment tools. Ultraview is suitable for brands, designers, and mills and manages LED tunable calibrated light sources.

VisionView tool includes a DigiEye viewing station for digital imaging and non-contact color measurement. It is helpful for the digital and visual color assessment by merging digital and visual color workflow.

Omnistretch is suitable for the stretch-based opacity assessment for knitted fabrics in different stretch levels. It contains two assessment plates that let to grade the transparency of clothes.

Technical Developments and Problems in the Textile Testing Industry in Recent Years

Software, quality control instruments, and test methods are important in textile testing. Textile testing plays a crucial role in the textile industry. Here, individuals understand technical development and problems in textile testing.

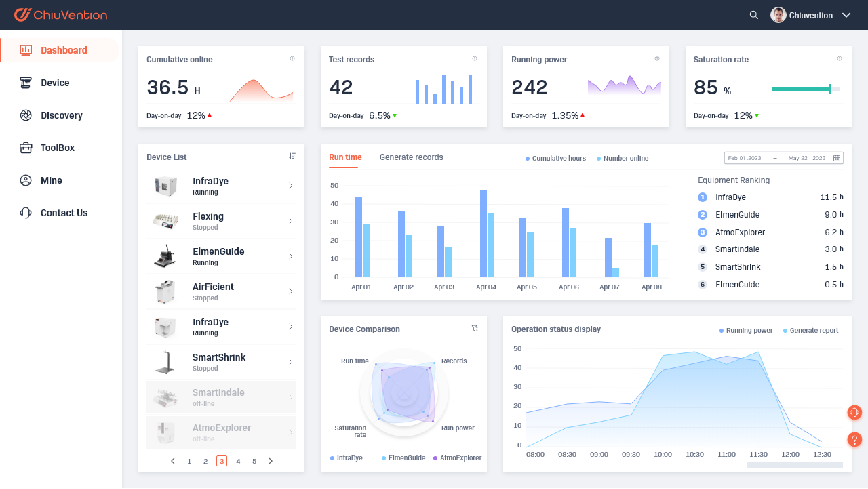

Lab management software

Accelerated Technology Laboratory Inc. proposes a lab information management system. The company partners with diverse industries, and trust software is ideal for the textile industry. It is a good choice for small and large-scale organizations.

It comes with attributes like master query functionality, smooth user interface, integrated calculation, scheduling, automated alerts, configurable caption, and reporting. These are customizable depending on consumer-specific requirements.

On the other hand, ATL also provides web portal solutions that aid the organization’s outside departments in acquiring key reports and data. It is a crucial thing for clothes manufacturers that manage decision-makers in diverse offices and plants.

On the other hand, some textile testing companies can provide intelligent testing solutions that combine instruments with software, so you can master the whole testing via digital ways, such as getting the test reports on your smartphone and sharing the benefit parties directly.

Odor control technology

AATCC is an important leader in launching different test methods. The main goal of this technology is to reduce odor in clothes without a quantifiable way to calculate odor elimination. With the help of technology, companies make true colors for antimicrobial garments. The sensitive test provides a visual and real-time depiction of clothes within forty-eight hours. Technology is also implemented by many labs worldwide.

Testing problems:

Retailers and brands need help with enhancing their textile testing capabilities. Incorporating the right test result is vital for a broad view of the quality of operation. Here are some of the issues in the textile testing.

Insufficient testing facilities

Garment testing facilities must strictly test the clothes as per desired specifications. AATCC develops colorfast test methods and standards. Diverse testing facilities across the globe have different equipment and techniques to carry out the test. Some facilities comply with requirements, and others need more equipment and tools to test the product.

Insufficient clothes testing facilities may make the product defective and low-quality dangerous to consumers. Whether the garment reaches the end consumer and is identified as being out of compliance, the outcome is disastrous.

Poor garment quality

Poor garments may be tight or loose in the construction, dense in weight, and low breaking. You can experience surface fuzz, high pilling, and coloration issues in the poor fabric. Clothes testing detaches problems in different ways.

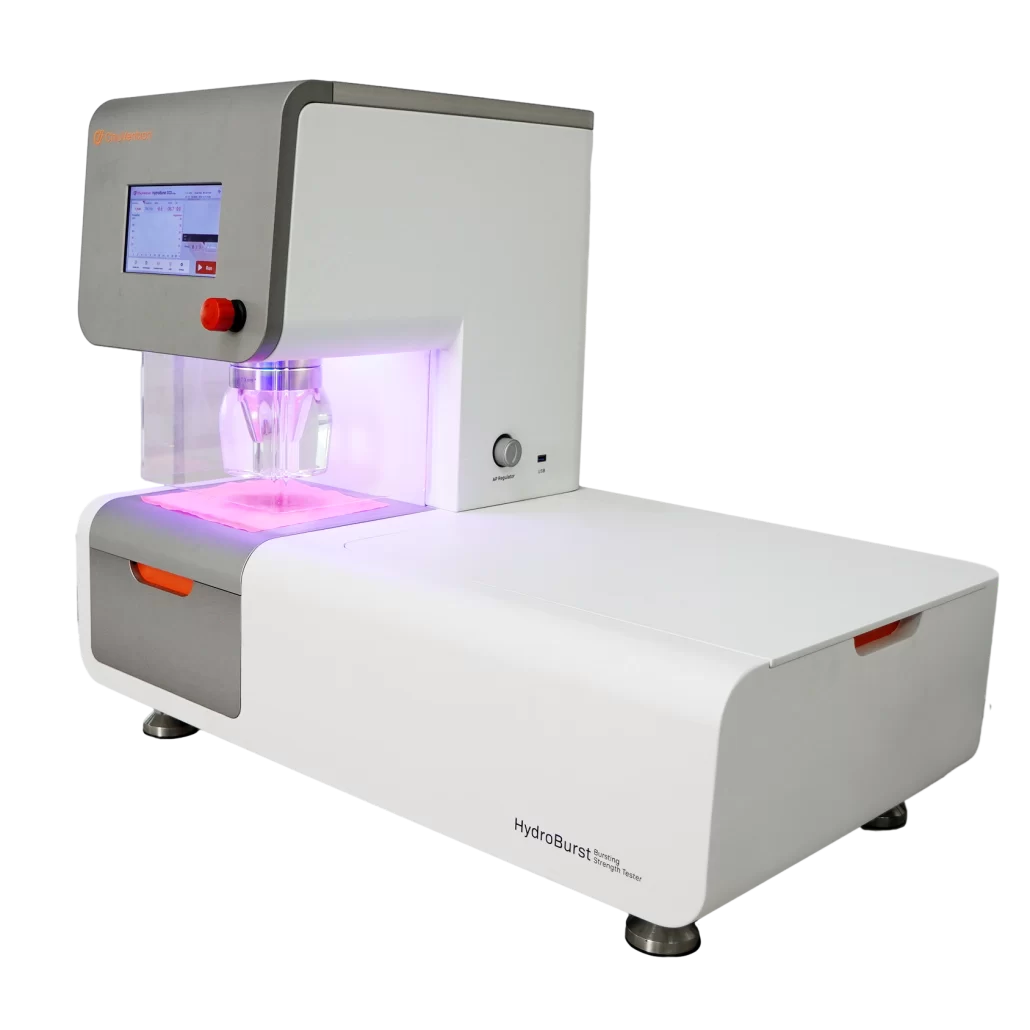

When it comes to strength tests, professionals focus on the garments to preset the stretching and determine elongation. The bursting strength test lets garments endure compression under a hydraulic press. It evaluates how much pressure they need before fibers break.

Abrasion resistance test reviews fabric durability from continuous abrasion as specific pressure and roughness. Colorfast tests verify how the clothes dye or coloration defies change after exposure to pollutants, UV radiation, chemicals, and sweat.

Lack of the qualified professional

The need for qualified professionals is a major problem in textile testing. If a clothes testing facility needs more skilled and qualified professionals to monitor activities, retailers and brands experience untrustworthy results.

Testing laboratories must have the quality technical equipment and processes to perform fabric examinations. It needs high skill, consistency, and honesty. Retailers, brands, and stakeholders need facilities to employ and examine trained employees.

What are the Unique Experiences of Apparel Giant Companies?

Testing is the main requirement in deciding clothes properties. Many textile giants extremely rely on testing and identifying flaws quickly in clothes. Textile testing is necessary to meet compliance with the changing regulations and laws. When it comes to textile testing, textile companies gain a unique experience.

Cater to regulatory and quality standards for the market.

Complete quality assurance solution aids textile giants very much in fulfilling the regulation and quality standards in the market. Testing is a good approach for textiles, including home textiles, curtains, carpeting, apparel, accessories, and upholstery. Textile manufacturers highly invest in testing services to guarantee that garments meet quality standards and requirements.

Mitigate risk for garment manufacturing:

Business owners mitigate risk in textile testing and quality management by following advanced regulations. Varying enforcement and modifying rules for diverse markets present compliance issues for manufacturers, retailers, and importers. With proper certification, inspection, and testing, textile companies mitigate risk. When working with the professional testing service, the company gains huge benefits, including.

- Choose the right test for the market

- Send lab test report

- Realize regulatory compliance

- Perform independent third-party testing

- Achieve recognized garment certification

- Develop action plan

Optimize garment production:

Textile companies leverage advanced technology tools to perform certain jobs, including material cutting and handling, to boost accuracy and precision. It is perfect for higher productivity and reduces error. It is the best way to gather and analyze the data from garment production to production schedules.

Manage quality and find defects:

Quality equipment and tools in the textile factories enhance the efficiency and accuracy of the quality control process. In real-time, it is a good approach to finding defects, including stains, holes, and uneven stitching. Textile industries benefit from a high degree of accuracy.

Keep track of inventory:

Textile manufacturers heavily need advanced tools to analyze sales data and guess future demand. Based on it, they make the right decision about the inventory level. It is a good asset to prevent stockout risk and overstocking. The latest technology helps the garment giants to the core and lets them find slow-moving items. With this, they perform changes to track the inventory and distribution strategy readily.

What are the New Demands of Apparel Brand Owners for Textile Testing?

Many apparel brand owners are increasingly using textile testing for different aspects. It is the best approach to guarantee safety, quality, and performance. Textile testing is a vital thing for garment quality and fulfills consumer expectations and compliance with the regulations. Some of the specific demands of apparel owners for textile testing are.

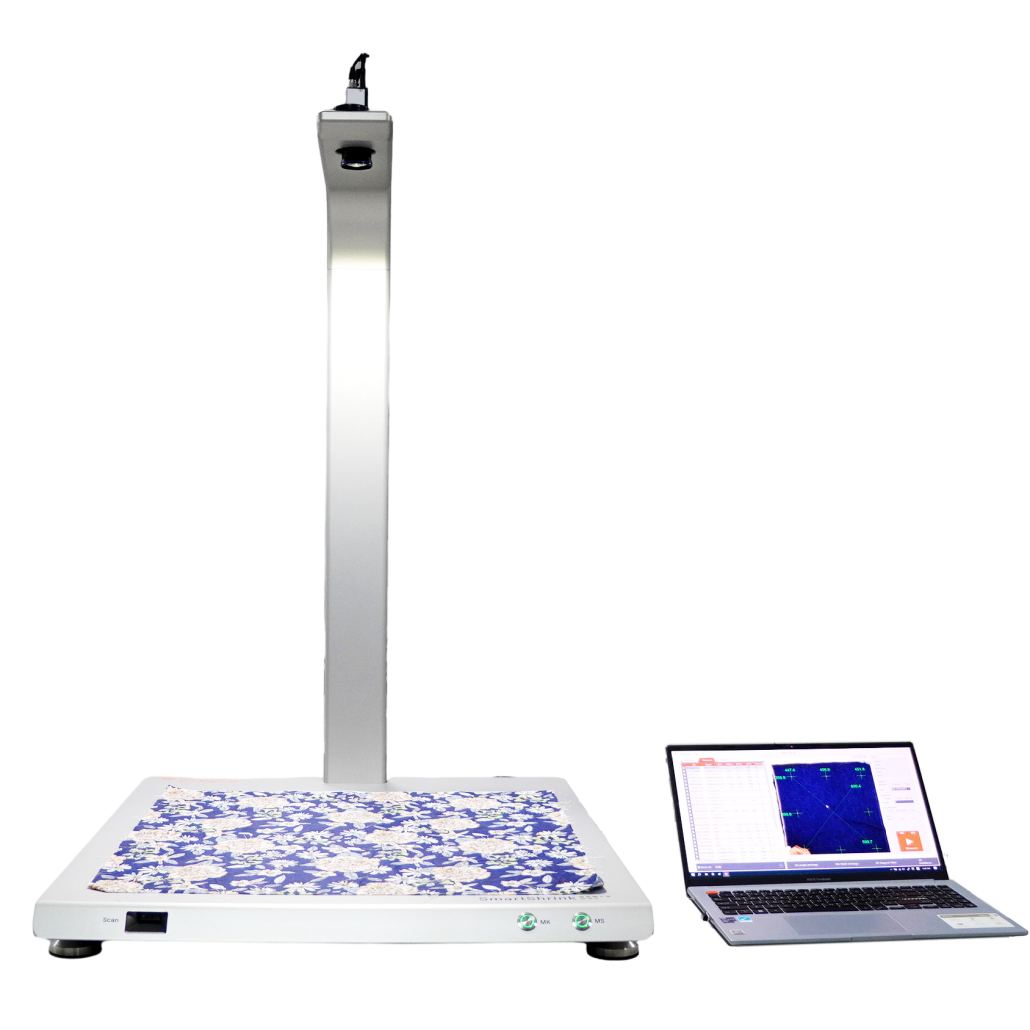

Yarn and fiber measurement:

Innovation in testing devices for yarn and fiber is essential for textile testing. A weak spot tester is ideal for spun yarn, and modular testing is effective for deciding the fiber quality parameters. Work safety is also a new demand for testing reinforcement. Textile is an electronic wrap reel that works well on technical yarn, reinforcement fiber, and textile yarn.

Favimat+airbot 2 is a perfect tool for testing different fibers like glass, carbon, aramid, and polyethylene. The testing device is a good option for the resource-saving and greener production process. It is effective for improving testing efficiency, accuracy, and reproduction.

Artificial intelligence-based tools are ideal for fabric inspection. It replaces insufficiency in the industry and makes the testing process smoother. Mill owner makes wise decision that impacts the profit and revenue.

Regarding fabric quality management, Uster Fabriq assistant is an essential platform for automated processing, visualization, and analysis of quality data. The web-based tool supports textile giants in different forms. It comes with individual accounts and specific dashboards.

The main aim of this tool is to reduce manual data processing and accelerate decision processes considerably. Fabric companies can release products for delivery automatically depending on specific business rules without any human interference. It is the best way to prevent bottlenecks and enhance reproductivity.

Fabric performance testing:

Material testing technology is a crucial aspect of textile testing. Lightfastness testing services and instruments are beneficial for the textile industry. By adopting weathering instruments, professionals closely create real-world exposure to sunlight, temperature, and moisture in accelerated conditions. It enables manufacturers to calculate the product service life accurately.

Advanced digital control systems and optical technologies in the weathering instrument are responsible for managing all test factors. It has a stunning ability to give accurate predictions of garments life. Such an instrument is rich in a large and intuitive graphical user interface.

An automatic tensile strength tester is ideal for yarns, fibers, hanks, and fabrics that integrate an automatic yarn loading system. A pneumatic bursting tester is a stunning choice for deciding the bursting resistance of knitted, woven, and nonwoven fabrics.

Apparel brand owners introduce products that cater to performance standards. They deliver customers perfect durability, breathability, UV protection, and moisture-wicking. Performance testing is ideal for abrasion resistance, shrinkage, colorfastness, and tensile strength.

Currently, in Which countries Does the Textile Testing Industry Develop Faster?

In the present scenario, different countries in the world are experiencing great development in the textile testing industry. It happens because of advanced technology, quality assurance in the textile sector, and government support. Here, you can understand major countries in the textile testing landscape.

China

China is a well-known leader in the textile industry and has a massive manufacturing base. In this country, the textile testing field is growing at a fast pace. The country highly invests in advanced testing equipment and methods and follows strict regulations for garment production.

India

India is the most popular destination for the garment testing and production. Indian government puts effort into enhancing textile testing growth via different initiatives. Textile testing is a good aspect to fulfill the growing demand for quality assurance.

Vietnam

Vietnam is also a leading textile industry player, attracting many international retailers and brands. The demand for textile testing services is to guarantee compliance with regulations and product quality. They implement advanced methods and technology for product testing.

Turkey

The well-established country is popular for its craftsmanship and quality. The country is rich in strong infrastructure for the testing process. In addition, it also manages modern testing facilities and laboratories. It keeps the international accreditation to stay ahead in the market.

United States

The United States often relies on automation, digitalization, and innovation. It uses advanced instruments for quality control, predictive maintenance, and inspection. It keeps steady growth in the textile testing market.

What Can We Learn from These Countries?

Textile business owners worldwide must understand popular players’ markets and strategies for new heights. Textile testing may differ from one destination to another. Moreover, it is necessary for product safety, quality, sustainability, and technological advancement.

Government support

In every country, government support is essential for the garment business owner to reach growth. Business owners use government incentives, policies, and investments to boost textile testing growth.

Innovation

Many countries wish to invest in research and development to focus on advanced technology and methods to beat the competition.

Quality and Compliance

Countries highly prioritize quality and compliance for textile testing and are strict with them. It is an important requirement for getting credibility and trust in the market.

Networking and collaboration

Countries keep good collaboration and networking among testing labs, regulatory bodies, manufacturers, and other facilities.

Market demand

The above countries quickly respond to market demand, including digitalization trends and sustainability requirements.

The developing trend of textile testing

In fast-paced textile manufacturing, every textile manufacturer in this industry focuses on developing trends for testing. Textile giants want to embrace the power of technology. Automation, real-time data analysis, and sustainability bring peace of mind to textile business owners. Business owners must pay attention to developing trends to thrive in the competitive landscape.

Sustainable practices

The textile industry emphasizes sustainable practices to prevent unwanted issues. Testing covers environmental impact assessment, including water usage, biodegradability testing, and carbon footprint. Many brands wish to sell sustainable products that are safe for humans and the environment. Through environmental practice, brands are conscious of enhancing the awareness of using sustainable products.

Automation and digitalization

Integrating digital technologies and automation is greatly changing textile testing processes and making them precise and efficient. Textile business owners gain complete advantage with automated testing equipment and digital imaging techniques.

Testing laboratories use robotics and digital imaging techniques to simplify operations, enhance accuracy, and decrease turnaround times. Moreover, the digital platform is highly in demand for data management and analysis, which has become prevalent in the textile industry. It is effective for the quick interpretation of test results and collaboration among stakeholders.

Modern materials testing

Textile industries heavily use new materials and technologies like smart fabrics and nanomaterials. The advanced textile testing method is ideal for assessing the unique properties of the garments. It is easy to know functionalities include temperature regulation, conductivity, and antimicrobial properties. Advanced material testing needs modern approaches and dedicated equipment to ensure accurate assessment and quality.

Supply chain transparency and traceability

Textile testing is a major aspect of guaranteeing transparency and traceability in the supply chain. The testing methods are mainly helpful for bearing out material authenticity, keeping track of fiber origin, and finding discrepancies in labeling. It is useful for brands to support sustainable sourcing practices, eliminate counterfeit items, and boost the trust with customers.

By following new trends, the textile industry experienced exponential growth. Brand owners adopt the latest trends and focus on innovation to stay competitive and bring valuable customer service.

Conclusion of Textile Testing Industry Status and Trends

Overall, one can understand the importance of garment testing in the industry and how it is beneficial for building a good reputation and brand image. The above things are helpful for people who wish to enter the world of textile manufacturing and realize the role of textile testing. So, you can look at the important points and survive in the market in the long run.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com